What should be the shield under the bathroom

There are a lot of options for what can be done under the bathroom. They differ from each other in appearance and functions.

When choosing the material of manufacture and the method of installation, they usually focus on the following design requirements:

- moisture resistance. Given the fact that the humidity in the bathroom is constantly elevated, it is recommended to make a screen exclusively from moisture-resistant materials that will not deteriorate in such a microclimate. If this condition is neglected, the fence will begin to accumulate fungus and mold on its surface. There is also the possibility of rotting and destruction of the material under the influence of high humidity and temperature fluctuations.

- Air tightness. To prevent water from the room from falling under the bath, it is necessary to create an airtight barrier in its path.

- Ability to access communications. It is forbidden to build a completely blank partition under the bathroom, since from time to time the drain and overflow pipe will need maintenance. To do this, the screen is equipped with windows and doors, or make it sliding.

Most often, a do-it-yourself bathroom screen is made from the following materials:

- Plastic. The most common option for self-implementation. Plastic partitions are hygienic, moisture resistant and durable. The construction of such a design will be very inexpensive, and installation work will take a minimum of time. As a decorative design of the finished screen, you can use a special film, choosing its color to match the overall decoration of the room. In addition, marine-themed stickers look stylish. In addition to monophonic designs, sets of plastic panels of various colors are often used.

- MDF panels. They rank second in popularity when creating bathroom screens. MDF is chosen in cases where the bathroom is well ventilated, because. this material is not completely moisture resistant. To ensure that such a partition lasts as long as possible, it is additionally coated with a water-repellent composition. Installation work is in many ways reminiscent of the construction of shields for a bathtub from plastic panels.

- Plasterboard sheets. To finish the bathroom, it is necessary to use a moisture-resistant type of drywall (such sheets have a specific green color). The advantage of GKL boards is that they can be used to create a very even base, convenient for tiling, moisture-resistant wallpaper, decorative plaster, painting with moisture-resistant paint, film gluing.

- Wooden panels. A similar screen is built in country-style bathrooms. To protect the finished structure, varnishing or special hydrophobic impregnations are often used.

Self-made sliding screen

Technological openings and doors for access to communications are made differently. They open vertically (swing) or horizontally (folding). The installation requires additional profiles, awnings and a special mechanism for the hinged doors to keep them in a fixed position. In a limited space, they are inconvenient - they take up space when opened.

MDF has good properties. Sheet sizes are suitable not only for sliding doors, but also for other types of screens. Due to the increased susceptibility to moisture, the panels are pre-treated with a special impregnation, then with a primer. Arrange an additional ventilation hole on the side opposite the inspection hatch. Decorate a small opening with a plastic grill.

Screen made of MDF panels with sliding doors

Guides for doors consist of a special profile along which they move.It has a W-shaped section. It happens to be plastic, but aluminum is preferable, which is stronger and holds its shape well. Sold in hardware stores selling furniture components

They are installed at the top and bottom of the structure, paying special attention to the location in the same plane, otherwise there will be distortions. The same profiles are placed on the sides as spacers.

With two sliding doors

For the manufacture of doors, materials similar to the main one, or acrylic, are used. It is sold in specialized stores, has a thickness of 5-8 mm and a variety of colors. It is sawn with an electric jigsaw, then the edges are processed with a file with small notches. Finished doors are inserted into guide profiles. Screw furniture handles and use.

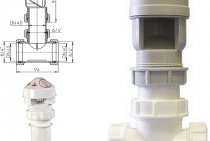

Sliding panels based on PVC window profile

There are various options for the device of sliding screens. Often it is divided into three parts: the central fixed one, on the one hand, access to the sewer pipes is opened, on the other hand, there are shelves for storing small things. If preference is given to doors that move along the entire length, two parts are prepared. Dimensions are calculated so that they overlap one another by several centimeters. Installed in different grooves.

Creation of designs nuances of technology

There are certain requirements for a home-made product, as well as for a factory one. During the installation process, they provide for the possibility of free access to communications. The design must have a door, a window, a sliding or removable canvas. The material is chosen in accordance with the conditions of the room: high humidity and constant temperature changes. Not all finishing materials are suitable, some are quickly destroyed.

The screen does not serve as a support for the bath; legs are used for this purpose. The free space under the bowl is used as a niche for storing detergents, household chemicals, various small things, although this is not necessary. From the outside, you can also install shelves. This option is especially relevant for small spaces.

Types and features of bath screens

The future design can perform several functions: be a decorative element, serve as a place to store things, or both at the same time. Depending on the purpose, there are types:

- 1. Stationary - the simplest and fastest solution. The disadvantage is the monolithic structure. For repairs, small hatches are provided, which is not very convenient. The corner screen is mainly made in this design.

- 2. Removable - the space under the bathroom is not used, but there is access to communications. If necessary, the casing can be easily dismantled and reinstalled.

- 3. Sliding - all pipes are hidden, takes up little space. Allows easy access to sewers.

- 4. Swing - has doors that open towards the room. Convenient to use, but more suitable for spacious rooms.

- 5. Folding - has sashes that open in a horizontal position. Every little thing is stored behind them, but in a small room it takes up a lot of space.

A modern acrylic bath is purchased with ready-made plastic screens. They are made exactly to size, easy to assemble and install. Owners of old steel and cast iron are forced to make them with their own hands or leave the space open and contemplate sewer pipes. To close the place under the bathroom or not is a matter of taste of the owners.

Screen made of plastic panels with hinged doors

A bathroom with a screen is transformed, aesthetics and finishing are given to it. But there is another reason to get involved in the fabrication of the structure: the space can be exploited to good use. The place under the bathroom is ideal for storing small things: the door opens, and shelves behind it.

To make a screen yourself, you will need quite a few inexpensive materials of the owner's choice:

- any bricks;

- moisture resistant drywall;

- plastic panels;

- MDF or OSB.

With the exception of plastic, everything else requires subsequent finishing. It costs little, is practical, biologically neutral, stable in a humid environment, easy to clean. Despite the low strength, this drawback does not present big problems. If any element is damaged, it is easy to replace it without disassembling the entire structure. Using popular MDF panels, they must be treated with special compounds, because they are afraid of moisture.

Hinged door model

There are other options left. With design, it is easier here: finishes for every taste are allowed to match the style of the bathroom. The brick is faced with decorative plaster or ceramic tiles. Drywall and panels (not plastic) are painted, painted, pasted over with wallpaper, tiles. The possibilities for imagination are endless, the main thing is that after decorating the screen does not lose functionality.

Gypsum boards for baths

To close the space under the bathtub of a traditional shape, moisture-resistant green plasterboard sheets are sometimes used. The finished structure is additionally impregnated on both sides with an acrylic primer. It is allowed to use oil paint to finish the inner surface of the plate. When cutting drywall, they are guided by the height of the frame, indenting by 20 mm. Fixation of sheets is accompanied by indents from the upper and lower edges by 10 mm. This makes it possible to protect against moisture ingress, which can lead to swelling of the material. Fixing the plasterboard sheathing to the profile frame is carried out by means of black self-tapping screws with fine threads. Their landing step is 15-20 cm opposite the line of the lower and upper profile.

At the site of the technological window, a hole is cut, which, upon completion of the installation activities, will be decorated with a hinged door. If it is planned to use ceramic tiles as a finish for the shield, then its thickness should be taken into account when determining the thickness of the hatch. It is attached with furniture hinges. Ready-made plumbing hatches with fasteners are on sale, the installation of which usually does not cause any difficulties.

Screen selection nuances

Before you put the screen on the bath, it must be purchased in advance, carefully considering which model is best suited.

When making a choice, you need to take into account:

- appearance;

- durability;

- functionality;

- price;

- the complexity of the installation.

If the screen is mounted under the bathtub in order to close communications that have an unsightly appearance, you can consider installing simple removable or stationary products with a hidden hatch.

When the active use of the space available under the plumbing is planned, the home craftsman will need to deal with the question of how to install a sliding screen with doors under the bathtub. This most convenient option in operation is universal for bathrooms of any size. As for swing doors, they are convenient to use only in spacious bathrooms.

When starting such work as assembling a screen for a bathtub, it is necessary to prepare fittings, but it must be made of corrosion-resistant materials, otherwise the product will soon lose its original attractive appearance. It should be borne in mind that plastic components wear out quickly and are of low strength.

In turn, parts made of galvanized steel retain their inherent qualities throughout the entire period of operation. When purchasing all the elements, you need to make sure that they are of high quality, they have a smooth running of the doors and there is a snug fit to the frame.

The decorative design of the structure should match the style of the bathroom in terms of texture and color scheme. In small bathrooms, mirror products look favorably, since their reflective surface expands the surrounding space.

The image on the front panel and photo printing must match the interior. For example, a floral print screen in a nautical-themed room would look out of place. An image of the inhabitants of the sea or waves is ideal.

When there are a lot of contrasting and bright elements in the bathroom, it is better to install a single-color screen and vice versa, for a bathroom with a finish in soothing colors, a product with a large colorful pattern is well suited.

When making a choice before putting the screen under the bath, it is advisable to pay attention to the manufacturer of the product. The most popular models among consumers are TM OSM, Wannbock, MetaKam, as they differ in the variety of materials and colors used.

Ceramic tile screen

The easiest way to make a bath screen is to tile it with ceramic tiles - this method is perfect for making a stationary screen for a cast-iron bath; however, then you will not have access under the bath to store various items there.

As you know, tiles are the most suitable facing material for walls and other surfaces in rooms with constant high humidity. In addition to aesthetic functions, it also has excellent physical characteristics - it resists the appearance of various kinds of pollution well, it is easy to clean, it does not warp or deform from frequent temperature changes, and it also does not swell from moisture, like, for example, wood or wood boards.

Photo: tile bath screen

To assemble a bathroom screen from tiles with your own hands, you will need metal profiles for assembling the frame, some tools and suitable fasteners, drywall for the tile base, and, in fact, the ceramic tile itself.

To assemble the frame, it is advisable to dismantle the bath itself for a while; on the walls and on the floor, apply all the dimensions necessary for marking and prepare in advance the required size of the sections of the metal profile.

A U-shaped structure is assembled from the profile (along the perimeter of the bathtub), which is mounted on vertical wooden or metal racks for reinforcement.

In the process of assembling the frame, it is necessary to think over and calculate the location of the hole or door for servicing the technical communications under the bathroom, as well as the niche for the legs. The presence of this very niche, which is rectangular or under the “bevel”, will greatly facilitate access to the bathtub.

Next, the finished frame is sheathed with sheets of drywall; it is very important that the joints between the sheets fall on the guides, and the sheets themselves are securely fastened together. The joints formed in the places where the sheets are fastened must be leveled with a special moisture-resistant putty designed for drywall

And finally, the final stage of screen manufacturing bath and its installations - finishing the resulting frame with ceramic tiles; for this purpose, it is best to use tile adhesive, and it is advisable to seal the tile joints with a special tile grout, which contains substances that protect it from mold.

Screen for small corner bath