Design features of the gas boiler Baksi baxi, Navien, Ariston

In any case, familiarization with the technique of this class and the features of modern models is useful. This knowledge will help to choose the right equipment, not to make mistakes during operation.

In domestic boilers Baksi (baxi), Navien and Ariston, gas, diesel and solid fuels are burned to heat water, electric heating elements are used. For a more complete use of the potential of energy resources, heat exchangers are being improved. They make long ducts of complex shape to ensure that the liquid remains in the working area for a long time.

Compactness is the current trend. Manufacturers offer gas boilers with square bodies of relatively small thickness. Some models, due to their aesthetic characteristics, deserve to be placed in a conspicuous place.

The next feature is the introduction of automated control systems. They control the combustion process, change the operating modes, taking into account the readings of temperature sensors on the street and in separate rooms. When overheating, the equipment turns off without user intervention.

It is necessary to carefully consider situations when the Baksi gas boiler does not heat water. This happens, for example, when the supply of energy resources is interrupted. It is not difficult to make an appropriate check even without special professional training.

Circulation pumps, valves, other typical components and assemblies rarely fail. Their designs are designed for many years of operation without mandatory maintenance. There are no moving parts in electronic circuits. Their breakdowns are due to marriage. Subject to the rules established by the manufacturer, the resource of modern gas heating boilers is more than 10 years.

Voltage surges in the power supply network can damage the electrical part of the equipment. To exclude such influences, an external stabilizer is installed. Checking the grounding system will come in handy. This completes the set of preventive measures for this group of problems.

It is much more difficult to provide protection against the most common cause of breakdowns in gas boilers - scale.

It is she who will be studied in detail in this article. When heated, calcium and magnesium salts are converted to a solid state. It is these impurities that clog narrow technological holes in heat exchangers. They also form a porous structure on the surface of electric heating elements. With a significant violation of the normal heat dissipation, their cases are damaged.

To prevent the formation of scale and lime inside the boiler, it is advisable to install non-chemical filters (water converters), magnetic and electromagnetic, which will ensure a long “life” for your boiler and an uninterrupted supply of hot water, as well as protect the heating circuit.

The boiler does not heat water

This video is the solution to your problem!

Watch until the end and you do not need to call a specialist.

It is impossible to survive without boiler houses in the climatic zones of Russia. And this also applies to the warmest areas, Sochi, Anapa and Rostov-on-Don. Winters are still harsh and people cannot survive without heating. Therefore, it will definitely not work without heating systems and hot water. And only boiler houses can provide the city with all this. Today we will consider the reasons why the boiler does not heat water - how to solve this problem and what to do for this ......

They are very different. It all depends on the heat source. They can be either steam or water. They may vary in location. If the house itself decided to build its own boiler room, then a specially separate room in the house can be allocated for it. Or they make extensions to the house for these purposes.One of the main requirements for the construction of boiler rooms is good ventilation.

If the boiler works with steam, then very high demands are made on the quality of water purification, and then on steam. Therefore, it will definitely not work out at such boiler houses without a whole complex of purification plants. This includes the AquaShield electromagnetic softeners, which are highly valued by boiler house employees today.

If a gas boiler suddenly stops heating water, the reasons may be different, but most often when using water from a central water supply without softening installations, lime deposits may be the cause. And hard and poorly eliminated. The table shows possible signs of the cause of the boiler shutdown due to scale.

|

Reason for stopping the boiler |

signs |

|

High rigidity |

Heating the bottom of the gas boiler, but at the same time weak water heating A sharp increase in the consumption of electricity or solid fuel White-gray coating on the bottom of the boiler The boiler does not heat water up to a certain temperature Poor pipe capacity Increasing the electrical conductivity of heat |

Other reasons for stopping the boiler are simpler. Maybe a piece of scale can get stuck in the pipe and block normal operation, and a crack in the gas boiler can also contribute to a shutdown. But in these cases, there will definitely not be scale residues on the walls of the equipment. If water softeners for boilers or treatment facilities are not installed in the boiler room, then the root cause will of course be water hardness. If the treatment facilities are standing, and the equipment was checked recently, then most likely this is not the problem.

If the video did not help you, then try installing anti-scale filters (polyphosphate or electromagnetic) in front of the boiler. Because hard water and scale are the root cause malfunctions and breakdowns of gas boilers!

In any case, if there is no cleaning in the system, then you will have to urgently deal with this cause and solve it. For boiler rooms, there are a number of water softening devices that are suitable:

- AquaShield;

- Ultrafiltration and conditioning for steam boilers;

- Ion exchange for economical consumers of gas boilers

The most wasteful process of purification and softening will be in steam boilers. There will have to remove not just all organic and inorganic impurities. Even dissolved gases will have to be removed. Degassing is quite troublesome and costly. But the operation of the boiler depends on the quality of the steam. This is where membrane softeners work to make the water completely isolated.

Many consumers of gas boilers choose AquaShield for the simple reason that it does not need to be looked after and it does not need to be spent on it. But its biggest advantage for boiler equipment was and remains the ability to remove old lime deposits even in the most difficult places. Usually, to eliminate such residues, the equipment needs to be untwisted, the spare parts are soaked in aggressive acidic environments and kept there for up to two hours. But even after boiler water treatment, it is necessary to clean the surfaces with metal brushes or cleaners. If your gas boiler does not heat water to the desired temperature, then the reason is scale deposits. The electromagnet does all this work without damaging surfaces, at the molecular level.

Errors and their codes

Error codes that may occur during the operation of Baksi gas boilers can be divided into two groups:

- complete blocking of equipment operation;

- the device goes into standby mode.

In the event of a complete blockage of the installation, it will be necessary to restart the boiler in manual mode. The blocking is activated in case of serious malfunctions in the operation of the boiler, which can pose a serious danger to human health. The failures, in the event of which the boiler is blocked, include overheating of the equipment, and besides it, the lack of traction.Blocking occurs even in the absence of gas supply. Self-correction of the error is carried out in rare cases. If this happens, the device starts automatically.

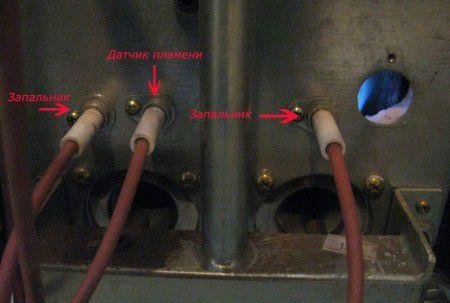

Error E01

This mistake is the most common. When the flame control sensor is triggered, this code is displayed on the display. Several reasons can lead to its appearance:

- no gas supply;

- there is no correspondence between phase and zero; this reason is relevant for phase-dependent models;

- no contact with the flame sensor;

- the sensor is dirty or defective;

- failures in the ignition system;

- the gas valve is faulty or the electronic board is out of order;

- air access is insufficient for normal combustion;

- the gas pressure in the system is insufficient.

If this code is displayed on the display, then the first thing to do is to check if the sensor is connected correctly. It is also worth checking the gas supply. If everything is normal, then in this case you can press R. It should be held for 3 seconds.

In the event of an accidental operation, the equipment will continue to operate normally. If the error continues to appear, then in this case, you should contact a specialist. Note that the occurrence of this error is associated with a malfunction in the electronics. If you try to solve the problem on your own, then everything can end badly for gas equipment.

Error E10

Another common mistake is E10. The main reason for its occurrence is sensors that monitor the operation of pumps and monitor the circulation of water. This error may appear on the setup display in the following cases:

- coolant pressure in the system has decreased;

- contact has disappeared between the board and the pressure switch;

- the pressure switch is faulty;

- the pump operation sensor has become faulty;

- there were malfunctions in the operation of the pump;

- clogging of the heat exchanger.

If this error occurs, you do not need to try to fix it on your own. Self-repair is acceptable if the pump needs to be replaced. It will not be difficult to carry out this event. You can also clean the filters without assistance. All other work related to the repair of the Baksi boiler must be performed by an experienced specialist.

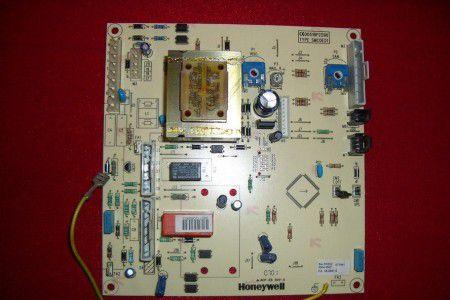

Errors E96, E97, E98

Urgent repair by a qualified specialist is required if errors E96, E97, E98 are displayed on the display of the gas boiler. If they occur, it is unacceptable to interfere in the operation of the boiler by the owner of the equipment. The prohibition on intervention for these errors is due to the fact that these three codes appear when the electronic board has become faulty.

Types and causes of malfunctions

If the Baksi boiler has stopped working normally, then you can repair it on your own, without seeking help from specialists. But troubleshooting is possible only if the breakdown is small and easily fixable. If you have never encountered the repair of boilers, then in this case you should not take risks - contact the master immediately.

- the boiler burner does not turn on or goes out;

- it is impossible to light the boiler;

- when the boiler is operating in the combustion chamber, pops are heard;

- boiler overheating;

- becomes insufficient max. heat carrier heating temperature;

- during operation of the equipment there is a lot of noise;

- one of the sensors in the system fails.

Causes of failure of Baksi boilers:

- moisture got into the boiler;

- the quality of the coolant used is low;

- gas pressure has decreased in the gas pipeline or a drop has occurred;

- there was a voltage drop in the power supply;

- the installation of the heating system was carried out with errors.

What to do if the Vailant boiler does not heat hot water

I found such a way. I have a magnetic converter at the entrance to the boiler, which should remove the hardness of the water, but it does not remove it, in my opinion this is a fiction. But for me it is good that it is installed directly at the entrance to the boiler. You can see it in the photo below.

But for this you need to turn off the water. Next to the boiler I have a collector. He is in the photo below.

Now all the ducts on it are open and with one easy movement I block the water supply to the boiler.

I twist the American back and open the tap for supplying tap water to the boiler.

Now it is important to understand when the acid enters the heat exchanger. Since my water tap is located a meter from the boiler, I determine whether the acid has reached the heat exchanger to taste

I just open the faucet in short jerks and taste it, how “sour” went, which means the entire system from the magnetic filter to the faucet is filled with citric acid.

A question may arise, but will the acid heat exchanger not eat through? I poked around on a forum of chemists and came to the conclusion that organic acid (citric refers to it) is harmless to copper.

I use this method as needed. If you don’t like how the boiler heats water or the pressure of hot water has become weak, I take and treat the heat exchanger with citric acid.

If you have polypropylene connections to the boiler, and there is no place to fill the acid, then think of something similar, it will not take much time.

Control board errors

The control board should be considered as the cause of hot water problems when all other checks have failed. The cause may be a malfunction in the flame modulation circuit. The boiler control unit constantly adjusts the burner power depending on the conditions, and if there is a malfunction on the board, the boiler may spontaneously reboot or turn off when reaching the maximum power, which in most cases is required in the hot water preparation mode.

As board errors, it is still possible to incorrectly configure it. But this only applies to those cases when problems appeared after its replacement. BAXI boards are universal and require customization for a specific boiler.

Italian gas boilers Baxi occupy a strong position in the heating equipment market due to their high efficiency, stable operation.

even in adverse conditions and thoughtful stylish design

. But, despite their high reliability, sometimes

in the operation of Baxi boilers malfunctions occur

caused by violation of operating conditions or failure of individual elements of the boiler. Most often, you can eliminate them yourself, without resorting to calling specialists.

The line of Baksi gas boilers includes a number of models that differ in volume, type of installation, and functionality. At the same time, the principle of their work is generally similar.

The most popular boiler models:

- Baxi Luna (Baxi Luna);

- Baxi Slim (Baxi Slim);

- Baxi Main four (Baxi Mine for);

- Baxi Main 24 fi (Baxi Main 24 fi);

- Baxi Nuvola (Baxi Nuvola);

- Baxi EKO four (Baxi Ecofor, Baksi Ecofor).

By installation type

gas boilers are divided into wall and floor.

Wall heater fixed

with special brackets in any convenient place,

which makes wall models very popular. Chambers with a closed combustion chamber, such as the Baxi Main 24 fi, have increased efficiency and environmental friendliness in a small size.

Coolant volume

in the heat exchanger depends on the model, in the most powerful it reaches 80 liters

. By functionality

models can be single

for heating, or double-circuit

- in addition to the heating system, they also feed the DHW circuit.

Work

they can both on natural main gas and on liquefied

, from cylinders, which makes it possible to install them in non-gasified areas. Boilers fully volatile

and require AC power.

The principle of operation of gas heating equipment:

- The sensors analyze the temperature in the room, and when the minimum value is reached, they give a signal to turn on the circulation pump.

- The pump turns on, creating a vacuum in the return pipe, while the heated water enters the heating system.

- The microprocessor gives a signal to ignite the burner at low power, it gradually increases, and the coolant heats up to the temperature set by the user.

- Further, the boiler operates in modulation mode - it maintains the temperature within the specified limits, turning on when it decreases.

At any of these stages, a malfunction may occur, which the boiler notifies with the help of coded errors.

.

Possible malfunctions of the boiler Baxi Main for, Baxi Main 24 fi, Baxi Eco for:

- the burner goes out immediately after switching on or during heating (error codes e01, e04);

- ignition of the boiler is not possible;

- overheating occurs (error code e02);

- the water pressure in the system drops (error code e10);

- extraneous noise is heard in the work;

- pops occur in the combustion chamber;

- the coolant does not heat up to the set temperature;

- one of the sensors fails (various error codes may appear).

The most common causes of the appearance of certain malfunctions, according to service center specialists, can be:

- wrong

- errors when connecting the boiler to the mains;

- water ingress onto the board, into the burner or into the electrical part of the boiler;

- low quality of network water or other heat carrier;

- a sharp drop in gas pressure;

- the voltage drops or increases unacceptably in the network.

The resulting malfunctions can be easily eliminated by adjusting the boiler, but sometimes it is necessary to call a specialist to replace parts of the boiler.

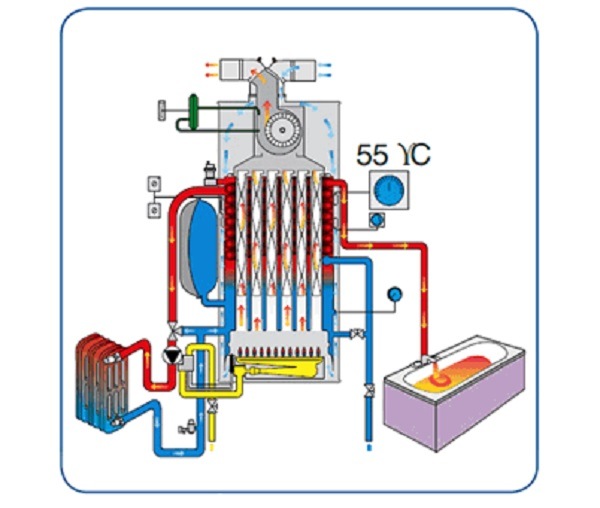

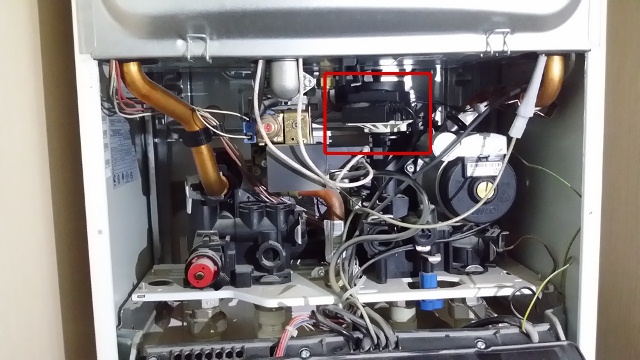

Work principles

Gas boilers, as a rule, have two circuits - heating and water heating. Double-circuit devices are a combination of several blocks responsible for a certain functionality of the system. So, the gas block is responsible for the ignition and combustion of the burner, which allows the heat-conducting liquid to warm up, water is supplied in the water unit and the necessary pressure is provided in the line, the chimney unit releases combustion products into the environment, the control unit controls the operation of all boiler systems.

When the unit is started using a pump, water is pumped into the system, passing through the pipes of the heat exchanger. As soon as the liquid enters the water unit, the gas supply valve opens and the burner is ignited. The process of heating the body of the heat exchanger occurs evenly and is controlled by temperature sensors.

Important! Heating cycles are controlled by sensors. When the water temperature drops to a certain temperature, it is the sensors that transmit an impulse to the control module to resume heating

When hot water enters the faucet, a flow sensor is connected. A signal is sent from it to the board, after which the three-way valve is activated and switches to heating the water supply.

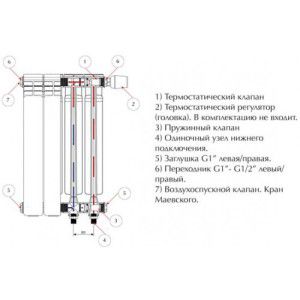

The radiator does not heat up

Most often, problems with normal heat transfer occur in heating radiators. This is due to their specific design - the coolant does not move through one pipe, as in the transport line, but is distributed over several.

In what cases does the heating radiator not heat up? There are several factors that directly affect the correct operation of the battery.

Air pockets in heating

There are several reasons for the appearance of air locks in the heating system - exceeding the temperature regime, water evaporation, etc.

It is important that the consequence of this is the appearance of places in the line that are not filled with coolant. Most often these are radiators.

To eliminate them, it is necessary to install a Mayevsky crane - an air valve that releases excess air from the device.

How to determine why the heating radiator does not heat well? The simplest method is the temperature difference on the surface. At the place of formation of an air lock, it will be much lower, thereby preventing the normal passage of the coolant. To fix it, follow these steps:

- With the help of a screwdriver or a rotary lever, the Mayevsky tap is opened;

- Add water to the system until the coolant begins to flow out of the tap together with air;

- Shut off the water supply.

After starting the heating system, the surface of the radiator should heat evenly. Otherwise, repeat the procedure.

Incorrect installation and limescale in pipes

The efficiency of its operation depends on the correct installation of the radiator. It should not be inclined relative to the plane of the floor and wall. If this condition has not been met, then the question will inevitably arise - why the heating battery does not heat up.

To check the correct installation of the radiator, you can take a standard building level. If the upper plane of the battery has deviations, re-installation should be performed. It is best to use new reinforced mounts for this.

If, after this, the question of why the heating radiator does not heat up remains unresolved, it is recommended to flush the heating system. This problem is relevant for old pipes and radiators made of steel and cast iron. Over time, a lime layer accumulates on the inner surface, preventing the normal flow of the coolant. There are several ways to perform the flushing procedure:

- Hydraulic. A special pump is connected to the system circuit, which creates a large pressure of water. Under the influence of this force, the scale is broken into small fractions and retained in the pump filter;

- Chemical. Special additives act on limescale, which loses its uniformity and flakes off the inner surface. Subsequently, hydraulic flushing is performed to remove residual debris.

Experts recommend using an integrated method to solve the problem in which the heating battery does not heat up. After checking the correctness of the installation, the system is flushed, and then the correct filling is performed with the Mayevsky tap open.

If a two-pipe heating system does not heat up due to clogged pipes, you need to carefully choose the cleaning technology. For pipelines made of polypropylene, chemical cleaning cannot be done.

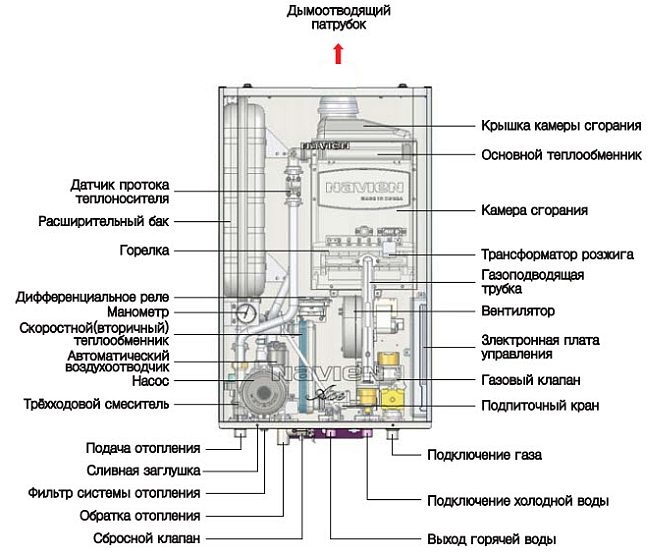

Features of Navien gas boilers

The double-circuit gas heater Navien stands out among a huge number of competitors for its compactness and attractive design.

Even if low-quality gas is used, subject to the requirements and recommendations of the manufacturer, the Navien gas boiler will delight the owner with reliable and long-term work for complex and expensive repairs.

The Navien gas boiler is able to maintain functionality with voltage drops of up to 30%, a drop in gas and water pressure in the supply lines. Navien boilers, regardless of type, are equipped with systems that guarantee uninterrupted operation in various operating conditions. The frost protection system will not allow the water to freeze in the cold season.

The control system is intuitive and remote controlled. The design uses steel heat exchangers to guarantee high efficiency and long service life.

The air pressure sensor used in the circuit ensures complete combustion of the fuel, which leads to lower costs.The water heating mode is activated simultaneously with the opening of the hot water tap. The burner automatically switches on, and when the tap is closed, the system is put into standby mode. The boiler heats water only for the heating system. The winter-summer mode automatically switches the system to hot water or vice versa.

The Navien boiler has a closed type combustion chamber. The coaxial smoke exhaust system prevents combustion products from entering the living quarters.

A wide range of temperature settings, both room and hot water, makes the Navien boiler competitive even with representatives from high price categories.

Do-it-yourself Baxi boiler repair Video lesson

Burner flame does not reach maximum power

The cause of the malfunction may be an incorrect pressure setting in the heating system, a malfunction of the gas valve modulator, or a breakdown of the diode bridge.

Remedy: adjust the system parameters using the boiler instruction manual.

Boiler starts and stops immediately

The reason is the low gas pressure in the gas pipeline.

Remedy: reduce the value of the incoming gas pressure to five mbar (standard - twenty-five mbar).

Weak heating in the hot water system

The reason for this is the incomplete opening of the three-way valve or its breakdown. To confirm a valve malfunction, allow the system to cool down, close the shut-off valves of the heating system, then turn on the boiler in hot water mode. If the valve is faulty, then simultaneously with the DHW heating will occur in the heating system.

When igniting in the boiler, "pops" are heard

Such noise appears due to: insufficient gas combustion (adjustment of the minimum pressure is necessary); changes in the distance from the gas supply to the igniter during inaccurate transportation of the baxi boiler (you should adjust the gap by setting it to 4-5 mm); excessive draft (using a damper to reduce the draft in the boiler).

How to adjust the gap between the burner and the igniter

Open the front panel and completely remove it from the boiler. Remove the shutter from the viewing hole. Behind him is an igniter

To change the gap, it is necessary to unscrew the screw on which the igniter electrode is attached, then remove and carefully bend the electrode. Then we install it in place and close the shutter of the hole

A sharp decrease in the temperature of the coolant in the circuit

The reason for this is: clogged filters (they need to be cleaned or replaced); damage to pipes, radiators, their clogging or freezing (the malfunction must be identified and replaced or the defective section of the pipeline must be cleaned).

How to clean the primary heat exchanger with your own hands (video)

We drain the water by unscrewing the tap on the boiler on the right. If possible, it is necessary to drain the water from the heating system. For cleaning, we use a device called Gel. We connect the nozzles of the device to the Baxi heating pipes. We unscrew the cap on the device, fill in the liquid for cleaning. We include Zhel in the power supply network. Within a couple of hours, with the handle on the device, we switch the direction of the washing liquid “forward - backward”. After two hours, turn off the device, unscrew the tap to drain the water from the baxi boiler. We remove the hoses, making sure that the washing liquid of the glass is back into the device. We connect the boiler to the system, fill it with coolant. Cleaning the boiler will remove scale from its parts and prevent clogging and breakdowns.

Cleaning the secondary heat exchanger (heating circuit)

We use the washing machine again. We connect it to the boiler, turn it on. Close the gas valve and open the hot water supply valve. And then turn off the device for cleaning. Thus, the liquid will be driven along the short circuit of the system.

Before installing the boiler, its operation and repair, be sure to consult a specialist.Despite all the positive qualities of baxi boilers, they, like all equipment, have their own margin of safety and service life. In this article, we examined the main types of breakdowns, and also saw how to repair Baksi boilers with our own hands. We wish you and your boilers success.

The main problems why the boiler does not heat water

More often, malfunctions at the boiler are detected during the heating season, when both circuits of the device are working. There are two main problems faced by owners of wall-mounted gas boilers such as Ariston:

- all boiler systems work, the device turns on, but heats the water weakly or does not heat at all;

- the boiler does not start, and, as a result, there is no hot water supply.

Each of these problems has its own causes and solutions. To troubleshoot, you need to figure out what caused and caused them.

Before finding out the causes of a malfunction of the unit, you should look into the instruction manual, read the instructions and check the correct settings and connection of the device.

Note! Modern gas boilers are equipped with a diagnostic system that detects malfunctions and displays an error code on the display. The instructions for the unit will help decipher the codes

If all requirements and conditions are met, the most common causes of malfunctions should be considered:

- blockage. Experts say that the use of unfiltered working fluid increases the risk of clogging of the heat exchanger tubes. The resulting scale reduces its thermal conductivity, which makes the unit work with an excessive consumption of energy. In this case, the optimum temperature regime is not achieved even with continuous operation of the device. Due to the limescale deposited inside the pipes of the heat exchanger, the metal undergoes corrosive changes, which can lead to its rupture.

- Faulty pump. The circulation of the coolant can be stopped due to the accumulation of air, the so-called air plug in the pump. The second cause of a pump failure may be a rotor that is jammed. A circulation pump that has ceased to function can lead to overheating of the gas boiler.

- The flow sensor is stuck. Inside the boiler is a sensor in the form of a turbine, resembling a small fan. When the turbine rotates inside the sensor, an electrical impulse is generated due to the fluid current, which is applied to the control unit. Thus, the electrical system understands that it is necessary to warm up the coolant.

- Stuck three-way valve. Such a malfunction will not allow switching the water supply from heating to DHW. A valve stopper can occur due to blockage, both of the part itself and of the gas hose or filter.

- Insufficient pressure. If the volume of liquid in the system does not create the desired pressure, the water supply valve does not open, which leads to burner ignition failure.

Burner modulation errors

To heat running water, in most cases, a boiler power close to maximum is required. In modern boilers, the burner power is regulated over a wide range. Adjustment occurs by changing the amount of gas supply by the gas valve. The amount of adjustment is determined by the control board, depending on the logic of operation and settings.The process can be observed visually by the height of the flames on the burner.

If the boiler settings are set to 100% boiler power in DHW mode, but visually the flames on the burner are weak, or obvious interruptions are visible, then you should check:

gas valve setting (static and dynamic gas pressure)

control board

Such checks may only be carried out by a qualified technician.