The connection of polypropylene and metal pipes plays an important role in replacing the plumbing and heating system. In most apartment buildings, metal is mainly used for plumbing and plumbing. This material quickly rusts, respectively, the permeability of pipes decreases, leaks begin. Plastic has a shelf life of about 50 years. But replacing pipes is not as easy as it seems at first glance. The best option would be to change the entire riser, but this requires the consent of all residents. As practice shows, this option is rarely implemented. Often, residents carry out a plastic insert into the general water supply only in their apartment.

Connection options

There are two ways to combine metal with plastic: using threads or flanges. Each of the methods has its own characteristics. For example, the threaded version is optimally suited for pipes with a diameter of up to 40 mm. In other words, for residential apartments. Docking between pipes is carried out using a special adapter - a fitting. This fixture is ideal for combined connections. On the one hand, it is made in the form of a smooth sleeve for polypropylene, on the other - a threaded connection.

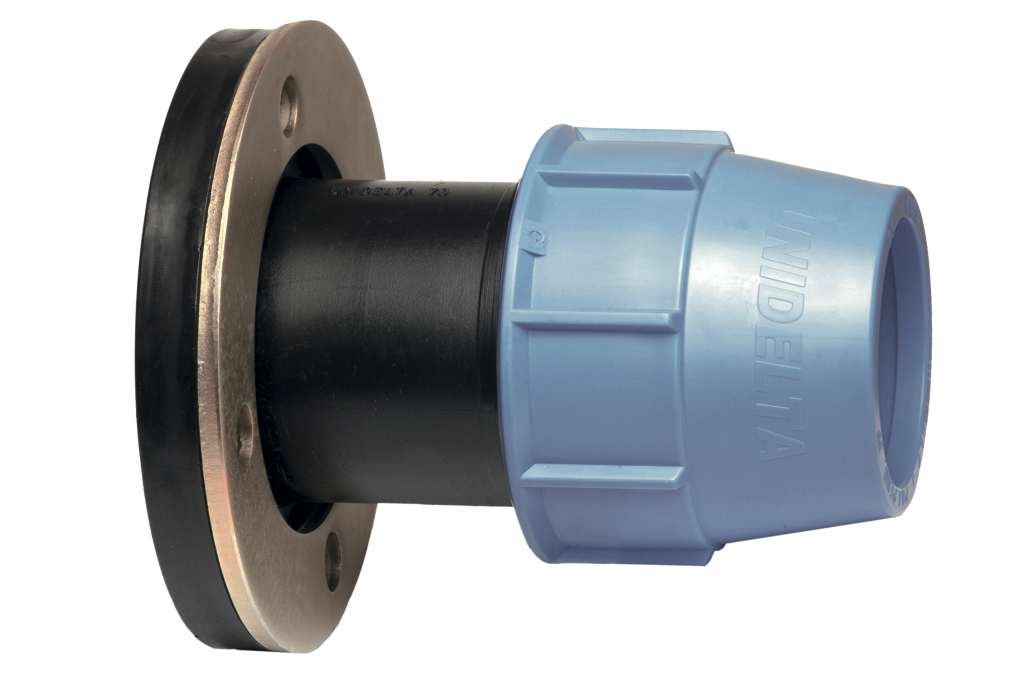

Flanges are only suitable for large pipelines over 100 millimeters in diameter.

Threaded

This type of plumbing connection is called "American". Plastic is soldered from the side of the coupling. By the way, they are considered plastic polypropylene, metal-plastic, polyethylene and PVC pipelines. The metal part is respectively attached to the thread. Here's what it looks like in practice:

- Installation begins with unscrewing the coupling at the site of the intended joint. If there is no coupling, then the pipe is simply cut off. Then at the junction it is necessary to cut the thread. To do this, it is recommended to lubricate the place where the thread cutter enters with oil or grease.

- The threaded connection must be sealed to prevent possible leakage. This is done using a fum tape or linen, which is wound between the threads. For greater reliability, silicone is applied on top. The amount of wound material should not exceed 1-2 turns. Otherwise, it will be problematic to screw the fitting. It is necessary to wind linen or fum-tape in a clockwise direction.

- Then they wind up fitting. It is best to do this by hand, without using a gas key. The fittings are made of a rather brittle material and excessive compression can damage the adapter. The best solution is to tighten the fitting slightly if a leak is detected after the water has been supplied. But remember that you need to use the tool very carefully.

- From the side of the smooth coupling, a polypropylene pipe is welded.

- Water is supplied to the pipes.

Advice. If the screw connection is used for a heating system, it is recommended to replace the rubber seal on the coupling side with a silicone one. Temperature changes will quickly destroy the rubber, and water will flow at the junction of the pipes. Silicone looks more reliable in this regard.

Flange connections

This method is based on the joining of a steel pipe and a plastic insert with a detachable device - a flange. A flange in the form of a sleeve is inserted into the metal pipe, a union flange is attached to it with the help of bolts with a transition to plastic. This is done as follows:

- The insertion point is determined and a neat cut of the pipe is made. Irregularities at the cut point must be processed with a grinder.

- The flange in the form of a sleeve is inspected, the sharp edges are smoothed with a file. This precaution will protect the plastic pipe from damage.Only after that the flange is installed in place.

- Another flange with an adapter for polypropylene pipes is attracted to it with bolts. A rubber gasket is installed at the junction. Mounting bolts tighten with no extra effort.

To make a pipe connection from different materials, within the power of any person. But if you are not sure that you can do a quality job, it is better to contact a plumber.