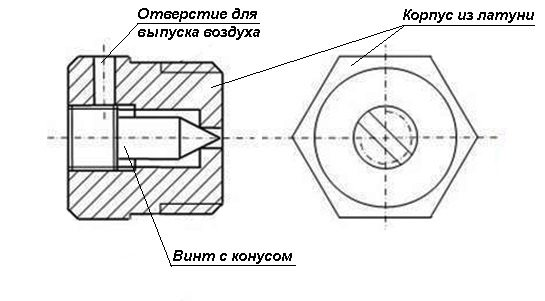

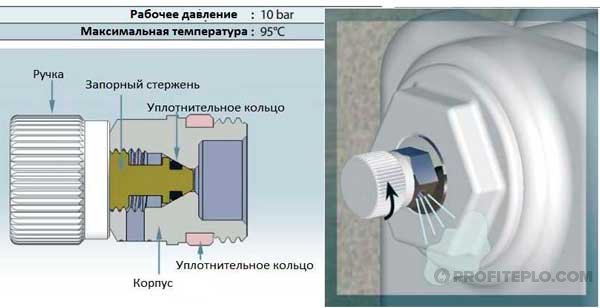

Construction and working principle of manual air valve

- Brass body (plug) with external thread 1/2 // or 3/4 // for connection to the radiator. There are two air outlets Ø 2 mm in the case - one is at the end of the case, the second is on the side wall;

- Brass screw. On one side of the screw there is a groove for a slotted screwdriver, on the other side the screw is machined into a cone that closes the air hole (“closed” position);

- Plastic casing.

On sale you can find the so-called "faucet on hand." To use it, neither a key nor a screwdriver is needed - the cork is easily unscrewed by hand.

To remove air from the housing, unscrew the screw. To do this, you can, of course, use a screwdriver, but there are special keys that most often come with the kit. After several revolutions, the screw cone leaves the end hole and air enters the body cavity, which is immediately bled through the second side hole. The main thing is not to rush to turn off the tap. About 30 - 40% of the air should come out with water, so you need to stock up on time, a basin and rags. After the air is released, the lost water must be added to the system.

Installing a Mayevsky crane on a cast-iron battery is much more difficult. Let's start with the fact that these valves are much more powerful than those that are on aluminum radiators - they can withstand pressure up to 16 atmospheres and temperatures of 150 ° C. Sequencing:

- 1 Drain the water from the radiator;

- 2 Cut a hole in the upper plug of the cast-iron battery and cut a thread corresponding to the external thread of the air vent;

- 3 Screw in the Mayevsky tap;

- 4 Add water to the system.

Faults and solutions

- Manufacturing defects. One out of fifty taps does not hold pressure at all. The only way out is a replacement;

- Screw too short. In this case, its conical part cannot completely cover the hole, so a certain force must be applied to screw the screw in until it stops;

- Solid particles of debris, getting between the screw and the body, can damage the internal threads. A one-time fum tape can help here, but later you still have to change the tap.

(No ratings yet)

Air vents are the main task

A device for venting air from a heating system makes it possible to remove gases accumulated in the pipeline and radiators.

Airing the system occurs for a number of reasons, including :

- Due to the high content of dissolved gases in the coolant, which has not undergone special training - deaeration. The solubility of gases depends on the temperature of the medium, and when the coolant is heated, the air separates from the water and accumulates, forming plugs.

- Due to the excessively rapid filling of the circuit with coolant, the liquid in the branched network does not have time to displace air in a natural way. The coolant must be poured from the bottom so that the air is forced up and out through the open valve.

- Due to the penetration of air through the walls of the polymer pipeline, if it is made of a material without a special anti-diffusion coating. When choosing pipes, this point must be taken into account.

- In the course of repair work related to the replacement of elements without completely draining the coolant - in this case, the heating device or circuit being repaired is cut off from the rest of the system, and then connected back.

- Loss of tightness.

- As a result of corrosion processes, when oxygen interacts with iron, hydrogen is released from the air molecule, which also accumulates in the system.

What is dangerous air in the heating system?

The air dissolved in the coolant gradually disables steel pipes and radiators, elements of the boiler unit. The corrosive activity of air, which was first dissolved in water and then released during heating, significantly exceeds that of atmospheric air due to the increased oxygen content.

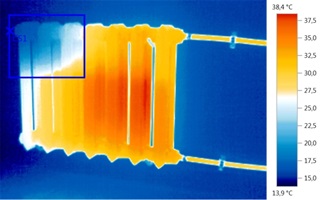

The gases accumulated in the pipeline not only provoke or accelerate the corrosion of metal elements, but also form air pockets that prevent the heating system from fully functioning :

- Due to gas plugs, the circulation of the coolant worsens; in serious cases, the movement of fluid through the pipes can be completely blocked. In such a situation, the heating devices cool down quickly.

- Air locks work as a heat insulator, and if gases have accumulated in the upper part of the battery, it warms up worse and gives off less thermal energy to the room.

- In the presence of air pockets, the movement of the coolant along the heating circuit is accompanied by loud gurgling sounds and murmuring, which violates the acoustic comfort in the house.

- Circulation pumps are not designed for pumping gases; when working with air coolant, the bearing and impeller of the pump unit wear out much faster.

Special air vents allow you to solve the problems associated with airing the heating system

It is important to choose the right valves for bleeding air and correctly determine the location of these elements.

Causes and consequences of air locks in an open heating system with natural circulation

- After repair, air remained in the heating radiators;

- Incorrect (too fast) filling of the system at start-up;

- The circuit is filled with water through the expansion tank;

- When heated, air begins to be released from the water, which was previously in a dissolved state;

- When filling the circuit, water was supplied from above.

It is not difficult to predict the consequences - stopping the circulation, cold batteries, rapid corrosion of the inner surface of the system elements. To avoid this, it is enough to install manual air vents on all radiators - Mayevsky taps.

Types of air vents

To remove air pockets in the central heating system, drain valves are installed on the extreme radiators in each branch. Valve cocks make it possible to bleed the air displaced to the extreme point of the branch when the system is filled with coolant.

Autonomous heating systems, as well as new radiators connected to the central heating network, are equipped with special air vent valves. There are two types of devices - an automatic valve for air release and a manual valve (Mayevsky's tap).

Devices are selected taking into account the principle of operation and ease of use, they are mounted in those places of the heating circuit where the risk of air pockets is greatest - on the upper manifold of each radiator, at the highest point of the heating system.

Automatic air vent

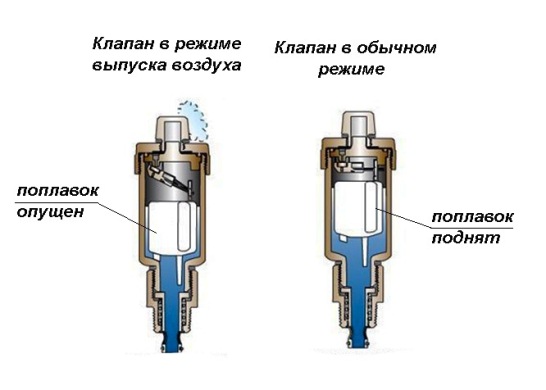

The automatic air valve consists of a hollow cylinder with a plastic float inside.The device is installed vertically, its inner chamber is normally filled with coolant, which enters under pressure through an opening in the lower part of the chamber. The air vent is equipped with a needle exhaust valve - it is to it that a float is attached to the lever.

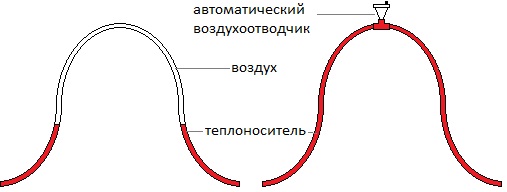

When an air lock forms in the pipeline, it tends to the highest point of the radiator or the heating circuit as a whole. If an air valve operating in automatic mode is installed in this place, the coolant is displaced from its inner chamber by gases. When the liquid is displaced, the float goes down and opens the valve, as a result of which gases are bled from the heating pipeline, and the chamber is again filled with coolant.

Note! The valve for automatically venting air from the heating system becomes silted over time, overgrown with scale. This leads to jamming of the mechanism, loss of tightness of the valve - moisture begins to seep through it

Such a device requires replacement - automatic air vents cannot be repaired.

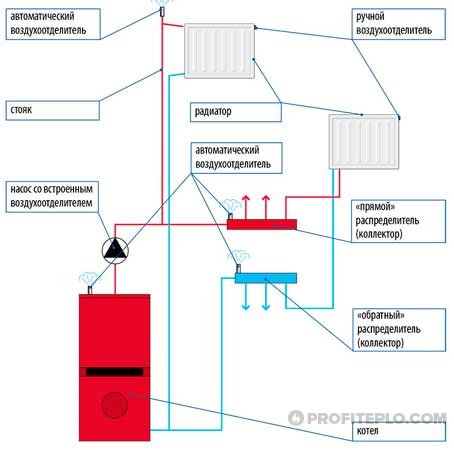

The number of automatic air vents depends on the characteristics of the heating system.

Device required for installation :

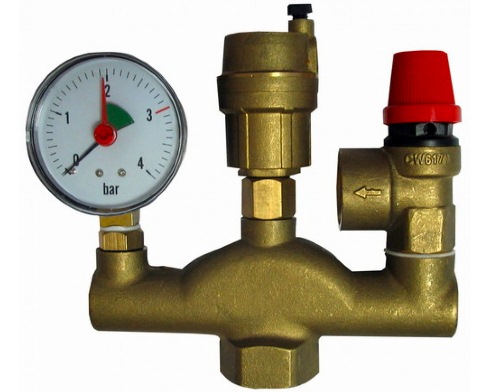

- as part of the safety group of the boiler unit at the outlet pipe of the water jacket, where the coolant is heated to the maximum temperature;

- at the highest point of the vertical risers - it is there that gaseous substances rise and accumulate;

- on the distribution manifolds of underfloor heating, so that air can be bled from the circuits;

- on U-shaped loops made of polymer pipes, which are equipped to compensate for the thermal expansion of the pipeline.

Manual air vent

A manually operated drain valve is commonly known as a Mayevsky tap. This device has no moving parts, so it is more durable and reliable than automatic.

The cylindrical body of the air vent has an external thread. The longitudinal through hole in the body is closed with a screw with a cone-shaped end. A channel of circular cross section departs from the central hole.

The principle of operation of the Mayevsky crane is extremely simple: unscrewing the screw releases the passage into the side channel, due to which the accumulated gases go out through the hole in the body. After removing the air lock, the screw is screwed into place.

Manual air vents are designed for pipeline installation as standard. But Mayevsky's radiator valves, which are mounted on sectional and panel-type heating devices, are in the greatest demand.

Causes and consequences of air locks in a closed heating system with forced circulation

- A loose impeller of the circulation pump can “grab” air during operation;

- If hot water is supplied to the expansion tank from above, then air can enter the system through cracks or ruptures in the tank membrane.

An air lock in a closed circuit will increase the pressure in the system and actuate the safety valve. The valve will bleed water over and over again until the boiler burns out or breaks the heating pipes. Therefore, the security requirements for closed systems are much stricter. In particular, for air release, a closed circuit is equipped not only with Mayevsky manual cranes, but also with automatic air vents. One of these automatic valves is included in the safety group. The group is placed on the water supply, immediately after the boiler.

Important! A leaky piping or radiator cannot cause an airlock. A working system, whether closed or open, is under pressure

Air will never go in the direction of higher pressure - this is contrary to all the laws of physics.

Automatic air vent

There are mainly Italian and German models of automatic air vents on the market. These are Caleffi, Pettinaroli, Valtec, Watts, Oventrop and Flamco. Basically, there are air valves of the so-called float-valve type.

Design

The float is housed in a brass or stainless steel body. To it, one of the edges is attached to the simplest hinged mechanism, which has the name "rocker". A needle (rod) is attached to the other end of the mechanism. When the body is filled with water, the needle is at rest and the valve remains closed. But as soon as air accumulates in the air vent housing, the water level, and with it the float, drops. The needle together with the "yoke" comes into motion. When the needle enters the spring-loaded spool, it presses on the rod, which, moving, opens the holes for air release. This is how an automatic air vent works.

In order to be able to remove the automatic air vent without emptying the entire system, its threaded part (G1 / 2 ″, G1 / 4 ″) is connected to the heating pipe through a shut-off valve.

This simple device is a boss with a plastic flap. When the air vent is screwed in, the damper automatically opens, when unscrewed, it closes.

When installing the air vent, a conventional open-end wrench is used; the lower part of the air vent body is made in the form of a hexagon. The air nipple cap must be closed during installation.

Valve malfunctions and solutions

To prevent clogging of the automatic air vent, it makes sense to put a mechanical filter directly in front of it.

Very often the air vent is made collapsible. The body and cover are connected through a special ring. If it collapses, then it leads to a leak. Buying such a ring at retail is unlikely to succeed. It is easier to use fum tape or silicone sealant.

If the air vent is mounted with a deviation from the vertical, then it will leak. There is only one salvation - to dismantle, plug the fitting and install it in a new place strictly vertically.

The cause of the leak may be a warped float. It is easy to fix it yourself, when disassembling.

Air valve recommendations

Theoretically, in all necessary places, you can put an automatic valve to release air. But in practice, the scope of automata is limited for many reasons. For example, the Mayevsky crane device is simpler and has no moving parts, so it is more reliable. The manual faucet is a cylindrical body made of tap brass with an external thread. A through hole is made inside the body, the passage in which is blocked by a screw with a conical end.

A round calibrated channel departs from the main hole located in the center.When the screw is loosened, a message appears between these two channels, due to which the air leaves the system. During operation, the screw is completely tightened, and in order to relieve gases from the system, it is enough to unscrew it a couple of turns with a screwdriver or even by hand.

In turn, the automatic air valve is a hollow cylinder, inside of which there is a plastic float. The operating position of the device is vertical, the inner chamber is filled with coolant flowing through the lower opening under the influence of pressure in the system. The float is mechanically attached to the needle outlet valve by means of a lever. The gases coming from the pipelines gradually displace the water from the chamber and the float begins to sink. As soon as the liquid is completely expelled, the lever will open the valve and all the air will quickly leave the chamber. The latter will immediately be filled with coolant again.

The internal moving parts of the automatic air bleeder are gradually covered with scale, and the working openings are silted up. As a result, the mechanism seizes, and the gases exit slowly, water begins to flow through the needle assembly. Such an air release valve is easier to replace than to repair. Hence the conclusion: air vents are installed only in those places where you can’t do without them. They are selected for:

- boiler safety groups, where the coolant temperature is the highest;

- the highest points of vertical risers, where all gases rise;

- distribution manifold of underfloor heating, where air accumulates from all heating circuits;

- loops of U-shaped expansion joints made of polymer pipes turned upwards.

When choosing a device, you should pay attention to 2 parameters: maximum operating temperature and pressure. If we are talking about a heating scheme for a private house up to 2 floors high, then in principle any automatic air release valve will do.

The minimum parameters of air vents offered on the market are as follows: operating temperature up to 110 ºС, pressure range in which the device operates effectively is from 0.5 to 7 bar.

In high-rise cottages, circulation pumps can develop higher pressure, so when choosing, you need to focus on their performance. As for the temperature, in the networks of private dwellings it rarely exceeds 95 ºС.

Advice. Practitioners recommend purchasing air vents with an exhaust pipe pointing upwards. According to reviews, a device with a side exit begins to leak much more often. In addition, during installation, it is necessary to strictly observe the vertical position of the housing.

Manual air vents for heating systems (Mayevsky taps) are most often used for mounting on radiators. Moreover, many manufacturers of sectional and panel appliances complete their products with gas removal valves. In this case, there are 3 types of air vents according to the method of unscrewing the screw:

- traditional, with slots for a screwdriver;

- with a stem in the form of a tetrahedron or another shape for a special key;

- with handle for manual unscrewing without any tools.

Advice. The third type of product should not be purchased for a home where preschool children live. Accidental opening of a faucet by them can lead to serious burns from the hot coolant.

Initial installation and replacement of check valves

Check valves used in equipping pumping stations for a well or well are installed quite simply. A more difficult task is to choose the right place for installation. The choice of device model depends on the type of pump with which it will work.

As mentioned above, check valves installed at pumping stations for a well or well are selected at the design stage of autonomous water supply systems.To equip the water supply system, you can purchase a pump model, the design of which initially provides for check valves. They can be installed both on the inlet and outlet lines of pumping stations.

Check valve as part of a surface pumping station

If vacuum-type pumps are used for a well or well, check valves are installed directly after the suction device - in front of the accumulator. The best choice for pumping stations of this type are ball and lifting gates.

For borehole pumps installed on the surface of the earth, several check valves can be used at once. One of these valves is mounted on the bottom of the hose lowered into the well, the second - in front of the accumulator.

Placement of the check valve on the submersible pump

Individual manufacturers indicate in the instructions for the pumps the appropriate type of check valve. However, as a rule, pumping units of various models can be equipped with any type of check valves. In most cases, the brand name of the borehole pump, which is equipped with a check valve, does not matter.

The check valve for a borehole pump is installed on a hose or pipe using couplings and fittings of the appropriate diameter. When installing such a device, it is necessary to ensure the tightness of the connections made, for which a FUM sealing tape is used. In addition, during installation, it must be ensured that the opening direction of the device coincides with the direction in which the water moves in the pipeline. When choosing a check valve for installation in an autonomous water supply system, it is necessary to take into account the diameter of its conditional passage, as well as the working pressure for which it is designed.

Purpose and types of air vents

It is easy to guess the purpose of the device by its name. The element is used in the circuit to remove air from the system or individual devices and assemblies, which appears there under such circumstances:

- during the filling of the entire network of pipelines or individual branches of the system with water;

- as a result of suction from the atmosphere due to various malfunctions;

- during operation, when oxygen dissolved in water gradually turns into a free state.

For reference. In industrial boilers, make-up water goes through a deaeration stage (removal of dissolved air) before it enters the boiler. As a result, tap water, initially containing up to 30 g of oxygen per 1 m3, becomes usable with an indicator of less than 1 g / m3. However, such technologies are quite expensive and are not used in private housing construction.

The task of the air vent is to release air from the heating system in order to avoid the formation of air pockets. The latter seriously impede the free circulation of the liquid, due to which some parts of the system can overheat, while others, on the contrary, cool down. In addition to air, other gases can accumulate in pipelines. For example, with a high content of dissolved oxygen in the coolant, the corrosion process of steel pipes and boiler parts is significantly accelerated. A chemical reaction occurs with the release of free hydrogen.

In the current schemes of house heating systems, 2 types of air vents are used, which differ in design:

- manual (cranes Mayevsky);

- automatic (float).

Each of these types is installed in different places where there is a risk of air lock. Mayevsky cranes have traditional and radiator designs, and the configuration of air vents can be straight and angular.