Linoleum remains one of the most common and popular floor coverings. This is facilitated by its qualities: durability, practicality, low price and ease of installation. The Achilles' heel of the material loved by many are the places where the strips join each other or with other coatings. It is here that mechanical damage most often occurs, dirt and moisture get through the joints under the linoleum, which leads to a decrease in its service life. Let's figure out how to connect pieces of linoleum to each other in different ways.

Material types

Before talking about the connection of linoleum, you need to decide on its type. Said flooring may be residential, commercial, semi-commercial.

- Household linoleum based on foamed PVC or felt and with a top layer of polyurethane is selected for living rooms and rooms with low traffic, because it does not have high strength and wear resistance.

- The semi-commercial flooring has a PVC or polyester fiber backing. Compared to the household variety, it is distinguished by a greater density, thickness and the presence of a protective layer.

- Commercial linoleum is a special coating with increased resistance to stress, has a uniform structure and is dyed over the entire thickness.

Important! Such an effective connection method as hot welding is used only for commercial linoleum.

Preparatory work

Before connecting the linoleum at the junction, it is necessary to perform a number of manipulations to ensure the durability of the resulting seam.

- First of all, you should let the material lie down so that it straightens out and takes its final shape. Otherwise, after some time after the sealing of the seams, “waves” will appear on the surface.

- Sometimes it may be necessary to eliminate defects in the base of the floor - cracks and bumps.

- To obtain a reliable and durable seam, it is necessary to carefully remove all dirt and dust from the floor. This is especially true of the space between the connected pieces of linoleum.

Docking methods

In order to qualitatively connect the joints of linoleum strips with your own hands, you can:

- Glue the individual pieces of material with double-sided tape.

- Install special strips or sills with a T-shaped profile.

- Use dispersion adhesive.

- Seal the seams with cold welding.

- Apply the hot welding method when it comes to commercial linoleum.

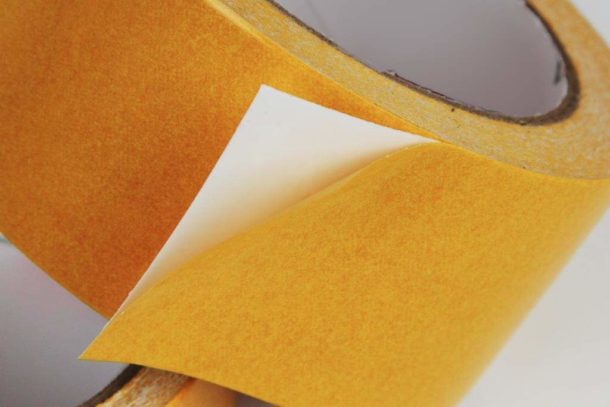

Double-sided tape

This is the easiest and fastest, but at the same time the most unreliable way. The adhesive tape is attached to the floor under the seam line and prevents it from coming apart. For better adhesion, the joint is rolled with a weighted roller. You should be prepared for the fact that under the influence of moisture, the connection will quickly lose its strength.

Planks and sills

They are made from various materials: metal, plastic, rubber. Analog thresholds - special pads that cover the places where individual fragments of the floor material are connected.

The method is optimal when joining dissimilar coatings, such as linoleum and ceramic tiles. Overlays are often used to ensure a smooth transition from one room to another.

Dispersion adhesive

This category includes bustilat, bituminous mastic, humilaks or acrylate glue. The listed compositions compare favorably with the absence of toxic substances among their components and environmental safety. The main disadvantage of bonding with glue is their poor tolerance to low temperatures in the room. At temperatures below 15 ° C, the adhesive loses its elastic properties and begins to crumble. Such compositions also tolerate high humidity with difficulty.

It should be noted that certain types of linoleum must be glued with a suitable composition:

- bustilat is used for a coating that has a base with a pile;

- bituminous mastic - for a fabric substrate;

- humilax - for material with a fabric or felt base;

- acrylate glue - for synthetics, fiber or jute.

- Use of dispersion adhesive

- Bustilat

Hot welding

The hot-weld joining method is ideal for commercial linoleum. Can it be applied to ordinary household material? Unfortunately, no: it is too thin and simply will not withstand heat. In addition, this method requires specific equipment, as well as certain work skills, so it is not recommended for beginners to resort to it on their own.

You will need a special hair dryer, with which the joint will be filled with meltable PVC cord. The temperature during this operation can reach 300–400 °C.

To create grooves for the cord and remove excess material, special knives and cutters are required, which are usually included in welding kit along with a hairdryer.

The process is as follows: in a commercial linoleum glued to the floor, a groove is selected along the seam, which is then filled with a molten mass of their PVC cord. You can read about all the intricacies of the process here.

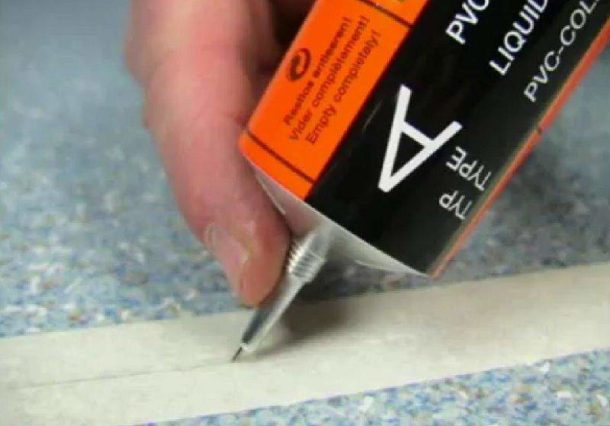

Use of cold welding

This is the best option for obtaining a single surface of linoleum at home. Cold welding allows you to create a strong and almost imperceptible seam, even if it has a curvilinear shape. In fact, these compounds simply dissolve the contacting parts of the linoleum through a chemical reaction, therefore, after hardening, it is possible to obtain a single layer of flooring. Read more about choosing the type of adhesive for cold welding and the rules for gluing with this method, read here.

To work, you will need masking tape, a sharp knife, a weighted roller and a tube of liquid glue. As a rule, the latter has a rather narrow neck and a special needle nozzle.

- When laying a new coating, the edges of adjacent fragments are laid with a slight overlap. Then they are cut through with a knife, forming a seam of minimum thickness.

- The edges of the fragments are attached with double-sided tape. For a tighter fit, the joint is rolled with a roller.

- To protect the front of the coating from the effects of glue, the area around the seam is sealed with masking tape. It should close the incision itself.

- The masking tape is cut with a knife and an adhesive solution is injected into the seam. The tube must first be shaken well. The needle is inserted into the joint as far as possible. Glue is injected until it is forced out of the seam.

This stage of work should be done with gloves and a mask, as the composition is chemically aggressive. The room must be well ventilated.

- The time for complete drying of the adhesive is indicated by the manufacturer on the packaging. After its expiration, the excess adhesive mixture and the remnants of masking tape are carefully removed with a knife.

More clearly, the process of sealing joints when laying new linoleum is shown in the video.