Maintenance of heating replacement of antifreeze

What is an antifreeze replacement?

Replacing antifreeze involves a lot of actions related to heating maintenance. The main effect of this concept is the change of water to antifreeze in the heating of an apartment building. Such a change of water avoids the defrosting of the heating system as a whole in the winter season. In another way, a change of water can be called the introduction of a substance that is not capable of freezing into the heating equipment. After the introduction of such a substance, the processed material must be changed to an updated one. All these actions can only be carried out by an experienced specialist, because replacing the heating material is a laborious task that can be performed with dexterity, certain skills and professional training. Antifreezes are considered harmful substances containing toxins in their composition. Toxins require careful handling because they can expand more than water.

Calculation of the volume of antifreeze

When buying expensive antifreeze, in order not to overpay money before filling the heating system, you should know the required volume of coolant. The easiest way to accurately determine it is to pump water into the line with a pressure of 1 - 1.5 bar, and then drain it and measure the amount received. 10% can be added to the mass of the liquid for airing, evaporation of the heat carrier.

V (systems) = V (boiler) + V (tank) + V (batteries) + V (pipes)

The working volume of the boiler and expansion tank is found out from the passport data for the equipment provided by the manufacturer. Similarly, from the operating instructions, the capacity of the radiators is determined by multiplying the indicators of one section by their number. In the absence, loss of passports for the boiler, accumulator or radiator heat exchangers, the necessary information is obtained from Internet sources.

The volume of the working fluid in the pipeline is determined by multiplying its cross-sectional area by the length according to the well-known formula:

V (volume) = S (area) x L (length) where

S (area) = 3.14 (pi) x R2 (radius squared).

Rice. 9 Example of calculation data for finding the volume

Antifreeze replacement algorithm

Replacement of antifreeze material includes the following procedures:

- getting rid of outdated non-freezing filler;

- complete washing of heating equipment with deep cleaning solutions;

- injection of a new frost-resistant filler into the equipment.

It does not matter at all where the antifreeze is replaced - in the country heating system, in the garage heating system - everywhere you need to follow the above algorithm. The replacement of antifreeze must be carried out at regular intervals, since any non-freezing substance can wear out and lose its functions after a certain period, the duration of which is 5-6 years.

What is used for electrode boilers

In houses where this type of heating equipment is installed, a special type of antifreeze is used. This is due to the fact that an alternating current passes through the coolant and the solution is ionized. This puts forward certain requirements for the chemical composition of the product. Appropriate ionization, electrical and thermal conductivity, and electrical resistance must be provided. Usually the boiler manufacturer will make recommendations on which product is best to use. And often, depending on the implementation of the recommendation, the guarantee for the equipment is preserved.

Antifreeze is an excellent tool for extending the life of the heating system, especially if it is preserved for some time. However, this product must be used wisely.Before use, read all operating instructions of the manufacturer of the heating equipment, as well as the instructions for using the products. Only in this case success will be guaranteed, radiators and pipes will last for many decades.

Heating with antifreeze or water

After reading this section, you are likely to refuse antifreeze in the heating system. The main plus of antifreeze is the safety of the system at low temperatures, completely crossed out by its minuses.

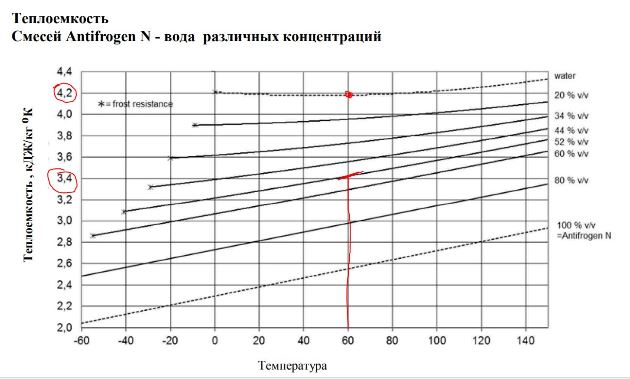

Low heat capacity of antifreeze. Increasing the size of radiators by 20-23% The heat capacity of antifreeze is significantly lower than the heat capacity of water. By diluting water with 35% antifreeze, we lose approximately 200 W from 1 kW of thermal energy. This means that it is required to increase the dimensions of pipes, radiators and boiler by 20%. In terms of a country house of 300 m 2, we lose about 60 thousand rubles by increasing the size of the system.

- The service life of antifreeze is from 5 to 10 years. Over the years, antifreeze oxidizes and safely destroys brass joints. After 5 - 10 years, ethylene glycol and propylene glycol must be drained, disposed of and replaced with a new one. You will have to not only buy new antifreeze, but also pay for the disposal of the old one. Unfortunately, in our country there is no ethylene glycol recycling service in small volumes, so it will be difficult to find someone to hand over this chemistry to. I will not consider the idea of draining antifreeze to a neighbor on the site.

- The use of sectional radiators in systems with antifreeze is unacceptable. Rubber intersection gaskets quickly oxidize, and radiators leak. We use only steel panels. The use of galvanized pipes is also unacceptable. Antifreeze safely washes out the zinc, and the pipe remains bare.

- Why is antifreeze useless for a country house? Antifreeze will successfully cope with the task - the heating system will not freeze in the winter in your absence, but what to do with the water supply system? Water supply pipes at negative temperatures will freeze faster and with worse consequences, because. are laid not only in the floor, but also in the walls. You will have to remove the tiles, beat the screed and change the pipes in the bathrooms, showers, kitchen, replace the entire piping of the boiler room for water supply. Of course, pumping antifreeze into the water supply system will not work, as well as laying all pipes with heating cables.

Conclusion: Antifreezes are suitable either for heating small country houses for temporary residence, or large warehouses, workshops and enterprises. In the heating system of a full-fledged country house, antifreeze is useless.

Antifreeze for the heating system of a country house is needed if: you do not plan to live in the house in winter; in the house there are 1-2 bathrooms with a tee water supply system (without a collector), which can be drained before the onset of cold weather.

It is impossible to leave a full-fledged country house in winter without emergency heating. In winter, it is necessary to maintain a constant standby heating + 10-12 ° С. Heating a full-fledged country house for permanent residence with antifreeze is the same losing option as heating a house with underfloor heating, which is applicable only in the southern regions of our country.

So your engineering systems will be truly protected without antifreeze.

If you liked my article and you are looking for reliable design specialists - call and write to me by mail.

Starting heating of an apartment building

In a multi-storey building with a bottom filling, the heating system is started as follows:

- With a closed supply and a closed discharge, the discharge of the supply pipeline opens on the return;

- The return valve opens very smoothly. A sharp opening of the valve is likely to lead to water hammer, which can seriously damage the radiators, up to rupture;

- After a while, water without air will come out of the discharge. When this happens, the discharge closes and the supply pipeline valve opens;

- It remains to bleed air from all parts of the system where such an opportunity exists.

Replacing water with antifreeze

If the system has already used water, and you want to switch to antifreeze, then two things should be considered.

Secondly, it is never possible to completely remove water from the heating system. Some of the water remains. If you fill in simply prepared diluted antifreeze, then its concentration will be insufficient for reliable protection against freezing. Thus, you need to apply a concentrate. I usually mix concentrate with diluted antifreeze in a 1:1 ratio. After filling the system, you need to start the circulation pump (for a system with forced circulation) or turn on the boiler (for a system with natural circulation) so that the coolant mixes well. Then you need to pour a little coolant and measure its density. To measure the density there is a device that is sold in most car dealerships. This device is used to prepare a car for winter (checking the properties of antifreeze in the engine cooling system), but it is also perfect for our purposes. If the device shows a freezing temperature lower than necessary, for example -50 degrees, it's okay, but if the temperature is higher than we need, then we will have to drain part of the coolant and replace it with a concentrate. The drained coolant must be disposed of carefully, it is poisonous, it should not be poured into septic tanks and ditches.

I also want to draw your attention to the fact that different antifreezes may be incompatible with each other. There is an opinion that it is impossible to mix a red composition with a composition of a different color.

This is true, but in fact there are other undesirable combinations. Additives of different brands may react with each other or simply reduce each other's effectiveness. Unfortunately, manufacturers do not report which other antifreezes their product can be mixed with. My advice is to pick one brand and stick with it. If, nevertheless, there is a need to mix, then mix liquids of the same color and before pouring, drain a little coolant from the heating system, mix it in a jar with a new composition and see if a precipitate falls out, if the liquid becomes cloudy, if it loses uniformity.

Unfortunately, errors occur periodically in articles, they are corrected, articles are supplemented, developed, new ones are being prepared. Subscribe to the news to stay informed.

It is convenient to fill the system through the water drain valve - it stands at the lowest point of the system. With this method, airing is practically excluded, since the coolant enters from below, gradually squeezing out all the air into the expander. Read the answer.

Glue examples. Poksipol, liquid nails, universal superglue. Armir. Typical gluing mistakes. The right technology. Additional tricks - armir.

Techniques for fixing a threaded connection. Techniques for fixing (locking) a threaded connection. Protection against vibration and self-pro.

Apricot, apricot tree. Cultivation, planting, propagation, watering. How to plant and grow an apricot. We propagate, graft, water the apricot de.

Thrips. Colorless/yellowish spots, rough streaks, loose leaves. How to detect thrips infestation. Light spots, roughness are signs of illness.

How to replace antifreeze in a home heating system step by step instructions

Before starting to drain the antifreeze, the heating boiler is heated up, even if the replacement is carried out in the summer. All batteries are opened, the system is transferred to the gravity flow mode. Immediately before draining, the boiler is turned off, other devices involved in the system are disconnected from the power sources. You should also prepare a sufficient amount of containers for used antifreeze.

Then proceed in the following order:

Step 1. Insert the hose into the prepared container.

Step 2 Open the drain valve.

Step 3. Fill the container one by one.

Step 4If a tap is not provided for a riser, it is released from the coolant through the Mayevsky tap using an attached hose.

Step 5. Antifreeze is diluted in a large container according to the manufacturer's instructions.

Step 6. Connect the "Kid" pump to the injection hole into the heating system and fill the pipes with fresh coolant.

Step 7. When filling the system, periodically bleed air, pumping antifreeze until the desired pressure in the system is reached.

Comparison of water and antifreeze

Filling the heating system with water is the most popular way for the following reasons:

- Water is a publicly available and budgetary type of heat carrier, it is a natural source, so its use is environmentally friendly and safe.

- The highest heat capacity of water at 4200 J/kg∙K leads to the fact that it heats up for a long time and releases thermal energy. This property allows it to be transported over long distances with low losses of thermal energy.

- Compared to other heat-carrying liquids, the viscosity of water at 1.006 m2/s∙10-6 at 20 °C is the lowest and decreases with increasing heating temperature. This factor leads to a decrease in hydraulic resistance when it moves through the pipeline and, accordingly, to an increase in heating efficiency.

- The temperature coefficient of linear expansion of water is quite low, relative to the temperature of 0 °C at +80 °C, it increases in volume by only 2.8%.

- Water is neutral in chemical composition and does not have a destructive effect on pipelines made of thermoplastics - conventional, cross-linked, heat-resistant polyethylene, polypropylene, or their varieties with an aluminum sheath - metal-plastics, which are widely used in domestic communications.

- The disadvantages of water include the corrosive effect on metals and the presence of salts in the composition, which, when heated, forms scale, which reduces the efficiency of equipment and leads to blockages, failure of heat transfer elements (heaters). To avoid the negative impact of scale, instead of the usual circuit, fill with distilled water.

- The main drawback of water, in which antifreeze is poured into the heating system of the house instead of it, is its high crystallization temperature of 0 ° C. With a strong cooling of the aquatic environment, ice with a low density is formed, which grows in volume by approximately 10%. This leads to the rupture of pipes frozen with ice, heat exchange batteries, boiler equipment units.

Rice. 4 Crystallization temperatures of aqueous solutions of antifreeze liquids

To avoid freezing of water in emergency situations, antifreezes are added to it, which have the following distinctive features:

- Antifreezes have a 10% lower thermal capacity, so their use leads to a decrease in heating efficiency.

- The viscosity of antifreezes is 5-7 times higher than that of water, which means that to push them through the pipes, more power of the electric pump will be required, and the hydraulic resistance will increase.

- Antifreezes have a higher fluidity than water, therefore, during their operation, it may be necessary to replace gaskets or seals at the joints of pipelines and connected fittings with other denser materials.

- The thermal expansion of glycols is 1.5 times that of water, so an accumulator with a larger working capacity of the chamber may be needed.

- Factory antifreezes are usually designed for 5 years (heating seasons), after which their composition is subject to decomposition with precipitation. If the coolant in the heating system is not replaced in time (the disposal time is determined by the change in the color of the glycol), a sparingly soluble precipitate may appear in the circuit along with the pipes, boiler and batteries.

- Most glycols function up to +115 °C, however, it is not recommended to increase the operating temperature above +70 °C.From overheating, their composition decomposes with the formation of a sparingly soluble precipitate.

- A significant advantage of glycols relative to water is the absence of material expansion during crystallization, the preparation turns into a mobile sludge of the same volume, which, when heated, again turns into a liquid state.

- Many antifreezes contain additives that reduce foaming and their corrosiveness - this significantly reduces the amount of rust when they are in lines with metal pipes and fittings.

- After draining the spent anti-freeze, one of the problems is their disposal.

- One of the main drawbacks of antifreezes is the denial of warranty service by many boiler manufacturers when pouring any kind of non-freeze into their equipment.

Rice. 5 Table of dependence of the crystallization temperature on the concentration of ethylene glycol

Calculation of the volume of coolant

It is not necessary for residents of apartment buildings to know about the volume of coolant in the system, but in private houses this knowledge is very important:

- Firstly, the expansion tank is selected depending on the volume of the heating system. Exceeding the required dimensions does not threaten anything special, but too small a tank will lead to a constant overflow of the coolant, and it will have to be topped up regularly.

- Secondly, it is very difficult to maintain a stable temperature regime of heating in country houses, and it is impossible when using solid fuel boilers. It is impossible to leave the heating system in a filled state during frosts, therefore, non-freezing coolants will be the only solution to the problem. Since their cost directly depends on the volume of the coolant, then the volume of the system needs to be known.

There are two ways to determine the volume of the heating system without using complex calculation methods and regulatory documents:

- The first method is possible if, before filling the closed-type heating system, a connection to the water supply is established through a jumper. A completely empty circuit (without coolant and air) is filled with water with closed taps and valves. The amount of water spent to fill the heating system can be determined by the meter installed on the water supply system.

- The second way is to reset the system through the appropriate valve, and substitute any container, the volume of which is known, under the pouring water. With such a measurement of the volume of the coolant, it is necessary to open the air vents on each heater so that water does not remain in them and does not lead to measurement errors.

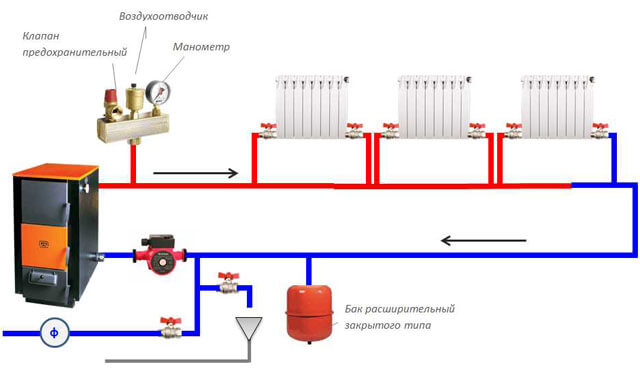

Filling and starting a closed heating system

The forced circulation heating system has a couple of key features:

When operating a system equipped with a heating boiler and a circulation pump, there is always a pressure that exceeds atmospheric pressure.

Before putting the system into operation, the system undergoes pressure testing, at which the pressure value exceeds the working one and a half times. Crimping is especially important for underfloor heating, which are laid in a screed

It is important that underfloor heating is crimped by a specialist.

Before pouring the coolant into a closed heating system, you need to take into account these factors and consider the technology of work.

In buildings with central water supply, the problem with pressure testing is solved in a very simple way. To do this, the heating is connected to the water supply by means of a jumper and filled with constant monitoring of the pressure on the pressure gauge. When the system is pressurized and checked for leaks, excess water is drained through a valve or air valve.

It is a completely different matter if water is poured into the heating circuit manually, or if various types of antifreeze compositions are used as a coolant.Before pouring the coolant into a closed heating system, in most cases it is enough to take a pump that allows you to fill in the coolant and pressurize the circuit. The pump is connected by means of a valve that closes when the required pressure is reached.

However, filling the system can be carried out without a pump. To inject 1.5 atmospheres in the system, you can use the fact that this value corresponds to 15 meters of water column. Given this knowledge, before filling a closed heating system with a coolant, you can solve the problem in the simplest way - connect a reinforced hose to the discharge valve, raise it to a height of 15 meters and fill it with water.

Replacing the coolant in the heating system of a country house can be carried out using an expansion tank. This element is designed to receive excess liquid during thermal expansion. The membrane tank is a structure in which there are two cavities separated by a movable membrane. One part of the tank receives the coolant, and the second contains air. Also, any tank is equipped with a nipple, with which you can increase or decrease air pressure.

Filling the heating system with water using a tank is carried out as follows:

- First, all the air is completely removed from the tank, for which you simply need to unscrew the nipple. The pressure in standard tanks is 1.5 atmospheres.

- The system is filled with water. It is not required to completely fill the tank - the air volume should be about 1/10 of the total volume of the coolant in the system.

- Air is pumped into the tank by any hand pump. The pressure is constantly monitored on the manometer.

Safety rules when working with antifreeze

It is not recommended to mix products of different brands. If such a need arises, a compatibility test is first carried out. In addition, not all manufacturers use the same additives. These components can cancel each other out. Then the anti-corrosion properties of the coolant are lost.

Experts do not recommend pouring antifreeze into an open system. The reason is an open expansion tank. Through it, harmful substances can enter the atmosphere. Therefore, when using "non-freezing", it is recommended to make the system closed.

The owner of the house does not always know which product was used to fill the heating system last time. In this case, the pipes are completely freed from the previous product, and only then fill the system.

Distilled water is used to dilute the concentrate. It should not contain calcium and magnesium salts. If you use tap water with a hardness above 5 mg-eq, there is a possibility of precipitation.

If it is assumed that antifreeze will be used in the heating system, then attention should be paid to the characteristics of the radiators. They prefer models with higher heat transfer rates, internal volume and diameter

The pump power must be 60% higher than that of equipment working with water.

Automatic air extraction devices are not designed to work with such coolants. To make it possible to free the system from air, Mayevsky cranes are installed on the radiators.

In the system, it is better to use tabs made of materials resistant to glycol media - paronite, teflon, etc. Threaded connections are laid with linen tow, a special sealing paste is used as a lubricant. Oil paint is not good. The active components of the coolant are good solvents for coatings, as a result of which the system begins to leak.

The antiphysic concentrate is mixed with water in a separate container, and only in this form the system is filled. If you first fill in the coolant, and then the water, the system may fail. Consequences of ignoring this rule:

- uneven heating of the system, and some radiators may be quite cold, due to uneven distribution of the product;

- failure of the circulation pump;

- foaming, which necessitates repeated emptying and refilling of the system.

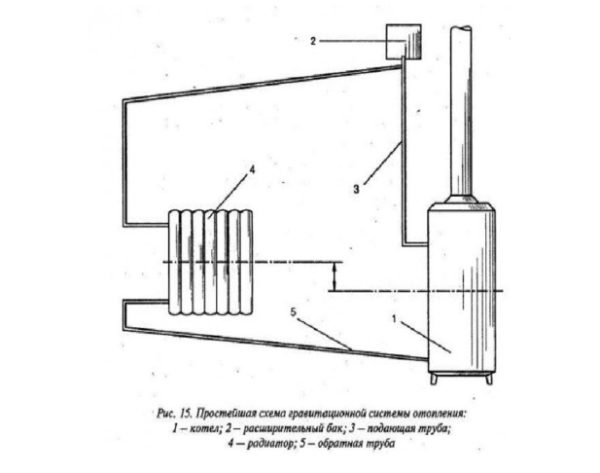

If, by mistake, the concentrate and water were poured separately, then the circulation pump should not be turned on at full power. They take a wait-and-see position and periodically release air from the system through radiators. After some time, more or less uniform mixing of water and antifreeze will occur. If the heating system is gravitational with a gravity function, then this process takes longer.

Video - Cons of using antifreeze in heating systems

Antifreeze should not be used in systems that do not have an accurate temperature controller. When the temperature rises to 70 ° C and above, the coolant decomposes, which is dangerous for the heating system.

After draining the antifreeze and before filling in a new portion, the system is washed with clean water or special solutions.

Antifreeze for heating and their features

Currently, several types of non-freezes are most famous among the average consumer, they are usually sold in plastic canisters with a capacity of 10, 20 or 50 liters. The package indicates the maximum negative temperature of the solution, it can be used ready-made or water is added to it before use, guided by special tables (the dependence of the crystallization temperature on the volume of antifreeze in the liquid is non-linear).

The composition of any antifreeze includes an active substance with a different percentage (usually about 60 - 65%), distilled or deionized water (30 - 35%), additives, corrosion inhibitors (3 - 4%).

Rice. 6 Cost of 10 liters of ethylene glycols

ethylene glycol

The distribution network sells red ethylene glycol in canisters of 10 and 20 liters with a freezing point of -30 or -65 ° C. The drug has a sweet taste, is poisonous when it enters the human body, prolonged inhalation of ethylene glycol vapor can also cause short-term health problems.

Poisonous ethylene glycol may be used in closed circuits where it will not be able to have a harmful effect on human health when evaporating. The service life of ethylene glycol is 5 years, before use, the drug is diluted with water to a concentration that implies obtaining the desired freezing point.

propylene glycol

Antifreeze made of green polypropylene with the complementary commercial name ECO, unlike its ethylene glycol counterpart, is not only non-toxic, but also serves as an additive in food products. Propylene glycol is produced in the same container as ethylene glycol with a freezing point of -20, -30 or -40 ° C, its price is almost 2 times higher than its ethylene glycol counterpart.

In terms of its physical parameters (fluidity, thermal expansion, crystallization point), propylene glycol is close to ethylene glycols, with the exception of viscosity, which is 2 times higher. Propylene glycol can be safely used in both open and closed heating circuits.

Rice. 7 Propylene glycols in a package of 10 kg and their price

Glycerol

- Glycerin is harmless, it is used in closed and open systems.

- When the temperature limit of 115 ° C is exceeded, glycerin decomposes with the release of toxic gas.

- If the content of the water component in the solution decreases, glycerin begins to burn and decompose.

- Has a high viscosity.

- It is less corrosive to metal parts than water due to the addition of rust inhibitors.

- It is subject to foaming, which is removed by the introduction of a composition of special additives.

- Glycerin solution has increased fluidity, requires the use of dense paronite or Teflon seals.

- Its temperature instability makes it difficult to tune the boiler.

- Decomposes over time with the formation of a sparingly soluble precipitate and chemically active components that adversely affect metals.

- The drug is prohibited for use in the European Union.

Taking into account the above features of glycerin, it is not recommended to use it in heating circuits - this will not bring significant financial savings, and the elimination of problems that have arisen with its use can result in a much larger amount.

Rice. 8 Glycerin antifreezes