Leading classification

This will depend on the type and quality of material used in the manufacture of radiators. The main varieties include:

- from cast iron;

- from bimetal;

- aluminum;

- of steel.

Each of the materials has some disadvantages and a number of features, so to make a decision, you will need to consider the main indicators in more detail.

Made from steel

They function perfectly in combination with an autonomous heating device, which is designed to heat a significant area. The choice of steel heating radiators is not considered an excellent option, since they are not able to withstand significant pressure. Extremely resistant to corrosion, light and heat transfer performance is quite satisfactory. Having an insignificant flow area, they are rarely clogged. But the working pressure is considered to be 7.5-8 kg / cm 2, while the resistance to possible water hammer is only 13 kg / cm 2. The heat transfer of the section is 150 watts.

Steel

Made from bimetal

They are devoid of the shortcomings that are found in aluminum and cast iron products. The presence of a steel core is a characteristic feature, which made it possible to achieve a colossal pressure resistance of 16 - 100 kg / cm 2. The heat transfer of bimetallic radiators is 130 - 200 W, which is close to aluminum in terms of performance. They have a small cross section, so over time, problems with pollution are not observed. Significant disadvantages can be safely attributed to the prohibitively high cost of products.

Bimetallic

Made from aluminum

Such devices have many advantages. They have excellent external characteristics, besides they do not require special care. Strong enough, which allows you not to be afraid of water hammer, as is the case with cast iron products. Working pressure is considered to be 12 - 16 kg / cm 2, depending on the model used. The features also include the flow area, which is equal to or less than the diameter of the risers. This allows the coolant to circulate inside the device at great speed, which makes it impossible for precipitation to form on the surface of the material. Most mistakenly believe that too small a cross section will inevitably lead to a low heat transfer rate.

Aluminum

This opinion is erroneous, if only because the level of heat transfer of aluminum is much higher than, for example, that of cast iron. The cross section is compensated by the area of the fins. The heat output of aluminum radiators depends on various factors, including the model used, and can be 137 - 210 watts. Contrary to the above characteristics, it is not recommended to use this type of equipment in apartments, since the products are not able to withstand sudden temperature changes and pressure surges inside the system (during the run of all devices). The material of an aluminum radiator breaks down very quickly and cannot be subsequently restored, as in the case of using another material.

Made from cast iron

The need for regular and very thorough care. A high rate of inertia is almost the main advantage of cast iron radiators. The level of heat transfer is also good. Such products do not heat up quickly, while they also give off heat for quite a long time. The heat output of one section of a cast-iron radiator is equal to 80 - 160 watts. But there are a lot of shortcomings here, and the main ones are considered to be the following:

- Perceptible weight of the structure.

- Almost complete lack of ability to resist water hammer (9 kg / cm 2).

- A noticeable difference between the cross section of the battery and risers. This leads to slow circulation of the coolant and rather rapid pollution.

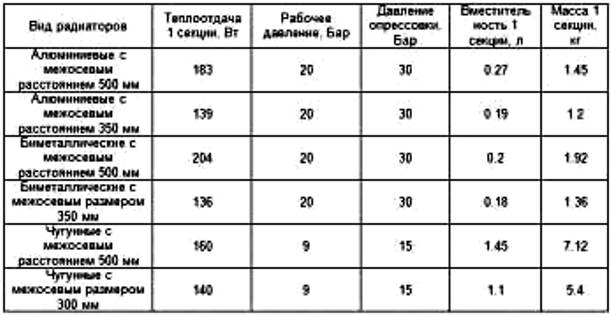

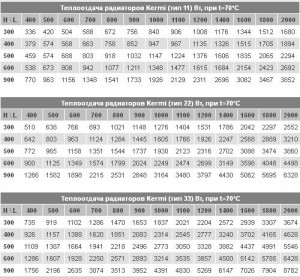

Heat dissipation of heating radiators in the table

Formulas for calculating the power of a heater for various rooms

The formula for calculating the power of the heater depends on the height of the ceiling. For rooms with ceiling height

- S is the area of the room;

- ∆T is the heat output of the heater section.

For rooms with a ceiling height > 3 m, calculations are carried out according to the formula

- S is the total area of the room;

- ∆T is the heat transfer from one section of the battery;

- h is the height of the ceiling.

These simple formulas will help to accurately calculate the required number of sections of the heater. Before entering data into the formula, determine the actual heat transfer of the section using the formulas given earlier! This calculation is suitable for an average temperature of the incoming coolant of 70˚ C. For other indicators, it is necessary to take into account the correction factor.

Let us give examples of calculations. Imagine that a room or non-residential premises has dimensions of 3 x 4 m, the ceiling height is 2.7 m (the standard ceiling height in Soviet-built city apartments). Determine the volume of the room:

3 x 4 x 2.7 = 32.4 cubic meters.

Now we calculate the thermal power required for heating: we multiply the volume of the room by the indicator required to heat one cubic meter of air:

Knowing the real power of a separate section of the radiator, select the required number of sections, rounding it up. So, 5.3 rounds up to 6, and 7.8 rounds up to 8 sections. When calculating the heating of adjacent rooms that are not separated by a door (for example, a kitchen separated from the living room by an arch without a door), the areas of the rooms are summed up. For a room with a double-glazed window or insulated walls, you can round it down (insulation and double-glazed windows reduce heat loss by 15-20%), and in a corner room and rooms on high floors, add one or two "in reserve" sections.

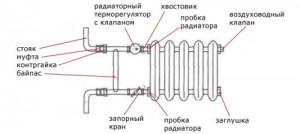

Why is the battery not heating up?

But sometimes the power of the sections is also recalculated based on the actual temperature of the coolant, and their number is calculated taking into account the characteristics of the room and installed with the necessary margin ... but it's cold in the house! Why is this happening? What are the reasons for this? Can this situation be corrected?

The reason for the decrease in temperature may be a decrease in water pressure from the boiler room or repairs at the neighbors! If, during the repair, a neighbor narrowed down a riser with hot water, installed a “warm floor” system, began to heat a loggia or a glazed balcony on which he arranged a winter garden, the pressure of hot water entering your radiators will, of course, decrease.

But it is quite possible that the room is cold because you installed the cast iron radiator incorrectly. Usually, a cast-iron battery is installed under the window, so that the warm air rising from its surface creates a kind of thermal curtain in front of the window opening. However, with its backside, a massive battery does not heat the air, but the wall! To reduce heat loss, glue a special reflective screen on the wall behind the heating radiators. And you can also buy retro-style decorative cast-iron batteries, which do not have to be mounted on the wall: they can be fixed at a considerable distance from the walls.

General provisions and algorithm for thermal calculation of heating devices

The calculation of heating devices is carried out after the hydraulic calculation of pipelines of the heating system according to the following method. The required heat transfer of the heating device is determined by the formula:

, (3.1)

where - room heat loss, W; when installing several heating devices in a room, the heat loss of the room is distributed equally among the devices;

- useful heat transfer of heating pipelines, W; is determined by the formula:

, (3.2)

where - specific heat transfer of 1 m of openly laid vertical / horizontal / pipelines, W / m; taken according to the table. 3 Annex 9 depending on the temperature difference between the pipeline and the air;

- the total length of vertical / horizontal / pipelines in the room, m.

Actual heat dissipation of the heating device:

, (3.4)

where is the nominal heat flux of the heating device (one section), W. Accepted according to the table. 1 annex 9;

- temperature difference equal to the difference between the half-sum of the temperatures of the coolant at the inlet and outlet of the heating device and the room air temperature:

, °С; (3.5)

where is the flow rate of the coolant through the heating device, kg/s;

are empirical coefficients. The values of the parameters, depending on the type of heating devices, the flow rate of the coolant and the scheme of its movement, are given in Table. 2 applications 9;

- correction factor method of installing the device; taken according to the table. 5 applications 9.

The average water temperature in the heater of a single-pipe heating system is generally determined by the expression:

, (3.6)

where is the water temperature in the hot main, °C;

- cooling of water in the supply line, ° C;

- correction factors taken according to table. 4 and table. 7 appendix 9;

- the sum of heat losses of the premises located before the premises in question, counting in the direction of water movement in the riser, W;

- water flow in the riser, kg / s /determined at the stage of hydraulic calculation of the heating system /;

— heat capacity of water, equal to 4187 J/(kggrad);

- coefficient of water inflow into the heating device. Accepted according to the table. 8 applications 9.

The coolant flow through the heating device is determined by the formula:

, (3.7)

The cooling of water in the supply line is based on an approximate relationship:

, (3.8)

where is the length of the main line from the individual heating point to the calculated riser, m.

The actual heat output of the heating device must not be less than the required heat output, i.e. The reverse ratio is allowed if the discrepancy does not exceed 5%.

Characteristics and features

The secret of their popularity is simple: in our country, such a coolant in centralized heating networks that even dissolves or erases metals. In addition to a huge amount of dissolved chemical elements, it contains sand, rust particles that have fallen off pipes and radiators, “tears” from welding, bolts forgotten during repairs, and a lot of other things that got inside. The only alloy that does not care about all this is cast iron. Stainless steel also copes well with this, but one can only guess how much such a battery will cost.

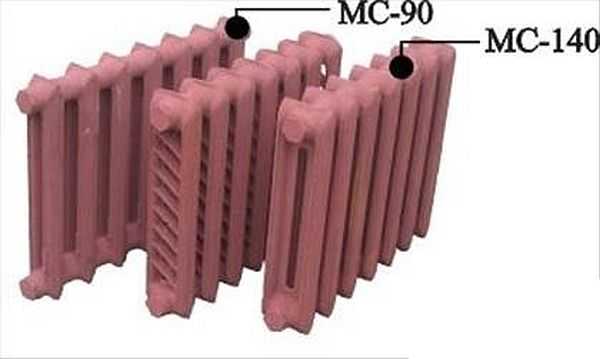

MS-140 - an undying classic

And another secret of the popularity of the MS-140 is its low price. For different manufacturers, it has significant differences, but the approximate cost of one section is about $ 5 (retail).

Advantages and disadvantages of cast iron radiators

It is clear that a product that has been on the market for many decades has some unique properties. The advantages of cast iron batteries include:

- Low chemical activity, which ensures a long service life in our networks. Officially, the warranty period is from 10 to 30 years, and the service life is 50 years or more.

- Small hydraulic resistance. Only radiators of this type can be installed in systems with natural circulation (in some, aluminum and steel tubular ones are also installed).

- High temperature of the working environment. No other radiator will be able to withstand temperatures above +130 o C. Most of them have the highest limit - +110 o C.

- Low price.

- High heat dissipation. For all other cast iron radiators, this characteristic is in the "disadvantages" section. Only in MS-140 and MS-90 the thermal power of one section is comparable with aluminum and bimetallic ones. For MS-140, heat dissipation is 160-185 W (depending on the manufacturer), for MS 90 - 130 W.

- They do not corrode when the coolant is drained.

MS-140 and MS-90 - difference in section depth

Some properties under some circumstances are a plus, under others - a minus:

- Large thermal inertia. While the MS-140 section warms up, an hour or more can pass. And all this time the room is not heated.But on the other hand, it is good if the heating is turned off, or an ordinary solid fuel boiler is used in the system: the heat accumulated by the walls and water maintains the temperature in the room for a long time.

- Large cross-section of channels and collectors. On the one hand, even a bad and dirty coolant will not be able to clog them even in a few years. Therefore, cleaning and washing can be carried out periodically. But due to the large cross section, more than a liter of coolant “fits” in one section. And it needs to be “driven” through the system and heated, and this is an extra cost for equipment (a more powerful pump and boiler) and fuel.

"Pure" disadvantages are also present:

Big weight. The mass of one section with a center distance of 500 mm is from 6 kg to 7.12 kg. And since you usually need from 6 to 14 pieces per room, you can calculate what the mass will be. And it will have to be worn, and also hung on the wall. This is another drawback: difficult installation. And all because of the same weight.

Brittleness and low working pressure. Not the best features

For all their massiveness, cast iron products must be handled with care: upon impact, they can burst. The same brittleness leads to not the highest working pressure: 9 atm

Crimping - 15-16 atm.

The need for regular staining. All sections are only primed. They will need to be painted often: once a year or two.

Thermal inertia is not always a bad thing...

Application area

As you can see, there are more than serious advantages, but there are also disadvantages. If we summarize everything, we can determine the area of \u200b\u200bits use:

- Networks with a very low quality of the coolant (Ph above 9) and a large number of abrasive particles (without mud collectors and filters).

- In individual heating when using solid fuel boilers without automation.

- In networks with natural circulation.

What determines the power of cast iron radiators

Cast iron sectional radiators are a method of heating buildings that has been proven for decades. They are very reliable and durable, however, there are a few things to keep in mind. So, they have a somewhat small heat transfer surface; about a third of the heat is transferred by convection. We recommend that you first look at the advantages and features of cast iron radiators in this video

The section area of the MS-140 cast-iron radiator is (in terms of heating area) only 0.23 m2, weight 7.5 kg and holds 4 liters of water. This is quite small, so each room should have at least 8-10 sections. The area of a cast-iron radiator section should always be taken into account when choosing, so as not to hurt yourself. By the way, in cast-iron batteries, the heat supply is also somewhat slowed down. The power of a cast-iron radiator section is usually about 100-200 watts.

The operating pressure of a cast iron radiator is the maximum water pressure it can withstand. Usually this value fluctuates around 16 atm. And heat transfer shows how much heat one section of the radiator gives off.

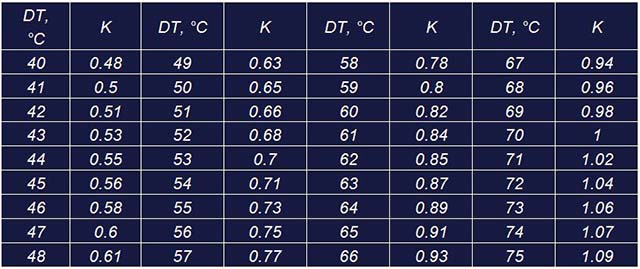

Often, radiator manufacturers overestimate heat transfer. For example, you can see that cast iron radiators heat transfer at delta t 70 ° C is 160/200 W, but the meaning of this is not entirely clear. The designation "delta t" is actually the difference between the average air temperatures in the room and in the heating system, that is, at delta t 70 ° C, the operating schedule of the heating system should be: supply 100 ° C, return 80 ° C. It is already clear that these figures do not correspond to reality. Therefore, it will be correct to consider the heat transfer of the radiator at delta t 50 °C. Now cast-iron radiators are widely used, the heat transfer of which (and more specifically, the power of the cast-iron radiator section) fluctuates around 100-150 watts.

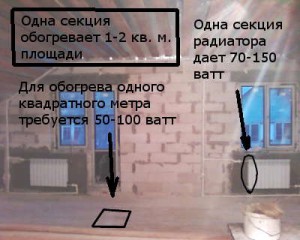

A simple calculation will help us determine the required thermal power. The area of your room in mdelta should be multiplied by 100 watts. That is, for a room with an area of 20 mdelta, you need a radiator with a power of 2000 watts.Be sure to note that if the room has double-glazed windows, subtract 200 W from the result, and if there are several windows in the room, too large windows or if it is angular, add 20-25%. If you do not take these points into account, the radiator will work inefficiently, and the result of this is an unhealthy microclimate in your home. You should also not choose a radiator according to the width of the window under which it will be located, and not according to its power.

If the power of the cast-iron radiators in your house is higher than the heat loss of the room, the appliances will overheat. The consequences may not be very pleasant.

- First of all, in the fight against stuffiness arising from overheating, you will have to open windows, balconies, etc., creating drafts that create discomfort and illness for the whole family, and especially for children.

- Secondly, due to the very heated surface of the radiator, oxygen burns out, air humidity drops sharply, and even the smell of burnt dust appears. This brings special suffering to allergy sufferers, since overdried air and burnt dust irritate the mucous membranes and cause an allergic reaction. And it affects healthy people too.

- Finally, the wrong power of cast-iron radiators is the result of uneven heat distribution, constant temperature fluctuations. Radiator thermostatic valves are used to regulate and maintain the temperature. However, it is useless to install them on cast-iron radiators.

If the thermal power of your radiators is less than the heat loss of the room, this problem is solved by creating additional electric heating or even completely replacing the heating devices. And it will cost you time and money.

Therefore, it is very important, taking into account the above factors, to choose the most suitable radiator for your room.

Advantages and disadvantages of cast iron radiators

Cast iron radiators are made by casting. Cast iron alloy has a homogeneous composition. Such heaters are widely used both for central heating systems and for autonomous heating systems. The sizes of cast-iron radiators can be different.

Among the advantages of cast iron radiators are:

- possibility of use for the heat carrier of any quality. Suitable even for coolant with a high alkali content. Cast iron is a durable material and it is not easy to dissolve or scratch it;

- resistance to corrosion processes. Such radiators can withstand coolant temperatures up to +150 degrees;

- excellent heat storage properties. An hour after turning off the heating, the cast-iron radiator will emit 30% of the heat. Therefore, cast iron radiators are ideal for systems with irregular heating of the coolant;

- do not require frequent maintenance. And this is mainly due to the fact that the cross section of cast iron radiators is quite large;

- long service life - about 50 years. If the coolant is of high quality, then the radiator can last for a century;

- reliability and durability. The wall thickness of such batteries is large;

- high heat radiation. For comparison: bimetallic heaters transfer 50% of heat, and cast iron radiators - 70% of heat;

- for cast iron radiators the price is quite acceptable.

Among the disadvantages are:

- great weight. Only one section can have a weight of about 7 kg;

- installation should be carried out on a previously prepared, reliable wall;

- radiators must be covered with paint. If after a while it is necessary to paint the battery again, the old layer of paint must be sanded. Otherwise, heat transfer will decrease;

- increased fuel consumption. One segment of a cast iron battery contains 2-3 times more liquid than other types of batteries.

Connection method

Not everyone understands that the layout of the pipes of the heating system and the correct connection affect the quality and efficiency of heat transfer. Let's examine this fact in more detail.

There are 4 ways to connect the radiator:

- Lateral. This option is most often used in urban apartments of multi-storey buildings. There are more apartments in the world than private houses, so manufacturers use this type of connection as a nominal method for determining the heat output of radiators. For its calculation, a coefficient of 1.0 is used.

- Diagonal. An ideal connection, because the coolant passes through the entire device, evenly distributing heat throughout its volume. This type is usually used if the radiator has more than 12 sections. When calculating, a multiplying factor of 1.1–1.2 is used.

- Lower. In this case, the supply and return pipes are connected from the bottom of the radiator. Usually this option is used for hidden pipe wiring. There is one drawback in this type of connection - heat loss of 10%.

- Single pipe. This is essentially the bottom connection. It is usually used in the Leningradka pipe distribution system. And here, heat losses were not without, however, they are several times larger - 30–40%.

How to correctly calculate the actual heat transfer of batteries

You should always start with the technical passport that is attached to the product by the manufacturer. In it you will definitely find the data of interest, namely, the thermal power of one section or a panel radiator of a certain size. But do not rush to admire the excellent performance of aluminum or bimetallic batteries, the figure indicated in the passport is not final and requires adjustment, for which you need to calculate the heat transfer.

You can often hear such judgments: the power of aluminum radiators is the highest, because it is well known that the heat transfer of copper and aluminum is the best among other metals. Copper and aluminum have the best thermal conductivity, this is true, but heat transfer depends on many factors, which will be discussed later.

The heat transfer prescribed in the passport of the heater corresponds to the truth when the difference between the average temperature of the coolant (t supply + t return) / 2 and in the room is 70 ° C. This is expressed using a formula:

For reference. In the documentation for products from different companies, this parameter can be denoted differently: dt, Δt or DT, and sometimes it is simply written “at a temperature difference of 70 ° C”.

What does it mean when the documentation for a bimetallic radiator says: the thermal power of one section is 200 W at DT = 70 ° C? The same formula will help you figure it out, you just need to substitute the known value of room temperature - 22 ° C into it and carry out the calculation in reverse order:

Knowing that the temperature difference in the supply and return pipelines should not be more than 20 ° C, it is necessary to determine their values as follows:

Now it is clear that 1 section of the bimetallic radiator from the example will give off 200 W of heat, provided that there is water heated to 102 ° C in the supply pipe, and a comfortable temperature of 22 ° C is set in the room. The first condition is unrealistic to fulfill, since in modern boilers heating is limited to 80 ° C, which means that the battery will never be able to give off the declared 200 W of heat. Yes, and it is a rare case that the coolant in a private house is heated to such an extent, the usual maximum is 70 ° C, which corresponds to DT = 38-40 ° C.

Calculation procedure

It turns out that the real power of the heating battery is much lower than stated in the passport, but for its selection it is necessary to understand how much. There is a simple way to do this: applying a reduction factor to the initial value of the heater's heat output. Below is a table where the values of the coefficients are written, by which it is necessary to multiply the nameplate heat transfer of the radiator, depending on the value of DT:

The algorithm for calculating the real heat transfer of heating devices for your individual conditions is as follows:

- Determine what should be the temperature in the house and the water in the system.

- Substitute these values into the formula and calculate your real Δt.

- Find the corresponding coefficient in the table.

- Multiply by it the passport value of the heat transfer of the radiator.

- Calculate the number of heaters needed to heat the room.

For the example above, the thermal power of 1 section of a bimetallic radiator will be 200 W x 0.48 = 96 W. Therefore, to heat a room with an area of 10 m2, you will need 1 thousand W of heat or 1000/96 = 10.4 = 11 sections (rounding always goes up).

The presented table and the calculation of the heat transfer of batteries should be used when the documentation indicates Δt equal to 70 ° C. But it happens that for different devices from some manufacturers, the radiator power is given at Δt = 50 ° С. Then you can’t use this method, it’s easier to dial the required number of sections according to the passport characteristic, just take their number with a one and a half margin.

For reference. Many manufacturers indicate heat transfer values under such conditions: supply t = 90 °C, return t = 70 °C, air t = 20 °C, which corresponds to Δt = 50 °C.

Radiator heat transfer what does this indicator mean

The term heat transfer means the amount of heat that the heating battery transfers to the room over a certain period of time. There are several synonyms for this indicator: heat flow; thermal power, power of the device. The heat output of heating radiators is measured in Watts (W). Sometimes in the technical literature you can find the definition of this indicator in calories per hour, while 1 W \u003d 859.8 cal / h.

Heat transfer from radiators is carried out due to three processes:

- heat exchange;

- convection;

- radiation (radiation).

Each heating device uses all three options for heat transfer, but their ratio differs for different models. Radiators used to be called devices in which at least 25% of the thermal energy is given off as a result of direct radiation, but now the meaning of this term has expanded significantly. Now often so called convector-type devices.

Technical characteristics of cast iron radiators

The technical parameters of cast iron batteries are related to their reliability and endurance. The main characteristics of a cast iron radiator, like any heating device, are heat transfer and power. As a rule, manufacturers indicate the power of cast-iron heating radiators for one section. The number of sections may vary. As a rule, from 3 to 6. But sometimes it can reach 12. The required number of sections is calculated separately for each apartment.

The number of sections depends on a number of factors:

- area of the room;

- room height;

- number of windows;

- floor;

- the presence of installed double-glazed windows;

- corner apartment.

The price per section is given for cast-iron heating radiators, and may vary depending on the manufacturer. The heat dissipation of batteries depends on what material they are made of. In this regard, cast iron is inferior to aluminum and steel.

Other technical parameters include:

- maximum working pressure - 9-12 bar;

- maximum coolant temperature - 150 degrees;

- one section holds about 1.4 liters of water;

- the weight of one section is approximately 6 kg;

- section width 9.8 cm.

Such batteries should be installed with a distance between the radiator and the wall from 2 to 5 cm. The installation height above the floor should be at least 10 cm. If there are several windows in the room, batteries should be installed under each window. If the apartment is angular, then it is recommended to carry out external wall insulation or increase the number of sections.

It should be noted that cast iron batteries are often sold unpainted. In this regard, after purchase, they must be covered with a heat-resistant decorative composition, it must first be stretched.

Among domestic radiators, the ms 140 model can be distinguished. For cast-iron heating radiators ms 140, the technical characteristics are given below:

-

- heat transfer of the MS section 140 - 175 W;

- height - 59 cm;

- the radiator weighs 7 kg;

- capacity of one section - 1.4 l;

- section depth is 14 cm;

- section power reaches 160 W;

- section width is 9.3 cm;

- the maximum temperature of the coolant is 130 degrees;

- maximum working pressure - 9 bar;

- the radiator has a sectional design;

- pressing pressure is 15 bar;

- the volume of water in one section is 1.35 liters;

- heat-resistant rubber is used as a material for intersectional gaskets.

It should be noted that cast iron radiators ms 140 are reliable and durable. Yes, and the price is quite affordable. Which determines their demand in the domestic market.

Features of the choice of cast iron radiators

To choose cast iron heating radiators which are best suited for your conditions, you must consider the following technical parameters:

- heat transfer. Choose based on the size of the room;

- radiator weight;

- power;

- dimensions: width, height, depth.

To calculate the thermal power of a cast-iron battery, one must be guided by the following rule: for a room with 1 outer wall and 1 window, 1 kW of power per 10 sq.m is needed. area of the premises; for a room with 2 outer walls and 1 window - 1.2 kW .; for heating a room with 2 external walls and 2 windows - 1.3 kW.

If you decide to buy cast-iron heating radiators, you should consider the following nuances:

- if the ceiling is higher than 3 m, the required power will increase proportionally;

- if the room has windows with double-glazed windows, then the battery power can be reduced by 15%;

- if there are several windows in the apartment, then a radiator must be installed under each of them.

Modern market

Imported batteries have a perfectly smooth surface, they are of better quality and look more aesthetically pleasing. True, their cost is high.

Among domestic analogues, konner cast-iron radiators, which are in good demand today, can be distinguished. They are distinguished by a long service life, reliability, and fit perfectly into a modern interior. Cast iron radiators konner heating are produced in any configuration.

- How to pour water into an open and closed heating system?

- Popular Russian-made outdoor gas boiler

- How to correctly bleed air from a heating radiator?

- Expansion tank for closed heating: device and principle of operation

- Gas double-circuit wall-mounted boiler Navien: error codes in case of malfunction

Recommended reading

2016–2017 — Leading heating portal. All rights reserved and protected by law

Copying site materials is prohibited. Any copyright infringement entails legal liability. Contacts

What to consider when calculating

Calculation of heating radiators

Be sure to take into account:

- The material from which the heating battery is made.

- Her dimensions.

- The number of windows and doors in the room.

- The material from which the house is built.

- The direction of the world in which the apartment or room is located.

- Building insulation.

- Type of piping system.

And this is only a small part of what needs to be taken into account when calculating the power of a heating radiator. Do not forget about the regional location of the house, as well as the average street temperature.

There are two ways to calculate the heat dissipation of a radiator:

- Regular - using paper, a pen and a calculator. The calculation formula is known, and it uses the main indicators - the heat output of one section and the area of \u200b\u200bthe heated room. Coefficients are also added - decreasing and increasing, which depend on the previously described criteria.

- Using an online calculator. It is an easy-to-use computer program that is loaded with certain data about the size and construction of the house. It gives a fairly accurate indicator, which is taken as the basis for designing a heating system.

For a simple layman, both options are not the easiest way to determine the heat transfer of a heating battery. But there is another method for which a simple formula is used - 1 kW per 10 m² of area. That is, to heat a room of 10 square meters, you need only 1 kilowatt of thermal energy. Knowing the heat transfer rate of one section of the heating radiator, you can accurately calculate how many sections you need to install in a particular room.

Let's look at a few examples of how to correctly carry out such a calculation. Different types of radiators have a large size range, depending on the center distance. This is the size between the axes of the lower and upper collectors. For the bulk of heating batteries, this figure is either 350 mm or 500 mm. There are other options, but these are the most common.

This is the first. Secondly, there are several types of heaters made of various metals on the market. Each metal has its own heat transfer, and this will have to be taken into account when calculating. By the way, which one to choose and install a radiator in your home, everyone decides for himself.

Conclusion on the topic

Radiator power table

You yourself were able to make sure that you can correctly calculate the heat transfer of a radiator in a simple way, however, it is not very accurate. In addition, it is necessary to take into account a wide range of dimensional parameters of batteries, the materials from which they are made, plus additional factors. So everything is complicated.

Therefore, we advise you to do it easier. Take as a basis the same formula with the ratio of the area of \u200b\u200bthe room and the required amount of heat. Make a calculation and add up to 10% to it. If your house is located in the northern region, add 20%. Even 10% is very generous, but there is no excess heat. Moreover, it is possible, using various devices, to control the supply of coolant to radiators. It can be reduced or it can be increased. The only disadvantage of such an increase is the initial cost of purchasing radiators with a large number of sections. This is especially true for aluminum and bimetallic heating devices.