How to drill cast iron with a drill Machine tools, welding, metalworking

Before you learn how to properly handle a cast iron pipe, and in particular, how to drill a cast iron pipe, you need to figure out what it is, where and what it is used for.

The main purpose of cast iron pipes is the discharge of waste water for the main collectors.

You may need the following tools:

Connection of cast iron pipes. SMU (both pipe ends are smooth); SME (one end of the pipe is smooth, the other has a detachable connection)

- electric drill or brace;

- drills with victorious nozzles;

- grinder and discs for metal;

- marker for marking.

There are two types of cast iron pipes:

- SMU (both pipe ends are smooth);

- and SME (one end of the pipe is smooth, the other has a detachable connection).

Before you start using pipes, you need to make sure that the location that is chosen for them does not contradict building codes. It is desirable that there are no turns and slopes.

Cast iron pipes must not be processed, only pipe cutting is allowed. Today, this metal is simply indispensable in some types of industry, which is why cutting and drilling cast iron is so important.

LLC DESIGN PRESTIGE

Methods for cutting cast iron pipes

In modern industrial conditions, there are many ways and various equipment that solve the issue of cutting cast iron.

In order to cut pipes, you can use a special tool for cutting cast iron, a hacksaw for metal, or a grinder with metal discs.

In the process of iron production, if it is necessary to cut castings, methods that use thermal cutting methods have been widely used:

- arc;

- plasma;

- electrocontact;

- air-arc and others.

It is forbidden to cut the pipe with a gas burner, as well as weld cast iron pipes.

When cutting with an arc method, electrodes of the following brands are used: ANR-2, LIM, OZR-1.

LLC DESIGN PRESTIGE

Insertion into a cast-iron pipe

During the operation of a summer house or a country house, it sometimes becomes necessary to make a selection from the water supply or an additional drain into the sewer for a washing machine.

This issue is solved using the "insert" method. How to make a tie-in in a cast-iron pipe?

In most cases, it is possible to use a ready-made tee, the diameter of which is slightly larger. It is necessary to cut off from it that part of the pipe where there is no branch pipe.

The pipe usually has to be cut lengthwise, a hole drilled and a branch pipe welded to the rest.

In addition to quick and high-quality repair of heating pipes, we provide professional installation of turnkey heating systems. On our heating page > resant.ru/otoplenie-doma.html

For communication, use the contact phone of LLC DESIGN PRESTIGE 8 (495) 744-67-74, which can be called around the clock.

note

Our company LLC DESIGN PRESTIGE is a part of the non-profit organization ANO INTERREGIONAL BOARD OF JUDICIAL EXPERTS. We also provide services for independent construction technical expertise.

news

What and how to drill cast iron?

In connection with the development of the metallurgical industry, a variety of metals and their alloys appear on the market. Metal is able to replace steel because it is a material with a high price. When processing, you need to know how to drill cast iron in industrial production, private workshops.

Drilling cast iron with a machine

Methods for cutting cast iron pipes

In modern industrial conditions, there are many ways and various equipment that solve the issue of cutting cast iron.

In order to cut pipes, you can use a special tool for cutting cast iron, a hacksaw for metal, or a grinder with metal discs.

In the process of iron production, if it is necessary to cut castings, methods that use thermal cutting methods have been widely used:

- arc;

- plasma;

- electrocontact;

- air-arc and others.

It is forbidden to cut the pipe with a gas burner, as well as weld cast iron pipes.

When cutting with an arc method, electrodes of the following brands are used: ANR-2, LIM, OZR-1.

LLC DESIGN PRESTIGE

How to drill a hole in cast iron

Often there are situations in everyday life when you have to work in extreme conditions. One of the most difficult jobs is to drill cast iron, because. it refers to abrasive materials. The reasons can be many: from refining the bath to personal technical ideas.

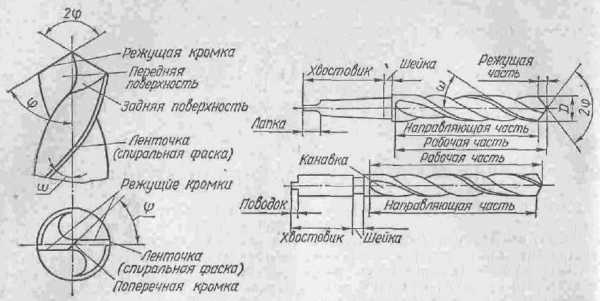

Elements of a twist drill for cast iron.

Detailed instructions for drilling cast iron

Necessary tools and materials for work:

- ruler;

- marker;

- wooden block;

- Bulgarian;

- kerosene solution.

Auger drills for drilling cast iron.

Before you drill a hole in cast iron, you need to clearly define goals and objectives in advance, because. you need to see the end result. When drilling holes in a bath without prior experience, mistakes are made. The three most common are slipped holes, chipped enamel, and even broken drills.

Before you start doing anything, you need to make sure that you really have cast iron in front of you. The easiest way is to try to lift the product. If it does not rise due to the huge mass, then no error has occurred. Otherwise, it is ordinary steel.

The most important aspect that must not be forgotten throughout the work is the lack of haste. Even if it is very necessary and the deadlines are tight, it is necessary to drill cast iron at cruising speed, because. the material is not only very hard, but also very brittle, because of which you can inadvertently say goodbye to the cast iron product.

Now you can start preparatory work. At the very beginning of the preparation, it is necessary to set all the necessary marks on the surface using a black or red thick marker. The points are set small so that when working, you do not accidentally remove the drill from the selected positions.

The drill must be made of carbide steel, and its sharpening must be impeccable. The drill should be for metal with an angle of 116-118 degrees, so as not to scratch the surface, but to dig in. If this moment is not taken into account, then with a very high probability the enamel will not be cut off in a careful circle, but will split, leaving cracks around it.

If you want to be safe, you can use a wooden block. A hole is made in it, 2 mm larger than the drill used, so that in the process of professional activity there are no difficulties. This bar should be, if possible, 2-2.5 cm thick so that the drill does not walk even if the hand trembles. When working, the bar will be applied to the surface in such a way that a pre-marked point can be seen in the center. It will need to be pressed with 1 hand while the whole workflow is organized with the other.

Often, beginners forget or purposefully ignore the cooling of the drill, which is why the work process is much slower, and the drill itself wears out faster. In order to avoid this, you must use a kerosene solution. Its consumption is small enough to be able to evaluate drills more expensive.

There is another way not to harm the enamel and at the same time to do everything with the highest quality - to use a grinder. Instead of the usual cutting disc, you need to string a grinding disc, with which the patch is safely cleaned of enamel, and only then the steps described above are carried out. This approach not only minimizes risks, but also significantly speeds up the process. Usually an additional 2 mm to the diameter is tacked, because. in this case, the result will be flawless.

The final stage of the workflow

Types of cast iron.

Tools and materials:

- Bulgarian;

- alcohol;

- sealant.

After you managed to drill a hole in the bath, you need to take up the grinder again, but this time the angle grinder is used for the correct purpose, for grinding the metal surface. If the hole is not sanded, then sharp ends will protrude in different directions, which will not only prevent the work process from being completed, but can also injure the skin.

The polished surface of cast iron immediately after the end of the working process is degreased with alcohol or any other similar solution, after which a sealant must be applied. Like all metals, cast iron has an increased reaction to exposure to a humid environment, which is why protection is vital for it.

It does not take much time or any serious modern equipment to drill cast iron with your own hands. instead of the most modern drill, you can use an old brace, and replace the grinder with emery.

Drilling a cast iron pipe

It is not always possible to drill a hole of the required diameter in a cast-iron sewer pipe. This is due to the diameter of the available drills. The size of the drill chuck rarely exceeds 10-12 mm. To make a hole with a diameter of more than 10 mm, it is perforated in a circle and cut out with a hacksaw blade.

This work requires care and patience. To facilitate drilling, it is necessary to remove the upper hardened layer of metal

The work is carried out with a low-speed drill. Holes are made in several steps, using drills from a smaller diameter to a larger one. The sharpening angle of the cutting edge should be within 110-115°. Periodically, the drill must be cooled, preferably in machine oil. When drilling a hole, you need to apply minimal force to the drill.

Pipes and fittings are made of gray cast iron. If white products are caught, then they cannot be processed at home, but their service life is disproportionately higher.

Drilling process

When drilling, you need to follow a number of simple rules.

- You need to drill at minimum speed - no more than 400 rpm. It makes sense to even think about drilling not with an electric drill, but with a mechanical or rotary one. Low speed is needed so as not to overheat the drill and not dull it.

- It is not necessary to exert strong pressure on the drill. With strong pressure, it again overheats. But it happens that cast iron is very hard, so you have to press hard. In this case, the turnover must be made even less.

- For cooling, you can add water to the drilling site, but it is better to use special coolants that contain lubricant. Some prefer to cool with kerosene.

- When drilling cast iron, chips are not formed, but crumbs. It is far from being completely removed along the grooves of the drill, so the drilling site should be periodically cleaned of it.

These are the rules for drilling cast iron. We hope these tips help you get the job done!

The development of industry leads to the emergence of new materials with properties that are in demand for modern products and assemblies. Despite this fact, cast iron, in all its diversity, remains an iron-carbon alloy, without which it is hard to imagine any branch of everyday life, a communication system or production equipment. Fittings, shut-off valves, pipes, bathtubs, radiators, fastening elements of the railway track and brake pads of cars, cast parts replacing steel ones. These are the components of a list that can be continued for a long time.

The processing of this material deserves special attention for large enterprises and home craftsmen. One of the main aspects of how to drill a hole in cast iron.

Where to start Some features of use

You may need the following tools:

Connection of cast iron pipes. SMU (both pipe ends are smooth); SME (one end of the pipe is smooth, the other has a detachable connection)

- electric drill or brace;

- drills with victorious nozzles;

- grinder and discs for metal;

- marker for marking.

There are two types of cast iron pipes:

- SMU (both pipe ends are smooth);

- and SME (one end of the pipe is smooth, the other has a detachable connection).

Before you start using pipes, you need to make sure that the location that is chosen for them does not contradict building codes. It is desirable that there are no turns and slopes. Cast iron pipes must not be processed, only pipe cutting is allowed. Today, this metal is simply indispensable in some types of industry, which is why cutting and drilling cast iron is so important.

LLC DESIGN PRESTIGE

Detailed instructions for drilling cast iron

Necessary tools and materials for work:

- ruler;

- marker;

- wooden block;

- Bulgarian;

- kerosene solution.

Before you drill a hole in cast iron, you need to clearly define goals and objectives in advance, because. you need to see the end result. When drilling holes in a bath without prior experience, mistakes are made. The three most common are slipped holes, chipped enamel, and even broken drills.

Before you start doing anything, you need to make sure that you really have cast iron in front of you. The easiest way is to try to lift the product. If it does not rise due to the huge mass, then no error has occurred. Otherwise, it is ordinary steel.

The most important aspect that must not be forgotten throughout the work is the lack of haste. Even if it is very necessary and the deadlines are tight, it is necessary to drill cast iron at cruising speed, because. the material is not only very hard, but also very brittle, because of which you can inadvertently say goodbye to the cast iron product.

Now you can start preparatory work. At the very beginning of the preparation, it is necessary to set all the necessary marks on the surface using a black or red thick marker. The points are set small so that when working, you do not accidentally remove the drill from the selected positions.

The drill must be made of carbide steel, and its sharpening must be impeccable. The drill should be for metal with an angle of 116-118 degrees, so as not to scratch the surface, but to dig in. If this moment is not taken into account, then with a very high probability the enamel will not be cut off in a careful circle, but will split, leaving cracks around it.

If you want to be safe, you can use a wooden block. A hole is made in it, 2 mm larger than the drill used, so that in the process of professional activity there are no difficulties. This bar should be, if possible, 2-2.5 cm thick so that the drill does not walk even if the hand trembles. When working, the bar will be applied to the surface in such a way that a pre-marked point can be seen in the center. It will need to be pressed with 1 hand while the whole workflow is organized with the other.

Often, beginners forget or purposefully ignore the cooling of the drill, which is why the work process is much slower, and the drill itself wears out faster. In order to avoid this, you must use a kerosene solution. Its consumption is small enough to be able to evaluate drills more expensive.

There is another way not to harm the enamel and at the same time to do everything with the highest quality - to use a grinder. Instead of the usual cutting disc, you need to string a grinding disc, with which the patch is safely cleaned of enamel, and only then the steps described above are carried out. This approach not only minimizes risks, but also significantly speeds up the process. Usually an additional 2 mm to the diameter is tacked, because. in this case, the result will be flawless.

Most people who use a cast-iron bath bowl one day come to the idea of introducing some innovations into water procedures.Often, improvements relate to the installation of a mixer directly on one of the sides of the product or the installation of hydromassage equipment.

Whatever the owners conceived, this process can lead to enamel chips and damage to the bathroom in the absence of sufficient experience and knowledge on how to drill a cast-iron bath.

The drilling procedure should be carried out without haste, because the base in which the hole will be located has a high level of fragility.

Inset with overlay

Such an operation is carried out without removing the riser segment. To do this, it is necessary to accurately determine the tie-in point, drill or

cut a hole and install an adapter with an outlet of the desired size. Installation of the lining can be carried out on pipes of different diameters. The size of the hole being made will depend on their size, which should not be more than half the diameter of the pipe.

The lining can be purchased at the store or made by yourself. To do this, take a shaped part with the removal of the necessary

size and cut it out, leaving part of the wall of the product. This is necessary to seal the installation site. To ensure sufficient density, the pipe is cleaned, burrs and casting defects are removed. The installation site of the lining is lubricated with sealant. The device is fixed with clamps. Excess paste is removed.

The industrial adapter is installed in the same way, only it is attached with bolts. The tightness of the site is ensured by rubber sealing rings. Insertion using welding on cast iron pipes is not carried out, since it is impossible to achieve the required tightness.

The subtleties of working with cast iron

Compliance with simple rules will allow you to achieve the desired result, leaving the drills, tools, hands intact:

- Control the load applied to the drill or machine without causing the drill to break. Cast iron products are mainly obtained by casting. The appearance of shrinkage shells and voids is possible. Falling into such a void, the drill breaks in 95% of cases. Threat of injury or a broken drill in an unfinished hole.

- Do not overheat the drill. Take a break from work. This will prevent the metal from softening and extend its service life.

- For drilling a cast-iron bath, use a pre-diamond drill bit for tiles and glass. This is a simple move to prevent cracking of the enamel.

- If the diameter exceeds 11mm, then the best solution would be to pass with a drill of a smaller diameter, and then the required size.

With the right approach and care, drilling cast iron is not an impossible task. The information presented in this article gives a complete picture of how to drill cast iron, about all the nuances and subtleties

Cast iron can be drilled with any metal drill!

You can use drills from ordinary cheap to expensive ones with various coatings and made of special high-strength materials.

The main thing is that the drill is sharpened for ferrous metal, and not for non-ferrous metal, since if it is not sharpened correctly, it will become dull very quickly. And even better, if there is such an opportunity, then sharpen the drill specifically for cast iron. The sharpening angle should be within 116-118 degrees

In addition to the angle, it is also necessary to take into account that the outer corner of the drill is cut for cast iron, because if it is not cut, then the drill will immediately become dull at the edges and begin to lick the inside of the hole, which not only makes drilling difficult, but also makes the surface of the hole uneven .

It is necessary to drill cast iron at very slow speeds with a small drill feed, because with an increase in the number of revolutions, the drill will immediately become blunt, and with an increase in pressure it can simply break.

It is also not unimportant that during the drilling of cast iron, the drill at the drilling site must be constantly cooled, as there is a large thermal release and if the temperature is not controlled, then the drill simply fails. It is best to cool not just with water, but with a special coolant in which lubricants are also located.

www.remotvet.ru

Drilling on an industrial scale

In industrial production, if it is necessary to solve the problem of how to drill cast iron, appropriate machines are used with working tools that have special working surfaces of appropriate sharpening. A supply of coolants is required to ensure the desired operating temperature.

In addition to the question of how to drill cast iron, it is imperative to ask yourself the question of safety during such work. It is necessary to take into account the possibility of the presence of cavities, voids and similar defects in the array of the processed material. This is more often due to the large amount of carbon in the cast iron and a number of other components.

Even these sudden defects lead to the fact that during the processing of metal a large amount of fine crumbs and dust is released. Processing methods depend on the type of cast iron, but there are general rules and safety requirements.

As a consequence, generally accepted protective measures must be taken during the execution of work. You need to protect your respiratory system. Why is it necessary, in addition to equipping the place of work with a ventilated hood, to use a respirator or cotton-gauze “petal” for personal protection.

You should also protect your eyes. Safety requirements include the presence of protective screens, the use of goggles with closed side edges. Work should be in special working clothes, gloves and headgear.

So that during the drilling of a cast-iron pipe there are no problems, you need to know the properties of the material and the rules for handling it.

Cast iron pipes are used in pipelines designed to drain waste liquids and create main collectors. Among the advantages of cast iron are resistance to fire and low noise level. However, this metal requires a more careful attitude than PVC pipes. We also note that cast iron pipes, as a rule, are coated with an anti-corrosion compound from the inside and outside.

To work with cast iron pipes, it is necessary to prepare the following tools:

- brace / electric drill;

- drills and nozzles from Pobedit;

- a marker with which marks will be applied to the pipes.

How to drill cast iron at home and on professional equipment

The development of industry leads to the emergence of new materials with properties that are in demand for modern products and assemblies.

Despite this fact, cast iron, in all its diversity, remains an iron-carbon alloy, without which it is hard to imagine any branch of everyday life, a communication system or production equipment.

Fittings, shut-off valves, pipes, bathtubs, radiators, fastening elements of the railway track and brake pads of cars, cast parts replacing steel ones. These are the components of a list that can be continued for a long time.

The processing of this material deserves special attention for large enterprises and home craftsmen. One of the main aspects of how to drill a hole in cast iron.

How to drill cast iron

Before starting work on drilling cast iron, pay attention to surface preparation. Deburring and cleaning the surface with sandpaper and degreasing it allow you to achieve a smooth hole in the right place without any unpleasant surprises

This preparation will allow you to remove the heat that is generated during the machining of metal products.

The structure of cast iron, regardless of the form of graphite in it, is prone to chilling when areas heated to critical temperatures are cooled sharply. At the same time, cast iron becomes brittle and prone to destruction at the slightest mechanical load.

Before you start work, you need to understand how to drill cast iron - what tool and what consumables are needed.

Drill selection

A conventional metal drill is able to cope with the task.The only condition in this situation will be the correct degree of sharpening of the cutting tool.

Without theoretical justification, drill manufacturers, together with representatives of machining enterprises, found out that the optimal sharpening angle range would be a run-up of 116-118 degrees.

The use of tipped drills made of special steels and alloys is also justified if it is necessary to make holes in large quantities and large diameters. Most often used will win. The design of the drill must correspond to the processing of metal.

At the enterprises, toolmakers got out of delicate situations by sharpening concrete drill bits with a diamond wheel. However, such manipulations require certain skills, and can be unsafe when drilling. The selection of a drill for cast iron is an important step.

See also: DIY metal sandblasting principles

Tool selection

In factories and enterprises where the processing of cast iron blanks is put on a wide stream, drilling machines are equipped with an emulsion supply to the contact point of the drill. Such a technological move allows avoiding phase transformations in the treated area.

A special requirement for drilling machines is an increased requirement for the ability to control and smoothly change the speed of rotation of the cutting tool and feed into the workpiece. As emulsions, specially designed substances are often used. Mostly these are sulfonated and chlorinated oils. For gray cast iron, kerosene can be used.

If there is no need to speed up the process, gray cast iron can be drilled without the use of a cooling lubricant.

Interesting information. After drilling a hole, treat its edges and cavity with sealant or epoxy glue. In this way, additional protection against corrosion can be obtained.

The subtleties of working with cast iron

Compliance with simple rules will allow you to achieve the desired result, leaving the drills, tools, hands intact:

- Control the load applied to the drill or machine without causing the drill to break. Cast iron products are mainly obtained by casting. The appearance of shrinkage shells and voids is possible. Falling into such a void, the drill breaks in 95% of cases. Threat of injury or a broken drill in an unfinished hole.

- Do not overheat the drill. Take a break from work. This will prevent the metal from softening and extend its service life.

- For drilling a cast-iron bath, use a pre-diamond drill bit for tiles and glass. This is a simple move to prevent cracking of the enamel.

- If the diameter exceeds 11mm, then the best solution would be to pass with a drill of a smaller diameter, and then the required size.

With the right approach and care, drilling cast iron is not an impossible task. The information presented in this article gives a complete picture of how to drill cast iron, about all the nuances and subtleties