Why is it beneficial to use foam

The performance of the cladding of the facade of the house with foam plastic is fully justified by the relative low cost of the material and its excellent heat and sound insulation properties. It is resistant to sudden changes in temperature and practically does not absorb moisture (up to 1% of the total volume), so it can be used in any climatic conditions.

Installation of foam sheets does not require special skills to carry out such work or the use of complex tools. Outside the insulation, the installation of a waterproofing layer is not necessary, since all joints can be formed airtight, and the material itself does not allow moisture to pass through.

The minimum service life of foam sheets is at least 20 years, which will allow, after finishing the walls, not to carry out additional technical inspections or replace the insulation earlier than this period. Periodically, it will only be necessary to update the plaster, which will not cause significant financial costs.

Our advantages

Specifications:

| Name of indicator | Norm for PSB-S 25f |

| Density, kg / m 3 | 16-18 |

| Compressive strength at 10% linear deformation, MPa, not less than | 0,1 |

| Bending strength, MPa, not less than | 0,18 |

| Thermal conductivity in dry state at (25±5)°C, W/(m K), not more than | 0,039 |

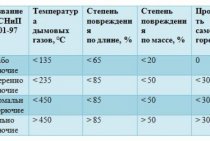

| Self-burning time of PSB-S slabs, s, no more | 4 |

| Humidity, %, no more | 12 |

| Water absorption for 24 hours, % by volume, no more | 2,0 |

The appearance of PSB-S-25F polystyrene practically does not differ from other brands. It has exactly the same white color and structure in the form of foamed and fused granules.

Like other brands of foam, PSB-S-25F has the same favorable and high-quality characteristics, among which builders especially appreciate:

- environmental safety;

- Resistance to moisture;

- Durability;

- Resistance to harmful microorganisms.

Most of the facades of houses, for the decoration of which PSB-S-25F foam was used, today retain their attractive appearance, even after many years after finishing. The purchase of this brand of foam is not only practical and effective from the point of view of builders, but also beneficial from the standpoint of the buyer.

Styrofoam 1000x1000x100 mm (density 15) Styrofoam Mosstroy-31 1000x1000x100 mm (tight.

Foam plastic 1000x1000x30 mm (density 15) Foam plastic Mosstroy-31 1000x1000x30 mm (density.

Polyfoam 1000x1000x50 mm (density 15) Polyfoam Mosstroy-31 1000x1000x50 mm (density.

Foam plastic 1000x1000x100 mm (density 25 F) Foam plastic Mosstroy-31 1000x1000x100 mm (plot.

Foam plastic 1000x1000x30 mm (density 25) Foam plastic Mosstroy-31 1000x1000x30 mm (density.

Foam plastic 1000x1000x50 mm (density 25) Foam plastic Mosstroy-31 1000x1000x50 mm (density.

Styrofoam 1000x2000x100 mm (density 25) Styrofoam Mosstroy-31 1000x2000x100 mm (tight.

Foam plastic 1000x2000x50 mm (density 25) Foam plastic Mosstroy-31 1000x2000x50 mm (density.

Styrofoam 1000x2000x30 mm (density 25) Styrofoam Mosstroy-31 1000x2000x30 mm (density 25).

Foam plastic 1000x2000x30 mm (density 25 F) Foam plastic Mosstroy-31 1000x2000x30 mm (density 25.

Foam plastic 1000x1000x100 mm (density 35) Foam plastic Mosstroy-31 1000x1000x100 mm (density 35.

Styrofoam 1000x1000x30 mm (density 35) Styrofoam Mosstroy-31 1000x1000x30 mm (density 35).

Foam plastic 1000x1000x50 mm (density 35) Foam plastic Mosstroy-31 1000x1000x50 mm (density 35 & nb.

Facade plaster for foam and expanded polystyrene preparation, grouting and application technology

Facade plaster on foam and expanded polystyrene

Insulation of any important element of the structure is carried out taking into account technological standards and is aimed at reducing the impact of the insulated surface from the environment. But few homeowners and careless builders think that the heat-insulating layer itself also needs reliable protection.

But few homeowners and careless builders think that the heat-insulating layer itself also needs reliable protection.

Facade plaster on foam and expanded polystyrene is one of the ways to protect heat-insulating boards from the harmful effects of low temperatures and increase their service life.

The fact is that the insulation, although it can be a good heat insulator, its other properties still leave much to be desired. For example, the impact on some heaters of precipitation and moisture can lead to a drop in their properties and even to zero.

To protect foam and expanded polystyrene, the best, if not the only worthy option, is warm facade plaster.

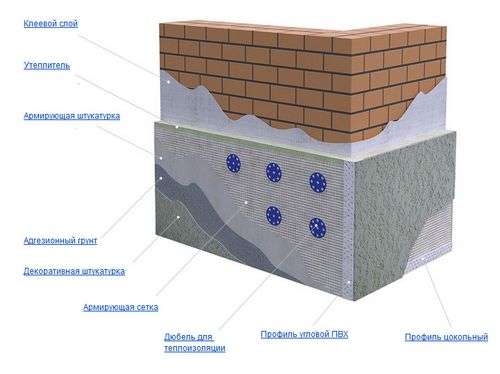

The general scheme of finishing the facade and walls with a plaster mortar for insulation

In this article, we will try to talk about the entire technology of plastering on top of the insulation, starting from the preparation of the mixture, and ending with the final touches. Read about the technology of the thermal insulation device in the corresponding article on the insulation of facades with expanded polystyrene.

So, facade plaster on foam is applied in the following sequence:

- Preparation of plaster mortar;

- Installation of the reinforcing layer;

- Implementation of grouting over the reinforcing mesh;

- Leveling surfaces with plaster;

- Grouting a plastered surface;

- Primer;

- Applying a decorative finish.

Surface leveling for finishing

Leveling the surface of the facade for further finishing

Now the entire resulting pie needs to be leveled. This process is done, oddly enough, again using the universal plaster mixture that was used earlier.

A very important point in this process is the completion of work on one wall without interruption.

Alignment is done as follows:

- A leveling compound is applied to a 35 cm spatula. You need to put it with the help of an additional small spatula.

- The mixture is distributed with uniform movements on the working wall. The thickness of the new layer of material is most often about three millimeters.

- The joints of individual sections should not coincide with the joints of the grid - place them the farther the better.

Advantages of facade insulation with foam plastic

To increase the energy efficiency of various objects, it is necessary to perform facade insulation. This will increase the service life of buildings by preventing the freezing of load-bearing structures, as well as improve the appearance of the walls by applying decorative layers.

For wall insulation outside houses, it is most advantageous to use foam sheets, since they allow you to get the following advantages:

- get the most even surface for mounting the reinforcing layer and applying plaster;

- provide a level of thermal conductivity in the range from 0.04 to 0.03 W / m K, depending on the thickness and density of the foam sheets used;

- to protect the walls as much as possible from the appearance of mold, fungus, insects and other pests;

- increase the level of sound insulation of premises;

- reduce heating costs and extend the life of the entire facility.

Styrofoam plaster

Expanded polystyrene (polystyrene) is used in different ways for facade decoration. This material can serve as a layer of insulation in the facade system of bonded thermal insulation. In this case, expanded polystyrene is covered with an adhesive layer, reinforcing mesh and decorative plaster. There are also open ways to finish with foam. Expanded polystyrene is used to make decorative architectural elements and finishing panels with a hard coating.

Expanded polystyrene consists of granules sintered together under the influence of high temperature. Heterogeneous granules provide the main feature of the material - the finished polystyrene foam is 98% air, therefore it has a low thermal conductivity. Also, expanded polystyrene is not at all afraid of moisture.

Recommendations for choosing foam parameters

Prices for foam plastic for facade insulation completely depend on its thickness, density and geometric dimensions. Therefore, in order to reduce the amount of waste and reduce financial costs, it is recommended to determine these parameters in advance.

For ease of installation and ensuring sufficient heat-insulating properties in the middle zone of the country, it is necessary to use foam plastic 100 mm thick or to lay in two layers with sheets of 50 mm. The foam density should be 15 or 25 kg/m 3 . Thicker sheets are recommended for applying a layer of plaster, and with an average density - for ventilated facades.

The use of foam plastic 35 kg / m 3 is justified only in the northern regions of the country or in the middle lane for thermal insulation of industrial facilities. This is due to the fact that its cost is at a fairly high level.

You can order foam sheets with the following dimensions: width 1 m, and length from 1 to 2 m. It is recommended to pre-calculate the area of \u200b\u200bthe walls in m 2 in order to reduce the amount of waste.

Plastering on polystyrene foam work technology

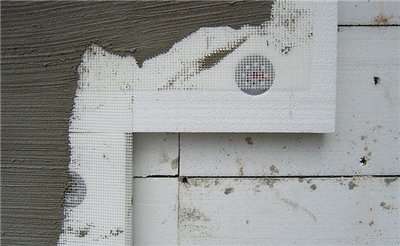

Therefore, in order for the plaster to adhere firmly to the foam, a special plastic mesh is used, which is attached to the foam, and a layer of plaster is already applied to it.

First, the mesh must be glued to the corners of the building. Using a wide spatula, apply the mixture with a thickness of about 3 mm to the foam. We apply the mesh and carefully smooth the mixture so that the mesh is completely covered with it. After all the corners are pasted over with a grid, you can start gluing it on the plane of the walls. One strip of mesh should overlap the previous one, and all joints should be carefully coated with the mixture.

The mesh glued in this way should be rubbed with a grater with an emery cloth. Grouting is done on a dried mixture. In this case, some effort should be applied, circular movements should be directed counterclockwise.

Now you need to apply a leveling plaster layer about 3 mm thick. After a day, the leveling layer should be rubbed in the same way as the mesh was rubbed. It should be remembered that a dry leveling layer will be much more difficult to overwrite. At this stage, it is necessary to achieve the most even surface, the quality of the decorative finish will depend on this.

The next step should be the priming of the surfaces of the walls of the building, which is done with a short pile roller.

And the final stage of finishing the facade on foam plastic is the application of decorative plaster. A layer of plaster is applied with a spatula to a specific area, and then a decorative texture is formed using a sponge, spatula or grater. After complete drying, the surface can be painted with facade paint.