How many rings to buy for a well

You can calculate the approximate depth of the well based on the depth of the water carriers in neighboring areas, adjusted for the relief. This value is divided by the height of one ring and their approximate number is obtained for arranging a well shaft. It is better to order not back-to-back, but with a small margin, so that at a crucial moment you do not have to urgently organize the delivery of 1-2 rings to the site. For example, for the Moscow region, the depth of wells is 10-12 rings.

The seams between the installed rings must be filled with a binder solution. The use of folk methods: tarred tow, etc. is undesirable. The use of rings with closing grooves creates a strong and watertight joint

This is fraught with additional costs, but the main thing is that the process of lowering the rings should not stop so that the soil does not have time to clamp the shaft. It holds the rings so tightly that sometimes it is necessary to ram the column from above with the help of heavy equipment. The remaining rings can be sold to the owners of neighboring plots, made into a reservoir for collecting rainwater, used to equip a makeshift septic tank.

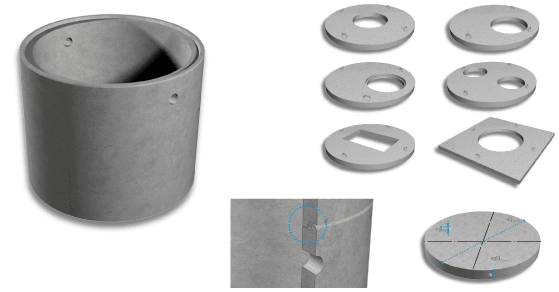

When arranging the well, perforated reinforced concrete rings are used - for the inflow of water through the sides of the shaft and for the introduction of water communications. To cover the protection of the upper part from debris, special covers are cast corresponding to the diameter of the rings, with a hole and a hatch. Rings of smaller diameter are called repair rings and are used to deepen shallow wells.

Why doborny rings are needed

When it is impossible to install ordinary ones, additional rings are used for the well. They solve problems caused by the width, slope or height of a standard through. The height of the additional ring is less than 40 cm, therefore, it allows you to bring the shaft to the desired height, if this is not possible with the help of a conventional one. In a specialized company, you can order additional rings according to individual measurements so that they exactly match the structure being erected.

When designing a well, much attention is paid to the decorative component. Rarely, the owners agree that the head, closed by a hatch, just sticks out on the site.

For such cases, the upper rings with a beautiful relief are cast.

What are drinking well rings

There is no single standard that regulates the sizes of rings for wells. For casing a well shaft, rings with an internal diameter of 90-100 cm and a height of 70-100 cm are used. These values are dictated by practicality: if you take less, it will be inconvenient to dig inside, if more, the front of manual labor will increase significantly. The larger the ring, the heavier it is, and these are additional shipping costs.

Concrete rings, indistinguishable from the outside, differ in casting technology and composition:

- drinking;

- Sewer;

- Gas pipelines.

The most stringent requirements are imposed on water intake rings. Each ring must have a standard marking. Before going on sale, they are subjected to production tests.

You need to order reinforced concrete rings only from certified sellers. Under the guise of wells, you can unknowingly buy simple technical ones, which contain harmful impurities

High-quality reinforced concrete rings have many advantages:

- The lowest price (compared to a wooden frame or rubble masonry);

- Solidity;

- Easy to install and repair;

- Ground pressure resistance;

- Wide assortment.

For strong and durable well concrete rings, a reinforcement frame is used, filled with a mortar of M-500 cement. The wall thickness is 10 cm.

In the production of rings for non-food purposes, casting molds are lubricated with petroleum products. Together with them, an oil film may appear in a new drinking well, which is not easy to get rid of.

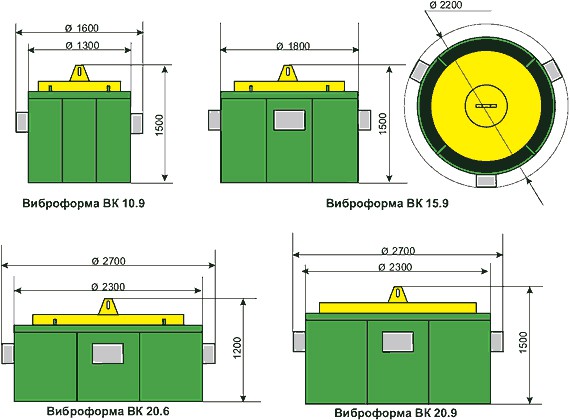

In industrial production, vibration is used to compact the solution in the molds, but the surface of the finished ring retains some porosity, so it is impossible to completely clean it of oil.

TRANSPORT AND STORAGE

4.1. Transportation and storage of structures - in accordance with GOST 13015.4 and this standard.

4.2. Structures are transported and stored in working position.

4.3. Structures should be stored:

- working chambers - in one row;

- wall rings - in two rows in height in accordance with the diagram shown in Fig. ;

- support rings and plates - no more than six rows in height on gaskets (linings) in accordance with the diagram shown in Fig. .

Scheme of storage of wall rings of wells

Scheme of storage of floor slabs and bottoms of wells

- gaskets (linings); 2 - mounting loops

Other storage schemes are allowed, provided that the structures are preserved and safety requirements are observed.

Installation of rings in the well shaft

After a promising place for the construction of a well is determined, a small area is cleared, a circle is marked for excavation. The diameter of the laid shaft should be several centimeters larger than the purchased rings. A small gap will ensure the free descent of the column into the prepared pit. After digging, the soil around the mine will settle and compact naturally. This takes several months. It is impossible to dig a mine end-to-end so that the rings are not pinched.

There are several methods for lowering reinforced concrete rings into a well. They differ in complexity, required equipment and safety. In the first case, a trench is dug in and deepened at the marked place, and the first ring is lowered into it. Further, the worker performs digging already inside it, gradually deepening the bottom and evenly choosing soil from under the walls. If there is a risk of uneven descent, sections of logs are driven under the ends of the ring to prevent premature movement. The soil is loaded into a bucket, which is pulled out with a winch or winch. As soon as the first ring has sunk enough, the next one is installed on it.

The work inside the mine is difficult, at depth there can be a lack of oxygen. For digging and lowering, at least two workers are needed, and optimally three. One works in the mine, the second lifts the soil up, the third has time to rest. Rings of standard size can be lowered without additional equipment. Using a winch or a truck crane greatly speeds up the process. The described method is the safest.

When digging a mine, you need to constantly control the verticality of the recess so that you do not get a slant or wave. In such a place, the rings either stop or fall to one side. Correcting the situation is problematic

Even if the mine is ringed as it goes deeper, there is a chance to open a quicksand. It is a fluid mass of suspended soil particles. A weak quicksand will fill the bottom with sand or clay, depending on the composition, and a powerful one can twist and carry away the rings.

The second method: first, the shaft is completely dug out until the water begins to rise rapidly. Then all the rings descend into it one by one. The worker has more space at the bottom, so it is easier to choose the soil, but there is a great danger that a collapse will occur or quicksand will open. This method is only suitable for dense clay soils that are not prone to shedding and collapse.

The cost of carelessness can be very high. When lowering the rings into the finished shaft, they cannot simply be dropped; for high-quality and accurate work, a winch is required

So that the rings do not move during construction and operation, they are produced with a groove for mutual closure.The shaft will be more stable, and the waterproofing seams will be more reliable. Simple rings are reinforced with rebar staples or strips of metal.

3. Characteristics

1.3.1. Structures must meet the requirements of GOST 13015:

- in terms of strength, stiffness and crack resistance, while there are no requirements for testing structures by loading;

- in terms of the actual strength of concrete (at the design age and vacation age);

- frost resistance and water resistance of concrete;

- by the thickness of the protective layer of concrete to the reinforcement;

- to steel grades for reinforcing and embedded products, including for mounting loops;

- Corrosion protection.

1.3.2. Structures should be made of heavy concrete according to GOST 26633 classes or grades for compressive strength specified in the working drawings of the structures.

1.3.3. The normalized tempering strength of concrete is taken equal to 70% of the class or grade of concrete in terms of compressive strength.

The specified normalized tempering strength of concrete can be reduced or increased in accordance with the requirements of GOST 13015.

1.3.4. The water absorption of concrete structures must comply with the established design documentation for a particular structure or specified when ordering structures.

1.3.5. Reinforcing steel of the following types and classes is used to reinforce structures:

— thermomechanically hardened rod of At-ShS and At-lVC classes according to GOST 10884;

— hot-rolled rod of classes A-1, A-11 and A-111 according to GOST 5781;

- reinforcing wire class Vr-1 according to GOST 6727.

1.3.6. The shape and dimensions of reinforcing and embedded products and their position in the structures must correspond to those indicated in the working drawings.

1.3.7. Welded reinforcing and embedded products must meet the requirements of GOST 10922.

1.3.8. In the cases provided for by the working drawings of the wells, running brackets should be installed inside the wall rings, located along the height of the ring every 300 mm and protruding from the inner surface of the rings by 120 mm.

Running brackets should be made of reinforcing steel of class A-I or A-P according to GOST 5781.

By agreement between the manufacturer and the consumer, wall rings are allowed to be manufactured without running brackets, provided that they are installed at the construction site.

1.3.9. The running brackets must be protected against corrosion according to the instructions of the working drawings of the wells.

1.3.10. The values of actual deviations of the geometric parameters of structures should not exceed the limit values indicated in Table. one.

Table 1

In millimeters

|

The name of the deviation of the geometric parameter |

Geometric parameter name |

Previous off |

|

Deviation from linear dimension |

Height (thickness) of the structure: |

|

|

up to 180 |

+ 5 |

|

|

» 300 |

+ 8 |

|

|

» 1000 |

+ 10 |

|

|

St. 1000 to 1600 |

+ 12 |

|

|

» 1600 » 2500 |

+ 15 |

|

|

» 2500 |

+ 20 |

|

|

The inner diameter of the working chambers, wall- |

||

|

outlet and support rings, outer diameter of floor slabs and bottom, diameter of manholes and openings for pipelines: |

||

|

up to 1000 |

+ 6 |

|

|

St. 1000 to 1600 |

+ 8 |

|

|

» 1600 » 2500 |

+ 10 |

|

|

» 2500 |

+ 12 |

|

|

Length and width of base and road slabs |

+ 10 |

|

|

Position of holes and cutouts |

10 |

|

|

Deviation from flatness of the lower surface of floor slabs (when measuring |

Outer diameter of floor slabs: up to 1000 St. 1000 to 2500 » 2500 |

4 |

|

from a conditional plane passing through three points) |

6 8 |

1.3.11. Requirements for the quality of surfaces and the appearance of structures are in accordance with GOST 13015. At the same time, the quality of surfaces of structures (with the exception of butt surfaces) must meet the requirements established for category A6. The surfaces that form the joint of structures, which are monolithic at the construction site, are subject to the requirements established for category A7.

It is allowed, by agreement between the manufacturer and the consumer, to all surfaces of working chambers, wall and support rings to impose the requirements established for category A7.

Concrete rings for a well

The main advantages of well rings are their durability, frost resistance and resistance to soil movements.Unlike plastic septic tanks, concrete wells are not threatened by a fracture or the aggressive effects of waste mass components. Nevertheless, the disadvantages of concrete rings for wells and sewage devices are present:

- The impossibility of manual transportation, which significantly increases the cost of installing concrete rings for a sewer or septic tank as a whole. It is possible to reduce the cost of sewage by making it from other types of material that are worse in quality and longevity, but nevertheless do not require special financial costs.

- The large size and weight of concrete rings - you can not do without the use of loading assistance. Sometimes the cost includes delivery of products, but you need to clarify this in advance. In addition, if the production is located far away from the installation site of the well sewer, then it makes sense to think about an alternative.

- The use of reinforced concrete well rings leads to cracks on the surface and corrosion of the reinforcement - structural fatigue, a significant nuance in the sewerage system. In addition, if a second-hand concrete ring was used, the production was carried out in an artisanal way, or a low-quality binder was used, then the well will crumble quickly, the sewage system will become unusable.

Products in the form of concrete rings for sewerage or a septic tank in a summer cottage are divided into numerous parameters. In this connection, they differ in various characteristics, sizes and conditions of use. For instance:

- Classification of sewerage by type of construction. Concrete rings are either straight or with locking joints. The first are a simple cylinder shape, fastened with staples and cement mortar. The latter have a protrusion and a notch on the edges, respectively. Due to this structural well effect, horizontal or vertical displacement of the sewer well and septic tank is impossible.

- By form. Concrete rings also exist in a square shape. They are used mainly for the installation of highways, but if you want to equip the sewer with them, there is no problem. The only inconvenience is that the dimensions of the reinforced concrete products and their weight do not allow the use of a small plot of soil. For covers, special reinforced concrete ceilings with double-level hatches are used to make insulation - the products themselves are cold, and freezing of the sewer cannot be allowed.

- By fittings. Well rings can be completed with bottoms and covers. Such a sewerage design will not allow the release of odor from sewage into the atmosphere, and will not pose a danger in terms of fecal runoff into groundwater or nearby drinking sources. The manufacturer offers combined septic tanks, then the installation will take place as soon as possible.

The correct selection of the dimensions of concrete rings and the weight of related products will allow the sewer system to last a long time.

To determine the dimensions, it is important to take into account many factors - from the number of people using sewage, to soil conditions and local climate

Installation of concrete well rings

All work related to the installation of concrete structures must be carried out with special equipment. So the installation of reinforced concrete rings for the well should be carried out using mobile cranes. Work order:

- Additionally, rubber inserts and concrete mortar are used, which help to more reliably seal the structure and thereby increase its service life.

- The installation process itself depends on which types were chosen. If the wall ones are with a bottom, then they are the first to be laid and only then the subsequent ones are placed on them.

Tongue-and-groove shorten the construction process, as they have their own specific fastenings and are quite firmly fastened together. And if their joints are smeared with concrete mortar, then the structure will last more than one fifty years.

Varieties of well rings

Rings for a well can be made of two materials:

- Concrete.

- PVC.

Peculiarities:

- Both of them have excellent properties and characteristics. They are widely used for the construction of water supply wells.

- With them, the process of constructing a structure is quite simple and all actions are performed very quickly.

Types of concrete rings

The concrete well ring is made from:

- Solution of concrete.

- Fittings.

- Various additives that increase its strength and environmental friendliness.

At the moment there are several types that are used for arrangement:

- Support.

- Wall.

- Additional.

- Castle.

- Bottom.

- tongue-and-groove.

More:

- Support rings for wells are needed if a hatch is to be built in the future. They are installed in front of the floor slab and can provide reliable fastening of the hatch.

- Wall rings for wells are ordinary, which are installed one above the other during the construction of the well. All joints must be filled with concrete mortar to ensure their secure fastening.

Additional rings for wells in their design are the same wall rings, only they have non-standard sizes. They are used to provide the desired depth.

They are installed at the very beginning of the wells below and wall wells are already attached to them.

- Castle wells are very similar to ordinary concrete ones. Their main difference will be that they have a special lock on them.

They are also called tongue-and-groove. In addition to the lock on the top, there are special combs on the bottom. The design, which is assembled from this type of rings, is distinguished by its strength. - There are also certain holes that are filled during the installation process with concrete mortar. All of them, when securely fastened, are not able to have horizontal shifts.

Reinforcement is also involved in their production, which gives them greater strength.

- Rings with a bottom are not particularly difficult in their design, as they are made according to the type of wall rings, only they are additionally equipped with a bottom. Accordingly, they are laid during the construction process on the bottom of the structure and serve as a support for it.

- There are also adjusting rings for wells. They are used to increase the depth of the well in the range of 50 cm.

This results in cleaner water. They are made of reinforced concrete or PVC.

The photo shows all types that are used in water supply facilities.

What can wells be?

At the moment, there are three types of wells that are used in suburban areas:

- Water pressure.

- Lookouts.

- Sewer.

Functions of water wells

The main function of this design is to provide water to a residential building. can be different, since the aquifer is located differently in each area. As a rule, wells with water supply are mine and various materials are used for their arrangement inside:

- Wood, which is laid out around the entire perimeter of the internal walls of the structure.

- Stone (brick or natural agglomerate), which is used in a similar way.

- Rings. Here the choice of such material for arrangement is quite wide.

TRANSPORT AND STORAGE

4.1. Transportation and storage of structures - in accordance with GOST 13015 and this standard.

4.2. Structures are transported and stored in working position.

4.3. Structures should be stored:

- working chambers - in one row;

- wall rings - in two rows in height in accordance with the diagram shown in Fig. one;

- support rings and plates - no more than six rows in height on gaskets (linings) in accordance with the diagram shown in Fig. 2.

Other storage schemes are allowed, provided that the structures are preserved and safety requirements are observed.

Scheme of storage of wall rings of wells Scheme of storage of floor slabs and bottoms

wells

Crap. one

1 - gaskets (linings); 2 - mounting loops 2

APPENDIX

Mandatory

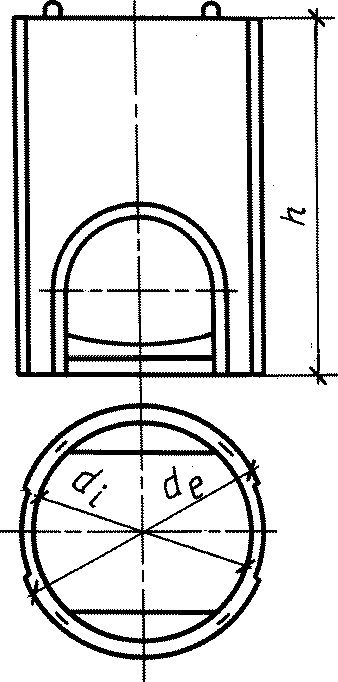

SHAPE AND BASIC DIMENSIONS OF WELL STRUCTURES

Working chamber types KLV and KLK

KLV8

KLK10

KLK13

KLK15

820

960

1550

1000

1160

1800

1250

1410

1500

1680

1980

Working chamber type

Sewer ladders KL-1

We manufacture ladders for sewer wells of any size at the request of the customer.

| Type of stairs | Length (m) | Price |

| CL-1-2.0 | 2,0 | 2430 |

| CL-1-2.5 | 2,5 | 2955 |

| KL-1-3.0 | 3,0 | 3480 |

| CL-1-3.5 | 3,5 | 4000 |

| CL-1-4.0 | 4,0 | 4530 |

| CL-1-4.5 | 4,5 | 5000 |

| KL-1-5.0 | 5,0 | 5570 |

| CL-1-5.5 | 5,5 | 6110 |

| KL-1-6.0 | 6,0 | 6650 |

The price list shows average prices including VAT and delivery.

During the construction of modern drinking wells, special reinforced concrete rings are used. So that the work does not stop, they are immediately brought to the site, unloaded near the place chosen for digging the well. The exact amount that will be required for the construction of the mine becomes known only after finding the aquifer.