What is a circulation pump and why is it needed

A circulation pump is a device that changes the speed of movement of a liquid medium without changing the pressure. In heating systems, it is placed for more efficient heating. In systems with forced circulation, it is an indispensable element, in gravitational systems it can be set if it is necessary to increase the thermal power. Installing a circulation pump with several speeds makes it possible to change the amount of heat transferred depending on the temperature outside, thus maintaining a stable temperature in the room.

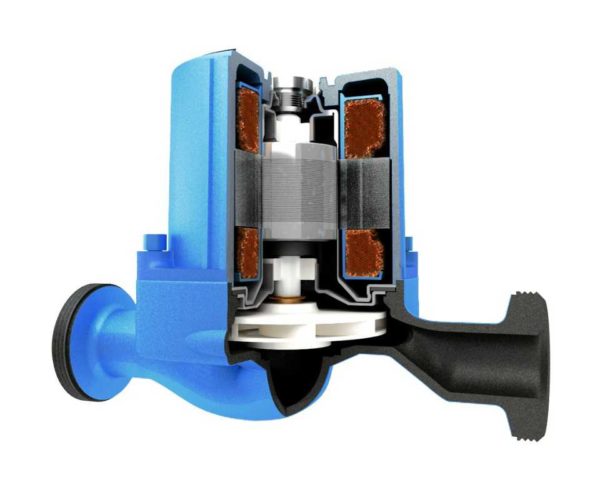

Sectional view of a wet rotor circulation pump

There are two types of such units - with a dry and wet rotor. Devices with a dry rotor have a high efficiency (about 80%), but they are very noisy and require regular maintenance. Wet rotor units operate almost silently, with normal coolant quality, they can pump water without failures for more than 10 years. They have a lower efficiency (about 50%), but their characteristics are more than enough to heat any private house.

Pump device

Since the motor stator is energized, it is separated from the rotor using a glass made of stainless steel or carbon material.

The main elements that make up the circulation pump are:

- housing made of stainless steel, bronze, cast iron or aluminum;

- rotor shaft and rotor;

- a wheel with blades or an impeller;

- engine.

As a rule, the impeller is a construction of two parallel disks, which are connected to each other by means of radially curved blades. One of the discs has a hole for fluid to flow through. The second disk fixes the impeller on the motor shaft. The coolant passing through the engine performs the functions of lubrication and coolant for the rotor shaft at the place where the impeller is fixed.

Since the motor stator is energized, it is separated from the rotor by a cup made of stainless steel or carbon material. The walls of the glass are 0.3 mm thick. The rotor is fixed on ceramic or graphite sliding bearings.

Recommendations for the correct installation of the pump

In order for access for servicing the pump to be convenient, the unit must be properly connected. In practice, when installing the pump, the basic installation rules should be taken into account:

After installing the circulation pump, it must always be accessible so that in the event of a breakdown, it can be easily repaired or replaced.

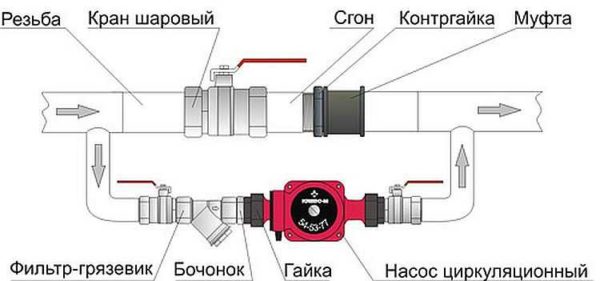

- Both sides of the pump unit must be equipped with special ball valves, which are necessary when carrying out maintenance of the entire heating system or during the dismantling of the unit.

- It is necessary to equip the entire system with a filter in order to protect the device from the effects of small particles that lead to damage to the unit and its components.

- Since the water passing through the heating system is far from ideal, additional protection will be required for the normal operation of the pumps. Therefore, the heating bypass must be provided with a valve from above, which must be installed. You can choose any valve: automatic or manual. Its purpose is to release air pockets that form in pipes; its terminals must be directed clearly upwards.

- The wet type pump must be installed in a horizontal position so that it is completely submerged in water, and not just a separate part. Incorrect installation may cause damage to the working surface of the unit, and the installation will be meaningless.

- To increase the working potential of the structure, it is necessary to perform a special treatment of all fasteners and connections in the system with a sealing agent.

- It is necessary to follow the sequence in the process of connecting the pump and fasteners.

Unit features

The principle of operation of circulation pumping equipment is based on the creation of continuous circulation of fluid in the system without changing the pressure indicator.

A circulation pump is a device that operates in a closed heating system and performs the movement of water in the pipeline. The unit maintains a certain temperature of the coolant in the system. The device does not compensate for the loss of coolant and does not fill the system. The filling of the system is carried out due to a special pump or a certain pressure in the pipes.

The principle of operation of circulation pumping equipment is based on creating a continuous circulation of fluid in the system without changing the pressure indicator. Since the device works constantly after installation, the main requirements for such pumps are low noise level during operation, economical energy consumption, reliability, durability and ease of use.

Important: circulation pumps are compact devices that do not take up much space and do not create noise during operation. The scope of use of circulating units for heating systems is quite extensive.

They are installed:

The scope of use of circulating units for heating systems is quite extensive. They are installed:

- in traditional radiator systems;

- when arranging a water-heated floor;

- in geothermal systems;

- at the organization of hot water supply of cottages and dachas.

Unlike forced circulation systems, this pumping equipment does not need pipes with an increased diameter. In addition, the device has the following advantages:

- the speed of heating the room;

- the boiler can be installed in any suitable place;

- coolant losses and air locks are minimized;

- due to the thermal relay, automatic control of temperature conditions is provided;

- energy costs are reduced due to the use of auto-regulation of the rotor speed;

- Since liquid is constantly supplied to the heating devices, their service life is extended.

How the unit works

The principle of operation of the circulation unit is very similar to the operation of the drainage pump. If this device is installed in the heating system, then it will cause the movement of the coolant due to the capture of liquid from one side and forcing it into the pipeline from the other side

The principle of operation of the circulation unit is very similar to the operation of the drainage pump. If this device is installed in the heating system, then it will cause the movement of the coolant by capturing the liquid from one side and forcing it into the pipeline from the other side. All this happens due to the centrifugal force, which is formed during the rotation of the wheel with the blades. During the operation of the device, the pressure in the expansion tank does not change. If you want to increase the level of coolant in the heating system, install a booster pump. The circulation unit only helps to overcome the resistance force with water.

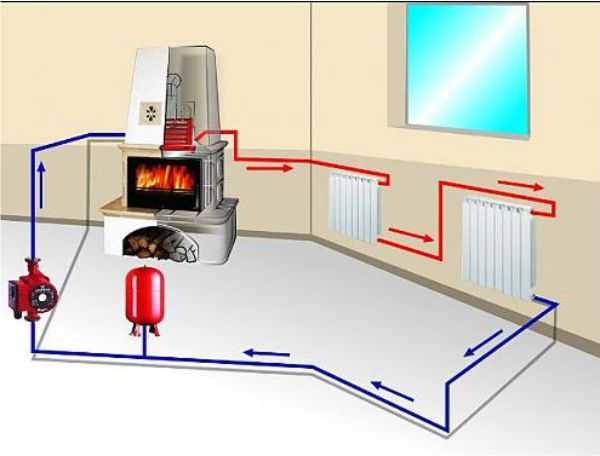

The installation scheme of the device looks like this:

- A circulation pump is installed on the pipeline with hot water coming from the heater.

- A check valve is mounted on the section of the line between the pumping equipment and the heater.

- The pipeline between the bypass valve and the circulation pump is connected by a bypass to the return pipeline.

Such an installation scheme implies the release of the coolant from the device only if the unit is filled with water. In order to keep the liquid in the wheel for a long time, a receiver equipped with a check valve is built at the end of the pipeline.

Circulation pumps used for domestic purposes can develop a coolant speed of up to 2 m / s, and units used in the industrial field accelerate the coolant up to 8 m / s.

Worth knowing: any kind of circulation pump is powered by the mains. This is a fairly economical equipment, since the engine power for large industrial pumps is 0.3 kW, while for household appliances it is only 85 watts.

Purpose and scope

Hot water recirculation pumps have a very important function. With the help of such devices, operation in the required mode of closed pipelines through which hot water is transported is ensured. By forcing liquid into the pipeline due to the rotation of special elements, recirculation electric pumps increase the pressure of the liquid medium pumped by them and, accordingly, the speed of its movement.

Most often, recirculation pumps are equipped with heating systems, which makes it possible to increase not only the efficiency, but also the economy of the latter. Most of these systems, as you know, work due to the coolant, which, moving through the pipeline, gives off heat to the room. Heating of the coolant (in this case, before it is fed into the pipeline) is provided by a boiler, boiler or water heater. After passing the entire heating circuit, the water must return to the heating equipment, where it is again given the required temperature.

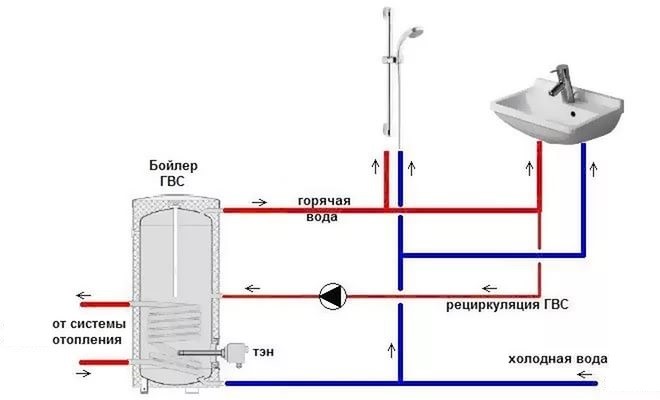

DHW recycling scheme

Without the use of special pumping equipment, the circulation of water in the heating system will proceed slowly, and in some cases it may not flow at all, since the pressure of the coolant flow, which is not further increased in any way, will be extinguished by the pipeline elements. The result of this is unevenly heated heating pipes and, accordingly, an uncomfortable temperature in the premises of the house.

The circulation pump for hot water supply increases the pressure and pressure of the hot liquid moving through a closed pipeline circuit. Especially important is the use of circulation pumps for hot water in the pipeline systems of houses with an area of more than 200 m2, in which there are several points of water intake, and the boiler is installed in a separate room or in the basement. Water in such pipelines (usually quite long), if they do not have a recirculation system using a special pump, cools down quickly enough. This leads to the fact that when opening the tap, you have to wait a long time until the liquid heated to the required temperature flows out of it.

In addition, when some taps are opened at the same time at the water intake points, the water pressure in them drops, because the pressure of the liquid moving through the pipeline by gravity is not additionally supported by anything. To solve precisely such problems that owners of private and residents of apartment buildings face, a DHW pump is designed to provide forced movement, as well as the creation of a stable pressure and pressure of water in the hot water supply system.

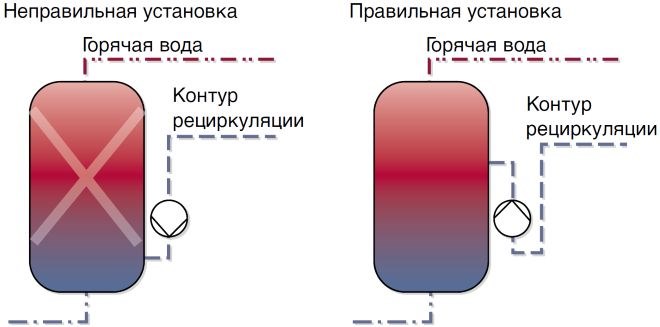

The recirculation pump should not be installed near tanks and water heaters, the heat from which can act on the thermostat

The use of a circulation pump for heating and hot water supply of a private house, in addition to the above advantages, allows you to save on energy costs. Since in systems with recirculation, water from the boiler is transported through pipes forcibly and reaches all points of water intake and heating radiators much faster, its temperature during such transportation decreases slightly. The boiler, if forced water recirculation is provided in the pipeline it serves, takes less time to heat it, respectively, the consumption of energy carriers used to operate the heating equipment is reduced.

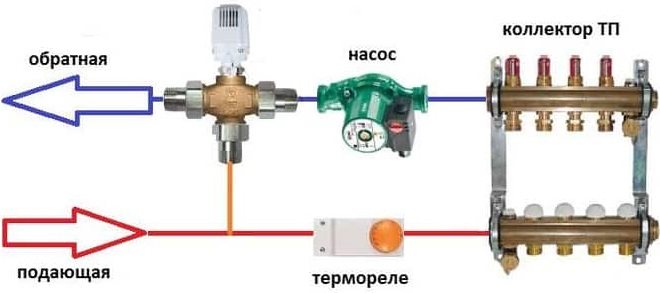

Hot water circulation pumps are actively used to equip "warm floor" systems, the scheme of which assumes the presence of an extended pipeline circuit of complex configuration, consisting of pipes of small diameter. The circulation pump in such cases ensures the constant movement of the coolant through the pipes.

The circulation pump is an indispensable element of the underfloor heating system

Varieties of circulation pumps

The wet rotor pump is available in stainless steel, cast iron, bronze or aluminium. Inside is a ceramic or steel engine

To understand how this device works, you need to know the differences between the two types of circulation pumping equipment. Although the fundamental scheme of the heating system based on a heat pump does not change, two types of such units differ in their operation features:

- The wet rotor pump is available in stainless steel, cast iron, bronze or aluminium. Inside is a ceramic or steel engine. The technopolymer impeller is mounted on the rotor shaft. When the impeller blades rotate, the water in the system is set in motion. This water simultaneously acts as an engine cooler and lubricant for the working elements of the device. Since the “wet” device circuit does not provide for the use of a fan, the operation of the unit is almost silent. Such equipment only works in a horizontal position, otherwise the device will simply overheat and fail. The main advantages of the wet pump are that it is maintenance-free and has excellent maintainability. However, the efficiency of the device is only 45%, which is a small drawback. But for domestic use, this unit is perfect.

- A dry rotor pump differs from its counterpart in that its motor does not come into contact with the liquid. In this regard, the unit has a lower durability. If the device will work "dry", then the risk of overheating and failure is low, but there is a threat of leakage due to abrasion of the seal. Since the efficiency of a dry circulation pump is 70%, it is advisable to use it for solving utility and industrial problems. To cool the engine, the circuit of the device provides for the use of a fan, which causes an increase in the noise level during operation, which is a disadvantage of this type of pump. Since in this unit water does not perform the function of lubricating the working elements, during the operation of the unit it is periodically necessary to carry out technical inspection and lubricate the parts.

In turn, "dry" circulating units are divided into several types according to the type of installation and connection to the engine:

- Console. In these devices, the engine and housing have their own place. They are separated and firmly fixed on it. The drive and working shaft of such a pump is connected by a coupling. To install this type of device, you will need to build a foundation, and the maintenance of this unit is quite expensive.

- Monoblock pumps can be operated for three years. The hull and engine are located separately, but are combined as a monoblock. The wheel in such a device is mounted on the rotor shaft.

- Vertical. The term of use of these devices reaches five years. These are sealed advanced units with a seal on the front side made of two polished rings. For the manufacture of seals, graphite, ceramics, stainless steel, aluminum are used. When the device is in operation, these rings rotate relative to each other.

Also on sale there are more powerful devices with two rotors. This dual circuit allows you to increase the performance of the device at maximum load. If one of the rotors exits, the second one can take over its functions.This allows not only to enhance the operation of the unit, but also to save electricity, because with a decrease in heat demand, only one rotor works.

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but it does not matter on the supply or return pipeline. Modern units are made from materials that normally tolerate temperatures up to 100-115 ° C. There are few heating systems that work with a hotter coolant, therefore considerations of a more “comfortable” temperature are untenable, but if you are so calmer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter whether there is a pump in the supply or return branch. What matters is the correct installation, in the sense of tying, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If there are two separate branches in the heating system - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule is preserved on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal regime in each of the parts of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

There are two types of heating systems - with forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is slammed into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

All heating systems with underfloor heating are forced - without a pump, the coolant will not pass through such large circuits

forced circulation

Since a forced circulation heating system is inoperative without a pump, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running. One ball shut-off valve is installed on the bypass, which is closed all the time while pumping is in operation. In this mode, the system works as a forced one.

Scheme of installation of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the faucet on the jumper is opened, the faucet leading to the pump is closed, the system works like a gravitational one.

Mounting Features

There is one important point, without which the installation of the circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow. There is an arrow on the body indicating in which direction the coolant should flow. So turn the unit around so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. This must be taken into account when choosing a model.

What indicators to consider when choosing a pump

The correct choice of the pump is based on the hydraulic resistance index overcome by the device itself, in the process of creating the required pressure and force of the water flow. For an optimally selected pump, the recommended power should be lower than the calculated one by 10-15% of the calculated power indicator. If the required power level is exceeded, the device may have a shorter service life, which will lead to its rapid wear. It is possible to increase the noise level in the heating system. If the power of the unit is less, then under these conditions the required amount of coolant will not be provided.

Scheme of the device of the circulation pump.

The calculation of the pump power indicator is based on the diameter and length of the pipeline, the level of water temperature and the pressure of the coolant. Ten meters of the heating system must be provided with half a meter of pressure due to the pump. The flow rate of the coolant in the course of calculations is compared with the level of water flow used in the boiler, the power of which is known. You should have data for calculating how much water is needed for the normal operation of each of the rings of the heating system. Calculation of heat losses of a building can be made on the basis of tables of thermal conductivity of materials. The length of the heat pipeline, the number of heating radiators are also taken into account. The power of the battery is determined by the amount of water required per minute to ensure optimal heating of the room.

The circulation pump can be equipped with either electronic or manual speed control. If the speed of the pump shaft is set to the highest mark, then the maximum coefficient of operation of the device should be obtained.

Unit features

The principle of operation of circulation pumping equipment is based on the creation of continuous circulation of fluid in the system without changing the pressure indicator.

A circulation pump is a device that operates in a closed heating system and performs the movement of water in the pipeline. The unit maintains a certain temperature of the coolant in the system. The device does not compensate for the loss of coolant and does not fill the system. The filling of the system is carried out due to a special pump or a certain pressure in the pipes.

The principle of operation of circulation pumping equipment is based on creating a continuous circulation of fluid in the system without changing the pressure indicator. Since the device works constantly after installation, the main requirements for such pumps are low noise level during operation, economical energy consumption, reliability, durability and ease of use.

Important: circulation pumps are compact devices that do not take up much space and do not create noise during operation. The scope of use of circulating units for heating systems is quite extensive.

They are installed:

The scope of use of circulating units for heating systems is quite extensive. They are installed:

- in traditional radiator systems;

- when arranging a water-heated floor;

- in geothermal systems;

- at the organization of hot water supply of cottages and dachas.

Unlike forced circulation systems, this pumping equipment does not need pipes with an increased diameter. In addition, the device has the following advantages:

- the speed of heating the room;

- the boiler can be installed in any suitable place;

- coolant losses and air locks are minimized;

- due to the thermal relay, automatic control of temperature conditions is provided;

- energy costs are reduced due to the use of auto-regulation of the rotor speed;

- Since liquid is constantly supplied to the heating devices, their service life is extended.

DHW circulation pump

Constant circulation of hot water in the house is less than 500 sq. m is not an urgent need. For those who, for the sake of their own comfort, decided to purchase a circulation pump, it will be useful to learn about the criteria for its selection.

A circulation pump is a device that “drives” water through a closed system (DHW circuit).

In order not to wait until hot water flows from the tap, the DHW system needs a circulation pump. The pump ensures the movement of water in a vicious circle.

In systems without circulation, it takes longer to wait for water, the longer the distance from the water heater to the draw-off point. Arranging a circulating water supply is no more expensive than buying a high-quality well-known brand boiler. Let's figure out what you need to know for someone who chooses a circulation pump.

Examples of circulation pumps.

pressure - an indicator of the circulation pump, which allows you to judge the maximum possible height of the water supply. For a cottage, this is the distance from the lowest to the highest point of the DHW system, adjusted for the total length of the pipeline.

Circulation pump: parameters

- pump power - an indicator of how much electricity the device will consume. Power largely determines other characteristics of the device;

- circulation pump performance (or volumetric flow, or fluid circulation rate) - refers to the amount of water that the pump can move through pipelines per unit of time.

Circulation pump: calculation

Contact professionals - only they can adequately calculate the characteristics that a circulation pump should have. And then it is they who will be responsible if, due to an error in the calculations, problems arise with the functioning of the system.

It is necessary to take into account many factors that affect the operation of the device: the length and height of the pipeline, its hydraulic resistance, the characteristics of the water points connected to this section of the system, etc.

The estimated pressure of hot water flowing from the tap is taken into account. By the way, the maximum allowable value of the last parameter is 4.5 bar, but the minimum is not regulated by any regulatory document, except, perhaps, local instructions and recommendations.

A non-return valve must be installed on the pressure connection of the circulation pump. Without it, cold water can enter the pipeline and circulate in a closed circuit instead of hot. What can cause condensation in the pump.

The number of water taps that can be open at the same time is also important. Simple logic suggests that if a pressure of, for example, 5 bar is created in the circulation pipeline, then when one tap is opened, the pressure will exceed the permissible value and the jet can damage the plumbing equipment

However, if water is consumed simultaneously through 4–5 points of water intake, then the pressure in each of them will be relatively low.

The term "comparatively" in this case means that the amount of water will be enough to rinse your hands, but not enough for a normal shower.

A multi-circuit diagram with distribution manifolds, as well as special pressure relief valves, will help prevent this situation.

Interchangeability of circulation pumps

A separate issue when choosing a DHW circulation pump is the interchangeability of the device with a pump for the heating system. Despite the external similarity of the devices, interchangeability is limited.

The principle of interchangeability circulation pumps does not apply to the so-called "double pumps" - devices that secure each other.

The problem lies in the difference in the operating temperatures of the pumped liquid: 60–65°C for hot water and 90–95°C for the coolant.

If necessary, a circulation pump for heating can be used on DHW pipelines, but not vice versa! Note that neither a solid power reserve nor high performance, which distinguish the pumps of the heating system, is simply not needed for hot water supply.

Main conclusions:

- the circulation pump for hot water supply is selected in approximately the same way as for the heating system;

- it makes no sense to use a device whose performance is higher than that of a water heater connected to this circuit;

- calculating the parameters for a circulation pump is quite complicated, so you should entrust it to specialists: if you do it yourself, the savings will be negligible, and the probability of error will be too high.

The images used in the article are smedegaard.com, wilo.com, dabpumps.com, grundfos.com, salmson.com