When laying or replacing electrical wiring in an apartment, a VVG type wire is very often used. It deservedly gained wide popularity among electricians due to its low cost, combined with good quality. But for a simple layman who does not have specific knowledge, it is quite difficult to understand the whole variety of products of this type. How to choose the right cable depending on the connected load and what does its marking mean?

Types of VVG wires and their marking

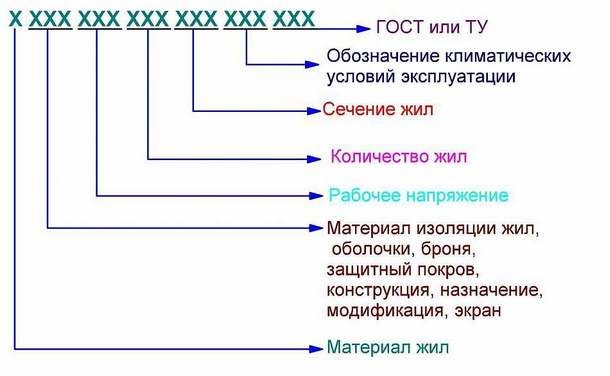

Distinguishing different types of cables in appearance is quite problematic, and it is not necessary. There are a huge number of varieties that differ in the number of cores, their cross section and material, the composition and qualities of the insulation, and various additional elements. For convenience, manufacturers place a special marking on the outer braid that gives a complete description of the cable. You just need to know how to read it correctly.

- Cable cores can be made of aluminum or copper. In the first case, the letter “A” is placed before the abbreviation VVG. If it is not, then this means that the wire is copper. It is these cables that are preferable to use when laying electrical wiring in an apartment.

- Two letters "B" indicate the material of external and internal insulation, which is polyvinyl chloride. Polymers (letter "P") or polyethylene ("PV") can also be used.

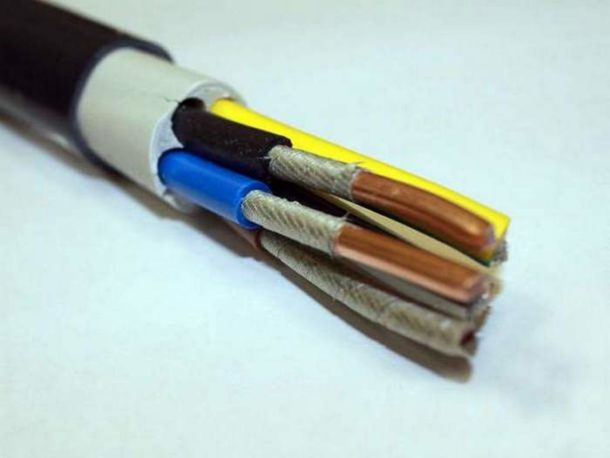

- The third letter indicates the degree of protection of the cable against mechanical damage. "B" denotes an armored wire, "G" - bare, that is, without additional protection.

Armored cable does not need to be placed in corrugations or pipes when laying underground or on the surface.

Additional letters after the letter combination VVG indicate the fire safety category to which this product belongs:

- The absence of signs means that such a cable, when laid alone, will not support open combustion.

- The designation "ng" - this ability is preserved during group laying.

- "Ng - ls" - reduced emission of smoke and gas.

- "Hg - hf" - no release of gaseous substances with active corrosion properties.

- The prefix "fr" indicates that the cable is fire resistant due to the additional wrapping with tape containing mica. Options: "ng-frls" and "ng-frhf", which have the corresponding properties.

Designation of the number of cores, their cross section and cable structure

Further designations indicate the number of cores, their thickness and design features:

- The first number is the number of cores.

- The second is the area of their section.

For example, a VVG 3×2 wire has 3 wires with a nominal cross section of 2 mm2.

The choice of the cross section of the cores is made taking into account the expected load, which will be connected via cable:

- For lighting, a VVG 3 × 1.5 cable is suitable.

- The sockets can have a much more significant load, so the wire must be taken more impressive. The cross-sectional area of \u200b\u200bits cores should not be less than 2.5 mm2, therefore the socket “minimum” is a VVG 3 × 2.5 cable. But it’s better to take it with a margin so that you don’t have to redo the wiring later.

- To connect electric ovens, washing machines or other energy-intensive electrical appliances, the wire cross section must be at least 4 mm2.

The marking also shows the structural structure of the cable:

- If the core consists of several twisted wires, then the letter “M” is indicated, single-wire ones are indicated by the letter “O”.

- The shape of the cores: "C" - sector, "K" - round.

- Through the "+" sign, the characteristics of the neutral or ground wire are indicated, if they are available and differ in cross section from the rest of the cores.

- The last digit indicates the rated voltage in kV for which the cable is rated.

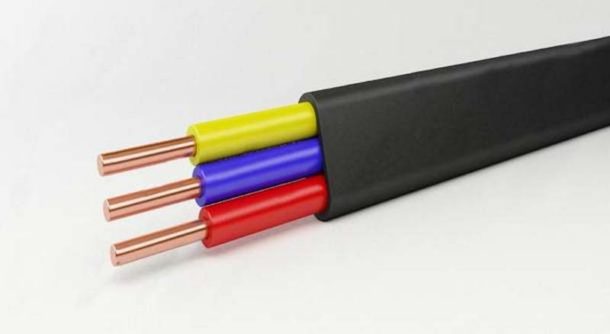

- A wire with the designation VVG-p (“p” - flat) is rarely used in everyday life. The veins in it are laid in a row, it itself has a flat shape. It is mainly used to connect powerful industrial installations.

In accordance with international standards, the core insulation has a certain color: the neutral wire is colored blue, and the ground wire is yellow-green.

Marking decoding example

Consider the features of decoding the markings using an example.

Thus, marking VVG 3×50ms+1×25ms(N) - 0.66 TU will denote a copper wire without armor with external and internal PVC insulation, having three multi-wire sector conductors with a cross-sectional area of 50 mm2 and a grounding conductor with a cross-sectional area of 25 mm2, rated for 660 volts.

Scope and features of operation

At home VVG cable it is not recommended to lay only in the ground. It does not have additional protection, so its laying in a trench is only possible in pipes or other protective structures. It is more expedient for these purposes to use an armored cable.

In an open way, it is possible to mount VVG wires only on surfaces made of non-combustible materials: concrete, brick, plaster or gypsum. But in this case, the possibility of mechanical damage to the cable remains. To eliminate it, the wire is placed in corrugated sleeves, cable channels or pipes. Such protection is required for open wiring on wooden walls.

In apartments, the hidden laying method is most often used. The cable is laid in special strobes or voids covered with plaster or other finishing materials. In this case, additional protection against mechanical damage is not required, but in wooden walls or when using combustible finishing materials, the cable must be placed in refractory boxes or corrugations.

At wiring you need to take into account some more characteristics of VVG wires:

- They can be operated at temperatures from -50˚С to +50˚С.

- The minimum radius to which the wire is allowed to be bent is 10 of its diameters.

- Installation at temperatures below -15˚С requires additional heating of the cable.