Preparation of the base for linoleum

Having decided on the choice of substrate, you can begin to prepare the base. Concrete floors are best treated with a self-leveling mixture. It will allow you to achieve a non-zero, but acceptable level of horizontality.

The procedure for preparing the floor is as follows:

- Identify all the flaws in the base - cracks, bumps, pits, horizontal differences. If there are any, it is necessary to cut off the bulges, cover up the cracks and depressions. Level determine the size of the differences in the horizontal. If the difference is small, then pouring the screed is not required. If the parameters are exceeded - more than 7 mm for every 2 m² - it is necessary to level the floor with a cement screed.

- The screed or “light” floor must dry thoroughly. Otherwise, the flooring of the substrate from any material will quickly fail due to excessive moisture.

- If it was decided to make a plywood base for linoleum, it is necessary to lay a layer of waterproofing on the concrete floor. The wooden base is better preserved and will last longer, protected from moisture. It is advisable to walk on a wooden surface with a grinder.

- The joints and seams of the substrate are treated with construction tape. Accordingly, the material is not overlapped, but joint to joint. The lining is not stretched, lies freely.

Types of bases for linoleum

Many mistakenly assume that a concrete floor does not need to be underlayed if it is sufficiently even. However, minor defects and differences in the base still remain, and the “coldness” of concrete has not gone away.

Of course, if the linoleum is already accompanied by a good and high-quality substrate, the expediency of laying additional material disappears. However, such linoleum is very expensive and rarely purchased. Often, flooring is chosen without additional grounds. In this case, the substrate is necessary, as it performs the following functions:

- Heat and sound insulation.

- Elimination of small horizontal differences (no more than 2 mm per 2 m²).

If the product spreads on the first floors, the presence of a substrate is mandatory. Many people prefer to lay waterproofing as an additional layer to the substrate. This measure is resorted to in case of increased evaporation from the base on the ground. Linoleum and concrete are cool materials, so insulation of coatings is desirable, especially if there are small children in the house.

Modern soundproofing materials

Having chosen a way to isolate the floor from noise, you will surely find suitable materials, which are very numerous on the market today, from fiberboard, chipboard, expanded clay screenings, fine-grained slag to Russian and imported soundproofing boards made on the basis of basalt and glass fibers, mineral cotton wool. When choosing a material, one should take into account its composition, as well as physical properties - to absorb sound, prevent its propagation or isolate.

So, drywall, concrete, brick - all rigid materials have sound-reflecting properties.

Materials with sound-absorbing properties are divided according to the degree of hardness. For example, those made from mineral wool based on vermiculite and volcanic perlite are also considered solid.

Semi-rigid ones include those that are based on mineral wool, but with a cellular structure.

Finally, traditional soft insulators are felt, fiberglass and rolled mineral wool.

The degree of sound reflection from sound absorption is a parameter in the choice of materials for sound insulation.

fiberglass

It has a very small thickness, therefore it is used in those rooms where the concrete base is quite even, but increased soundproofing qualities are needed.

Its advantages are:

- high acoustic characteristics;

- naturalness and environmental friendliness;

- resistance to deformation;

- possibility of laying directly on concrete.

Flaws:

- inability to use on the basis of poor quality;

- probability of deformations under high mechanical loads.

How to create soundproofing

Noise insulation of the floor in the apartment is created using environmentally friendly, practical and functional building materials, which are not very thick, which allows them to be laid under parquet, laminate or tile, while the area of \u200b\u200bthe space is practically not affected.

Before laying such a soundproof underlay, an optimal floor design should be ensured. This is necessary because, according to its purpose, it does not serve to align it. If you neglect the laying of the substrate, then the floor will become booming, will begin to knock and even creak with small grains of sand.

After the screed is made, you can proceed with the installation of sound insulation. Today the most demanded material is the made foam substrate. In addition to the fact that it has an acceptable cost and is considered an excellent sound insulator, it also has heat-insulating properties. However, under constant load and an uneven field, its surface may be dented, which will lead to damage to the interlocks of the laminated coating.

Also, floor sound insulation can be equipped with a cork substrate, which consists of natural crushed cork. This material is considered the most suitable, since it has an increased degree of sound absorption and is thermally conductive. At the same time, the cork coating is quite durable and resistant to deformation.

Soundproofing the floor in the apartment, materials

In some types of the most functional rooms, it is effective to create sound insulation using various types of heaters:

expanded polystyrene;

- perlite;

- expanded clay;

- mineral wool.

These materials are laid around the perimeter of the connection of walls and floor. In addition to the fact that this method will provide excellent sound insulation, the room will additionally receive a warm coating.

Modern materials for soundproofing:

1. Izover (rather light sound-absorbing slabs made of mineral wool based on fiberglass 5-10 cm thick. Used to create a floor on logs). 2. Vibrostek-V300 (elastic roll building material 4 mm thick, designed to isolate from impact noise. It is used as a substrate and basis for a floating type of screed). 3. Noise stop (elastic building material in the form of plates 2 cm thick, designed to isolate from impact noise. It is used as the basis for a floating type of screed).

4. Shumanet (elastic roll material, 3 cm thick, designed to isolate from impact noise. It is used as the basis for a floating type of screed). 5. Underfloor slab Izoplat (made of coniferous shredded wood 0.7 and 0.5 cm thick. It is used for floating floor type flooring with laminate or parquet flooring). 6. Softboard Isoplat (wood-fiber soft board having a thickness of 2.5 cm. Can be mounted under a concrete screed). 7. Texound (soundproof heavy membrane, made on the basis of the mineral aragonite and having a thickness of 3.7 mm).

Varieties of substrates for linoleum

Rolled sound insulation under linoleum is used even when the base is made using sound-absorbing materials. And when laying on an old concrete base, the use of a substrate becomes an innovative necessity. It will make the floor warm and increase the life of linoleum.

The main thing! Of the variety of noise-absorbing laying materials for linoleum, not everyone is suitable.The base for linoleum must be strong, due to this, elasticity is required from the substrate in order to resist punching.

Membrane

Today's membrane sound deadening materials help contain high frequency sound and dampen the low frequency vibrations of structural sound.

According to the property of sound insulation, texound is considered a real replacement for mineral wool. Two types of material have received the greatest recognition on the market: Tecsound70 and Tecsound FT75.

Tecsound70 is a single layer dense material. Composed of aragonite bonded with a flexible and elastic polymeric material. Due to the high specific gravity, good sound insulation properties (up to 28 dB) are provided in a wide frequency range. Texound is durable, not able to absorb moisture, so it is not prone to mold.

Soundproofing based on texound on a felt backing is available under the brand name Tecsound FT75. It is a real sound complex. The thickness of the felt can reach 1 cm, which makes it possible to achieve the highest sound insulation performance. Bitumen is not used in the material, thanks to this, Texound is environmentally friendly and does not smell.

The base of this material is a multi-layered glass fiber canvas. Fiberglass is not prone to decay, durable. Rolled vibrostack has a small thickness (0.4 cm), but provides a noise reduction of 29 dB.

Glass fiber canvas is tear-resistant, does not support combustion, does not contain chemicals hazardous to health, and is therefore environmentally less dangerous.

An even base is required for laying.

Isoshum, noise, noise stop

It is made by extrusion method from foamed plastic. It is produced in various formats: there is a roll iso-noise with a thickness of 3 mm, there is a sheet iso-noise with a sheet thickness of 2.5 and 5 mm. There is a material with a ribbed surface that provides additional ventilation and prevents the appearance of mold.

In addition to high noise insulation qualities (up to 15 dB), iso-noise performs a hydro- and insulating effect. Traditional foam plastic materials are used for thermal protection, and sound insulation is seen as a co-benefits. Isoshum - a material intended only for sound insulation. Although compared with previous materials, the noise insulation index iso-noise is lower, but the accompanying thermal insulation makes it popular when laying linoleum.

Fairly well-known inexpensive material from polyethylene foam. Structurally, the isolon consists of closed cells. It combines high heat-, hydro- and noise-protective (10 mm isolon thickness provides noise reduction up to 35 dB) properties.

This material is available in various formats. For laying under linoleum, a rolled isolon with a thickness of up to 6 mm is taken. Isolon is inferior to the materials described above in terms of resistance to bursting.

It's multifunctional material, which has a complex of protection qualities, among them sound insulation is not considered a priority. It consists of foamed plastic granules sealed between 2 layers of polyethylene. It makes it possible to reduce background noise by 8 dB. However, due to its good vapor barrier properties, TUPLEX is often used when arranging a multilayer substrate under linoleum.

Video on how to lay a duplex underlay:

To ensure good vapor barrier material has a layer of glue, and the joints are hermetically sealed.

Arrangement of sound insulation under the linoleum in the crate

If the base for laying linoleum was leveled using specialized plates, it is best to perform the crate as in the photo, which is necessary for the requirements for soundproofing rooms.

The design is recommended to be made of wooden beams, the height of which must correspond to the thickness of the noise insulator. They are attached to the floor surface with dowels. In order to eliminate the occurrence of vibration, which often leads to the appearance of structural noise in the ceilings, a layer of Texound is placed between the wooden beams and dowels.

Soundproofing the floor under the linoleum in the crate is created using a roll or tile noise insulator. It is installed with an interference fit between the elements of the wooden structure. The size of all sides of the plates should exceed the parameters of the crate by 2-3 centimeters. Then the soundproofing material will tightly adjoin the beams. In order to get rid of structural noise, it is recommended to carry out the Noisestop soundproofing material along the wooden bars.

Additional screed or dirty floor on wooden bars

Even when using multilayer linoleum with an additional substrate, it is possible to improve the sound insulation properties of the floor by producing a screed or a rough base on wooden bars.

Noise isolation between timber blocks

A "dirty" floor on wooden bars is a quick and inexpensive way to level and insulate the base. After preparing the base, performing a vapor barrier and attaching the cross beams, any rolled or slab soundproofing material is laid between the bars. To do this, materials from basalt mineral wool (Rockwool or Izover) or modern aragonite texound are used.

Soundproofing wooden floor on wooden bars

Pieces of cotton wool are cut with a margin so that it fits snugly between the bars. After laying the material for insulation under the plywood, they additionally put rolled sound insulation (“Shumostop”, “Isoshum”).

After laying plywood or OSB, a multi-layered linoleum.

Soundproofing concrete floors

When arranging a new screed (dry, semi-dry or wet), soundproof boards are laid as the first layer. ISOPLAAT boards are considered an excellent option. With a not very large thickness (2.5 cm), this material with fibers provides noise absorption up to 26 dB.

The screed is made according to standard technology, only the first layer is a noise-absorbing material. This substrate is covered with rolled roofing material or polymeric ethylene and a screed is made.

After drying the screed, you can additionally lay a roll of sound insulation and apply a multi-layer linoleum.

What functions does the substrate perform

To determine the choice of a particular material for the role of the substrate, you need to understand exactly what it will serve for. First of all, it is designed to provide compensation for irregularities on the rough surface. In this regard, concrete is one of the most problematic substrates. However, much depends on how the linoleum screed was made and on what solution. If there are obvious defects, then it is not recommended to lay the decorative coating without a substrate, since the smallest cracks, depressions and tubercles will appear on its surface. The presence of a dense substrate will provide the linoleum with good protection and minimize the intensity of wear.

Underlay soundproofing is more important in laying squeaky laminate, but depending on the characteristics of the linoleum, it can also be a useful performance feature. In general, linoleum and concrete do not belong to materials that are problematic in terms of acoustics. But in terms of thermal insulation properties, it is difficult to find a less effective base-coating combination. Cold concrete and thin linoleum in the living room must be supplemented with good insulation.

Back to content

How to get rid of high-pitched sounds in the room

When soundproofing is being prepared for the floor under linoleum, the substrate should act as a shock absorber and protect against the penetration of foreign sounds, both percussive and structural. This problem can be solved with the help of landscaping, as they say otherwise, of the “pie”, the constituent elements of the layers of which are different noise insulators.

For example, the sequence of actions could be as follows:

- First of all, the membrane sound insulation is laid out (it can be a heavy aragonite Texound substrate);

- On top of the first layer lay 5 cm Isover (mineral fiberglass wool) or Rockwool slabs. You can also use materials in rolls that overlap and fix the docking points with adhesive tape specially prepared for such work.

As a result, this sound insulation under linoleum and impact screen will significantly reduce, and structural sounds

It must be taken into account that the soundproofing "pie" will reduce the height of the room

Types of linoleum

According to the binder material, linoleums can be divided into five types:

- polyvinyl chloride (PVC);

- natural;

- rubber (relin);

- alkyd;

- nitrocellulose.

But in the decoration, polyvinyl chloride is most often used, in second place in popularity is natural.

PVC linoleum, in turn, happens:

- Homogeneous, that is, uniform throughout the thickness. Made from a mixture of dye and PVC granules, this linoleum is uniform in color in depth, making it resistant to abrasion. But it is difficult to supplement it with additional properties (sound insulation, gloss, anti-slip).

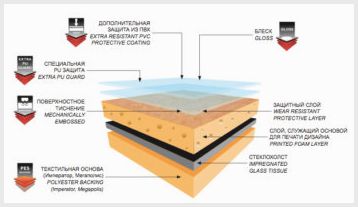

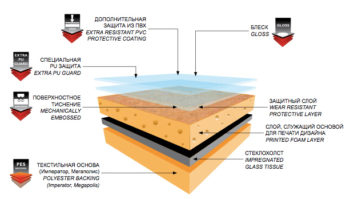

- Heterogeneous, that is, multi-layered. The number of layers is determined by operational characteristics, but usually does not exceed six. The basis of such linoleum is fiberglass. The substrate can be made of natural linen (jute, linen), non-woven felt, extruded cork or foamed PVC. The remaining layers are made of PVC with the addition of dyes and substances that give the final material the required properties.

If soundproofing the floor in the apartment is required, soundproofing linoleum will be a good choice. This material is one of the most effective decorative and finishing materials for soundproofing an apartment. Perhaps only carpet is on the same level with it in terms of vibration isolation properties, but it is very limited in terms of possible places of use.

The soundproofing effect is achieved in linoleum due, firstly, to the elastic properties of polyvinyl chloride (it softens impact noise), secondly, due to the fleecy substrate, and thirdly, due to special sound-absorbing additives.

Why do you need a substrate for linoleum a few examples

Of course, uneven floors are not the only reason why it is recommended to lay one or another lining material under the linoleum. But perhaps this is one of the most important factors to consider. After all, it is known that when you press on a soft floor material, the embossed surface underneath will be imprinted on the floor. All protrusions and recesses will appear. However, dents and tears can also appear if the lining under the laid linoleum is chosen incorrectly, in particular, if it is too soft material. It will be enough to put a chair on such a surface or roll the wheels of a computer chair over it so that clear marks remain.

With the help of the substrate, you can achieve an increase in sound insulation, it can also serve as a heater. Of course, not every material can perform such functions, but only one that has the appropriate properties and at the same time satisfies the above condition, that is, not too soft. Next, we present options for substrates that are suitable in terms of characteristics. In the nursery, some materials can create additional elasticity of the floor, which will save the child from bruising when falling.

Also, a dense base will simply muffle steps, which is important where silence is valued, for example, in an office or in a toddler’s bedroom.

Lining is not required only in two main cases: if the linoleum is to be laid on an already laid once old, but still completely intact floor covering, or if you have chosen a multi-layer material.In the first case, the old linoleum with the substrate already under it, or carpet, serves as the basis. The main thing is that there should not be too obvious irregularities that would be imprinted on the previous coating, otherwise it will have to be removed and the relief of the rough floor surface smoothed out.

Linoleum with its own backing is a special case. You always have a choice, since this material is sold as a single-layer or multi-layer. The second type can have a jute or foamed PVC backing, the latter often being preferred in rooms with high humidity and high temperatures, such as bathrooms. The fact is that there is a type of linoleum, which is fiberglass coated with polyvinyl chloride, which means that if the same component makes up the bottom layer, the coating does not deform during expansion. Natural eco-friendly flooring material usually has a natural jute or linen fiber backing.

Which linoleum absorbs noise

There is a wide range of linoleums on the market. Natural material, the composition of which has not changed significantly since the invention, is not used as often as synthetic ones. Linoleums made of PVC or rubber (relin) are considered more practical and inexpensive.

All linoleum is divided into two types:

- Homogeneous. Represents the single-layer material consisting of the painted polymer.

- Heterogeneous. This is an expensive multilayer floor covering. The base is made of fiberglass, the front layer is made of PVC, and the backing is made of jute, felt, cork or foamed PVC.

Thus, homogeneous linoleum will allow you to get a high-quality coating without any additional properties. Heterogeneous linoleum due to the substrate has soundproofing and heat-insulating properties, it is recommended to use it for soundproofing the concrete floor in an apartment under linoleum. Multi-layered linoleum will allow you to hide minor irregularities in the base and create a coating that is comfortable when walking.

If the plans for repairing the floor provide for the construction of a rough foundation or a new screed, then soundproofing should be taken care of even at this stage. If linoleum is laid on an existing base, then sound insulation can be improved by using flooring under the linoleum with special soundproof materials.

Traditional floor soundproofing methods

There are several of the most common methods.

- "Soft floor". The easiest and most common way is to lay a soft carpet or synthetic floor on the floor, for example, foam-based linoleum or felt, carpet, or other carpet. To do this is quite simple.

- A very common method includes a cement screed, poured according to the principle of a "floating floor". Its advantages are obvious: it is easy to make a screed, it is relatively inexpensive. Cons - that it dries for a long time, sometimes up to several weeks. In addition, the screed significantly burdens the floor and is not allowed in all houses for this reason. If there is permission for the screed, then it is not difficult to fill it.

The “floating floor” is good because it isolates the walls from the floor, as well as the floor covering from the floors and walls.

If a cement screed cannot be made in your home, you can replace it with a dry screed. it is much lighter than cement-sand. As materials for sound absorption, materials for insulation can be used.

With all the advantages of the "floating floor", it has its drawbacks, except for those mentioned above. So, mistakes in laying such a floor will nullify all efforts and soundproofing will not work.

In addition, the screed will “steal” a dozen very useful centimeters of height, which is important in our standard low apartments.

Therefore, it makes sense to look at other ways of soundproofing using modern materials.

The subtleties of the floating floor device

"Floating floor" on concrete is done like this:

- lay a thick plastic film as a waterproofing;

- lay mineral wool or other insulating material;

- a damper tape or a strip of insulating material is laid along the walls. Thus, the floor will be completely separated from concrete and walls and exclude the spread of impact and structure-borne noise;

- then lay the reinforcing mesh under the screed;

- concrete is poured over the lighthouses;

- after the final hardening, a laminate or other finishing decorative coating is laid.

Laying a dry screed under the "floating floor" can be done as follows:

- vapor barrier material is laid;

- a layer of mineral wool is laid;

- along the perimeter of the walls, strips of insulating material with a thickness of at least 2 cm are laid;

- a layer of dry mixture is poured;

- the layer is leveled along the beacons, after which two layers of gypsum fiber boards are laid on it with an indent from the wall of at least 10 cm;

- decorative coating is laid - laminate, parquet, etc.

When laying gypsum fiber boards, it is necessary to exclude the coincidence of their joints, so one layer is placed on top of the other with an offset. Between themselves, they are glued with PVA glue and then tightened with self-tapping screws. Self-tapping screws need to be drowned in the slab.

Soundproofing the floor in an apartment is an important step in the process of overall noise reduction in your home. However, we recall that without soundproofing the ceiling and walls, as well as replacing double-glazed windows on the windows, it is still unlikely to achieve silence in the apartment.

Chipboard and plywood

They are usually used where it is necessary to level the concrete base, but it is not possible to do this with a screed or "wet" work is undesirable.

Therefore, usually a rolled substrate is still used over a wooden base. This method should not be used in living rooms, it is more suitable for practical premises. In addition, the heat and sound insulation properties of such a substrate are low.

The advantages of wood materials are:

- full alignment of the irregularities of the base;

- the hardness of the coating, ensuring the integrity of linoleum for a long time;

- environmental friendliness;

- affordable cost.

The disadvantages include:

- poor heat and sound insulating properties;

- the need to use additional softening materials;

- low moisture resistance of wood.

Which linoleum reduces noise

There is a large selection of linoleums on the market. Real material, whose composition has not changed significantly since the invention, is not used as often as artificial ones. Linoleums made of polyvinyl chloride or rubber material (rubber linoleum) are considered more practical and cheaper.

All linoleum is divided into 2 types:

- Homogeneous. It is a single-layer material, which consists of a colored polymer material.

- Heterogeneous. This is an elite coating consisting of several layers for the floor. The base is made of fiberglass, the top layer is made of PVC, and the backing is made of jute, felt, cork or foamed PVC.

Similarly, a single-layer linoleum will provide an opportunity to obtain a durable coating without any additional parameters. Multilayer linoleum due to the substrate has soundproofing and thermal insulation properties, it is recommended to use it for soundproofing concrete apartment flooring under linoleum. Multi-layer linoleum will make it possible to hide small irregularities in the base and make the coating comfortable when you walk.

The main thing! Although such linoleum reduces background noise by 15 dB, this is not enough for complete sound insulation.

If the plans for repairing the floor include the construction of a rough foundation or a new screed, then you should worry about sound insulation at this step.If the linoleum lies on the existing base, then sound insulation can be improved by using flooring under the linoleum of special materials for sound insulation.