The problem of panel houses is excellent audibility. Even respectable and calm neighbors who do not have noisy parties and do not drill walls every weekend cause inconvenience. A variety of noises penetrate through the inter-apartment partitions and interfloor slabs: loud conversation, the sound of falling objects, and even the sound of steps and moving chairs. To create a quiet and comfortable environment in the apartment, soundproofing of the ceiling is required. Let's find out how to make it yourself and what materials to choose for different occasions.

Choose the level of protection

The effectiveness of a soundproofing structure will depend on several factors, including:

- Selected insulating material. Each type has different noise absorption indicators.

- Layer thickness. Some of the latest generation of insulators provide a high level of noise protection even at low thicknesses. But for traditional materials, the principle works: the thicker the better.

- Number and composition of layers. Practice shows that combining many materials with different properties and creating a multilayer "pie" gives the best results.

- Type of finish.

For an apartment with high ceilings, you can choose any type of soundproofing system, regardless of the thickness. The most effective will be a multi-layer construction that combines rolled sound-reflecting materials, sound-absorbing boards and gypsum boards or gypsum boards. In this case, the ceiling will be lower by 7.5–12 cm.

For a room with low walls, soundproofing under a stretch ceiling is suitable. It can also be multi-layered, but in this case thinner materials are used. As a result, the ceiling will drop by a maximum of 6 cm, the average is only 3 cm.

If the ceiling height allows, no one interferes with the use of a thick frame structure, reinforced with plasterboard, in combination with a stretch ceiling.

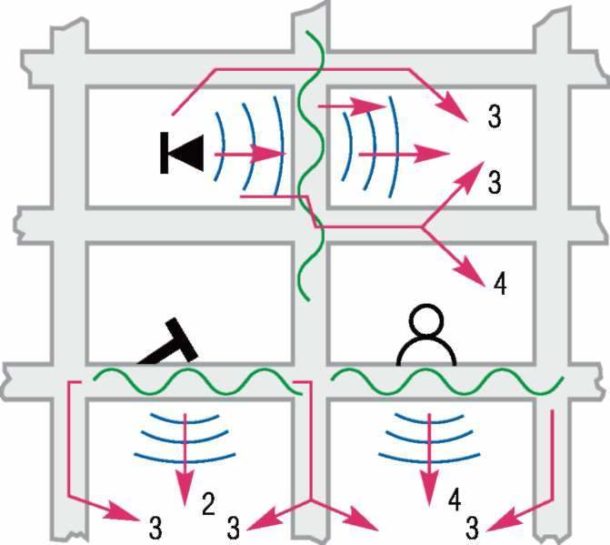

Types of noise and features of its distribution in different houses

To fully understand the issue, you need to know that 2 types of noise penetrate the room through the ceiling:

- air, caused by air vibrations (talking, singing, music, crying, dog barking, etc.);

- percussion, formed during mechanical action on the floor (stomp, movement of furniture, blows to the floor).

Next, we will find out what technologies and materials will help protect the apartment from both types of noise.

And one more important point. Before you start soundproofing your ceiling, you need to understand how noise from above is distributed in different types of buildings.

- In a panel house, sounds from neighbors are transmitted through the ceiling itself and through the walls, therefore, ideally, sound insulation will be required not only for interfloor floors, but also for partitions.

- In brick houses, the walls dampen sounds, so it will be enough to isolate only the ceiling.

- In monolithic-frame buildings, the partitions are thinner than the ceiling slab, so sounds propagate mainly through them. In this case, the walls protect against noise first of all.

What do we soundproof: our ceiling or the floor of the neighbors from above?

From the point of view of efficiency, it is much better to equip the soundproofing of the floor of the apartment located above. If it is possible to negotiate with neighbors, then it will be cheaper to pay for the soundproofing of the floor in their home. Impact noise protection with this approach will be much higher. About the methods of soundproofing the floor is described in detail in this article.

Soundproofing systems: frame and frameless

If you decide to protect the floor slab from below, from your apartment, from noise, it remains to choose the type of system, which can be framed and frameless.

frame

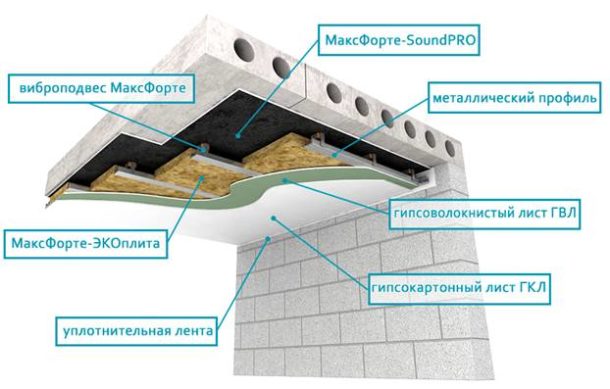

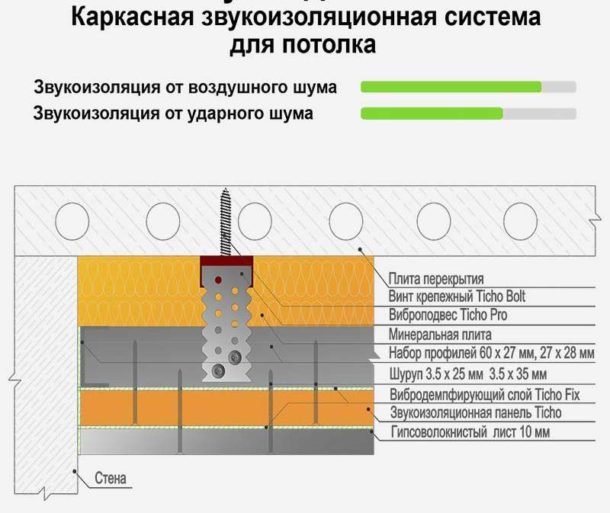

This mounting scheme allows you to protect against both shock and airborne noise. Vibration hangers, on which the metal profile is attached, are designed to eliminate shock noises (such as: stomping, falling objects, moving objects, etc.) Due to them, a vibration decoupling of the ceiling is created - it turns out 2 levels of the ceiling that do not have rigid connections with each other. EcoStove is a fibrous material for absorbing airborne noise (such as conversations, barking dogs, loud music, etc.) Due to the correct laying of the fibers, the sound wave is frayed and extinguished, transferring sound energy into heat energy.

In this design, the formula "Mass - elasticity - mass" is observed, where in the first case the mass is the floor slab, the elasticity is the sound-absorbing material EcoSlab, and the second mass is the GVL and GKL layer. The sound wave entering this structure is reflected from two "masses" and is damped by a sound-absorbing, fibrous material (EcoPlate).

The frame version, when properly executed, provides more reliable protection than the frameless one. The design consists of a sufficiently large number of elements, therefore, it involves significant labor costs. But, despite the certain complexity of installation, it is based on technologies for arranging plasterboard suspended ceilingswhich are known to every master.

Elements of the frame system:

- metal guides forming a crate;

- vibration suspensionsholding the frame;

- sealing tape that prevents the transmission of sound through the profiles;

- soundproofing materials - sound-absorbing plates, shields, soundproofing panels or a membrane in various combinations;

- vibroacoustic sealant;

- drywall, standard or denser soundproofing, or gypsum fiber in 1 or 2 layers.

The thickness of the structure varies between 75–120 mm. The index of additional sound insulation is 11–21 dB (excluding the soundproofing ability of the floor itself).

Modification of the frame system is also used in the arrangement of a stretch ceiling, but in this case, instead of profiles, wooden slats with a thickness of about 2.5 cm are used.

It is the frame technology that allows you to protect the room from all types of noise, both air and shock.

Frameless

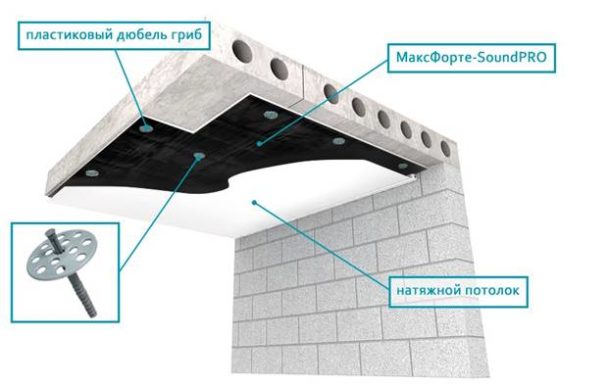

For those who have every centimeter in the account, and there is no way to spend 7-8 cm, there is a frameless soundproofing.

We will consider 2 options for frameless soundproofing under a stretch ceiling.

MaxForte SoundPro:

Roll sound insulation for ceilings, walls and floors is a new generation material that effectively dampens airborne and impact noise. Rolls of material are made of aluminosilicate fiber, show a high increase in sound insulation and fully comply with the requirements of SNiP dated 03/23/2003 "Protection from noise".

The material is completely non-combustible, does not attract rodents, is resistant to the occurrence of fungus, mold. Rolls are resistant to moisture, do not rot.

It has excellent acoustic properties, high sound absorption coefficient αW at all frequencies. Maximum class "A" for sound absorption. Noise reduction coefficient = 0.85.

MaxForte EcoAcoustic:

Plates made of polyester fiber (acoustic synthetic winterizer) are made using thermal bonding technology and undergo aerodynamic laying of fibers for maximum sound absorption. In production, only primary raw materials are used, white material.

The composition does not contain harmful substances (glue, glass, slag). The plates are easy to install, do not prick, do not dust, do not crumble. Work does not require overalls, gloves or a respirator. Hypoallergenic product. Suitable for allergy sufferers or asthmatics. Not afraid of moisture. Maximum class "A" for sound absorption.

The frameless system is more often used under a stretch ceiling. But there is a separate variety of it, where the same drywall acts as the finishing layer.

With a stretch ceiling, the situation is as follows: the sound wave coming from the ceiling is reflected from the stretched film, again reaches the plate and bounces again. There is a "drum" effect. Soundproofing in such a situation will eliminate this effect and protect against airborne noise, but its effectiveness against shock is low.

Elements of a frameless system for a stretch ceiling:

- soundproofing material - membrane, plates or panels;

- glue;

- dish-shaped dowel-nails;

- stretch fabric.

The index of additional noise absorption of the floor when using this design is approximately 7–9 dB. Its thickness is 14–40 mm.

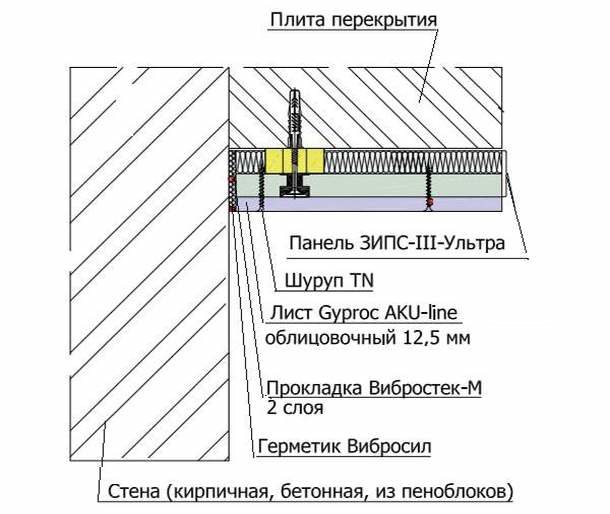

The second version of the frameless system consists of the following elements:

- sandwich panels ZIPS (soundproof panel system) with special fasteners;

- vibration isolation pad;

- sealant;

- special fixture;

- the finishing layer of drywall screwed to the sandwich panels.

Additional sound insulation of the floor, provided by the construction using ZIPS - 11-18 dB. Thickness - 55–133 mm.

Soundproofing materials

Consider the features of common sound-reflecting and sound-absorbing materials.

- Plates made of basalt (mineral wool), polyester or fiberglass. They have an excellent noise absorption coefficient - up to 85%. Effective against any type of noise. Mounted, as a rule, by the frame method. The only drawback is the large thickness. Well-known brands - Rockwool Acoustic, Shumanet, Stopzvuk, Aku-Light.

- soundproof membranes. They have a high density and a small thickness - 2.5–14 mm. Due to their structure, they do not absorb noise, but reflect, and allow achieving high-quality sound protection. The disadvantage is the high cost. The most famous representatives are Tecsound (a self-adhesive ultra-thin heavy membrane made from the aragonite mineral), MaxForte (composed of aluminosilicate fibers, a layer of one-component rubber), Fkustik-metal slik (foamed polyethylene and lead plate 0.5 mm thick).

- Soundproof panels. Due to the massiveness, multilayer structure, elastic-viscous consistency and free particles of the filler, both shock and sound energy are reduced. For example, EcoZvukoIzol from SoundGuard has a seven-layer cardboard profile filled with quartz sand.

- ZIPS. The sandwich panels of this system consist of gypsum fiber and mineral wool, are equipped with vibration nodes for fastening, are mounted on special fasteners without a frame, and are sheathed with plasterboard on top.

- Cork. Natural cork material provides good noise insulation, but to achieve a significant effect, a thickness of several cm is needed. When using technical rolled cork with a thickness of 10 mm, one layer will not be enough.

In addition to these materials, coconut coir, felt, liquid soundproofing and others are used for ceilings.

Additional methods of soundproofing

As already mentioned, the degree of protection of the room from extraneous sounds also depends on the final sheathing of the ceiling. For these purposes, use:

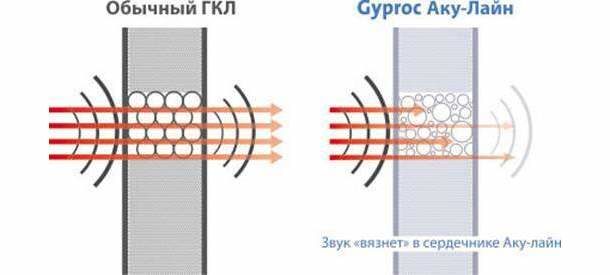

- increased density drywall, for example, Giprok Aku-Line, Knauf Diamant;

- acoustic triplex - 2 weighted gypsum-fiber sheets with increased moisture resistance (GVLVU), connected with a special sealant. The total thickness is 16.5 mm. From above it is sewn up with a finishing layer of GKL;

- noise-absorbing boards Knauf Piano.

Installation of sound insulation using frame technology

Instructions for creating a frame soundproofing system for the ceiling:

- The base surface is thoroughly cleaned and primed.

- All holes and cracks in the ceiling plate are filled with sealant. This will prevent airborne noise from penetrating through them.

- A noise-absorbing mat or a multifunctional membrane of the Texound type is glued to the ceiling.

- At a distance of 50 cm from each other, vibration suspensions are attached.

- Profiles for the frame are glued with sealing tape.

- According to the standard technology, a frame is mounted, which is lowered relative to the ceiling surface by 5–15 cm, depending on the required thickness of the soundproof layer.

- Soundproofing material is placed in the cells of the frame.

Then you can choose one of several options for the last layers (arranged in ascending order of sound protection level):

- Two layers of drywall or gypsum fiber.

- Soundproof panel + GKL or GVL layer.

- GKL layer + heavy noise-absorbing membrane + one more GKL layer.

The layers of the "pie" can vary, especially since new, improved materials are constantly appearing. You can peep effective solutions for self-implementation on the websites of companies involved in soundproofing at a professional level.

Frameless installation of sound insulation

The standard sequence of actions for arranging a frameless system:

- Ceiling cleaning, priming.

- Bonding the selected sound insulator. It can be roll varieties, panels or slabs. Sticking starts from the corner, the material is pressed tightly.

Note! Glue is not applied over the entire surface of the panel, but only around the perimeter and in the center. Even the slightest gaps between elements are unacceptable.

- Additional fastening of the panels with dish-shaped dowel-nails (they are called "umbrellas" or "fungi"), which are located in the corners and in the center.

- Stretch ceiling installation.

Important Points

When planning to soundproof the ceiling, you need to remember that:

- the best results are obtained by combining several materials with different properties - sound-absorbing and sound-reflecting;

- self-assembly is possible only with careful observance of technology. It is enough to forget to glue the damper tape or loosely lay the material, and the desired effect will not be achieved.

And finally, the recommendation: since the soundproofing of the ceiling is an expensive undertaking, it is worth consulting with a specialist before choosing a material and installation. Ask your questions in the comments and get a detailed answer. The subtleties of self-arranging the soundproofing of an apartment are in the video below.