Properties of PVC pipes

Polyvinyl chloride tubular products are used in many areas, since this type of plastic has a large set of positive properties and a small number of negative ones:

| Advantages | Flaws |

|

|

Advantages and disadvantages of gluing PVC pipes

Connecting pipes with glue or cold welding, unlike other joining methods, has the following features:

- Ease of installation. Connecting elements with glue is perhaps the easiest way to lay pipelines in comparison with other methods. For example, pipelines made of PP polypropylene are mounted by soldering, this requires a special soldering iron and good installer skills. Pipes made of metal-plastic, cross-linked and heat-resistant PE polyethylene, popular among the people, are usually connected using tension or press fittings, which requires special tools and expensive fittings. Theoretically, any user can do the installation of an adhesive PVC pipeline with their own hands; this does not require special skills, expensive tools and components.

- High speed of work. Glue for polyvinyl chloride is classified as a quick-drying compound; after washing and joining the parts, the setting time of the joint takes no more than 10 seconds.

- Ease of installation. For laying a pipeline on glue, the presence of electricity is not required; operations can be carried out at any positive air temperature. The method provides convenient installation in the most inaccessible places, which cannot be achieved using soldering irons or fittings.

- High connection strength. The principle of operation of the adhesive is based on the dissolution of polyvinyl chloride, while mutual diffusion of the material of the connected fragments occurs, linking them into a single whole. It is clear that such a connection is very strong in comparison with other docking methods and is in no way inferior to soldering.

Rice. 4 Threaded PVC fittings and fittings for gluing

- Versatility. With the help of adhesive PVC pipes, water and sewer networks are mounted, which cannot be said about other materials for their manufacture - polypropylene, metal-plastic and cross-linked (heat-resistant) polyethylene are used only for laying water pipes. PVC pipes are indispensable for the installation of pressure sewers - the methods of arranging it using products from other materials are more laborious, require special equipment (for example, soldering machines, electric couplings for soldering polyethylene) and take much more time.

- Restrictions when laying high-temperature pipelines. Most glued PVC pipelines have an upper temperature limit of no more than 60 ° C - this limits their use in hot water supply and heating lines. The chlorinated variety of CPVC polyvinyl chloride can be used for domestic hot water supply, however, the upper temperature limit of 95 ° C makes their operation in heating mains unsafe.

- Wide range of. Adhesive pipes presented in the distribution network usually have diameters from 16 to 500 mm; a wide range of smooth-walled fittings and fittings is provided for their joining.Also, many manufacturers supply the market with a wide range of PVC adhesive threaded fittings and shut-off valves in the form of ball valves.

- Aesthetics. Pipe joints with glue have an aesthetic appearance due to the use of a transparent composition that does not leave visible marks on their surface.

- Fragility. A distinctive feature of any PVC elements is low flexibility and elasticity. Pipes do not withstand sharp impacts and mechanical stress in the form of bends and excessive physical impact on the shell - this leads to cracks.

Rice. 5 Fittings and combination fittings CPVC Corzan with thread transition

High price. The main disadvantage of adhesive PVC pipes is the retail price, which is unbearable for a huge number of consumers, due to the fact that the goods are supplied to the market by European manufacturers from Italy and Holland. For one running meter of a product with a diameter of 110 mm for a pressure sewer, where the use of adhesive PVC is most rational, you will have to pay a minimum amount of 300 rubles. A piece of 25 mm pipe 1 m long will cost the consumer 80 rubles, which is also a rather high price. If we additionally consider the cost of glue, a liter jar of which costs from 1000 to 2000 rubles, then the costs will become quite significant. It should be noted that some companies, for example, the Russian Agrigazpolimer, offer PVC pipes and fittings for glue of their own production at prices three times cheaper than the above European counterparts. This is quite attractive for large, small companies, private customers. Also, if you do the installation of a PVC adhesive pipeline with your own hands without calling hired specialists, you can get significant financial savings.

Rice. 6 PVC physical characteristics

About connection technology

The installation of PVC pipes by gluing is more accurate and visually less noticeable than the traditional method using o-rings. This method is also more preferable from the point of view of reliability - as a result, we get a high-quality and durable monolithic joint of two pipes without intermediate rings, which tend to age and wear out. Adhesive joints are practically unlimited in use, except for work in conditions of high temperatures and excessive loads.

It should be said that by means of adhesive bonding, it is possible to assemble a significant part of the pipeline before connecting to the system, in a place convenient for work. But for successful installation, you will need to strictly follow the instructions.

How to glue PVC pipes - video

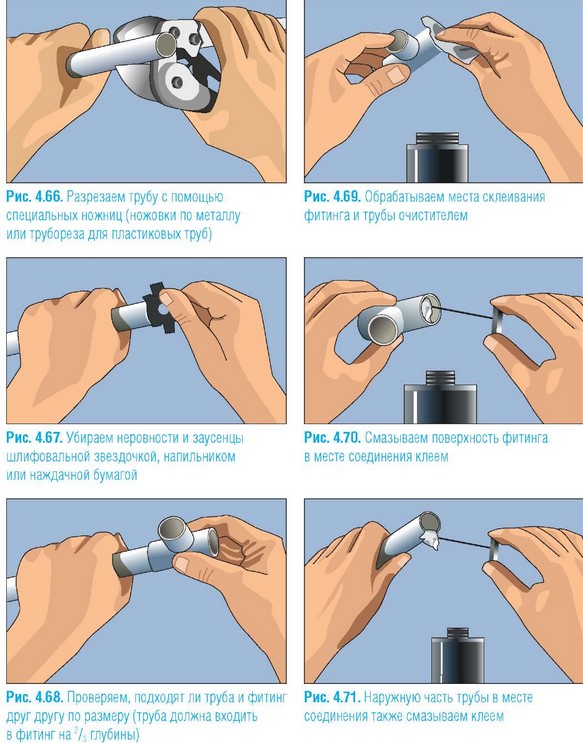

No professional tools are needed for gluing pipes. Before proceeding with gluing, you need to check whether the pipe and fitting fit each other in size. To do this, the pipe is inserted into the fitting, into which it must enter by%. In this case, the pipes are cut with special scissors or a roller cutter; for a large diameter pipe, a hacksaw can be used. In the process, a right cutting angle is maintained relative to the pipe axis. Then the ends of the newly cut pipes are turned with a file. Before gluing, the pipe is wiped with a dry rag, degreased, blown, the segments to be joined are lubricated with a primer, then a thin layer of glue is applied to the pipe and into the fitting socket, after which the pipe is inserted into the fitting socket to the end. The pipe is turned in the fitting socket by 1/4 turn to glue is evenly distributed. After a maximum of 1 min, the glue should hold the parts to be joined (Fig. 4.66-4.71).

The glue that has come out at the edges is removed. The adhesive recommended by the manufacturer should be selected, otherwise the tightness and strength of the connection are not guaranteed. Gluing plastic pipes should be carried out in a ventilated area, glue and cleaner should be tightly closed with lids so that liquids do not evaporate. An open jar of glue should be used within a week.Glue that has thickened and turned into a jelly-like mass is not good.

Glue for plastic from various manufacturers

Similar content

Do-it-yourself external sewerage in a private house. Video, instructions

How to install a bidet with your own hands. Video, photo

How to install a faucet in the kitchen, in the bathroom. Video, photo, instructions

How to repair a damaged sink (chip, scratch). Video

Laying sewer pipes inside the house (apartment), how to do it right. In and

Installing a heated towel rail with your own hands. Video, photos, tips

Pipe cutting and threading. Tools and recommendations

How to make a bathroom under the stairs in the house. Photo. Description

How to install a urinal yourself. Video, photo, device

How to install a floor-standing toilet with your own hands. Video, photo

How to install a water heater (boiler) with your own hands. Video

How to install and connect a dishwasher (dishwasher) yourself

Do-it-yourself installation of metal-plastic pipes. Video

How to install a washbasin (sink) with your own hands. Video, photo, manual

Do-it-yourself jacuzzi (hot tub) installation

Do-it-yourself installation of a radiator heating system. Video, diagrams, photos

How to repair a mixer and a faucet with your own hands. Video

Purification (filtration) of water at home. Video

How to restore a bath with your own hands

How to install a wall hung toilet. Video, photo, system

Load More...

Areas of use

The scope of adhesive PVC pipelines depends on their physical and chemical characteristics, products are used for communications in the following areas:

- Construction of swimming pools. PVC adhesive pipes are widely used in the construction of water supply and purification systems in swimming pools. Due to the tightness of the joints and the high anti-corrosion characteristics that polyvinyl chloride has, such pipes are the most suitable when working with chlorinated water.

- Air conditioning, cooling systems. PVC adhesive pipes are suitable for transporting liquid low-temperature and corrosive substances such as refrigerant, chlorine and so on in the construction of industrial air conditioning units, chillers, coolers.

- Laying of pressure sewerage. An ordinary consumer is well aware of the sewage system, which is laid in apartments and country houses. It is assembled in a bell-shaped way, inserting pipes into each other, while sealing is provided by internal rubber rings mounted in expanded pipes. This type of installation does not withstand the high pressure of the liquid working medium, which cannot be said about the sewer line assembled by gluing. Most often, glued PVC sewer pipes are laid in swimming pools and water parks to move significant water volumes at high speed.

- Water purification and preparation systems. Due to the resistance of polyvinyl chloride to solutions with a high percentage of various types and concentrated sulfuric acids, sodium hypochlorite, demineralized and deionized waters, PVC pipes are widely used in water treatment plants.

- Chemical industry. Glued PVC pipelines are mounted at chemical industry plants for the transportation of aggressive liquids - mineral acids, alkalis, salt solutions, oils, fats, gasoline without the presence of benzene.

Rice. 2 Application examples of glued PVC pipes

- Agriculture. From glued PVC pipes, greenhouse piping is mounted - drip irrigation systems, pipeline units for supplying solutions with fertilizers. In animal husbandry, engineering structures are assembled from polyvinyl chloride for the delivery of feed and drinking water, and manure removal.

- Systems of cold and hot water supply.Almost all PVC adhesive pipes and fittings are designed for use in temperatures up to +60 ° C, so they are used to supply cold water. In pipelines with a high-temperature working environment, pipelines made of chlorinated polyvinyl chloride CPVC are used, which have a higher heat resistance index up to +95 ° С.

- in air supply systems. Since the glued joint provides a high degree of tightness of the pipeline, PVC pipes are often used for the installation of natural or forced ventilation.

Rice. 3 Shaped PVC parts for gluing

How to glue polypropylene pipes

Gluing polypropylene pipes has its own specifics. To work, you will need a pipe cutter, a glue gun and a brush with natural bristles. Let's dwell on this issue in more detail.

Work process:

- cutting pipes with a pipe cutter in accordance with the required dimensions;

- cleaning edges and cuts from roughness (you can use sandpaper);

- markup. To do this, it is necessary to combine the design and mark the gluing points;

- degreasing the surfaces on which the adhesive will be applied;

- applying glue. If canned glue is used, then it must be applied with a brush. If glue was purchased in a tube, then you will need a special gun;

- connect the elements of the pipeline, focusing on the marks made earlier;

- removing excess glue.

You can check the reliability and tightness of the connections no earlier than a day later by passing a stream of pressurized water through the structure.

To repair the pipeline, you can use special couplings that sit on the damaged place with polypropylene pipe glue. In order not to have to turn off the water supply during operation, it is better to use a collapsible coupling.

Bonding technique

Use a natural bristle brush to apply the adhesive. You need to cut the pipe with special pipe cutters. They allow you to get a smooth cut. If they are absent, you can use a saw, the blade of which has fine teeth. After you will need to clean the edges with sandpaper, this will allow the connection to be airtight. When all the pipeline elements are ready, assemble the structure without glue to make sure that all components are the right size. Next, the design should be disassembled and further preparation should be carried out:

- degreasing surfaces, it is best to use a cleaner from the same manufacturer as the adhesive;

- stir the adhesive vigorously before application;

- apply glue evenly in a thin layer using a brush with natural bristles;

- connect all the details in one system;

- hold the pipes in one position for more than 20 seconds to allow the glue to dry;

- excess glue must be removed with a paper towel;

- set aside the finished products for 10-15 minutes and do not touch them so that the glue dries completely.

After the pipes are glued, a water test can be carried out no earlier than a day later.

How to prepare and glue plastic pipeline elements

Since pipe adhesive contains toxic volatile components, all work should be done in a well-ventilated area. The temperature should be within +5…+35°С. It is recommended to protect your hands with rubber gloves so as not to cause an allergic reaction or irritation.

Watch this video on YouTube

The sequence of actions is as follows:

- Pipe sections of the required length are cut using special scissors (pipe cutter) or a fine-toothed saw. The edges of the cut are cleaned with a file and sandpaper to remove chips and burrs.

- Then the glued area of the surface must be well cleaned of contaminants and dried thoroughly.

- Preliminary assembly of the pipeline structure and final adjustment of all elements are carried out.

- Before sealing damage or gluing all parts together, the gluing points must be degreased with a special solution or an alcohol-containing liquid.

- The adhesive composition is thoroughly mixed. When applying the repair method with two-component glue, measure the required amount of material and knead it with your hands to the finished state (plasticine consistency).

- Using a brush or applicator, the adhesive is evenly distributed over the prepared surface. The parts are joined and fixed in a stationary state for several minutes (the exact time is indicated in the instructions). Sometimes a reapplication is required. A thick mastic is applied to the repaired area and strongly pressed with a tourniquet.

- Excess glue protruding along the edges of the joint is removed with a paper towel or rag.

- The connected parts are left alone until the adhesive is completely dry.

The overall tightness of the joints and the reliability of the entire structure are checked no earlier than after 24 hours. When sealing a leak, the repair mass hardens in an hour.

Instructions for glued pipe joints

Before adhesive bonding, make sure that the fixtures used and the parts to be joined are suitable and in good condition. Check the homogeneity, fluidity and shelf life of the adhesive.

- Cut the pipe perpendicular to the axis. To obtain a high-quality cross section, it is recommended to use special pipe cutters with rollers for cutting thermoplastic pipes.

- Bevel at a 15° angle. This operation must be carried out without fail, since as a result of improper processing of the ends, adhesive scraping from the surface of the fitting may occur, as well as a violation of the connection.. When performing this operation, use the appropriate chamfer cutters.

- Measure the depth of the fitting and make an appropriate mark on the end of the pipe.

External diameter

de(mm)Glue depth

L (mm)Chamfer width

Sm(mm)16 14 1,5 20 16 1,5 25 18,5 3 32 22 3 40 26 3 50 31 3 63 37,5 5 75 43,5 5 90 51 5 110 61 5 160 86 5 225 118,5 5&pide;6 Table 1: Insertion depth, adhesive bonding and chamfer width

- Using a clean paper towel or piece of cloth soaked cleanser Primer, remove any remaining dirt and/or grease from the outer surface of the pipe along the entire length of the adhesive joint, as well as from the inner surface of the fitting.Dry the surfaces for a few minutes and then apply the adhesive. It should be remembered that cleaners, in addition to rinsing and cleaning, also soften and prepare the surfaces to be joined for the application of adhesive, which allows you to obtain an optimal connection.

- Apply the adhesive in an even layer to the longitudinal surfaces of both components to be joined (external surface of the pipe and internal surface of the fitting) using an appropriately sized applicator or coarse brush (Table 2).

Outer pipe diameterde(mm) Type and size of brush or applicator 16-25 Round shape (8-10 mm) 32-63 Round shape (20-25 mm) 75-160 Rectangular/round shape (45-50 mm) > 160 Rectangular/cylindrical (45-50mm) Table 2: Characteristics and sizes of brushes and applicators

It is recommended to use an applicator/brush that is at least half the diameter of the pipe.

The adhesive must be applied to the entire length of the pipe and fitting surfaces to be bonded:

- to the full depth of the fitting;

- for the entire length of pipe gluing, previously marked on the outer surface.

- Quickly insert the pipe into the fitting to the full depth of the connection without rotating it. Only then can both ends be turned slightly (no more than ¼ turn of pipe and fitting). Turning the components distributes the applied adhesive even more evenly.

- The insertion of the pipe into the fitting must be carried out quickly (it is recommended to perform all necessary actions within 20-25 seconds).

Given the outside diameter of the pipes and various manufacturing difficulties, inserting the pipe into the fitting must be done:

- manually by one person, if the outer diameter is not more than 90 mm;

- manually by two people, if the outer diameter is between 90 and 160 mm;

— using a suitable pipe connector if the outer diameter is more than 160 mm.

- Immediately after inserting the pipe into the fitting (to the very end), press both components for a few seconds, and then immediately remove any adhesive residue from the outer surface using a piece of crepe paper or a clean cloth, and from the inner surfaces, if possible.

- Drying the glue

Leave the connected components for a while to allow the glue to dry naturally; at the same time, ensure that these elements are not affected too much. Drying time depends on the pressure to which the joint is subjected. In particular, depending on the ambient temperature, the minimum times are:

- before affecting the connection:

— from 5 to 10 minutes at an ambient temperature of 10°C and above

- from 15 to 20 minutes at an ambient temperature of less than 10 ° C

- for repair joints that are not hydraulically tested, for all sizes and pressures:

- 1 hour at any pressure

in relation to connections that are subjected to a hydraulic test for pipes and fittings of any diameter up to PN 16:

- at least 24 hours.

The indicated time required for proper drying of the adhesive is based on an ambient temperature of around 25°C and certain climatic conditions (humidity, temperature, etc.).

For more information, we recommend contacting our technical service department and/or the respective adhesive companies.

A little about PVC pipes

The abbreviation PVC can be deciphered as "polyvinyl chloride". This polymer has a rather low temperature resistance, since it melts easily and is not able to withstand severe frosts. The material is an environmentally friendly polymer. Despite the low temperature resistance, PVC copes very well with mechanical stress.

It is worth noting that this material has a high ring stiffness, which means that it is not afraid of water hammer, because it can withstand up to 120 atmospheres of pressure. At the same time, PVC deforms when exposed to temperature by a maximum of 5% of its original dimensions. To be more precise, this polymer deforms at 78 degrees Celsius above zero. It is for this reason that it should only be used in connections where the water does not heat up above 40 degrees. But at sub-zero temperatures, the material loses its durability faster, already at -15. Therefore, it can be used only in fairly warm regions, and in order to increase strength in winter, it is recommended to insulate the pipeline if it is made of polyvinyl chloride.

About the installation of pipes from the video:

During the operation and gluing of a PVC pipe, one should be aware of its characteristics. Due to the high smoothness of the inner surface, silting or clogging does not occur, so that the pipeline does not need to be cleaned for a long time. This type of pipe is well suited for creating a pipeline in the sewer system, due to the fact that it has a small wall thickness. Polyvinyl chloride pipes are durable if used correctly, this is due to the fact that the material is highly resistant to ultraviolet radiation.