It often turns out that even in an ideally shaped room it is impossible to lay linoleum without a single joint due to the standard dimensions of the material. The resulting seams should not only be invisible, but also durable so that the coating does not bulge over time. The linoleum joint between rooms requires special attention, because it is in this place that the load on the seam is especially high. In order to choose the appropriate method for connecting the coating, it is worth considering the possible design options for the joint and the devices used for this purpose.

Linoleum connection options

Linoleum joints can be sealed in several ways. They differ both in the complexity of the work being carried out and in the cost of materials and tools. At the same time, the quality of the final result will also be different.

- Fixing the edges of the cover with double-sided tape. This method is good for its low cost and ease of execution. But the reliability of the connection of the joints in this case will remain in question - the glued edge of the coating will quickly begin to puff up.

- The use of sills and overlays for linoleum. Another inexpensive way, while quite reliable. The only negative is that such an element will differ from the rest of the coating and protrude slightly above the floor surface.

- Edge bonding with dispersion adhesive. Such compositions, which are also used for gluing the material to the rough surface, are environmentally friendly, but do not provide complete sealing of the seam.

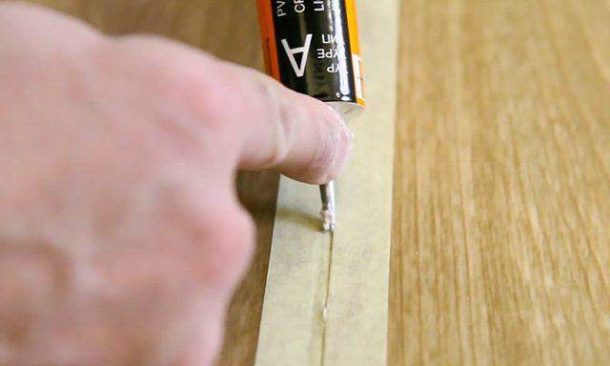

- Cold welding of linoleum joints. For a monolithic connection of the coating strips, an adhesive is used that melts the edges and, after drying, firmly fastens them together. You can work with it at home, suitable for both domestic and commercial linoleum.

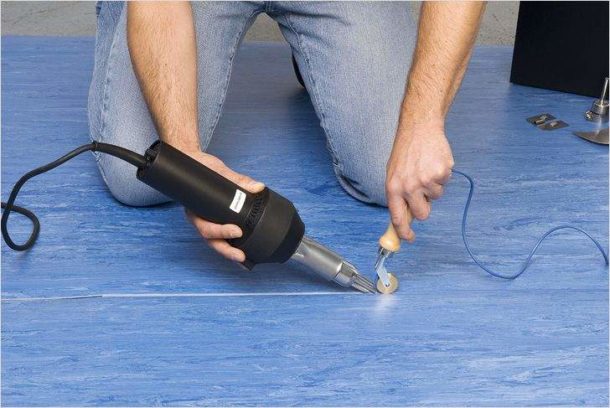

- Hot welding. Carried out with the help hot air gun and a special cord made of PVC, which melts under the influence of high temperature and fills the seam, firmly fusing with the edges of the coating and forming a single whole with them. The method is used for the commercial type of linoleum, it is quite complicated for independent execution. The connection is invisible.

Let us dwell in more detail on how to seal the joints of household linoleum using decorative thresholds.

What are sills for linoleum joints

A threshold in the doorway connecting the joints of floor materials between rooms is a simple and cheap way to fix the edges of the coating, hide the seam and possible installation flaws.

Advantages of the method:

- It is very easy to fix the threshold with the included screws or Liquid Nails directly to the subfloor.

- The pad can be used multiple times and is easy to replace.

- The bar will protect the material from moisture, dust and dirt getting under it.

- The product will last a long time, especially if it is made of metal. Competent color selection makes this element practically unobtrusive.

- The sills have a decorative function - the design of the room will look complete.

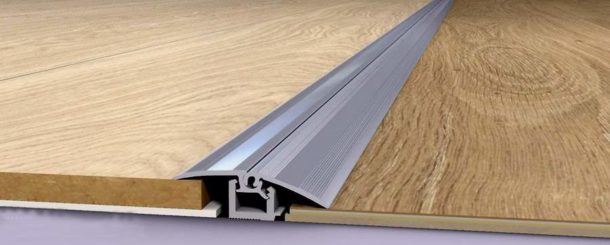

- In the event that you decide to lay coatings of different thicknesses on a single-level floor, an overlay on the seam will help smooth out the difference between them.

But the thresholds also have their drawbacks:

- The plank will stick out (albeit slightly) above the floor surface.

- The threshold can only be mounted in the doorway or under the arch; the seams in the middle of the room cannot be hidden in this way.

When installing the thresholds, you need to remember that they should not interfere with the complete closing of the doors - the edge of the canvas will have to be filed or installed after finishing the floors.

Nut types

It is possible to close the joints of pieces of linoleum with each other or with another floor covering with overlays of different purpose and material.

Depending on the design and method of application, the following types of thresholds exist:

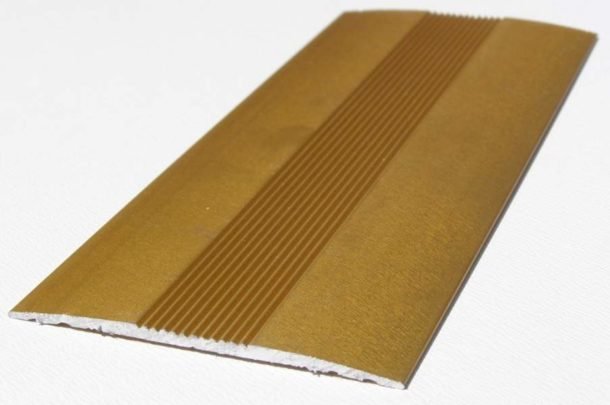

- Straight lines - for joints of linoleum of the same thickness.

- Multi-level - compensate for height differences on the floor, with their help, coatings of different thicknesses can be joined.

- Finishing - for sealing the edges of linoleum without connecting with other materials.

- Corner - for the design of seams and edges of the flooring on the stairs.

Planks are made from different materials:

- Brass and aluminum metal thresholds are the most popular, because the connection is strong, aesthetic and durable. Most often painted in bronze, gold or silver.

- Plastic thresholds have a shorter service life, but some flexible models can be used to decorate rounded joints, and the price of products is much lower. The requirements for them are spelled out in GOST 19111-77, which classifies door sills as semi-rigid products. In the photo below, the flexible bar performs several functions: it zones the space of the room and hides the difference in the thickness of the floor coverings.

- Rubber pads can have an aluminum base, prevent slipping.

- Wooden sills and planks made of MDF are rarely used due to their high cost and tendency to swell from moisture.

- Cork products are popular due to their environmental friendliness, softness and long service life. They perform a compensatory and shock-absorbing function.

How to fix the lining on the joints of the coating

Self-tapping screws or glue can be used to fix the slats. When choosing a mounting method, you need to take into account the features of both methods:

- Mounting on self-tapping screws is much more reliable; fasteners are not visible in products with a decorative plug.

- Glue cannot provide such a strong connection, but it is suitable for cases where the subfloor is loose and cannot hold self-tapping screws.

The procedure for working with sills will be as follows:

- First, laying linoleum. The joints fit together as tightly as possible.

- The length of the entire seam is measured, then a piece of the nut of the desired size is cut off.

- Part of the linoleum near the joint, as well as the subfloor under it, are thoroughly cleaned of grease stains, moisture, dust and other contaminants.

- The cut off threshold is tried on to the joint, then places for drilling holes for dowel-nails are marked on the subfloor.

- Holes are made according to the marks, then plastic fasteners are inserted into them.

- Next, a bar is installed over the seam and fixed with screws.

- The decorative cap is latched.

Remember that when screwing in the fastener, it is important not to overdo it, otherwise the plastic or wooden plank will burst.

A video will help you visually familiarize yourself with the process of fastening the thresholds with your own hands.

Strips of linoleum are easily docked with each other and with other floor coverings using ordinary thresholds. Of course, they are not suitable for hiding the seams in the center of the room, but with their help you can beautifully decorate doorways and joints on the stairs.