What is geotextile and how is it used, how to choose for drainage, laying in a photo

To answer this question, you need to understand the main types of material. Classify this non-woven fabric according to the following criteria:

Basic properties and selection rules

How to choose a geotextile for drainage and which one is better to use in order for the system to work with maximum reliability? Here you need to take into account all the physical characteristics of the material, which will vary depending on the specific type of web. Among the main ones it is worth highlighting:

After the answer to the question of how geotextile is used and what it is, it remains only to decide which canvas should be chosen for the drainage system.

Laying drainage pipes using geotextiles

Experts recommend a material with the following characteristics:

Geotextile laying technology

Before laying geotextiles, it is necessary to clarify the basic technological requirements for installation. In particular, it is believed that geotextiles are too susceptible to sunlight, so they are taken out of the package not in advance, but before direct installation. It is also recommended to cover the material with soil as soon as possible, without leaving it under the sun's rays. Proper preparation of trenches is also important - each of them must be with even slopes and without construction debris inside, because it can damage the coating.

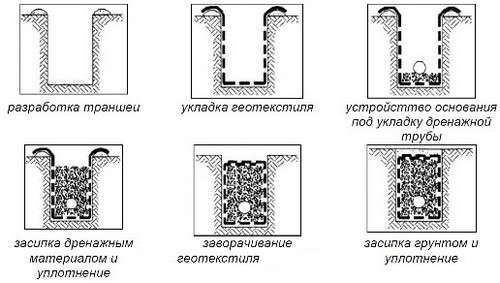

The geotextile laying technology here involves the following steps:

The photo shows the laying of geotextiles - step by step technology

All work on laying drainage pipes using geotextiles is carried out as quickly as possible. Thanks to the creation of such an effective system, silting of pipelines when draining the filtered liquid can be avoided.

Manufacturers and cost of geotextiles

Now, knowing the answer to the question, what is a geofabric and how it is laid, we will talk about how to choose a geotextile for drainage and which one is better to use. To determine the economic feasibility of using geotextiles, you need to choose the right material based on the cost factor. The price per square meter of geotextile will vary between 0.3-1 dollar and will depend on the brand, type of material and its performance characteristics.

Among the popular manufacturers are the Russian companies Dornit, Avantex, Geotex, Geopol, Gront, Montem, Nomotex. Foreign manufacturers are also widely represented on the market - the American company Typar, the Czech NETEX A, the English Terram, the Austrian Polifelt.

In general, the price of geotextiles suitable for drainage applications is low. You should not focus only on the cost or country of origin. The advantages of geotextiles, suitable for the installation of high-quality drainage systems, are evaluated comprehensively - density and strength, manufacturing method and type of feedstock are taken into account. The selected material must correspond to the existing operating conditions and the functional purpose of the system, and the fame and popularity of the brand in this case fades into the background. Moreover, many domestic companies have successfully mastered the technology of low-cost production of high-quality geotextiles.

Overview Geotextile: what it is and how it is used, how to choose for drainage, laying.

Geotextile is a waterproof fabric characterized by high strength. Numerous 100% polypropylene fibers are used as a base.

The use of geotextiles has found distribution in various areas of construction. This became possible due to the high performance properties of the material.Geotextile is resistant to mold, fungi, it does not rot and rodents do not spoil it. The material does not lose its qualities when the temperature drops from -60 to +100 degrees. Geotextiles are characterized by high strength, resistance to chemicals and ultraviolet rays.

Geotextiles in landscape design

Geotextile is a synthetic material widely used in landscaping and construction. Due to its unique properties, it is used in creating lawns and laying paths in the garden, it is used in the construction of reservoirs and strengthening slopes.

For the first time, in the mid-60s, geotextiles appeared in the USA and Europe (France). By the 1970s, non-woven needle-punched textiles were already being produced in Russia.

It is made by mechanical, as well as thermal bonding methods from polypropylene and polyester in industrial production.

The use of geotextiles in landscape design

This material is used to solve many problems. Due to its versatility and low cost, there are many applications and new original ideas are constantly appearing on sites dedicated to landscape design. Here are some use cases:

- when arranging paths in a garden or a playground, it is used to separate layers (for example, crushed stone and sand), preventing them from mixing;

when enriching soils in garden plots, it is used to separate layers of infertile local soil and imported fertile soil;

when forming embankments and slopes, it is used for reinforcement - a canvas laid under the turf will significantly strengthen the slopes, prevent erosion, divert excess rainwater and prevent weeds from developing;

in drainage work - hydrotextile passes moisture well, protects the drainage system from soil silting;

in decorative compositions it is an indispensable material, it is used to separate the soil and decorative gravel or mulch;

as protection against germinating weeds, it is laid under garden paths, flower beds and lawns;

to protect the waterproof film of reservoirs from the roots of plants, especially shrubs that can damage the pond bed;

when constructing water pipes or laying electrical cables, a bed of geotextile is laid out for them, the material protects against the germination of plant roots and allows you to fill communications with crushed stone or other loose material;

as a plant protection against sunburn, frost and rodents.

Use geotextiles in your garden, this is one of the most popular modern materials for a wide range of applications.

Tekspol (Tekspol) is a non-woven geotextile made of polypropylene or polyester fibers bonded using needle-punched technology. The product is used in many branches of construction, as well as in land management and landscape design.

2 What type of geotextile is best for drainage

For drainage, it is best to use a geotextile material that will ensure the stability of the entire drainage complex.

In particular, it should prevent soil subsidence in drainage trenches as much as possible and at the same time help prevent crushed stone from diffusing into water. Geotextile in the drainage system plays the role of a filter and prevents water from entering this system or drainage material.

Many experts prefer canvases produced using the thermal bonding method. However, the choice remains with the buyer, since for different needs it is best to use different types of geotextiles that meet the established requirements.

As for the density characteristics, here experienced builders recommend not choosing products that are too dense or containing too low density, but choose the “golden mean”.A normal indicator can be considered 150-250 g / m2. The thickness of the material should also be taken into account, which for drainage systems can vary in the region of 2.0-2.8 MPa.

2.2 How to lay out geotextiles during drainage work?

For the correct and reliable laying of geotextile building materials for drainage, a certain planned approach is needed, which must be applied systematically.

The procedure for laying geotextiles in the drainage system:

- dig a trench of the required size. When digging a trench, it is necessary to level the bottom as much as possible and clean it of construction and other debris;

- cut the geotextile sheet to the desired size, as well as make cuts for possible bends and the like;

- remove the factory packaging from the geotextile. It is advisable not to do this until the moment of laying in the drainage trench, since most products are sensitive to ultraviolet radiation emitted by the sun.

- lay the selected geotextile in the trench so that it is not stretched and does not have waves and folds. Observe the size of the overlapping of the canvases in the region of 0.3-0.6 m. It is recommended to fix the overlapping points with a heavy object before and at the time of backfilling the trench with filter material in order to avoid separation of the waterproofing;

- make sure that the overlaps of the panels on the slopes of the trench overlap the overlaps located at lower levels in size;

- immediately start backfilling the trench with a 30 cm thick layer of drainage material. Next, backfill and compact the trench;

- having filled the drainage material to the top of the trench, wrap the edges of the geotextiles with an overlap of at least 20 cm on each other. This will prevent contamination of the entire drainage;

- backfill the remaining space with backfill soil and compact it well.

When laying the panel, try not to damage it. If damage still cannot be avoided, replace the damaged areas by cutting sheets of the required size from an undamaged geotextile.

And remember that when building drainage, it is simply necessary to use geotextiles, as it is responsible for preventing flooding of pipelines that drain filtered liquid, which makes the life of the drainage system longer.

603

Popular manufacturers

In the building materials market, you can find geotextiles produced by various companies. However, professional builders prefer the following brands:

- Dornit. A Russian company engaged in the manufacture of various types of geofabric. Distinctive characteristics - low cost and resistance of the material to mechanical and chemical influences;

Geofabric of various types from the Dornit company

- Geotex. The company specializes in the manufacture of geotextiles resistant to ultraviolet rays. This quality is achieved through additional processing of the material with special compounds. The impregnated product is most optimally suited for outdoor work;

- Geospan. The manufacturer produces high-quality geofabric with various technical parameters. The user can choose a high-strength material intended for reinforcement and construction (Geospan TN) and an environmentally friendly material with resistance to chemical environments (Geospan TS) for use in a garden plot;

- TechnoNIKOL. The company specializes in the manufacture of needle-punched polyester geotextiles for a variety of applications;

- Geocomplex. Geocom is predominantly non-woven fabricated and intended for domestic use;

- Taipar. Typar geotextile, made in Luxembourg, is UV resistant, high strength, but at the same time more expensive than the Russian-made materials listed above;

Material from Taypar

In order for the geofabric to perform the functions assigned to it, it is necessary not only to choose the right material, but also to correctly lay it.

The geofabric is laid only on the prepared surface, completely cleared of dirt and plant roots. To achieve an insulating effect, the minimum overlap must be at least 10 cm on a flat surface and at least 30 cm in the presence of bumps and depressions.

What is geotextile for?

How does geotextile “work” in general? Imagine a drainage trench. Usually it is covered with rubble. This porous layer removes excess water - from a residential building, summer kitchen, fence. In a humid environment, the soil gradually penetrates into the space between the pebbles. The result - the channel is getting worse, the quality of water disposal is deteriorating.

This will not happen if you first lay a geo-textile in the trench, then pour crushed stone and wrap its layer with the edges of the geo-fabric (necessarily overlapping). As a result, soil water still passes through the drainage layer, but its mixing with the soil, clogging and disruption of drainage no longer occur.

Density is the most important characteristic

- ability to retain water;

- reinforcing properties;

- protection.

Sometimes there are disputes about what density geotextiles are needed for drainage. There is an opinion that 100 g/m2 is enough. The practice of using geofabric has shown that a canvas of this density is suitable only for landscape work.

In this case, do not give in to your desire to save money. If the drainage system is supposed to be arranged in the ground without any special "surprises", a density of 200 g / m2 will do. Areas where landslides occur and the soil can “float” require the use of a geotextile with a density of 300 g/m2.

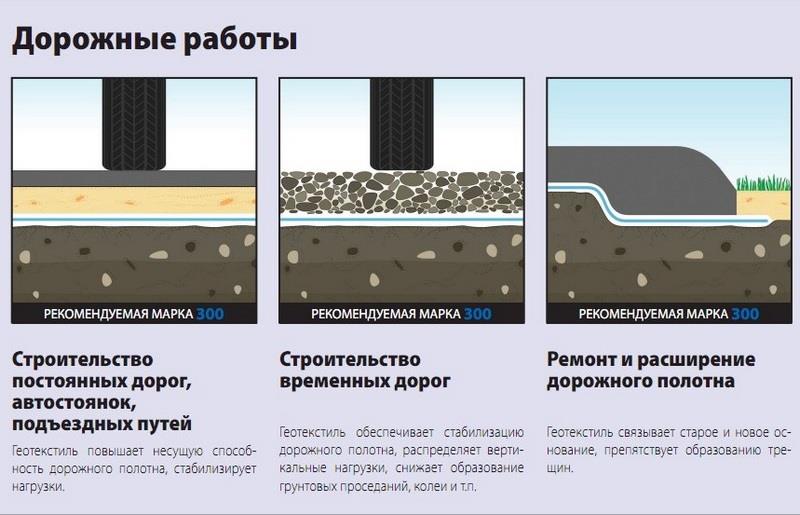

For the construction of runways at airfields, geofabric with a density of 800 g/m2 or more is used. A slightly thinner material in Europe is constantly used in the construction of roads. The canvas is laid under the main cover. This gives excellent strengthening of the entire ground, prevents blurring and failures if heavy vehicles often pass along the track.

Geotextile selection

You already know for sure that you will build a drainage system using geotextiles. There are so many offers for drainage textiles - how to choose the right one? It all starts with your project.

- First you need to determine the properties of the soil in which the drainage system will be arranged. So the main parameter of the geotextile - density - will become known.

- Then the material of the drainage itself must be taken into account. This will help determine whether to buy thermally bonded or needle-punched geotextiles.

- Further selection is made at the point of sale. You will be offered several brands and types of geotextiles in accordance with your parameters. Now important: the reputation of the manufacturer, the price, to some extent - the popularity of the brand.

Consideration

No geofabric will help your drainage system work properly and for a long time if you do not do all the work accurately and correctly.

What to look for:

- The drainage system must be carried out with a slight slope in the direction where the outflow of water is expected. Otherwise, the water will simply stagnate.

- The overlap when covering the drainage layer should be at least 100 mm in stable soils and about half a meter in difficult, unstable soils.

- After wrapping the drainage layer with geotextile, the edges must be firmly fixed. This can be done by welding or stitching the fabric.

- Before backfilling the trench with soil, it is desirable to arrange a small sandy layer on top of the geotextile.

- If the drainage system is arranged in "wet" soils, crushed stone may not be enough even taking into account the geotextile. In this case, it is desirable to place special drainage pipes in the middle of the drainage layer. Such a system allows you to cope with a large volume of melt water, precipitation and even streams.

The use of geotextiles in drainage systems solves several problems at once. If crushed stone is used as drainage. it will be required less than for a conventional trench backfill. This is due to the fact that the crushed stone will not mix with the soil and become clogged.

If the system, in addition to the filler, uses perforated drainage pipes. you can not be afraid of clogging their drainage holes with soil particles. The soil itself is strengthened thanks to geotextiles. The main thing is to choose the right density of the geofabric. In this case, you will appreciate all the advantages of using geotextiles for drainage.

http://stroyusnulya.com

Unique properties of Texpol geotextile

Texpol geotextiles, depending on the surface density, are divided into types. Density varies from 150 to 600 g/m2. Breaking load (length/width) – from 3/3.4 to 9.6/12 kN/m2. Elongation at break (length/width) - from 200/220 to 250/230%. The material has excellent physical and mechanical characteristics, well resists the negative effects of the biological environment and UV radiation, has a fairly good resistance to aggressive chemical environments.

Physical and mechanical characteristics of Texpol geotextile:

| The name of indicators | Texpol150 | Texpol200 | Texpol250 | Texpol300 | Texpol350 | Texpol400 | Texpol450 | Texpol500 | Texpol600 |

|---|---|---|---|---|---|---|---|---|---|

| Surface density g/sq.m. | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| Thermal conductivity, W / (m K), no more | 0,08 | 0,08 | 0,08 | 0,08 | 0,08 | 0,08 | 0,08 | 0,08 | 0,08 |

| Relative elongation at break, % not more than in length in width | 130 | 130 | 130 | 130 | 130 | 125140 | 125140 | 125140 | 125140 |

| Breaking load, kN/m2 not less than in length in width | 3,03,4 | 5,06,0 | 6,06,5 | 6,77,6 | 7,28,6 | 7,69,2 | 8,09,6 | 8,410,6 | 9,612,0 |

| Filtration coefficient, m/day (with vertical load P=0.01 MPa), not less, in the direction perpendicular to the plane of the canvas in the plane of the canvas | 6030 | 6030 | 6030 | 6030 | 6030 | 6030 | 6030 | 6030 | 6030 |

| Unevenness by weight,%, no more | 4,0 | 4,0 | 4,0 | 4,0 | 4,0 | 4,0 | 4,0 | 4,0 | 4,0 |

Download characteristics of Texpol geotextile

What is geotextile

At present, the most widely used non-woven geotextiles. Its distinguishing feature is the random arrangement of the fibers, which provides increased elasticity at the cost of some reduction in strength. In this group, two main types of material are distinguished - needle-punched (maximum elasticity, low strength), as well as thermally bonded (medium strength and elasticity). In addition, there is also a woven geotextile. It has very little elasticity, but is significantly superior to alternative options in terms of tensile strength. All types of geotextiles created from polypropylene, polyamide and polyester fibers have common properties. These include: • Increased strength compared to organic materials and mixed fibers; • Maximum durability, eliminating the need for constant renewal of the material; • Complete safety for humans and the environment; • Resistance to various influences, including humidity, abnormal temperatures and direct Sun rays.

The main types of geotextiles

Geotextile has several types:

- compact mats;

- roll geotextile;

- tiled.

The bases of geotextiles are divided into several types: mineral (glass and basalt), synthetic.

The most practical and popular is non-woven needle-punched. Its advantage is that it has the ability to pass water better than its other types, and also not to silt during operation.

Non-woven rolled textiles are less practical due to fragility, which is a consequence of the fact that when stitching, loops of threads are formed in it in large quantities. They are the cause of the breaks. A small gap leads to the destruction of the entire product.

Geotextiles are a range of products produced using new technologies.

Density of geotextile

In many ways, physical characteristics are determined by the density of the geosynthetic material, which depends on the manufacturing technology used by the manufacturer, as well as on the consumption of raw materials.Currently, the most common are geotextile fabrics with a density index of 100 to 600 grams per square meter. There are also options with a density of 600-800 g / m2, but they are used extremely rarely. The production of material with a density of less than 100 g/m2 is irrational, since it will have a very low density and be damaged by any slightest impact.

How to choose geotextile

Each strength has its own scope of application - after all, the material cannot be both very strong, elastic, and also pass water and perform waterproofing functions. You can get acquainted with the functionality of certain brands of geotextiles in the following table:

|

Material density, g/m2 |

Scope of use |

|

Mainly - mulching, weed control and soil cover in agriculture, as well as the creation of garden paths |

|

|

Agricultural application, creation of decorative lawns, paths and open bulk areas |

|

|

Agricultural applications, formation of paths, as well as sports and ornamental lawns, strengthening of slopes and creation of multi-level structures, arrangement of drainage channels |

|

|

Creation of paths, lawns for various purposes, as well as access roads and parking lots for light vehicles. Fixing soil on slopes and preventing water or air erosion |

|

|

Reinforcement of surfaces under roads and parking lots for vehicles of small mass. Strengthening the soil and creating small artificial reservoirs. Water filtration and wall strengthening in drainage channels. Covering and planting plants. |

|

|

Creation of public roads and universal parking lots. Drainage and strengthening of the foundations of buildings, as well as other structures. Hydraulic works, reclamation of waste collection sites, shelter and planting of plants. |

|

|

Construction of roads and highways, creation of parking lots for heavy equipment and access roads at enterprises. Strengthening of foundations, creation of artificial reservoirs, waste disposal. |

|

|

Construction of roads and parking lots for heavy equipment, highways. Strengthening foundations, securing the banks of natural reservoirs. |

|

|

Construction of roads, highways and railroad tracks. Strengthening the foundations. |

|

|

Construction of main road and rail transport routes. Strengthening the foundations of multi-storey buildings |

|

|

Construction of main transport routes and runways at airports. Strengthening the foundations of multi-storey buildings. |

It is best to purchase a geotextile fabric from the manufacturer, which is the GeoSM company. Such a solution will significantly reduce costs, as well as quickly and conveniently receive exceptionally high-quality goods.

Key features and benefits of use

Tekspol is especially in demand in civil and road construction. The product performs reinforcing, filtering, draining and separating functions. For example, geotextiles of this brand are often used as a reinforcing and separating component of road bases. The material does not allow soil to mix with the bulk layer, thereby keeping the crushed stone (gravel) in the same position, minimizing subsidence, increasing the bearing capacity of the base, and also reducing the volume of bulk building materials used at the construction stage of the facility.

Do you need a Dornit 2 blade? The company "NPO Geotechnologies" provides you with its services. Top quality materials and worldwide shipping. Here you can also buy geotextile dornit 300, the price of which compares favorably with the prices of our competitors.

Quality and properties of geotextiles

The best drainage geotextiles are fully synthetic.Some types of geofabrics use natural fibers (waste of textile production), but such material is of relatively low quality and is rarely used and not everywhere.

- Chemical resistance. Despite the constant stay in a humid environment, mold does not form on geotextiles. The processes of decay also do not affect it.

- The material is inedible for any insects and rodents.

- High environmental friendliness.

- Operating temperature - from -60 to +110 degrees Celsius.

- High coefficient of elasticity.

- Significant tensile strength.

Polyester or polypropylene monofilaments are used for the manufacture of synthetic geotextiles. The material can be needle-punched or thermally bonded.

- In the first case, the main layer of fibers is stitched with threads using serrated needles. In this way a very high quality fabric is obtained.

- In the second case, a solid canvas is created by significant heating of the warp fibers. The material made in this way is very durable, almost impermeable to liquids.

What is geotextile

Geotextile is a material that is made woven or non-woven from materials such as polypropylene or polyester. It is densely supplied to construction stores in rolls with a width of 200 mm to 550 mm and a length of 10 m to 150 m.

Advantages

The main advantages of the material are:

- high rate of elasticity;

- ecological cleanliness;

- the possibility of uniform distribution of the load;

- resistance to chemical aggressive substances and ongoing processes;

- density, which prevents the germination of plants;

- moisture resistance;

- resistance to rodents;

- strength, which contributes to the use of material for reinforcement;

- low cost;

- ease of use.

Areas of use

All these qualities allow the use of this type of building material in the following areas:

- Road construction.

The material is used as a solid base and helps to increase the bearing capacity of the roadway, protects against the negative effects of moisture and natural phenomena, as well as soil subsidence, helps to establish a strong connection between the old and new base, which prevents the formation of cracks.

All of these factors can increase the life of the route and reduce the need for repairs. Geotextiles are also used for garden paths and sidewalks.

Geotextiles in the construction of roads and sidewalks

Geotextiles are also used in the construction of railways and airstrips.

- Construction of houses and other structures. The material is used for the foundation and allows you to protect the foundation of the house from the effects of groundwater, which increases the strength of the structure and the period of use.

Protecting the foundation of the house from moisture

- Laying communications. The material is used for waterproofing and protecting pipes in the construction of sewer networks, outdoor plumbing systems, power supply and so on.

The use of geotextiles when laying a pipeline

- Agriculture. The material is used for drainage of the site, protection of plantations and crops, separation of plantings, as a covering material, for the construction of wells for garden paths, flower beds, strengthening slopes and so on.

Material use in agriculture

- The medicine. Certain types of geofabric are used to make personal protective equipment and hygiene products, as well as disposable clothing with high antibacterial properties.

- Furniture manufacturing.

- Packing and so on.

The main functions of geotextiles

Geotextile is a multifunctional material. It has properties that are an advantage over other materials. The essence of these properties is as follows:

- it does not collapse from exposure to both acidic and alkaline soils, does not mold, does not rot and does not decompose for more than 15 years;

- geotextile properties are preserved at temperatures from +60 to -60, which allows you to work on its installation in any season;

- suitable for reinforcing and strengthening weak soils;

- sunlight does not destroy geotextiles for a long time;

- he is not afraid of excessive moisture, as it goes through him into a horizontal plane.

- through it the roots of plants do not germinate;

Thus, 5 main functions of geotextiles can be distinguished: separation, filtration, drainage, protection, reinforcement.

Due to the versatility of the material and its wide application, geotextiles are conquering the consumer market. At the same time, its prices remain quite reasonable.