Do-it-yourself coupling installation

For connecting HDPE pipes during the construction of a pipeline for sewerage, water supply etc electrofusion couplings will need to prepare:

- tape measure and marker;

- pipe cutter;

- sandpaper;

- acetone;

- special welding machine.

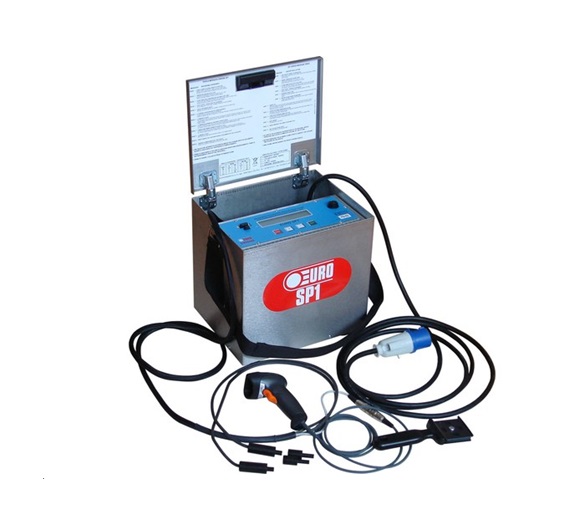

Apparatus for installing electrofusion fittings

The device for mounting electrofusion couplings can be rented from specialized stores.

The clutch installation technology is as follows:

- pipe preparation. The polyethylene pipe is cut in accordance with the dimensions established by the scheme of the future pipeline. The cut is made as even and clear as possible at an angle of 90º. Otherwise, it will not be possible to achieve complete tightness of the connection;

Preparing pipes for connection

after cutting, the ends of the pipes are cleaned of burrs and other roughness, completely cleaned of dirt using acetone or any other type of solvent;

pipes are very carefully fixed in the fitting

It is especially important to monitor the installation of pipes in the connecting element if old-style couplings are used for assembly, which are not equipped with special fasteners or large couplings, in the manufacture of which fasteners are not mounted; For a more correct installation of the fitting, it is recommended to pre-mark the distance on the pipe, which will be located inside the connecting element

For a more correct installation of the fitting, it is recommended to pre-mark the distance on the pipe, which will be located inside the connecting element.

Proper connection of pipes and electrofusion fitting

- an apparatus for heating and melting threads is connected to the electrofusion coupling, due to which the fitting is fixed;

Preparing to Install the Coupling

- the equipment is configured in accordance with the technical documentation supplied with the fitting. If an automatic welding machine is used to perform the work, then this step can be neglected, since the equipment will independently select the optimal operating mode;

- welding is performed in accordance with the indications of the indicator;

- after completion of work, the cables are removed, and the finished connection is kept until it cools down completely, which takes approximately 20-30 minutes;

- tightness and strength of welding are checked.

The step-by-step process of installing an electrofusion coupling is shown in the video.

Electrofusion couplings do not require special maintenance during the entire period of use. If during operation the fitting becomes unusable, then its complete replacement will be required.

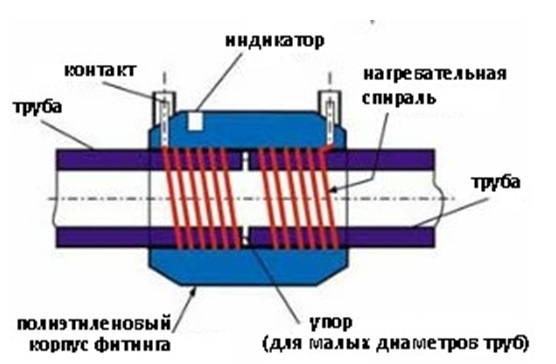

Electrofusion coupling device

A standard electric welding socket consists of the following elements:

- housing, which can be made of different grades of polyethylene;

- heating threads. Currently, threads made of copper or carbon are used. Carbon threads heat up faster, but such a fitting also costs more;

- contacts for connecting terminals of welding equipment;

- fasteners located on the pipe and designed for more durable joining of the fitting and pipes;

- indicator by which you can determine the progress of welding.

Components of an electrofusion coupling

Fitting Advantages and Disadvantages

The main advantages of couplings designed for connecting pipes by electric welding are:

- versatility. Couplings can be used in the construction of any pipelines (water supply, sewerage, gas supply, and so on);

- durability;

The average service life of an electrofusion coupling when properly installed is 50 years.

- resistance to corrosion;

- resistance to pressure and temperature drops in the pipeline;

- ease and simplicity of installation;

- variety of shapes and sizes of connecting fittings.

Significant disadvantages of PE electrofusion fittings is the impossibility of their use under the following conditions:

- at temperatures below 0ºС;

- at temperatures over 40ºС;

- at pressure in the pipeline over 16 atmospheres.

Coupling selection criteria

When choosing electrofusion fittings, consider:

- type of connecting element;

- fitting dimensions;

- manufacturing company.

Types of electrofusion fittings

The type of fitting is selected depending on the characteristics of the connection of the pipeline system and in accordance with the network diagram. Electrofusion fittings are intended for:

- for welding pipes at different angles;

- for connecting pipes of the same diameter;

- for screeding pipes of different diameters;

- to connect an additional outlet.

Selection of the type of electrofusion coupling

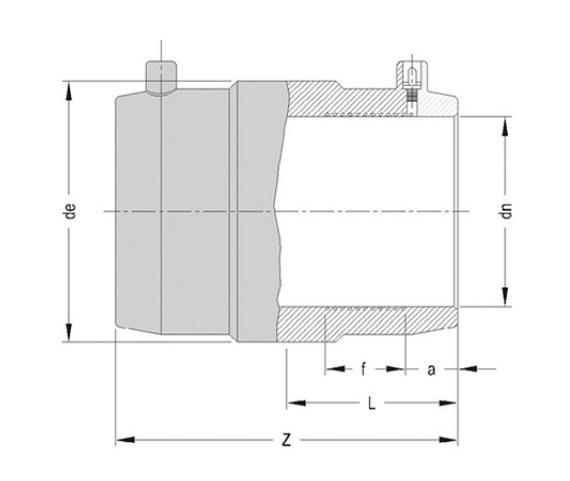

Variety of sizes

The next parameter is the selection of the overall dimensions of the connecting element. The overall dimensions are:

- inner diameter (dn);

- outer diameter (de). ;

- fitting length (Z);

- length of one component of the fitting (L);

- distance to the terminal and from the terminal (f) to the edge of the coupling (a).

Main dimensions of fittings

Couplings with diameters from 20 mm to 400 mm are currently produced. The pipe tie will be of better quality if the technical parameters of the fitting fully correspond to the parameters of the pipes to be connected.

Manufacturers

To ensure the quality of the weld and the fitting used, it is recommended to select connecting elements from the most popular manufacturers, which include:

- Chiorino (Italy);

- Optibelt (Germany);

- Nupigeco (Italy);

- Ammeraal Beltech (Holland).

The products of these companies are made from high quality materials in compliance with all norms and rules, which allows achieving the maximum quality of electrofusion fittings.