Steel and cast iron boilers

Boilers with a steel heat exchanger have a long flue gas path. In this regard, they better transfer heat to the heat exchanger. In addition, the flue walls are easy to clean. To achieve a high level of efficiency, in cast iron boilers, the surface of the heat exchanger has many fins that are close to each other. The design of such a boiler does not have a long flue gas path, so cleaning such a boiler is a complex and time-consuming process.

The use of materials is allowed only if there is an indexed link to the page with the material. For all questions, please contact dom@otopimdom.ru

Category: Building / Engineering systems | Date: January 15, 2013 | Views: 996 | Comments: 1

Water heating boilers use a heat source to heat cold water coming from a municipal water supply or well. The heated water is stored in a tank and distributed on demand to showers, bathtubs, sinks and other equipment that uses hot water.

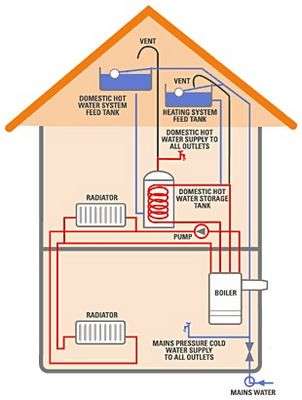

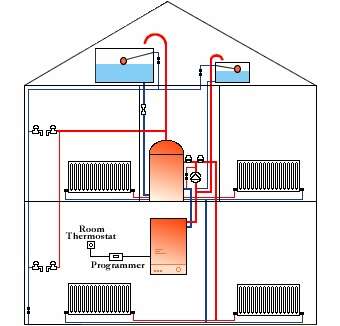

Water heating boilers for heating perform both the function of heating water and the function of heating, saving money on the installation of the entire system. Only one boiler is used, only one burner and one exhaust are required. Very often, such an integrated system uses an insulated external storage tank with a high-efficiency boiler to heat water that passes through a heat exchanger (as in a car radiator). The system then distributes the heat throughout the house via a distribution network, just like a traditional heating boiler.

For United heating systems. which do not use high efficiency boilers, very soon the initial savings are reduced due to the very low seasonal efficiency. The boiler is sized to produce enough heat to heat the house on the coldest winter day. However, in spring, summer and autumn, when heating is not required, the same boiler only heats water. The result is that an oversized hot water boiler is only used at full capacity for a few months of the year, resulting in low efficiency.

Quite often, alternative types of water heaters - without storage tank. The heat exchanger inside the boiler heats the water only on demand, without accumulating it in the tank. Water passes through the heating elements inside the boiler when one of the taps in the house is opened. The disadvantage of such a system is reduced efficiency during the warm months when there is no need to heat the room, while the water heater must be hot all the time.

Despite the constant increase in the cost of utilities, electric heating boilers remain in demand and popular. The high cost of heating with electricity pays off due to simple installation, relatively low cost of equipment, ease of use and other features of electric water heating equipment. The range of these useful and safe devices is wide enough to effectively heat both a large cottage and a modest cottage. We suggest you take a deeper look at these units in order to understand how they work and which one is better to buy for your home.

Solid fuel water heating boilers

Solid fuel boilers are another worthy alternative to gas boilers. The fuel can be wood, coal, coke or wood pellets. You can find such models of boilers that operate on any of the listed types of fuel.

Many solid fuel boilers are automatically able to maintain the desired “outlet” water temperature. It happens in this way. The boiler has a sensor that monitors the temperature of the water at the outlet. The sensor is connected to the damper. When the temperature begins to "roll over", the damper begins to close. Due to this, the combustion process is slowed down. When the temperature drops, the damper begins to react and open slightly. It should be noted that such a device does not imply a connection to the network. Let's look at the main types of solid fuel boilers: (See also: Bath water supply)

gas boilers

From an economic point of view, gas-fired water-heating boilers are the most profitable. They have a high efficiency, while the price of the thermal form of energy is much less than when generating the same amount of heat that can be obtained from equipment that operates on electricity or fuel oil. (See also: Choosing a wall-mounted gas boiler)

Gas boilers are divided into:

Floor models, in which the heat exchanger is usually made of steel or cast iron. It is difficult to say which of the materials is the best. Steel boilers are light, they are resistant to shocks that can happen during transportation. And cast iron models have a much thicker heat exchanger, and this has a positive effect on their service life. The gas type of fuel in our time is the most common, so these boilers are extremely popular. Most modern water heaters have an electronic ignition system, which is very convenient during operation. The main thing that makes sense to pay attention to when purchasing a gas boiler is the performance indicator. In this matter, it is necessary to take into account the total area that this boiler will heat. Modern heating equipment makes it possible to achieve the possibility of heating areas up to 350 sq.m. In order for the combustion products to be completely removed, heating gas systems are endowed with natural and forced draft.

Wall-mounted water heating boilers are attached to the wall surface, they can also be hidden in a closet or other niche. The advantage of wall-mounted boilers is their compact dimensions. They have a tube burner as well as a slow running heat exchanger.

If there is no gas, then an electric water heater can be used. The main advantages of electric boilers are: (See also: Single-circuit and double-circuit gas boilers)

Acceptable cost;

The main structural element is a heat exchanger, consisting of a pipe in which the heating elements are located. The control panel is located on the outside of the boiler. Consider its main elements: (See also: Production of heating boilers)

The principle of operation and the advantages of these units

Typically, an electric boiler is a cylindrical hot water chamber. Inside there are heating elements, with the help of which electric current passes through the coolant, heating it. The unit is connected to a three-phase network with a voltage of 380 V. Most often, the automatic control unit for the operation of the device is placed in a separate control cabinet. There are also models of electric boilers that use induction heating. There are no fundamental differences in the installation of these two types of boilers. Induction models are considered safer, and their efficiency can reach 90%.

Electric boilers operating on the principle of induction heating are considered safer and have a higher efficiency than electrode or heating elements. However, their prices are also the highest.

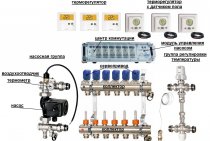

For more efficient operation of automation, it is recommended to connect a temperature sensor located in the heated room to the control unit. In this case, you can control the equipment taking into account changing weather conditions.In addition, the control unit is equipped with:

- automatic protection;

- automation scheme;

- contactors;

- devices for monitoring voltage and current load level.

This design allows you to automatically turn off the equipment in case of power surges or short circuits. Automation maintains the set temperature of the water in the boiler, and also monitors the heating of the device body and turns it off in case of overheating.

Modern electric boilers are equipped with an automatic control panel. The operation of the boiler can be programmed in such a way that the energy consumption is minimal.

The light indication informs not only about the device being turned on and working, but can also signal breakdowns, equipment switching to remote control mode, etc. If you need to heat up not only the coolant, but also provide the house with hot water, you should purchase a double-circuit electric boiler equipped with water boiler. Such a unit has a fairly high efficiency and allows you to spend electricity more economically.

The advantages of electric hot water boilers include:

- ease of installation (no need for a chimney, a separate boiler room, etc.);

- low equipment costs compared to other autonomous heating options;

- silent operation;

- stylish equipment design;

- the ability to install the boiler in almost any convenient place, on the wall or on the floor;

- environmental safety of the unit;

- the ability to control the operation of the device automatically or remotely.

When leaving for a long time, the owners of a private house do not have to turn off the heating system, since it is controlled automatically. It is possible to regulate the operation of some models of boilers even at a considerable distance using a mobile phone.