In rooms with high humidity or high operational load, it is best to use a tiled floor. But for all its advantages, the tile has one significant drawback: without additional heating, this is a rather cold coating. To ensure comfort, many owners use a system of "warm floors". The technology of laying an electric underfloor heating under a tile is the most affordable, and therefore it is most often used in cases where the work is done by hand.

Advantages of electric underfloor heating over water

Why choose underfloor heating under tiles using electric heating elements?

- For residents of apartment buildings, an important factor is that this option for heating the flooring is not associated with the risk of leaks. That is, if the underfloor heating system fails, then at least you will not have to compensate for the damage to the flooded neighbors from below.

- It is possible to produce space heating all year round. This is true for apartments with central heating. In addition, nothing will happen to the underfloor heating system when the electricity or hot water is turned off. Such accidents are not uncommon, and in the cold season, underfloor heating pipes with water heating can simply freeze.

- Laying an electric underfloor heating is made more compact, so the height of the room will not change as much as when laying pipes with water.

- Electric elements allow you to achieve more uniform heating of the surface, and temperature control is easier.

- Installation of a warm floor with electric heating is easier than with water. Almost any person who owns the most elementary skills of construction work can lay it with his own hands.

- The heat-insulated floor laid by means of electric heating elements practically does not need service.

Types of electric heating elements for underfloor heating

Before you make a warm floor with electric heating, you should decide on its type. There are three types of heating elements:

- Cable. Sold in the form of coils of a certain length. On the base surface, the cable is fixed using special strips with clamps. They may be included in the kit, or you will have to purchase them separately. Installation of a cable underfloor heating under a tile will require careful calculation of the required material. Under it will have to make the thickest screed. But the price per m2 for such a coating will be the lowest compared to other options.

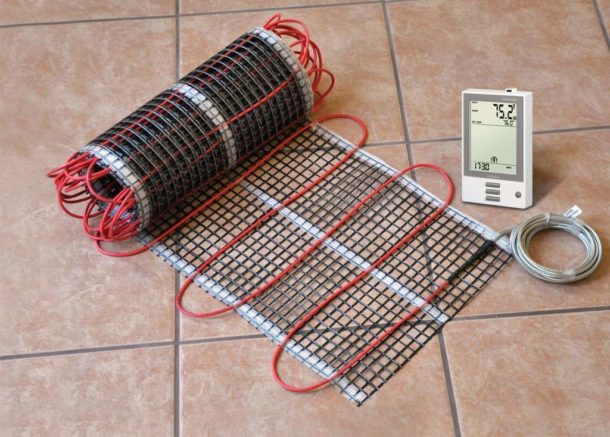

- Do-it-yourself installation of mats, which are a cable fixed on a fiberglass mesh, is much easier to do. They cost a little more, but they are much easier and more convenient to lay. In addition, the thickness of the screed required for arranging underfloor heating is reduced.

- Infrared film has the smallest thickness of all types of electrical heating elements. But the installation of a film underfloor heating is usually carried out under floor coverings that conduct heat better, such as laminate, linoleum, carpet. Installation of infrared heating film under the tiles Not recommended.

Preparatory work

It is necessary to start the installation of a warm electric floor under the tile with the preparation of the base.

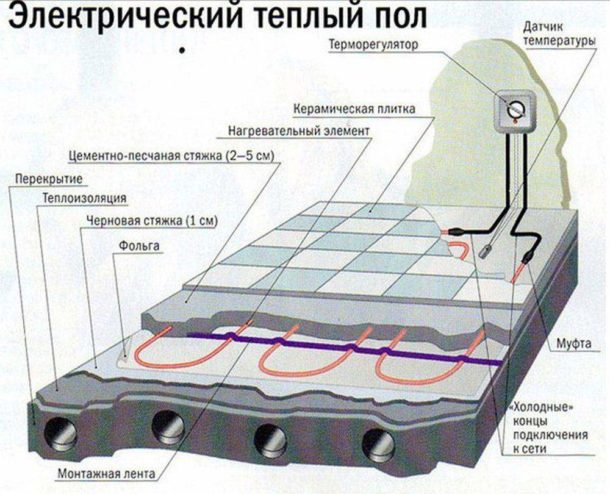

- The old floor covering is removed. Cement screed is most suitable for making underfloor heating. It is she who should be given preference if the work is done by hand.

- The base surface must be perfectly flat.Otherwise, it will not be possible to mount the heating with high quality: with any bend in the cable, the probability of its breakdown increases, and repair will be practically impossible. Therefore, all the irregularities of the base should be eliminated: knock down the protrusions, repair crevices and cracks. In advanced cases, you will have to make a leveling screed.

- A strobe is made in the wall for wires. As a rule, the controls for underfloor heating are located at a height of 70 to 100 cm from the floor, but not lower than 30 cm. In rooms with high humidity, it is better to bring the controls outside. If the temperature sensor according to the laying scheme should be located at the base of the floor, then a groove is made under it.

- A thorough cleaning of the base from dust and dirt is carried out, after which the surface is primed.

- A laying plan is being drawn up. Heating elements are located at a distance of at least 10 cm from the walls. The distance from other heating devices, such as hot water risers, must be at least 30 cm. Heating is not carried out in those areas of the floor that are intended for the installation of plumbing fixtures or heavy stationary furniture.

- A heat-insulating layer is mounted, which will increase the efficiency of underfloor heating. In apartments, foil penofol is more often used, it has a smaller thickness, so it does not reduce the height of the room so much. They put it with the foil up so that the heat from heating is reflected inside the room, retreating from the wall at a distance of 5 cm. The junction with the wall is glued with a damper tape, it compensates for the expansion of the screed when the warm floor is heated. Styrofoam or expanded polystyrene is used if the apartment is located on the ground floor or above an unheated room. In this case, the distance from the wall is 10 cm.

- All joints between the elements of the film heat insulator are glued with foil tape.

Heating cable laying

Before installing a cable for a warm floor, it is necessary to check its resistance. It must match the parameters indicated on the stickers or documentation. Then the sequence of actions is as follows:

- A special mounting tape is fixed on the surface in increments of 50 cm to a meter. Fastening elements are located on it with a step of 20 mm, which allows you to create the desired laying configuration. Instead of such a tape, you can use a metal mesh; in this case, the cable is fixed using plastic clamps.

- The cable is laid with a snake, observing the necessary indents from the walls. It is impossible to allow touching of one turns of the cable with others or their crossing.

- Heating cable laying

- Cable fixation

- A temperature sensor is placed at an equal distance from adjacent turns. It is wise to place it in a corrugated tube, the end of which should be carefully sealed to prevent the solution from entering.

- Controls for underfloor heating are being connected. If you are unsure of your qualifications, it is best to call a professional electrician. If you want to do everything yourself, follow the connection diagram indicated on the back of the rheostat or in the instructions.

- Using the tester, the resistance of the heating circuit is checked again. It must match the values obtained before installation.

- To check the performance of the underfloor heating system, turn on the heating for a short period of time. One minute is enough. The indicators on the rheostat should light up, the cable will start to heat up.

Laying heating mats

Their installation is much easier, since the cable is already fixed to the fiberglass mesh. It remains only to roll them out like a film on a heated surface.The mat under the entire floor must be integral, so to obtain the desired configuration, the fiberglass is cut with scissors without affecting the heating cable.

Otherwise, the whole scheme of work remains the same as when laying the cable. After connecting and checking the operability of the system, you can proceed to pouring the screed.

More clearly, the installation of an electric underfloor heating under a tile is presented in the video.

[smartcontrol_youtube_shortcode key="electric floor heating installation" cnt="2" col="2" shls="true"]Screed and laying tiles on underfloor heating

The thickness of the screed for a warm floor directly depends on the type of heating element chosen: in the case of a cable, this parameter ranges from 30 to 50 mm, and for heating mats - no more than 30. When using the latter, you can do without a screed at all with a sufficient thickness of the tile adhesive layer.

The screed should be leveled very carefully so as not to damage the heating elements. At the same time, the formation of air bubbles that impair the efficiency of the system should be avoided.

Laying tiles will differ significantly in only one circumstance: it is necessary to purchase an adhesive solution and a grout composition designed specifically for laying underfloor heating. There are some nuances to keep in mind:

- The laying scheme must be chosen so that the cut tiles are at the edges.

- Laying is better to start from the corner of the room, opposite the front door.

- After applying the adhesive solution with a notched trowel, the tile is pressed a little deeper by hand, controlling the position of each element with a level.

- To obtain even seams, plastic crosses are used.

- After the glue has dried, the joints are grouted, immediately removing the protruding parts of the solution with a wet rag.