Features of a septic tank from barrels with their own hands

The barrel cleaning system is carried out according to the same principle as other septic tank options. It may consist of two or three chambers. The process of moving wastewater in the tank is carried out by gravity. To achieve this effect, installation should be performed below the level of the sewer pipes.

This type of building can be operated for several years. To increase the terms of effective use, it is recommended to check the first container for the formation of blockage or siltation in it. The volume of the septic tank is increased by installing an additional barrel.

Septic tank made of concrete rings and a metal barrel

The cleaning system is made on the basis of plastic or metal barrels. The main condition for quality is tightness. Metal tanks require special anti-corrosion treatment with protective agents. Therefore, many owners of suburban areas prefer structures made of plastic barrels.

Advantages of plastic elements:

- an extensive range;

- simple installation system (no additional material preparation is required before installation);

- high degree of resistance to the aggressive effects of effluents;

- long service life;

- high rate of tightness (good protection of the system from seepage of waste or penetration of groundwater into the interior);

- light weight (simplifies the installation process, eliminates the need for heavy special equipment).

A septic tank made of plastic barrels is easy to install and durable

Features of installing a septic tank from plastic barrels

It is not difficult to equip a sewerage system from plastic barrels. If black drains are not allowed, this type of cleaning structure will not require special maintenance. For drains from the toilet, you will need to call the sewers.

An example of a septic tank made of plastic barrels

Installation step by step:

- Making holes on two containers (holes are placed in the upper part, their size corresponds to the diameter of the flange).

- Making a hole in one container to accommodate a fan pipe.

- Works on waterproofing joints (it is recommended to use mastic).

- Fastening pipes for drainage into holes previously prepared on the side.

- Organizations at the bottom of the excavation of a concrete base 25 cm thick (for the first chamber, which will be placed higher than the second).

- Connecting containers to each other.

- Installation of a drainage pipe system (rubble is used as a drainage filter).

- Checking the angle of inclination of pipes with a building level (permissible slope angle is 2 cm per meter of length).

- Falling asleep structure.

- Check for leaks and fill the system with water.

Preparing a pit for a septic tank

Septic tank and cesspool. What is the difference

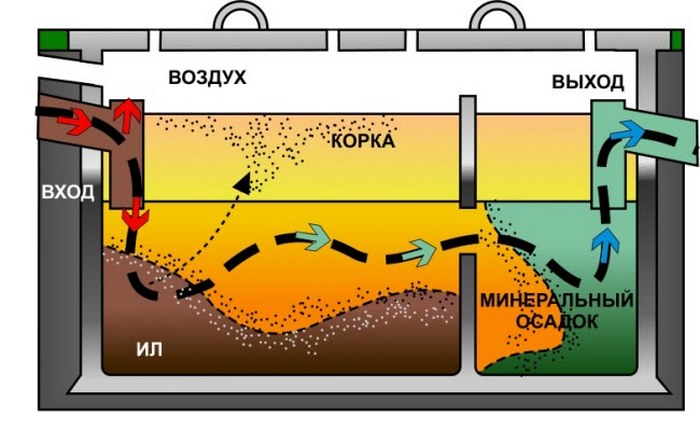

The main task of any septic tank is the disinfection and removal of treated water. Solid fractions in the total volume of effluents occupy an insignificant part. In the cesspool, they are mixed with water, and in the septic tank they are separated into solid and liquid fractions. Dirty water in the septic tank is well cleaned and continuously removed, and solid sediment (silt) slowly accumulates at the bottom. Therefore, a septic tank does not require as frequent cleaning as a cesspool.

Consider the structural differences between these structures.

A cesspool is a reservoir dug into the ground. If you make it impervious to liquid, then in a matter of weeks it will overflow, and sewage will go over the edge. Therefore, the side walls and the bottom in the cesspool are made draining (permeable to liquid). Solid fractions of pollution accumulate at the bottom, and water seeps into the soil. The need to pump out the sewer in the area with a cesspool occurs at the moment it is completely filled.

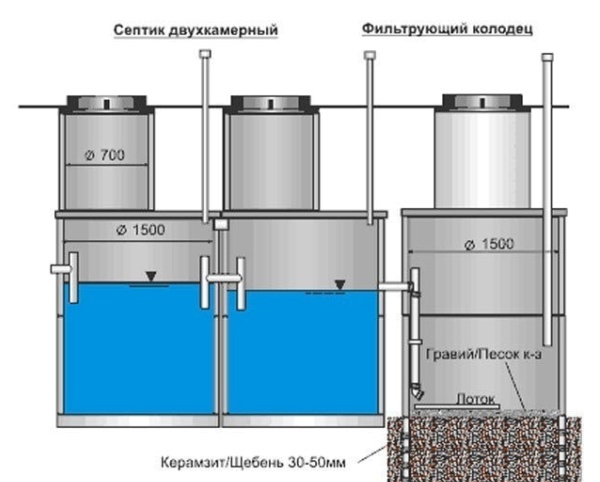

The septic tank is designed and works differently. It consists of several sealed containers interconnected by overflow pipes. Before starting operation, the containers are filled with clean water so that it reaches the lower cut of the pipes. At the outlet of the septic tank, a filtering well or drainage trench is arranged, in which complete oxygen decomposition of contaminants occurs.

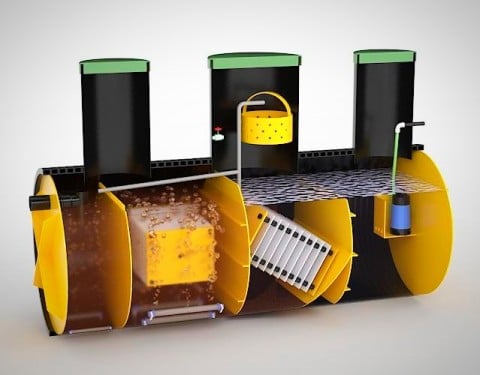

A variation of the classic two-chamber septic tank is a deep biological treatment station. It is more compact in size. Disinfection processes take place inside one container, divided into several sections. The main cleaning work here is performed by atmospheric oxygen and special bacteria.

Topol-ECO treatment plant Topas

The manufacturer's catalog includes both individual treatment facilities for private houses, as well as complex and specialized solutions - for a group of houses, villages and enterprises. Other plastic goods are also available: cellars, decorative stones, contact tanks, galvanizing baths, etc.

Production technologies and assortment

To assess the scale of production, we recommend that you first look at the "kitchen" from the inside. 13 minutes tour of the factory, from which you will learn about the applied assembly technologies and methods for controlling the finished product.

The company produces VOCs, which make up 3 large groups:

- For private houses. Topbio - non-volatile septic tanks for installation in sandy soils. Topas and Topas-S are stations with two or one compressor, respectively. Topaero - treatment facilities with protection against increased volley discharge of wastewater.

- For businesses and communities. Topglobal - a set of equipment with reinforced concrete tanks for cleaning households. and industrial waste. Topaero-M - a set of VOCs with increased total productivity for the treatment of domestic wastewater. Topaero-M / E - an analogue of the previous version for any type of wastewater.

- specialized stations. Toplos-FL - for cleaning wastewater from organic matter. Cyclone - a system for post-treatment of domestic wastewater. Toplos-KM - LOS container type for households. drains. Toppolium is a separator of fats from effluents from public catering establishments. Toprain - installation for the treatment of storm drains.

The presented equipment covers a wide range of performance. The youngest models are designed for 4 people, the oldest - up to 200. The use of active forced aeration guarantees 98% of domestic wastewater treatment. Therefore, the company positions its SBOs as treatment facilities that do not require the call of a sewage truck.

In most cases, polypropylene sheets with a thickness of 8 to 20 mm are used as the main material. The rigidity of the structure is achieved by using internal partitions and lattice structures as stiffeners.

| Model* | Topas 4 | Topbio | Topaero 3 |

|---|---|---|---|

| Operating conditions | For permanent use by a family of up to 4 people on a site with any groundwater level and type of soil. | For permanent or seasonal use by a family of 3-6 people on a site with sandy soil and low GWL. | Permanent use for a large family and guests - up to 15 people in total. Any ground conditions. |

| Short description | System with two compressors for aeration of drains and deep biological treatment. Effluent can be dumped into the ground or ditch. | Vertical 5-chamber non-volatile septic tank for which a filtration field is required. | Aeration system with the expectation of volley discharge of wastewater up to 1 m3. Effluent with up to 98% purification is odorless and can be dumped into a ditch. |

| Material | Polypropylene 12.5 mm for external walls, internal partitions 8 mm thick. | ||

| Size, L×W×H, mm | 950×970×2500 | 1600×1200×3000 | 2400×1200×2500 |

| Electricity consumption, W/h | 42-63 | — | 208 |

| Weight, kg | 215 | 400 | 605 |

| price, rub. | 89900 | 115900 | 218700 |

* you can choose a modification with a built-in pump for forced pumping of treated wastewater. Higher capacity models come with an extended neck for deep station installation when away from home, as well as heavy duty versions for difficult ground conditions.

Watch a short commercial about Topas systems. It tells about their principle of operation and features of installation on a real site.

Conclusion: the main part of the products from Topol-Eco, which can be used in a private house or in a summer cottage, are volatile biological treatment plants. They are made according to the most advanced technology to date, which is why they are more expensive than conventional septic tanks with a filtration field. But you also need to consider that such equipment requires qualified maintenance, does not tolerate a long power outage and is designed for continuous use.

Installation rules and restrictions on the installation of local sewage

Autonomous sewage, which works odorless and does not require pumping, is the only type of cleaning system that is allowed for installation in areas with a limited area within the city. Restrictions and installation requirements:

- The indent from the foundation is 5 m, but with a lack of space, it is allowed to reduce the indent to 3 m.

- Before the fence or the border of the neighboring area should be at least 2 - 4 m.

- Installation in the city is allowed, as well as for servicing several residential buildings.

Organizations accredited by the station manufacturer are entitled to carry out the installation: the manufacturer's representative supervises the installation process. The second option is to order stations with installation directly from the manufacturer, and carry out preparatory earthworks on your own.

Installation of the structure in the pit

The pit for installation is dug with a margin of depth to form a solid foundation. The bottom is poured with mortar, slabs are installed or sand is backfilled on a crushed stone pillow. The base must be strictly horizontal and even.

Pipe trench

The place for the pit is chosen so that the sewer pipe from the house is laid with a minimum number of turns and height differences, preferably in a straight line. In this case, the pipe is installed at an angle so that the liquid flows freely into the receiving chamber. Pipe diameter - from 100 to 120 mm. Manufacturers recommend using plastic parts for the pipeline - PVC or polypropylene.

Manufacturers of cleaning stations in the instructions indicate the list and frequency of preventive maintenance. General rules:

Weekly inspect the drain and check 2 parameters: transparency and odor. The liquid at the outlet of the autonomous sewer must be absolutely colorless, free of impurities, and unpleasant odor.

If the receiving compartment is equipped with debris traps, then it is necessary to remove the baskets for cleaning every few months. Access is through a hatch.

The basket is removed through the manhole cover

When using chlorine for disinfection, it is necessary to systematically insert a new tablet into the module - approximately 1 time in 14 days.

The amount of waste that will have to be removed from the plant is negligible. The total volume varies from 60 to 90 liters per year. Cleaning of biological treatment chambers is carried out once after several years of operation. You can drain the compartments yourself using a home drainage pump.

Replacement of consumable parts and maintenance of electrical equipment is carried out exclusively by representatives of the manufacturer - usually 10 years after the start of the station.

When choosing a system, you should not focus only on cost. Contact a company that sells and installs - they will help you choose an autonomous sewage station with the best combination of price, power and quality.Also, specialists will take into account all the individual characteristics: they will predict the volume, analyze the relief and technical characteristics of the site.

Types of existing autonomous septic tanks

To date, there are three types of them, the main difference of which is in the principle of action

To date, there are three types of them, the main difference of which is in the principle of action:

- Drives. They are sealed vessels that accumulate wastewater. For them, you need to do periodic pumping.

- Settling tanks with oxygen-free fermentation. Here, the effluent is settled, and the sludge is fermented due to the work of anaerobic bacteria. This method can clear 60-70% of impurities. For the final process, the water is sent to soil filtration.

- Stations for deep cleaning with biological components. Here they join anaerobic bacteria - aerobic, which increases the efficiency of the process.

Comparison of these species is inappropriate, since their purpose has its own characteristics.

PS: installation of any kind can be helped by numerous wizards who will do the turnkey work.

Volatile and non-volatile septic tanks: advantages and differences

A non-volatile mechanism is designed to purify water to a certain state and irrevocably drain water into the ground

First of all, we highlight the criteria by which volatile septic tanks differ from non-volatile ones:

- Price. A septic tank without electricity is cheaper than a volatile one. This is due to the components: compressors, pumps, fittings. Valves and hoses.

- The main goal. A non-volatile mechanism is designed to purify water to a certain state and irrevocably drain water into the ground. The second ones clean the drains to a maximum of 98% so that it can be used for irrigation and other purposes.

- Dependence on electricity;

- degree of care. If you have chosen a volatile septic tank, then it is worth remembering that it will be necessary to create all the necessary conditions for the vital activity of bacteria: air, water, temperature.

Advice! We recommend that you install a turnkey non-volatile septic tank, as it can be used both in the country and at home, not to be afraid of power surges or electrical breakdowns, and also save money.

Non-volatile septic tanks without pumping out principle of operation

September 6, 2016

Today, non-volatile septic tanks are becoming increasingly popular among consumers. As a variant of such a device, you can consider the "Tank", which is characterized by high performance and adaptation to country conditions. The capacity of the Tank-1 model is 1.2 m 3. Like other designs from this manufacturer, Tank-1 can be classified as a non-volatile domestic wastewater treatment plant. The model has high performance and low cost. If you still have not decided whether to purchase such equipment, you need to familiarize yourself with the principles of its operation in more detail.

What does an autonomous septic tank consist of and how does it work?

Most often, septic tanks are a plastic container.

Most often they are a plastic container, which is divided into three chambers. There is a hole at the top of the tank through which drains enter. At the bottom there is an outlet pipe through which the purified liquid is drained.

The chambers are connected to each other by special holes located in the upper part of the walls. Each compartment has ventilation to remove gas.

The principle of the mechanism is quite simple. Through sewer pipes, effluents enter the first compartment, where they settle. The solid components fall into the sediment, and the liquid passes into the second compartment, where it is clarified and purified. After all, the treated water is poured into the third sector, where it undergoes a fermentation process, suspended particles turn into silt, and the liquid enters the soil through the filtration field.There are also systems where bacteria are used.

Do not forget about drainage and filtration fields

There are 2 ways of post-treatment: drainage and filtration systems. Their features:

- A drainage well is the last tank in a septic system. The chamber has no bottom, water seeps through the soil. Below is a filter pad made of sand or gravel. The method is used for deep groundwater. On soils with a high content of clay, several drainage wells are built.

- A filtration field is a pipe through which water passes for complete purification. The system occupies a large area compared to a drainage well. Installation requires financial costs and effort. It is used when aquifers are located close to each other.

To calculate the area of the field, the number of water consumers, the cross-section of pipes and the average annual air temperature are taken into account.

The field is pre-covered with a filtration cloth, on which sand or gravel is poured.

Construction of a cleaning structure made of monolithic concrete

Structures made of monolithic concrete are durable and have an increased strength index.

Advantages of a treatment plant made of a monolith:

- practicality;

- long service life;

- availability of materials used for construction;

- high degree of waterproofing.

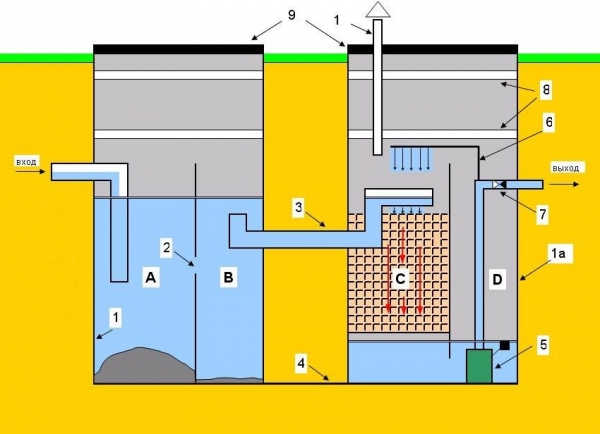

Diagram of a concrete septic tank: A - septic zone; B - zone of anaerobic digestion; C - biofilter; D - receiver-accumulator of treated effluents; 1, 1a - metal case; 2 - bypass holes; 3 - bypass between sections; 4 - base against ascent; 5 - pump; 6 - secondary cleaning pipe; 7 - check valve; 8 - foam; 9 - cover; 10 - pipe for removal of biogas

Disadvantages of a monolith:

- high construction costs;

- the need for a reinforcing base;

- the construction of the formwork structure is a mandatory procedure;

- low throughput.

Before concreting the bottom of the chambers, a reinforcing mesh is laid at the initial stage of construction. To prevent corrosion damage to the metal, a thick layer of concrete should be arranged in this area. The minimum thickness of the concrete layer above the grid is 3 cm.

The procedure for making a septic tank with your own hands: 1 - preparing the pit and supplying pipes; 2 - reinforcement; 3 - formwork device; 4 - concreting; 5 - formwork removal; 6 - installation of metal corners; 7 - laying flat slate, designing hatches, cementing, installing a ventilation pipe; 8 - arrangement of the revision shaft; 9 - waterproofing, insulation, falling asleep with earth

The construction of the formwork structure and reinforcement is in progress. After that, the walls of the chambers are concreted and the partitions between them are organized. At the final stage, the floors are poured with concrete. The drying period is about 2 weeks. It is recommended to cover the solution with a film in order to ensure uniform drying.

Do-it-yourself construction of a septic tank from eurocubes without pumping

Eurocubes are containers made of plastic. Under the installation of cameras from this material, a concrete base with a large thickness is made. A septic tank is fixed on this basis. This procedure is designed to ensure that the structure does not move under the influence of groundwater, which moves under the soil surface. Rising ground moisture can also move a poorly anchored structure.

The device of a septic tank from eurocubes: 1 - flasks of eurocubes; 2 - connecting overflow pipe; 3 - extension pipe; 4 - inlet tee; 5 - outlet tee; 6 - insulated wooden cover; 7 — hatch cover; 8 - ventilation pipe; 9 - wind vane; 10 - supply pipeline (100 mm); 11 - outlet pipeline (100 mm); 12 - concrete base; 13 - concrete pouring; 14 - thermal insulation layer; 15 - concrete well ring; 16 - reinforcing mesh

The plastic container is insulated with foam before installation. After which it is mounted in the pit. Then the filling with water and concreting of the tank on the sides is carried out. The country septic tank is insulated even from above. A pipe system providing ventilation must be brought to the surface.

This type of purification design requires the use of additional elements that will achieve a full level of wastewater treatment. For these purposes, it is recommended to use filter cassettes or filter fields.

The process of installing a septic tank from eurocubes

SNiP requirements for sewer collector equipment

The main document is used to check the correctness of the structure of the sewerage system without pumping - this is SNiP 2. 04.03-85. It contains a list of requirements in accordance with the law, to private areas for the construction of a septic tank.

Installation is carried out with pipelines made of the same material. Check the tightness of the seams in the pipes. With the help of tees, crosses, the line and the riser are connected.

There is a so-called hidden type in installation - open, connected to a home riser:

- mount the system at a distance of 5–15 meters from the structure and more than one meter from the fence;

- a septic tank is located at a distance of 50 meters from the water source;

- it is forbidden to locate the system with the presence of large vegetation, the roots will violate the integrity of the tanks.

Types of tanks for septic tanks:

- metal (the main drawback is an impressive weight and a tendency to corrosion);

- with the inclusion of concrete rings in the composition (the disadvantage is that it is difficult to build such a structure);

- fiberglass (considered optimal in durable use).

What material is better to choose

The main requirement for the material for a septic tank is its tightness and strength, because. the system must exclude environmental pollution. The main types of materials and their features:

- Concrete monolith. Formwork is built to fill the structure.

- Reinforced concrete rings. The design is resistant to corrosion, has high strength, however, installation requires the use of special equipment. Care must be taken during transport and installation due to the fragility of the material.

- Structures made of bricks and foam blocks are erected from the bottom of the pit. The surface of the bottom and walls is sealed with coating compounds or clay.

- Fiberglass. It is a durable material with a light weight. Due to the chemical neutrality of the material, the structures are durable and practical.

- Polymer materials are cheap. They are light in weight, but at low temperatures they are prone to cracking. Polymers are vulnerable to attack by rodents.

Septic tank made of concrete rings without pumping.

Steel tanks are a budget option. They have mechanical strength, but are prone to rust formation. To avoid this, apply waterproofing.

Advantages of septic tanks without pumping

Homemade septic tank without pumping.

Compared to alternative cleaning methods, septic tanks have a number of advantages. These include the following:

- Unlike a cesspool, septic systems comply with sanitary standards, their use is legal.

- The septic tank does not need to be connected to the sewer system, which saves money.

- Ready-made factory options are completely sealed, contamination of groundwater is excluded.

- There is no need to carry over after 10 or 20 years.

- Quicksand does not affect performance.

- There is no unpleasant smell.

- The treatment plant can be used for up to 6 months without inspection of the internal contents.

- An emergency warning system is provided.

Septic tanks without pumping are allowed for use in water protection areas.

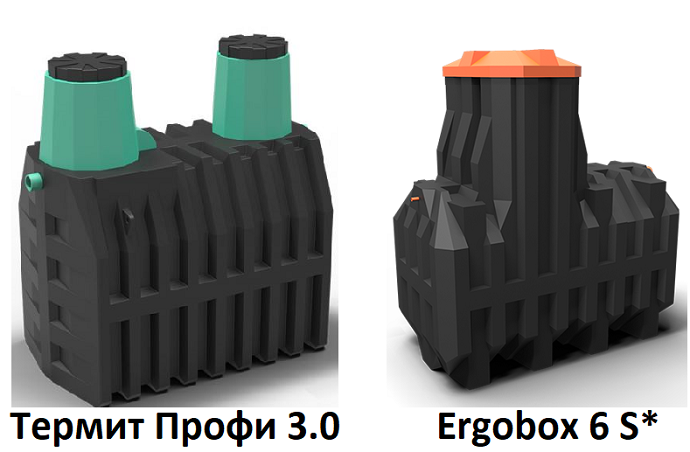

Multiplast septic tanks Termit

Production technologies and assortment

The equipment is represented by 2 main product lines:

- settling tanks. Produced under the brand name Thermite. Includes several modifications: Profi - 2- and 3-chamber septic tanks for summer cottages with low GWL; Transformer - the same as the Pro, but with one neck (more rigid construction); Transformer PR - modification with a pump for forced pumping of treated wastewater at high GWL. There are also accumulative models with a capacity of up to 5.5 cubic meters;

- biological treatment plants. Produced under the Ergobox brand. They are modifications of the Transformer (PR) models in which a compressor and aerators are installed.

All these products are made by rotational molding of Korean-made HDPE. It turns out a strong seamless construction with developed stiffeners. The wall thickness is 20 mm.

Watch a short commercial about the production and work of the Multplast company in general. You will learn how and from what materials cast containers are made and what capacities the company has.

| Model | Termite Profi 3.0 | Ergobox 6S* |

|---|---|---|

| Operating conditions | For a family of up to 6 people with a low GWL, when the soil is sand, sandy loam, loam. | For a family of up to 6 people with low GW, because it is a gravity version. The type of soil doesn't matter. |

| Short description | 3-chamber horizontal settling tank for primary treatment under anaerobic conditions. It is obligatory to arrange a filtration field for the post-treatment of wastewater. | 3-chamber LOS in horizontal execution with the Japanese compressor and the German pump. Discharge of treated effluents into a ditch, onto a relief, into the ground. |

| Material | HDPE 20 mm thick | |

| Size, L×W×H or D×L, mm | 2300×1155×1905 | 2000×1000×2100 |

| Electricity consumption, W/h | — | 63 |

| Weight, kg | 165 | 137 |

| price, rub. | 52100 | 73700 |

* S - gravity. There is a PR modification with a pump for forced pumping of treated wastewater. It costs 6 thousand rubles. more expensive than the gravity version.

Video demonstrating the process of installing a septic tank Termit. From a short video, you will also learn about the diameter of the supply pipe, whether it can have 90-degree turns, how and where to drain the treated wastewater, etc.

Conclusions: it is easy to notice the similarity of products from "Multplast" with products of the Tank type. All the same pronounced stiffeners and a simple design. Of particular interest may be versions with a compressor - a simple refinement gives the design special properties. However, it should be borne in mind that a small number of chambers can lead to a low quality of wastewater treatment and, as a result, the need for a field device or a filtration well for post-treatment.

The principle of operation of a septic tank without pumping

A septic tank is a structure of two or more tanks located in the ground and communicating with each other using a sewer pipe. Processing of sewage occurs in the following sequence:

- Wastewater enters the first tank and begins to decompose under the influence of anaerobic (not requiring oxygen to maintain life) bacteria. Heavy solid fractions settle to the bottom and are periodically pumped out. You can pump out the septic tank using a drainage pump.

- As a result, organic waste in the process of fermentation is converted into simple elements (alcohols, various types of acids, and others) and gases are released. The bacterial population recovers on its own, and in case of death of the colony, biologically active preparations are added.

- The second chamber is designed for deep processing of liquid freed from fatty film and light impurities. During processing, stable sludge is formed and carbon dioxide, methane and other gaseous substances are released.

- The clarified liquid enters the drainage well or filtration field, where the effluent is oxidized with the participation of aerobic bacteria and absorbed into the soil.

The price of septic tanks for a private house and design requirements

The domestic market offers an extensive range of treatment facilities, among which there are many budget septic tanks for giving without pumping.

The calculation of the cleaning structure is carried out taking into account the principles of cleaning of a multi-stage type. The purification process can be carried out by means of 3 or 2 chambers.

Rating and price table of popular designs:

| Name | Cleaning efficiency, % | Volley discharge, l | Cost, rub. |

| Topas 8 | 98 | 440 | 106900 |

| Eco Grand 5 | 98 | 250 | 73600 |

| Unilos Astra 3 | 98 | 150 | 66300 |

| Triton | 98 | 500 | 48000 |

| Rostock | 90 | 250 | 26800 |

| Tank 1 | 70 | 600 | 34900 |

| Termite | 70 | 400 | 73720 |

In some cases, the conditions make it possible to create a single-chamber treatment plant for 20-30 m², which will become more efficient than a three-chamber septic tank.

Diagram of a three-chamber septic tank with aeration

Purpose of cameras:

- the first one is intended for accumulation and subsequent separation of wastewater into fractions;

- the second - performs the function of purification (here the process of decay and purification from organic matter takes place);

- the third is used for final filtration and withdrawal of liquid into the ground.

With the exception of the effluent outlet tank, all chambers must be airtight.

Subtleties you need to know

When using septic tanks without pumping, it is necessary to prevent the contents of the tanks from getting to the surface. To do this, follow these recommendations:

- Tanks that do not have a filter system must have a sealed bottom.

- Liquid must not seep through the walls of the containers.

- The connecting elements between the chambers must be installed at an angle.

- The first tank should have the largest volume.

- Do not dig tanks far from each other. This can lead to clogging of the connecting pipes.

- Over time, the filtration elements become silted, which leads to the need to replace them. Sludge must be removed 1 or 2 times a year with a fecal machine.

TD Engineering equipment of septic tanks Tver

Production technologies and assortment

- for private houses. Biological treatment stations made of polypropylene of the Tver-P line are designed for 2-36 users, depending on the performance of the system;

- for residential complexes. Cleaning equipment in a metal or polymer case of high capacity for 30-1500 people.

- for shift camps. Container version Tver-S for 6-1000 people;

- in block-modular design. Modular designs Tver-BM with flexible adjustment of wastewater flow by varying the number of connected units;

- for landfills. Specialized Tver-MSW stations in container design for deep wastewater treatment of MSW landfills.

All models of treatment systems Tver are volatile installations for seasonal or permanent residence. Polypropylene 5 mm thick is used as the material for the walls of the containers. Rigidity of a design is provided with stiffening ribs and internal partitions.

| Model | Tver 1P* |

|---|---|

| Operating conditions | For permanent use by a family of 4-6 people. Can be installed under any ground conditions. |

| Short description | 6-chamber biological treatment plant with anaerobic and aerobic reactors. Horizontal design with two service hatches. Treated wastewater can be discharged into the ground or ditch. |

| Material | Polypropylene 5 mm thick |

| Size, L×W×H or D×L, mm | 2450×1100×1670 |

| Electricity consumption, W/h | 38 |

| Weight, kg | 150 |

| price, rub. | 103800 |

* There are 7 more modifications of this station, for example, the model with the PN index has a pump compartment with a submersible pump for forced supply of treated wastewater.

The video below provides detailed information on the installation of a septic tank Tver-0.75 PN. A company representative at a real facility explains the structure of the system and the role of each of its elements. The maintenance of the station is described in detail. If you're thinking about buying this model, be sure to check it out!

Conclusions: Trade House "Engineering Equipment" does not offer a wide range of systems for country houses. The guys just designed a model that works well and scaled it up. It turned out not the most compact water purification station at an average price. The main thing is that it works, right?

Do-it-yourself septic tank scheme from rings for a suburban area

Concrete rings are the most common material for building a septic tank.

Advantages of this method:

- high level of tightness;

- fast installation system;

- strength;

- durability.

The diameter of the rings is selected taking into account the required volume of the treatment plant. The maximum allowable number of rings for one chamber is 4.

Diagram of a septic tank made of concrete rings with your own hands

Disadvantages of the method:

- high construction costs;

- difficulties during installation (the issue of connecting the cameras to each other);

- volumes are strictly limited;

- the need for specialized equipment.

After the organization of pits. the bottom is being prepared for storage chambers. This area is being concreted. Other preparatory work is provided for the filter well. The specificity of this chamber requires the implementation of a crushed stone cushion at the bottom.

Installation of a three-chamber septic tank from reinforced concrete rings

Installation of concrete rings is carried out one on another. At this stage, it is necessary to take into account the supply of the pipe system to the wells

It is important to carefully calculate the diameter and angle of the slope.

The chambers are sealed from the inside and outside. To do this, it is recommended to use modern coating materials, cement mortar and waterproofing materials of the built-up type. After that, the pits fall asleep.

Dimensions of reinforced concrete rings for a septic tank

Conclusion

The process of sludge disposal is quite simple, it does not require the consumer to have special knowledge. What else are such non-volatile septic tanks good for? Judging by the reviews, the sludge processed during their operation can even be used as fertilizer.

Our ancestors slept differently than we do. What are we doing wrong? It's hard to believe, but scientists and many historians are inclined to believe that modern man sleeps in a completely different way from his ancient ancestors. Initially.

Unforgivable Movie Mistakes You Probably Never Noticed There are probably very few people who don't like watching movies. However, even in the best cinema there are errors that the viewer can notice.

These 10 little things a man always notices in a woman Do you think your man knows nothing about female psychology? This is not true. Not a single trifle will hide from the gaze of a partner who loves you. And here are 10 things.

How to look younger: the best haircuts for those over 30, 40, 50, 60 Girls in their 20s don't worry about the shape and length of their hair. It seems that youth was created for experiments on appearance and bold curls. However, already

10 Adorable Celebrity Kids Who Look Very Different Today Time flies and one day little celebrities become unrecognizable adults Pretty boys and girls turn into s.

What does the shape of your nose say about your personality? Many experts believe that by looking at the nose, you can tell a lot about a person's personality.

Therefore, at the first meeting, pay attention to the nose of an unfamiliar