How to connect fittings

For the installation of press fittings, a type of tool such as a crimping press is used.

The type of this connection can be divided into three main components:

- a body, which can be in the form of a tee, coupling, angle;

- a sleeve that is just subjected to compression and does not lose its shape during operation (usually made of stainless steel);

- clip, the task of which is to connect the body and sleeve to each other.

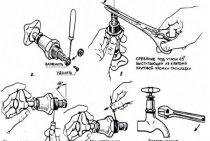

For the quality and tightness of the connection, the following steps must be performed:

-

We measure and cut the pipe at a right angle.

- We perform calibration (to eliminate ovality when cutting the pipe).

- We put a sleeve on the pipe.

- Then we insert the fitting into the pipe.

- After that, the sleeve is crimped with manual or hydraulic tongs (compression is performed once, repeated is not allowed).

Pincers are not a beast, but an installation tool

If everything is clear with press fittings, now we will take a closer look at the tool for their installation. These are pressing tongs that can be manual, electromechanical or hydraulic.

At home, manual press tongs will be enough

For home and infrequent use, a hand tool will suffice; if the work is done correctly, it will not yield to its hydraulic counterpart as connections, and its purchase price is lower.

Read about the hand tool here: http://kvarremontnik.ru/ruchnojj-press-dlya-press-fitingov/

For industrial use or for professionals who are professionally involved in the installation of various pipelines, hydraulic or mechanical ones are more suitable, which are able to perform a large number of pipe connections in a short period of time.

Man working with hydraulic tongs

The press fitting tool market today is represented by such companies as VALTEK, VIEGA, REMS, PEXAL, VIRAX and many others.

Advice! If you need to carry out minor work to mount press fittings, you do not need to buy a tool. Many stores offer to rent it. In the store, you leave a deposit (which is returned upon the return of the press tongs) and money for renting the tool.

Modern kits have nozzles for different pipe diameters.

Different types of press tongs are designed for mounting pipes of a certain diameter. But now there are models that can use special liners to work with the same tongs with different pipe diameters.

There are also improved versions of models that can be recognized by marking:

- OPS - due to the use of step-type clamps, the applied forces for crimping the sleeve increase.

- APC - automatic control of work is carried out, and the press will not open until the end of the successful compression of the sleeve.

- APS - the device automatically distributes the applied forces.

Electromechanical devices are powered by the mains, but there are models that can be powered by batteries, which makes them more versatile.

Advice! Experts recommend using tools for press fittings and the fittings themselves to make connections between piping systems, if possible. one manufacturer, for example, this is a company Valtex, but there are others. This will serve as an additional factor in the quality of the work carried out and the tightness of the system as a whole.

Today, prices for manual press tongs start from 70 USD and above, for professional electro-hydraulic - prices start from 500 USD.

We hope that the article was useful to you. If not difficult, please click the social media buttons below.

Main technical characteristics of pipes made of cross-linked polyethylene

Pipes made of cross-linked plastic are widely used in everyday life for:

- Installation of lines and elements of heating systems.

- The device of heat-insulated floors under a coupler.

- Connecting heating radiators when carrying.

Rice. 3 PE-X - material properties

The widespread use of polyethylene pipes made by stitching is due to their following properties:

- Unlike conventional polyethylene, which is designed to work under pressure with a liquid temperature not exceeding 40 C., PEX can function for a long time in systems with water temperatures up to 95 C. The maximum operating temperature that PEX pipelines can withstand depends on the method manufacturing and can reach 120 C.

- The material is 8 times lighter than steel.

- The smooth surface of the inner walls reduces pressure losses in the pipeline, scale does not form on them.

- Many grades of PEX are capable of operating at pressures up to 20 bar.

- The cross-linked polyethylene pipeline absorbs vibrations from operating equipment (compression electric pumps) and noise from the passing water flow.

- PEX is resistant to most aggressive chemicals, the number of which reaches 200 items.

- The service life of PEX is 50 years when operating at 90 C. / 7 bar. or 70 C./11 bar.

- The material is resistant to corrosion, does not emit harmful toxins and chemicals into the flowing liquid in the entire range of operating temperatures.

- Plasticity allows you to mount the pipeline with a minimum bending radius of 6 diameters.

- PEX does not lose its properties when the liquid inside freezes.

- The surface covered with a layer of polyvinylethylene (EVON) prevents the diffusion of oxygen.

- PEX piping is easy to assemble with your own hands using simple mechanical devices.

- Products have reverse shrinkage, that is, they take the initial shape in the case of plastic deformation.

Rice. 4 Examples of connecting XLPE pipes