Biological treatment

Unlike mechanical cleaning, biological cleaning is entirely dependent on viable bacteria and microorganisms, which, in fact, are already in the soil, water and other environments and perform their sewage work.

Living microorganisms also consume or process stormwater, due to which the water in the septic tanks settles and separates into sludge and purified water, which flows into a second tank, where it also undergoes the same treatment.

The performance of such treatment facilities is from 10 cubic meters. m per day, which can reveal high rates of service for medium-sized settlements.

How can storm water be purified?

Stormwater treatment can be done:

- mechanically. In this case, only large particles are captured, which are deposited in such elements of the system as a sand trap;

- physical and mechanical way. When using this treatment method, large particles and insoluble oils and petroleum products can be removed from the drain;

- in a chemical way. Allows maximum purification of wastewater using the above-mentioned elements and additional chemicals.

Domestic storm sewer treatment plants use the first two methods. The third method is designed to purify rainwater in industrial enterprises.

Equipment features and principle of operation

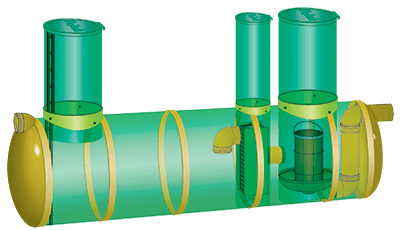

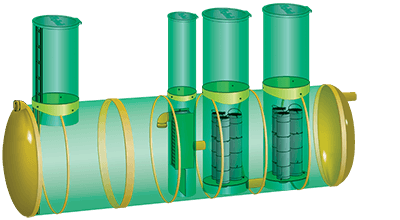

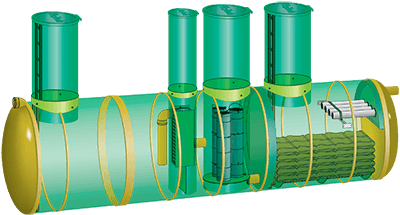

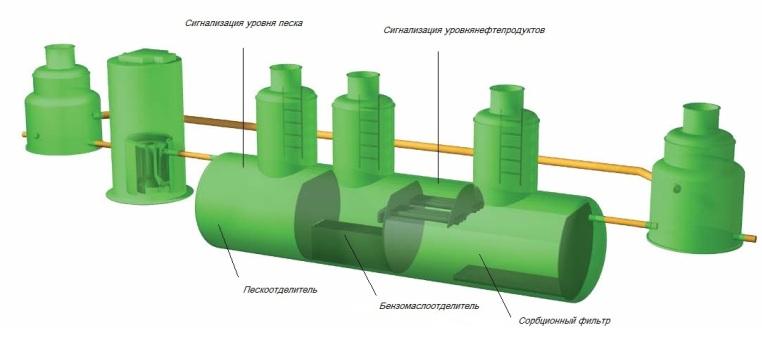

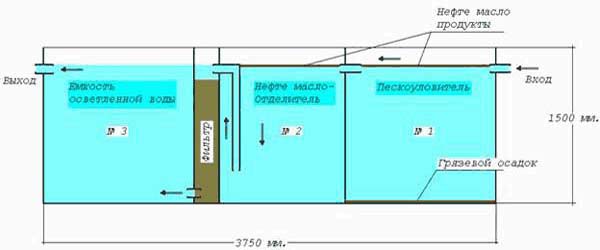

The complex cleaning system is a design with several filtration components, made in a monolithic housing. The equipment includes three complementary stages:

- sand-oil separator;

- sorption block;

- oil separator.

Together, the equipment demonstrates a high result in surface water purification from heavy contaminants, elements of petroleum products, oils, sand and soil compounds. The configuration of the equipment integrated into the system, the type of products depend on the basic purpose, place of discharge, as well as the source of wastewater.

The required degree of purification and quality indicators are regulated by state standards for operational and environmental safety. To discharge the runoff passed through the system to the relief, sponge-fabric filters are used. Installation is carried out in special drainage ditches of the sorption compartment. To ensure discharge into reservoirs for fishery and other purposes, it is necessary to use a sorbent.

Benefits of using an integrated stormwater treatment system

- ease of maintenance of the device;

- installation is carried out in the shortest possible time;

- effective filtration of water entering the system;

- a housing made of resistant to mechanical stress and temperature extremes guarantees the durability and reliability of the integrated storm water treatment system;

- low cost of maintaining the operation of the device;

- the ability to use the filtered effluent in various areas of the enterprise.

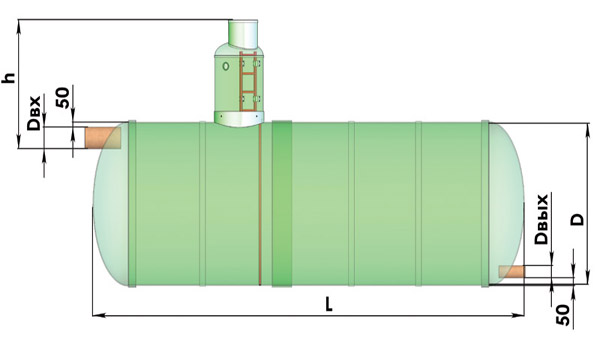

OP-OM

It is used when discharging treated effluent into the city sewer.

The size

| Effluent flow, l/s | Case diameter, D, mm | Case length, L, mm | Din/Dout, mm | Differential in/out, mm |

| 6 | 1600 | 4500 | 160 | 200 |

| 10 | 1600 | 6400 | 200 | 200 |

| 15 | 1800 | 6800 | 200 | 200 |

| 20 | 2000 | 6700 | 200 | 300 |

| 25 | 2000 | 8000 | 200 | 300 |

| 30 | 2300 | 6800 | 250 | 300 |

| 40 | 2300 | 8800 | 250 | 300 |

| 50 | 2300 | 10100 | 250 | 300 |

| 65 | 2300 | 12600 | 315 | 300 |

| 80 | 3000 | 9500 | 315 | 400 |

| 90 | 3000 | 11300 | 400 | 400 |

| 100 | 3000 | 13300 | 400 | 400 |

| 120 | 3200 | 13000 | 400 | 400 |

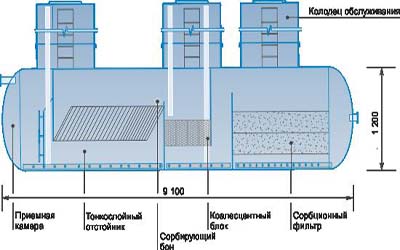

OP-OM-SB (filters)

It is used when discharging treated runoff onto the terrain, into ravines, into drainage ditches.

Dimensions

| Effluent flow, l/s | Case diameter, D, mm | Case length, L, mm | Din/Dout, mm | Differential in/out, mm |

| 1,5 | 1200 | 4000 | 110 | 120 |

| 3 | 1200 | 4400 | 110 | 120 |

| 6 | 1600 | 5500 | 160 | 200 |

| 10 | 1600 | 6400 | 160 | 200 |

| 15 | 1800 | 6800 | 200 | 200 |

| 20 | 2000 | 6700 | 200 | 200 |

| 25 | 2000 | 8000 | 200 | 200 |

| 30 | 2000 | 8000 | 250 | 200 |

| 40 | 2300 | 7600 | 250 | 200 |

| 50 | 2300 | 8100 | 250 | 300 |

| 65 | 2300 | 9100 | 315 | 300 |

| 80 | 2300 | 11600 | 315 | 300 |

| 90 | 2300 | 12600 | 400 | 300 |

| 100 | 2300 | 13100 | 400 | 400 |

| 120 | 3000 | 11300 | 400 | 400 |

OP-OM-SB (sorbent)

It is used when discharging treated effluent into reservoirs for various purposes.

Dimensions

| Effluent flow, l/s | Case diameter, D, mm | Case length, L, mm | Din/Dout, mm | Differential in/out, mm |

| 1,5 | 1200 | 4000 | 110 | 120 |

| 3 | 1200 | 4400 | 110 | 120 |

| 6 | 1600 | 5500 | 160 | 200 |

| 10 | 1600 | 6400 | 160 | 200 |

| 15 | 1800 | 6800 | 200 | 200 |

| 20 | 2000 | 6700 | 200 | 200 |

| 25 | 2000 | 8000 | 200 | 200 |

| 30 | 2000 | 8000 | 250 | 200 |

| 40 | 2300 | 7600 | 250 | 200 |

| 50 | 2300 | 8100 | 250 | 300 |

| 65 | 2300 | 9100 | 315 | 300 |

| 80 | 2300 | 11600 | 315 | 300 |

| 90 | 2300 | 12600 | 400 | 300 |

| 100 | 2300 | 13100 | 400 | 400 |

| 120 | 3000 | 11300 | 400 | 400 |

Storm sewer maintenance and pipe cleaning

Timely maintenance of storm sewers consists in cleaning and removing debris from pipes and gutters, but the specifics of these procedures differ significantly from work on.

Main stages of work:

- protective grilles are opened and repaired, or replaced with new ones, if necessary;

- cleaning of storm pipes - in long sections they are cleaned through special manholes;

- checking the accuracy of the control sensors.

Timely maintenance of storm sewers will ensure uninterrupted drainage of wastewater and will positively affect the environment. After all, garbage and sludge that settle in gutters and pipes can accumulate harmful substances.

Do not forget that during the period of operation, drainage wells and pipe outlets must be tightly closed with plugs and hatches, this will save them from debris.

It is also worth periodically checking the drainage well for the accumulation of sediment from particles of soil and sand in it, because due to large accumulations, dirt enters the pipes. To prevent this, the drainage must not be forgotten to be cleaned.

This is done independently if you have the necessary equipment, or you can contact the specialists of the Chisto Honestly company for professional help in maintaining storm sewers.

Installation of local rainwater treatment facilities

All storm water treatment facilities are installed according to the developed project, in compliance with all norms and rules.

Construction assembly

It is necessary to assemble the equipment into a single cleaning system according to the following rules:

- on the first level, a container is installed for the accumulation of liquid redistribution;

- then a sand trap is connected, in which rough cleaning of rainwater takes place;

- after the sand trap, an oil trap or other device is installed that separates large particles of oil, gasoline, and so on;

- the last stage of purification takes place in the sorption filter;

- then clean water enters the well for collection or disposal.

Hardware Installation Instructions

Installation of equipment at its permanent location is carried out as follows:

- using equipment or a shovel, the soil is removed at the location of the treatment plant. The dimensions of pits and trenches supplying sewage and discharging purified water must be at least 50 cm larger than the dimensions of the installed equipment. The trenches are also dug at an angle to ensure gravity flow of the liquid. The angle of inclination must be at least 3º;

- a sand cushion is laid out at the bottom of trenches and pits. Sand is spilled with water and carefully compacted;

- if the equipment to be installed is heavy, for example, a sorption filter, then a concrete base is mounted under the device;

- after carrying out land works, a preliminary assembly of the treatment plant is carried out;

- all components of the system are installed in the designated places. Inspection hatches of structures should protrude somewhat above ground level;

- the treatment plant is insulated with materials, for example, mineral wool. This is necessary for the normal operation of the system in the cold season;

- inlet and outlet pipes are insulated with waterproof materials, presented in a wide range of stores. For example, you can use isol;

- final assembly of the cleaning system;

- all joints are treated with sealant to increase water resistance;

- the system is checked;

- from all sides, pipes and treatment facilities are covered with sand, which is reliably rammed with water;

- the final backfilling of the soil and the laying of the removed sod are carried out.

All work on the installation of stormwater treatment plants must be carried out carefully and carefully. Any error can lead to the inoperability of the system and flooding and contamination of the site with rain or melt water.

Depending on the analysis of rainwater and the intensity of precipitation in the region, equipment for a local stormwater treatment plant is selected. Mandatory elements of rainwater treatment are a storage tank, a sand trap filter and a sorption well. It is desirable to develop the construction project together with professionals. The cleaning system requires constant monitoring and timely maintenance. Control can be carried out visually or with specialized sensors that signal the need for cleaning.

1.

2.

3.

4.

Treatment facilities for suburban or suburban areas are divided into two types: devices for the treatment of domestic wastewater and treatment facilities for storm sewage. It is the latter that will be discussed in this article.

Stormwater treatment plants are needed to process and purify the liquid that has fallen to the ground in the form of precipitation. Such structures are an element of the storm sewer system.

What is included in the system

These systems are very similar in principle to sewer septic tanks, the function of which is not only to receive and store household sewage, but also to defend them, clean them in several stages, and then bring them into the soil through filters.

Also here, in such systems as local treatment facilities, rain and melt water, which washes away various garbage, all kinds of oils, industrial waste, oil products, obsolete building materials.

Includes the following elements:

- storage capacity;

- traps and separators of water from sand, oil, oil, paint, gasoline and other heavy liquids;

- absorbent filter;

- a control tank in the form of a well, where samples are taken for the degree of water purification.

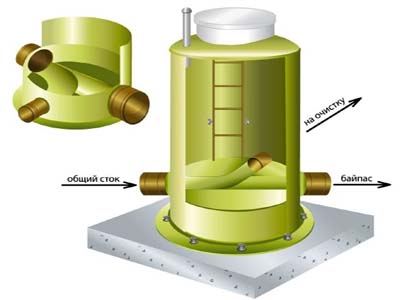

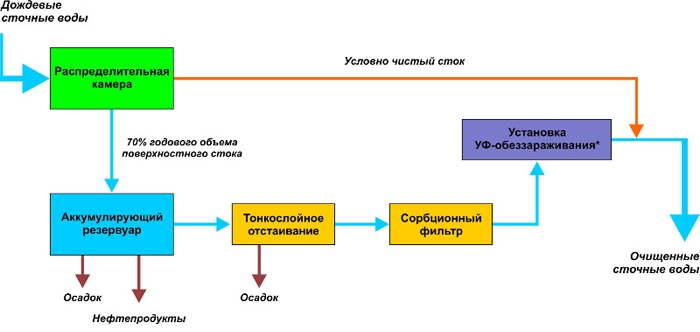

Stream separation chamber

Such structures are needed in order to be able to receive a large number of water flows at a time. And so that the system is not overloaded, water enters a special chamber, where it is divided in portions and fed into the sorption and filtration chambers.

Through the collector or pipes leading to the treatment plant, effluents are fed into the capacity of the separation chamber.

If the water volume level is exceeded, then excess runoff through a certain section of the pipeline is discharged directly into the storm water discharge facility, which can again enter the next entry into the chamber.

storage capacity

The function of the accumulation is to hold back some of the storm runoff for a while in order to keep the entire system from being overloaded, especially during periods of rainy seasons or heavy rainfall.

Such a container is released from water gradually as the intensity of the rain fades. The time for collecting storm flows and filling such a container per day is recognized as the most optimal.

sand trap

Such tanks in treatment facilities are simply necessary. Their filters are specially designed in such a way that sand can be effectively and maximally retained.

However, they retain not only sand, but also many other mineral particles by 65-75%, which are in the entire waste mass.

Here the principle of operation is such that the sand is delayed by braking the feed rate of the entire storm mass:

- in the first compartment of the sand trap, heavy particles settle immediately;

- in the second, under the influence of plastic plates located at a certain slope, the sand slides down;

- in the third, drains cleared of sand fall by gravity into the next compartment.

The sand trap is cleaned of sediment using a sewage machine.

Oil separator

The oil trap device allows you to separate and purify water from any oil, gasoline, kerosene and other fatty liquids that are heavier and denser than water.

The gravitational field and such a phenomenon as coalescence work here - the merging of fatty drops or particles by attraction.

In the first compartment

, as in a sand trap, the speed of incoming storm water decreases, where suspended particles settle.

Second compartment

- this is the coalescent module, where fat particles become larger and float up.

And in the third compartment

the same thing happens as in the sand trap - purified water is collected and fed to the next chamber for further processing.

Sorption filter

Such filters are used for post-treatment of storm water in order to supply them therefore to the control well.

Here, the effluents are treated from fine and very fine suspended particles, as well as from oil products with high emulsification ratings.

A layer of solid sorbent absorbs and absorbs all harmful substances, and seeps the purified water into the water intake well. This layer contains active carbons of various grades, so the sorbent is environmentally friendly.

Kinds

According to their purpose, they are divided into:

- purification of industrial effluents;

- purification of domestic wastewater;

- cleaning of storm drains;

- purification of combined wastewater.

Also, one should not forget that treatment facilities come in various parameters, dimensions and designs.

It all depends on what volumes, compositions and inclusions the wastewater treatment plant belongs to:

- individual (for offline use);

- local (centralized use of storm and domestic sewage);

- industrial (purification of industrial liquid waste).

They differ from each other in terms of the amount of effluent supplied to the treatment plant. If, for example, individual structures serve one private house, then local ones are designed to serve entire groups of houses. The latter facilities can be constructed into entire treatment plants.

The need for stormwater treatment

Treatment plants and systems of our company separate all types of pollution, which are very rich in storm and melted wastewater. According to the norms and rules in force in our country, these effluents can be discharged into the environment only when the content of substances harmful to the environment and human health does not exceed certain standards. The equipment for the treatment of storm drains, which our company offers, allows you to guarantee that they are brought to the required conditions. It should also be noted that untreated storm and melted wastewater is also dangerous for buildings and structures. The chemical impurities that they contain damage the waterproofing, as a result of which the destruction of foundations, as well as underground utilities, begins. Due to the increased humidity, a fungus appears on the structural elements, which causes serious damage to them. Thus, it is necessary to treat stormwater not only because it is required by environmental regulators, but also for purely practical reasons.

Stages of storm water treatment

Modern storm sewage treatment plants manufactured by our company remove harmful impurities in several stages:

- Separation of sand and other mechanical impurities;

- Cleaning of storm drains from oil products;

- Wastewater disinfection.

At the first stage of treatment, wastewater enters the sand separators. They are horizontally or vertically located reservoirs in which the flow rate of effluents slows down, and under the influence of gravitational forces, the mechanical impurities present in them settle to the bottom.

Further, wastewater is transferred to a device such as an oil and petrol separator.It separates emulsified oil products: they are concentrated into rather large drops and float to the surface, forming a film. As a result, the smallest particles of suspension also get into it. If storm drains have a high content of oil products, then the installation of a sorption unit is envisaged in the treatment plant. Its main element is a carbon filter, which is used for post-treatment of wastewater.

At the last stage, disinfection of storm drains is carried out. In the Flotenk treatment plant, special modules are used for this, following through which the wastewater is irradiated with ultraviolet light.

In order to significantly simplify and facilitate the operation and maintenance of these equipment complexes, our company equips them with automated control systems for the treatment of industrial storm water. Most often they are used at treatment facilities of large industrial facilities, cottage settlements, etc.

Updated: 04/12/2018

103583

Choosing an offline cleaning system

The selection of equipment to be included in the storm sewage treatment plant is based on the results of studies and calculations:

- the soil is examined at the site of the proposed location of the treatment plant to select the installation parameters (freezing depth, wastewater occurrence, and so on);

- the chemical composition of rainfall, as well as the presence of other insoluble particles in them, is studied to determine the filters necessary for cleaning the liquid;

The above studies are carried out in laboratories by qualified specialists.

- the amount of precipitation in the region where the structure is located is calculated. This is required to determine the volume of the constituent elements of the treatment plant;

To independently determine the volume of rainwater, the formula is used:

Volume = q20 ∙ F ∙ φ

, where

- F is the area of the site from which it is required to collect rainwater for purification;

- φ is a coefficient based on the priority coverage of the site (shown in the table below);

- q20 is a value that characterizes the average level of precipitation in the region (examples in the table below).

φ coefficient table

Table of q20 values

| Region | q20 |

| Moscow | 80 |

| Nizhny Novgorod | 90 |

| Saransk, Mordovia | 80 |

| Kazan | 80 |

| Samara | 70 |

| Penza | 80 |

- the place of discharge of treated effluents is determined. Options may be considered here to collect clean water and reuse it or dispose of it in roadside ditches or other bodies of water;

- a layout of the elements of the treatment system is drawn up.

The design of treatment facilities and the choice of their installation site should preferably be drawn up by specialists or with their direct assistance.