Installation

The algorithm for building walls from such a material is quite simple. Initially, you need to prepare the surface for the installation of tongue-and-groove plates. All debris must be removed from the floor. Before laying the slabs, it is necessary to prepare a good pillow, which is laid from a cement-sand mortar of a grade of at least M50

It is important at this stage to level all the bases under the building level. Surface preparation before laying the tongue-and-groove plates. Otherwise, even slight differences will create problems during the wall assembly process. After 24 hours, you can start construction. Step-by-step process of laying a wall of tongue-and-groove slabs Gypsum mounting mixtures of the Perlfix type or Fugenfüller putty are used as glue

A damper tape is laid on the prepared composition along the entire length of the pillow, along which the first row of GWP plates will be exposed. Do not immediately prepare a large amount of glue, it dries very quickly. The first row is mounted on gypsum glue strictly according to the building level, then making sure that no, even the smallest distortions occur. All individual elements are closed with a tongue-and-groove lock. The process of laying tongue-and-groove plates The second and subsequent rows are mounted on the same assembly adhesive, observing the dressing of each row. If necessary, the edge plates are cut to size. The alignment of each individual element is carried out with a wooden mallet, lightly tapping the gypsum-polymer tile.

The assembled partition is primed for further finishing. See in the video the installation process of tongue-and-groove plates.

Interior walls based on a metal frame

And yet, the most optimal option for internal walls in an apartment is plasterboard partitions, with sound-absorbing boards inside. Photos of the construction of such a partition in one of the Moscow new buildings are given at the beginning of the article.

Such interior walls, even in the basic version, will provide much better sound insulation between rooms than partition walls made of tongue-and-groove (or foam block). The sound insulation of interior walls made of plasterboard with a thickness of 100 mm is Rw = 50 dB (which is 9 dB better than the tongue-and-groove and 13 dB better than the foam blocks)!

But the most important advantage of this solution is that vibrations from the floors are practically not transmitted to the frame structures and the problem of noise re-radiation from neighbors above and below is automatically solved!

There are several common misconceptions associated with drywall partitions:

1. Weak bearing capacity. Fragility

In fact, the partitions on the metal frame are very durable. You just need to do them right:

- use only branded profiles KNAUF or Gyprok with normal metal thickness and reinforcing longitudinal grooves.

- rack profiles are fastened back to each other to form an I-beam.

- inside the partition, sound-absorbing boards are tightly inserted between the profiles.

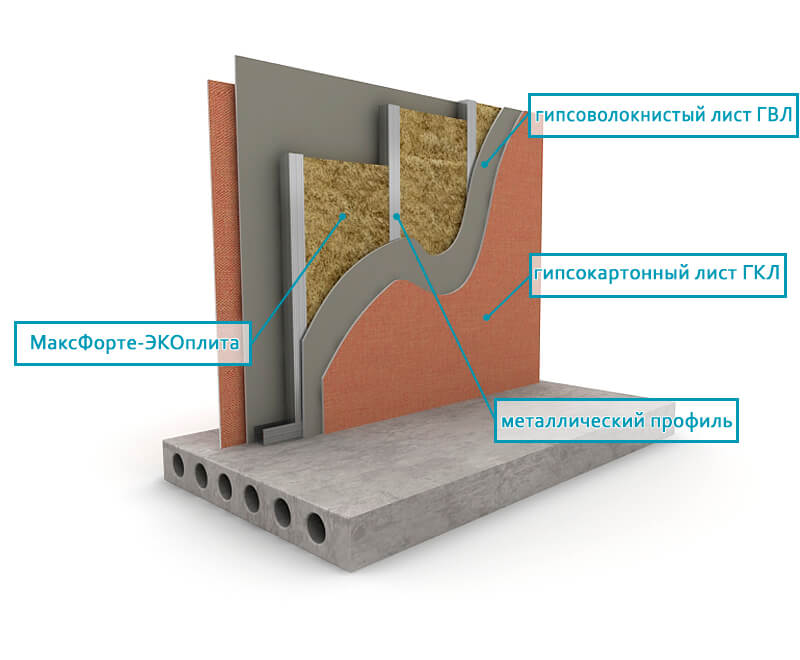

- on both sides, the frame is lined with GVL 10 mm + GKL 12.5 mm.

Such a wall will be very strong and have a high bearing capacity: cantilever loads up to 70 kg! You can safely hang a TV, air conditioning or shelves with books. You can read more about the bearing capacity of partitions here.

2. Large thickness

This myth is refuted in an elementary way. We count the thickness from left to right:

GKL 12.5 mm + GVL 10 mm + Knauf profile 50 mm + GVL 10 mm + GKL 12.5 mm = 95 mm.

The finish surface of such a wall is even, it is enough to apply a thin layer of putty to hide the joints between the sheets of drywall. Add another 5 mm and get the final thickness 10 cm with trim.

This is the standard thickness for interior walls in an apartment.

3. High cost

A square meter of conventional Knauf GWP boards in terms of 1 m2 costs 700-800 rubles.You also need to add to this: tile adhesive, metal reinforcing corners, plaster and other little things. As a result, a square meter of such a wall rarely comes out less than 1000 rubles.

Now let's calculate the cost of a metal frame partition:

- metal frame KNAUF ~150 rub./m2

- GVL 10 mm - 2 x 160 = 320 rubles / m2

- GKL 12.5 mm - 2 x 100 = 200 rubles / m2

- sound-absorbing boards ~ 200 rubles/m2

In total it turns out 870 rub./m2.

Add self-tapping screws, silicone sealant and other little things here. As a result, the amount will be the same (~ 1000 rubles / m2), as in the case of a conventional plaster wall / foam blocks.

Those. there is no difference in cost, and the sound insulation of interior walls on a metal frame will be noticeably better!

|

If you need high-quality sound insulation and professional installation, please contact us! Our experts will assemble proven schemes that will reliably protect you from the noise of your neighbors. Departure of the master for measurements and consultations is free in Moscow and the region! Dmitriy. Installation engineer 8 (916) 575-26-10 Nikita. Acoustic physicist 8 (915) 251-71-93 |

The technology of erecting a partition from PGP

Before installation, the HWP must be brought into the room and left there for a while.

Preparatory stage

We perform the following manipulations:

- We remove dust and dirt from the base base, walls and ceiling.

- If there are large irregularities on the base, we equip a leveling screed from a sand-cement mortar (grades not lower than M50).

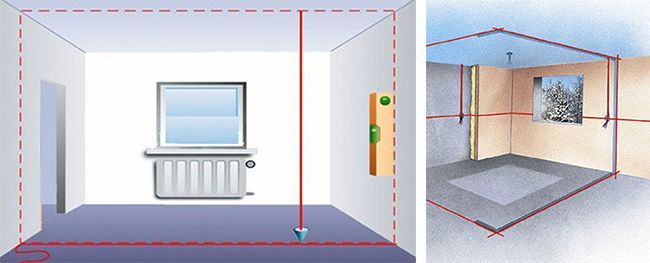

- After the leveling layer has dried and gained the necessary strength, we mark the location of the partition on the floor.

Important! It is necessary to mark the location of the doorway on the floor

- We prepare mounting glue for gypsum products: pour dry gypsum mixture into a container with cold, clean water; wait 2÷3 minutes and mix with a spatula until a homogeneous creamy consistency.

- Along the entire perimeter of the partition (that is, the floor, walls and ceiling), we glue the elastic gasket using mounting glue.

On a note! The prepared mortar mixture of adhesive putty must be worked out within 30 minutes from the moment the dry mixture is poured into the water.

Main works

The order of work is as follows:

Only after the assembly adhesive has completely hardened (under the gasket), we begin to apply the adhesive to the gasket and install the products of the 1st row: we install the GWP on the large edge with the groove up or down.

Advice! We recommend installing the products with the groove up: then the adhesive solution will be evenly distributed in the cavity of the groove. To do this, for all plates of the 1st row, we remove the ridges with a hacksaw. Then we process the surfaces with a peeling planer.

- We upset the GWP with a rubber mallet.

- When joining blocks, glue is applied to the groove located in the vertical end plane of the plate.

- The plates in contact with the wall are also installed on the glue.

- Using the level, we constantly control the correct installation of the GWP vertically and horizontally.

We cut out the cut elements of the plate (additional ones) with a hacksaw and lay them end-to-end with whole products. The thickness of the seams is no more than 0.2 cm.

Important! The presence of through vertical joints is unacceptable

- In the places where the plates join and where the partitions intersect with each other, we make a transverse groove at one of the plates, using a hacksaw and a trowel (to install the upper rows of plates with overlapping of the joints of the lower rows).

- We apply glue to the groove of the bottom plate and install the top plate so that the joint of the bottom row overlaps.

Important! Laying GWP must be carried out with a run-out of end joints

- We attach the plates to the walls using certain brackets. We install the bracket in the groove of the already mounted plate and fasten it with self-tapping screws to the plate and anchors to the wall. Then we install a plasterboard on top of the glue.

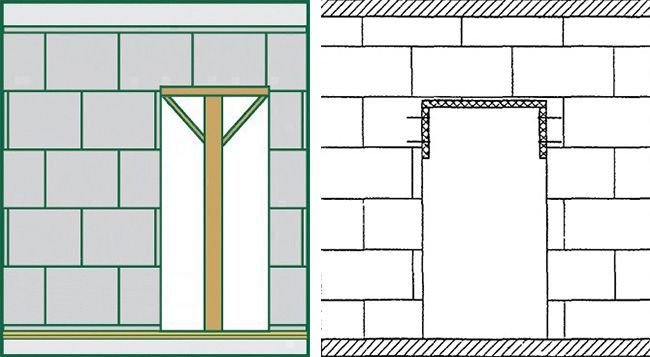

- When arranging openings for doors and windows, we install a wooden structure that supports the plates in a fixed position until the adhesive solution hardens.

On a note! After the glue has dried, remove the jumper.

We leave a gap (about 2 cm) between the ceiling and the last row of plates.

Advice! In order to reduce waste, the products of the last row can be laid on the smaller side (vertical).

The final stage

- After the mounting adhesive has hardened, we process the surface of the outer corner with a peeling planer.

- We apply putty on the surface of the corner, into which we press a galvanized metal profile to protect the corner.

- The gap between the erected wall and the ceiling is filled with glue or mounting foam.

- Putty the joints between the blocks.

- After hardening of the mounting adhesive that secures the corner profile, we level the corner surfaces with puttying.

We seal the internal corners between the wall and the partition, between the partition and the ceiling: first, we apply the mortar mixture on the surfaces of the sides of the corner, then level it (with a spatula for internal corners), lay the reinforcing tape and sink it into the mortar mixture (with a spatula).

Re-spackle the surface of the outer corner with a protective corner.

After the mortar mixture has dried, we clean and polish the surface of the partition.

The entire surface of the partition is primed and painted.

Guided by this description of the work, it will not be difficult to build a partition with your own hands.

Advantages and disadvantages of tongue-and-groove blocks

The main advantages of products with a tongue-and-groove lock:

- have a high level of vapor and gas permeability;

- can be used in areas with any climatic conditions;

- the speed of work increases due to the fixed dimensions of the material;

- are fire-resistant material (withstand temperatures of 1100°C for 3 hours without losing their load-bearing capacity);

- odorless and do not emit toxic gases;

- environmentally friendly;

- not subject to decay;

- do not conduct electricity;

- they are easy to mount (dimensions and weight allow, no need to use special equipment);

- there is no need to make finishing plastering of surfaces;

- any kind of final finishing is possible;

- have good strength characteristics (tongue-and-groove partitions can withstand furniture weighing up to 220 kg).

The only disadvantage of these products is the relatively high cost, but the cost of building materials is more than offset by the lack of need for finishing the walls.

What is better to choose: foam blocks, expanded clay concrete blocks or tongue-and-groove? Decide for yourself, guided by the technical characteristics of each type of product.