When replacing flooring, apartment owners often have to deal with the need to repair the concrete floor, which can be like a concrete floor. coupler, and the floor slab itself. Despite the fact that concrete is a durable and reliable material, potholes and cracks can appear on it under the influence of various factors. To prevent further destruction, timely measures are necessary, because the service life of the finishing floor depends on the condition of the concrete base. Find out how to repair concrete pavement using special concrete floor repair mixes.

Causes of defects in concrete

Defects on the concrete floor can be formed for various reasons, which are primarily associated with violations in the process of its arrangement.

Cracks often appear due to missing, untimely cutting or incorrect calculation of the thickness of the joints in concrete floors, designed to prevent concrete stress during thermal expansion and shrinkage. Properly made temperature-shrinkage seam will avoid many problems.

Other causes of cracks include:

- a large amount of water in the solution when pouring a concrete screed or its lack;

- low-quality reinforcement;

- lack of base waterproofing.

Defects can form even with high-quality work done. Any coating is subject to natural wear and tear, it is negatively affected by excess moisture. Potholes appear due to physical influences. It is impossible to exclude the influence of external factors on the concrete floor. The weak point is the junction of the wall and the floor, cracks often appear there.

The type of damage must be determined. This will allow you to draw up a work plan and select the right material. Often faced with the following varieties:

- small depressions, potholes;

- cracks of various sizes;

- the thinnest cracks and chips.

Repair should not be put off for a long time. The size of the defects may gradually increase, the concrete will begin to crumble and move away in pieces, which will complicate the sealing of problem areas.

The choice of mixture for the repair of concrete surfaces

Before you start repairing the floor in the apartment with your own hands, you need to prepare a mixture for restoring concrete surfaces and structures. In building stores, they are presented in large quantities. In order to choose the right brand of mixture, you need to determine the degree of damage to the concrete surface:

- First degree - there are shells, shrinkage cracks.

- The second degree is peeling of the surface, small chips.

- Third degree - cracks within 2 mm with a depth of not more than 40 mm.

- Fourth degree - cracks more than 2 mm, depth up to 10 cm.

- Fifth degree - large potholes and cracks, a depth of more than 20 cm.

The purpose of the repair mixture should be indicated on the packaging. Noteworthy are such manufacturers of mixtures for the restoration of concrete surfaces as Emaco, Birss, Ceresit, Bars.

You can use universal repair mixes, such as Ivsil Render.

Since the price of special thixotropic compounds containing reinforcing microfibers and polymers is quite high, the mixture can be prepared independently for a small amount of work. To do this, take 1 part of PVA glue and mix with 4 parts of water. On this solution, using a construction mixer or a special nozzle on a drill, the sand-cement mixture is kneaded in a ratio of 1: 3.

Preparatory work

After choosing a material for repairing concrete floors, you should start repairing. First comes the preparatory stage:

- All foreign objects are removed from the room.

- Existing debris, concrete chips and dust are swept away.Potholes and cracks are thoroughly cleaned with a vacuum cleaner.

- Any dirt, rust, mold or old soil is removed with a stiff metal brush.

- To eliminate greasy stains, you need to use a special solution.

- The concrete floor is swept with a wet broom, then it needs to be dried.

- If the reinforcement is visible, then it should be cleaned with sandpaper and primed with a composition with anti-corrosion properties.

Areas of the concrete surface that have lost strength should be hammered and cleared. The rule also applies to the edges of problem areas.

Filling holes in concrete floor

Repair of concrete floors begins with the expansion and deepening of the pothole around the perimeter. It is better to use a grinder with a diamond disc for this.

- The cut is made 1 cm deeper than the defect. To the sides, the pothole expands by 2–3 cm. If necessary, these figures are increased.

- Using a perforator or a hammer with a chisel, a notch is made in place of the pothole, a rectangular recess should be obtained. If a perforator is used, then it is better for outsiders to move away.

- The recess is thoroughly cleaned with a vacuum cleaner and primed.

- You can close up the pothole after the soil has dried. The mixture is carefully leveled, it is pierced several times to remove air. You can use a metal pin or trowel. Level the surface using the rule.

The depth of the hole matters. If it is more than 5–6 cm, then the composition is poured in several layers. The maximum layer thickness is 2 cm.

- After hardening, they proceed to grinding. A building level will help to achieve an even concrete base.

Work is recommended to be carried out in a respirator, goggles and gloves. Windows must be left open during renovations. The floor can be covered with paint on concrete, which will serve as additional protection. It is selected specifically for residential premises. A floor repaired in this way will serve for a long time.

Crack Repair Rules

The process of sealing cracks in a concrete floor differs depending on their size.

- Small gaps expand in depth and width by 2–5 cm. For this, you can use a chisel or a grinder.

- The recess is cleaned of pieces of concrete and dust, then processed primer.

- To repair cracks in the concrete floor, a home-made mixture based on PVA is used. It fills the crack and waits for shrinkage.

- A second coat is applied, dried and sanded.

In cases where sawing is accompanied by strong dusting, which indicates that the concrete is weakened, it is necessary to use only special thixotropic compounds.

Repairing cracks in concrete floors should not be put off for long. If they are deformable, then they need to be treated with special attention. You can determine their appearance using strips of paper. A few months before the repair, they are glued to cracks in the concrete floor. With shrinkage slots, the paper will remain intact, with deformation strips they will break, which indicates their expansion.

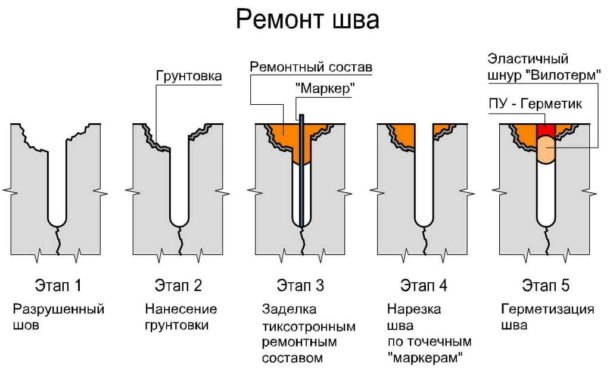

- Such a crack is sawn 5 cm deep and 3 cm wide.

- The edges of the cut are knocked off, a triangular notch is formed.

- After thorough cleaning, the recess is primed.

- Markers are inserted into the crack with a step of 3 m.

Markers are thin smooth metal rods. You can make them yourself from the spokes of a bicycle wheel.

- The crack is filled with a thixotropic compound; the use of home-made mixtures in such cases is not recommended.

- The concreted area after drying is polished.

- The marker rods are removed, a new expansion joint is cut out through the holes left after them.

- Dust is removed from the seam, and the Vilotherm cord or its equivalent is placed in it.

- The seam is finally sealed with a sealant based on silicone or polyurethane.

Some people notice small cobweb cracks on the floor, as in the next photo. Over time, they may become wider. When the concrete weakens in this part, they are cleaned and covered with soil. For embedding, you can prepare your own composition or use a store-bought one.

In order for the furniture to stand evenly after repairing the concrete floor in the apartment, it is necessary to use the building level throughout the entire process.

Concrete floor overhaul: cost

In the event of severe damage to the concrete pavement or when arranging underfloor heating systems it will be necessary to carry out a major overhaul - a complete replacement of the concrete screed. When contacting specialists, this procedure, taking into account the materials, will cost the following amount:

- in Moscow - from 420 rubles / m2;

- in St. Petersburg - from 380 rubles / m2.

The dismantling of the old concrete screed is not included in this amount, the price depends on the area of work: the larger it is, the cheaper it is.