Why is the quality of a metal-plastic pipe especially important?

Using pipes made of metal-plastic, it is possible to build both domestic and technical pipelines for various purposes: water supply, heating system, sewerage, etc.

Often, during the operation of pipelines, situations arise that adversely affect the pipes. For example, sudden pressure drops during pressure tests (more than 10 atm), temperature fluctuations depending on the season (amplitude from 50 C and above), defrosting of the heating system.

These factors affect the durability and reliability of pipelines in a bad way, causing leaks at the junctions of pipes with fittings or the formation of ruptures in the pipe body. It is in such difficult conditions that the quality or, conversely, the lack of quality of the material manifests itself.

As a rule, the service life of products is at least 50 years. But pipes can be used much longer if they were manufactured in compliance with all quality requirements, as well as professionally selected and laid.

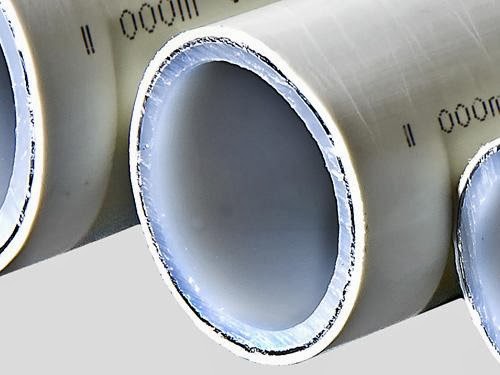

Professional testing of metal-plastic pipes: on the left is a low-quality pipe, on the right is an Italian Valtec pipe

Existing deficiencies

Along with these advantages, metal-plastic pipes also have disadvantages:

- Collet compression connection remains collapsible throughout the entire period of operation. The use of crimping can remove this factor, however, it will require additional investments for the purchase of an expensive tool and reduce convenience during operation.

- Although the pliable pipe is able to bend, the bending point can lead to deformation and destruction of the inner aluminum profile. If you use special fittings as corners and turns, you can reduce the likelihood of damage, but this will increase the cost of purchasing the material.

- The operating temperature excludes the use of metal-plastic pipes without installing additional thermal mixing units during the operation of solid fuel boilers.

Is it worth it to use metal-plastic pipes for plumbing

The metal-plastic water pipe is a multilayer structure, the main of which are two polyethylene (outer and inner) layers and one aluminum layer. The layers are connected to each other with a special glue. Today, metal-plastic water pipes are produced with an outer diameter of 16 to 63 mm, the most popular sizes for internal wiring are 16, 20 and 26 mm. If it is necessary to arrange external wiring for large objects, the most common diameters are 32 and 40 mm.

The metal-plastic pipe consists of 3 layers connected by an adhesive composition

In apartment buildings, it is recommended to use metal-plastic pipes with a diameter of 16 and 20 mm. From pipes of a larger diameter, the main wiring is performed, and from pipes of a smaller diameter, branches to household appliances (faucet, washing machine, toilet bowl, etc.) are made.

Scope of application

After the approval of the changes by the Ministry of Construction of the Russian Federation to SNiP 2.04.01-85, metal-plastic pipes began to be used everywhere in civil and industrial construction. They are successfully used in the organization of hot and cold water supply of multi-apartment and private houses, heating, in the reconstruction of plumbing systems, in the installation of irrigation systems, for supplying compressed air, in installations for taking water from wells and wells, for transporting various liquids, including chemical aggressive. Particularly relevant is the installation of systems made of metal-plastic pipes where it is impossible (forbidden) to use welding.

Advantages of pipes made of metal-plastic

Compared with polymer pipes, all metal-plastic pipes for water supply have a number of advantages, namely:

- low coefficient of linear expansion;

- high ability to keep the original shape;

- exceptional tightness.

Most models of metal-plastic pipes have an inner composite layer with nanosized silver particles. This improves the hygienic qualities of the pipe, since silver ions destroy harmful bacteria and prevent the deposition of various suspensions on the pipe walls. Therefore, metal-plastic pipes serve flawlessly and for a long time.

Compared to pipes made of steel, cast iron and copper, metal-plastic pipes also have a number of advantages:

- they have a lower cost;

- low operating costs (do not require maintenance and repair);

- their installation is carried out much faster (about 5 times);

- they silently convey the flow of liquid;

- they are much lighter, do not carry a significant load on building structures;

- more aesthetic;

- they are the tightest.

Elastic metal-plastic pipes withstand sub-zero temperatures, and also successfully cope with the transportation of hot (up to +90) water. They withstand water hammer and have low thermal conductivity.

With high-quality installation and careful operation, systems made of metal-plastic pipes can serve up to 50 years without the need for repair.

Disadvantages of metal-plastic pipes

With many indisputable advantages, metal-plastic pipes, like any other material, have their drawbacks. First of all, they are most susceptible to mechanical damage, especially for open communications. Even metal-plastic pipes for hot water are less resistant to high temperatures and water hammer, compared to the same metal ones.

Metal-plastic accumulates static voltage, so these pipes cannot be used for grounding.

When laying outside, metal-plastic pipes are at risk of mechanical damage, they are easy to damage even with a chopper or a shovel

Mounting units of the pipeline system made of metal-plastic during operation at low temperatures are subject to destruction.

Aging and weakening of the initial qualities of metal-plastic pipes are observed during their long-term intensive operation, especially if they are exposed to direct solar radiation or are operated at low temperatures.

What is metal-plastic

Metal-plastic pipes are composite products, which are a combination of several layers of material. The most common structure of such a pipe includes an outer protective plastic layer, an adhesive base, an aluminum profile along the entire length of the pipe, a repeated adhesive layer, and an internal plastic coating. The main advantage of such a structure is expressed in the complete absence of the influence of corrosion or aggressive chemical materials on the supporting metal profile.

The main characteristics of the metal-plastic pipe:

- outer diameter of the pipe;

- type of plastic used. In total, there are three types - PE-RT (heat-resistant polyethylene), PE-X (cross-linked polyethylene), PP-R (polypropylene);

- type of aluminum profile connection - can be overlapped or butt-to-butt;

- maximum temperature of the transported liquid - most manufacturers declare the maximum allowable operating temperature of 950 ° C;

- the maximum working pressure is 25 bar, however, at elevated temperatures close to 1000 ° C, this figure can drop to 10 bar.

What should be considered when choosing metal-plastic pipes for water supply marking, material and pipe dimensions

Information about the product and its operating conditions is contained in the marking. As a rule, it includes the following data:

- manufacturer;

- pipe name;

- material;

- outer diameter and wall thickness (usually indicated in millimeters, but sometimes in inches);

- maximum working pressure and temperature;

- icons indicating permission to use for water supply;

- date of manufacture, batch number;

- certificates;

- barcode;

- other information.

For ease of measurement, marks are applied every 0.5 or 1 meter, depending on the diameter.

The pipe material is designated as follows: inner layer-intermediate layer-outer layer. Adhesive layers are not indicated in the marking, but the quality of the pipe directly depends on the properties of the adhesive.

The intermediate layer of aluminum foil is designated AL. As for the rest of the layers, there are different options on the market. Due to the lower water temperature, less stringent requirements are applied to metal-plastic pipes for cold water supply compared to hot ones.

The most common metal-plastic pipe PEX-AL-PEX with an inner and outer layer of cross-linked polyethylene. If another letter is added to their designation, then it indicates the crosslinking method: a - peroxide chemical method, b - silane chemical method, c - physical radiation using an electron gun, d - nitrogen chemical method.

It is impossible to unequivocally judge by the method of polyethylene crosslinking which metal-plastic pipes are better for plumbing. The fact is that it determines the heat resistance and strength of the material, and with an increase in one indicator, the second simultaneously decreases. In addition, the advantage in parameters is not always necessary and justified by the difference in price. Therefore, the specific choice depends on the priorities of the consumer. Metal-plastic pipes for water supply are very popular.

In another commonly used pipe, PERT-AL-PERT, the inner and outer layers are made of high temperature resistant polyethylene. According to its characteristics, it is only slightly inferior to PEX-AL-PEX.

In practice, metal-plastic pipes for water supply are mainly used with an outer diameter of 16 (the most popular size) and 20 mm with a wall thickness of 2 mm and a diameter of 26 and 32 mm with a wall thickness of 3 mm. Large diameters are rarely used.

Low-quality goods - short service life: the price is responsible for the quality

When buying, pay attention to the quality of workmanship. The pipe must be without delaminations, with a constant thickness of aluminum foil along the entire circumference, not counting the seam

Mandatory marking with precise and indelible inscriptions at the same distance from each other.

Choose only quality materials

Choose only pipes specially designed for water supply, the rest may contain plastic that is unsafe for health, and even the presence of a certificate of conformity sometimes does not guarantee against the specific smell and taste of water. When using non-certified products, you may also encounter increased bacterial growth.

Cheap pipes made of HDPE polyethylene are not very durable. They quickly break down under the influence of ultraviolet rays and can lose their shape at temperatures above 75 degrees.

WATCH VIDEO

To avoid buying obviously bad goods or outright fakes, it is better to contact reliable dealers and give preference to products from reputable manufacturers: Nanoplast, Valtec, Oventrop, Henco, Wirsbo, TECE, Rehau, Golan, KAN, Viega and some other companies. Metal-plastic pipes for water supply are often used in construction.

Installation of metal-plastic fittings

The word fitting literally means "to mount", "to install". Fittings are elements that are installed at the ends of pipeline sections. The most common fittings are socket connectors, transitions to threaded connections, tees, elbows, compensators.

This manipulation is carried out using special pliers or a hydraulic press tool. Such a connection is durable, but completely eliminates disassembly in the future. If it is necessary to replace, for example, an elbow with a tee, it will be necessary to cut off an expensive disposable fitting and press a new one.

Pipe and fitting connection diagram

At the same time, in parallel with the press fittings, a collapsible compression fitting is also used. This connection consists of several components: a sleeve, a union nut, rubber sealing rings and a locking collet. A union nut and a retaining ring are put on the end of the pipe, subsequent tightening securely fixes the pipe and fitting, sealing is achieved. The advantages of this type of connection are:

- do not need special knowledge and skills for self-assembly;

- expensive tools are not required (only an adjustable wrench, scissors on a plastic pipe and a calibrator);

- the connection can be quickly disassembled at any time, the effect of the "American" is achieved.

Flaws:

- over time, especially with irregular use of heating and poor installation, the fitting may loosen.

- rubber sealing rings will need to be replaced over time, it depends on the individual characteristics and operating conditions of the pipeline, however, once every 10 years it may be necessary to replace gaskets or pull nuts.

Previously, adhesive fittings were also used, however, due to the inconvenience of installation, low reliability, this type of connection quickly disappeared from the shelves of plumbing stores.

Products made of metal-plastic have proven themselves well in application for heating, water supply and irrigation. This is an inexpensive, but at the same time reliable solution that will allow you to do all the work yourself.

Active competition with PPR systems has shaken the position of metal-plastic, however, there are installation organizations, plumbers who prefer this type of pipeline laying.

Advantages of metal-plastic pipes

Metal-plastic pipes, despite the emergence of such a competitor as polypropylene pipes (PPR), continue to be used in heating and water supply systems around the world. Such pipes fully comply with hygienic requirements, are quickly mounted, do not require complex and expensive equipment for installation. Fittings and pipe have an affordable price and perfectly withstand the entire operational period.

Unlike PPR systems, copper pipelines, metal-plastic bends easily, large sections of the heating circuit can be expanded and fixed directly on the wall from one bay. In terms of diameter, it is smaller than that of the PPR, but larger than that of a copper pipeline. This is due to the wall thickness of the metal-plastic pipe and the conditional passage of brass fittings. Thus, a diameter of 16 mm is equivalent to 15 mm in copper piping, and 20 mm in polypropylene.

Plastic pipes have an excellent efficiency indicator, which allows you to transport various types of coolant, including water, bischofite salts or antifreeze. The average service life of the pipeline in various conditions can be from 30 to 50 years, which allows you to safely use pipes in concrete floors, in closed areas or in a gate.

Installation is carried out without the use of additional equipment, in the form of a soldering iron, as for PPR pipes or a burner, as for copper. A couple of keys, special scissors and a device for leveling the edge are enough. Various diameters of pipe fittings will allow the use of metal-plastic in large water and heat supply systems. A wide range of fittings will allow you to solve any engineering problem with a system such as metal-plastic, including the transition to a threaded connection, turns, tees, plugs and couplings.

Brass fittings do not corrode, even if they are in a humid environment. The push-in connection is securely fixed by the fitting, and the compression ring ensures tightness. The material from which the pipeline is made allows you to freely bend the pipe up to an angle of 900, which is useful when installing heating radiators, connecting main pipelines.

In addition, such a problem of PPR systems, such as linear expansion of the material during heating, is not characteristic of a composite material, due to reliable reinforcement. The surface of the pipeline is protected by a special resistant plastic that will withstand minor mechanical damage and is not amenable to the destructive influence of the fungus. The cost of installing fittings and pipes of various diameters remains significantly lower than working with steel, copper or expensive seamless plastic piping systems.

Scope of application

Metal-plastic products have long become commonplace in everyday life and are used both in everyday life and in production. Due to the excellent technical characteristics, the products can be used for a long time and remain the same quality and reliability. Pipes made of metal-plastic are used:

- For plumbing. Metal-plastic products are chosen when replacing a water pipe, if a sweep is needed. Repair work can be carried out quickly, even without the resettlement of residents.

- For cold and hot water supply, heating.

- For transporting compressed air.

- To protect electrical wiring.

- For air conditioners.

- In production, agriculture, it is used in the transportation of water, used for gas.

- When compressed air is supplied.

- As a shield for protecting cables.

Advantages of a metal-plastic pipe for hot, cold water supply and heating

- It is produced in coils up to 200 m, from which a piece of the desired length is cut off, so waste is minimal.

- Lightweight and flexible, it effortlessly cuts and bends to the desired angle, reducing the number of fittings.

- Mounts quickly. No soldering, welding or threading required.

- There is no corrosion, rust, salt and lime deposits do not form on the smooth inner walls. Since water circulates unhindered, metal-plastic pipes for plumbing take a smaller diameter than metal ones.

- Due to the low thermal conductivity, heat loss is negligible.

- Good sound insulation: noiseless when moving water, there is no effect of sound propagation through the system.

- Dielectric, does not accumulate static voltage and protects against stray currents.

- Aesthetic appearance, no need to constantly paint.

- The price is lower than copper or stainless steel products.

- Unlike polypropylene, it keeps its shape well and does not allow oxygen to pass through, which slows down the internal corrosion of metal plumbing fittings.

How to choose a metal-plastic pipe to replace an old water supply

The market offers metal-plastic pipes for water supply at a variety of prices. There are pipes at very low prices, but do not rush to buy cheap products. The choice of pipes for arranging water supply should be approached with great care. After all, this work is done for a long time and the system must be reliable. Experts advise:

- First of all, the cut pipe should look perfectly glued, i.e. visually you should not observe bundles.

- It is recommended to purchase pipes with a metal layer thickness of at least 0.3 mm, but not more than 0.55 mm. Too thin a layer is easily destroyed, and too thick deprives the pipe of flexibility and ease of installation.

- Purchase pipes made using high quality polyethylene.

It is undesirable to purchase pipes marked HDPE, PE-HD and PE-RS. They are the cheapest, but, unfortunately, the most fragile.

- It is preferable to choose models with butt welding, which is performed by a laser, which is considered more reliable.

- Purchase building materials in specialized stores, in case of inadequate quality of the goods, you can always hold the seller liable. Whereas an item bought from a random merchant in the market is sometimes impossible to return, as the merchant may simply disappear.

Metal-plastic pipes are in great demand today, but the choice always remains with the buyer. The market offers various solutions for arranging pipeline systems, in each case it is better to enlist the support of specialists, and even better to entrust the installation work to a specialized company that provides guarantees for the material and work performed. In addition, experts will give you comprehensive advice on the operation of newly installed systems.