Pyrolysis plants of small manufacturers

If you cannot afford to make a pyrolysis unit on your own, and imported models are too expensive, then you can purchase a small-scale production unit. In the latter case, a number of rules must be followed:

- Request a license to manufacture this equipment. The license is not a complete guarantee of the purchase of reliable and efficient products, but the risk of purchasing low-quality equipment is significantly reduced.

- Evaluate the appearance of the unit, the quality of the welds. If possible, look under the decorative trim.

- If ceramics were used in the production, then it is necessary to clarify the price of replacing the nozzle, which can be up to a third of the cost of the pyrolysis unit.

- Determine for which heating system this equipment is intended - open or closed.

For example, bastion gas-generating boilers, according to the owners, work quite normally in brick housing construction, even in regions with cold winters. Although the duration of burning on one bookmark in winter is approximately 5-6 hours.

It is necessary to purchase with some power reserve. This is due to the fact that consumers are far from always able to get perfectly dry fuel.

Gas generating or pyrolysis (according to the principle of operation) boilers are in demand due to high fuel economy combined with attractive efficiency.

Fuel for gas generating boilers

The undoubted advantage of gas-fired boilers is the fact that they can operate on almost any type of solid fuel. That is, they can be loaded with ordinary chopped firewood, as well as any types of wood waste (sawdust, shavings) and briquettes, pellets and the like made from wood waste. In addition, gas generators are practically waste-free production: the fuel in them burns almost without residues.

Advantages of gas-fired heating installations

The installation of heating systems powered by gas-generating boilers operating on wood fuel has the following undoubted advantages:

- Extremely high fuel combustion efficiency. In any plant designed to burn wood fuel, but not using the pyrolysis effect, the efficiency cannot rise above 90 percent.

- Gas generator sets are non-volatile and can be installed even in buildings that do not have a connection to a stationary power grid. Note that during the war, gas generators were placed even on cars. The energy independence of the gas generator set also reduces the cost of its operation.

- Almost any type of wood fuel can be used in a gas generating plant, from classic firewood to wood waste. The use of wood waste, sawdust, wood chips and so on significantly reduces the cost of gas generating systems. However, remember that out of the total amount of fuel at a time, the percentage of wood waste should not exceed 30 percent.

- Large volumes of the combustion chamber allow gas-generating boilers to operate for a long time from one fuel load, which facilitates the operation of such an installation.

Disadvantages of gas generating plants

Despite all the attractiveness of heating and heating systems based on gas generating installations, such devices also have certain disadvantages. The disadvantages of gas generating systems generally coincide with the disadvantages of conventional solid fuel boilers.

A solid fuel boiler, unlike automated liquid or gas systems, has limited autonomy. Such a boiler always needs a human operator who will add fuel as it burns. Also, the gas-generating boiler must be regularly serviced, cleaned of soot and soot. Despite the almost complete combustion of organic wood fuel in gas-generating boilers, decay products are still present in such systems.

The acquisition of a system with a gas-generating boiler is quite costly financially. According to rough estimates, a gas-generating boiler will cost you one and a half times more than a conventional solid fuel boiler. But the difference in cost should pay off after a few heating seasons, based on the higher efficiency of the gas-fired boiler.

Also, when operating gas generating installations, it is necessary to use only dry fuel. On wet wood or sawdust, the pyrolysis process may simply not start. Therefore, gas-fired boilers are often equipped with a drying chamber in which the fuel reaches the desired condition.

Boilers of long burning on wood for the house

Solid fuel thermal installations are not new. In various variations, they have been used since time immemorial. While burning fuel in huge quantities was not a problem for anyone, they did not lose their relevance. However, in modern conditions, such a wasteful attitude to resources is inappropriate. Because of this, long-burning wood-fired heating boilers have become widespread. For their functioning in the operating mode, several times less firewood is required than in direct-flow furnaces and boilers.

Solid fuel boiler of long burning in the context

The installation is a furnace with two chambers. Firewood is loaded into one of them. They slowly smolder from top to bottom with minimal access to oxygen. One portion of firewood is enough for 12 - 15 hours of boiler operation. As a result of this smoldering, pyrolysis gas is released, which is forced through the nozzles into the second chamber. There it is subjected to intense combustion. After all, air enters this compartment in sufficient quantities. During combustion, a large amount of heat is released, which heats the liquid inside the circuit.

To increase the efficiency of the heating boiler, you need to take care of the insulation of the house

In addition to being economical, these boilers are highly environmentally friendly, as they are able to break down organic substances from fuel with almost no residue. Therefore, the smoke from such furnaces is completely safe for humans.

Useful advice! To get the maximum benefit from long-burning wood-fired heating boilers, you need to purchase their combined options. Such installations are also capable of operating on ordinary natural gas. Switching between modes in them is carried out automatically.

The structure of a solid fuel boiler for long burning

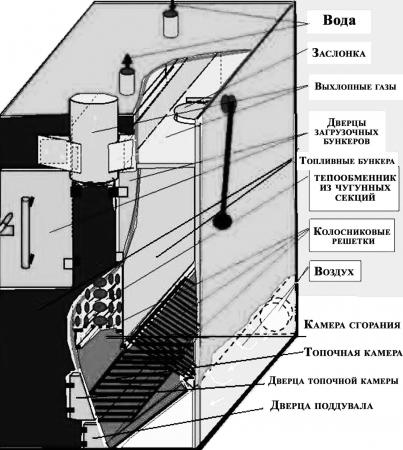

Blagodarov gas boiler

During the operation of the Blagodarov boiler, all substances that are produced as a result of combustion are burned.

The design of such equipment consists of 3 parts. These are combustion and gasification chambers and a bunker for burning fuel combustion elements. The fuel material burns in the 1st of 2 chambers, in the 3rd it becomes a gas.

The undoubted advantage of this heating equipment is the long burning of fuel (the device surpasses other heating boilers in this indicator) and good heat transfer. It, regardless of electricity, always gives out the power that is required.

In the process of burning firewood and wood processing waste, the grate covering the bottom of the fuel chamber contributes to the formation of a high level of heat under natural draft conditions.At the Blagodarov boiler, it is possible to expand the volume of the fuel bunker, while the efficiency of the device will not suffer. The rails installed in the combustion chamber are a good heat accumulator.

Coal, sawdust, peat can be used as fuel. In winter, the fuel chamber can be regularly replenished so that the optimum temperature is maintained in the heated room.

Device Features

Such heating devices have two combustion chambers. In the first, the decomposition of solid fuel combustible material occurs. In the second - the combustion of the resulting pyrolysis gas (it can be located in relation to the gasification compartment from below, above or on the side).

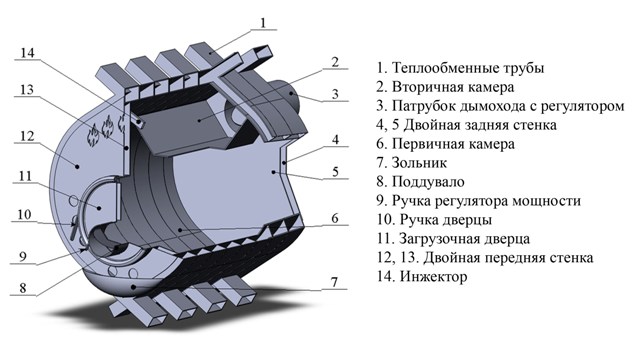

The classic gas generating furnace consists of the following elements:

- body (all structural elements are installed in it);

- filling hopper (solid fuel is placed there - firewood or wood industry waste);

- post-combustion chamber (combustion of pyrolysis gas occurs in it);

- grate grate (it serves to hold solid fuel material);

- doors (with their help, firewood is loaded into the equipment and the remains of combustion products are removed);

- air dampers (thanks to them, you can control the supply of oxygen to the working area of \u200b\u200bthe device).

Depending on the type of furnace, its characteristics, the gas generator either heats the coolant jacket, or transfers thermal energy to the environment, or combines both of these functions.

Advantages

Gas-generating heating devices have a lot of advantages, which led to their widespread use for heating country houses, cottages, and outbuildings. Their efficiency is many times higher than the efficiency of traditional heating equipment. In furnaces of this type, it is possible to regulate the temperature of the coolant, to control their operation. In this case, simply increase or decrease the oxygen supply to the furnace.

Such devices can be heated not only with firewood and wood processing waste, but also with coal, peat and, most surprisingly, linoleum.

The most common type of wood burning gas generator is the pyrolysis oven. Gas is not taken from it, but completely burned, resulting in the formation of thermal energy.

What air heating equipment is the best

Buyers have many questions regarding a long-burning stove: how to choose the best model or development, where can a catch be hidden? All models of this type of equipment have their own advantages and disadvantages. The choice must be made based on the requirements of a particular room.

Butakov oven, design.

Butakov's heating device. This is a long burning convection oven, which has the following structure:

- steel or cast iron body;

- combustion chamber;

- ash pan;

- convection pipes that run throughout the chamber;

- door with convector;

- chimney;

- adjusting gate.

Compared to the Canadian counterpart, the Butakov furnace is not divided into two chambers. However, this fact does not affect the performance of the device. Thus, the efficiency of Butakov's heating equipment reaches 80-85%. The principle of operation of the Butakov furnace, like all air heating devices, is based on two phenomena: pyrolysis and convection.

Pyrolysis takes place directly in the combustion chamber, where firewood is laid. Under the action of high temperature and in an environment of insufficient oxygen, organic matter decomposes into gas and water. The latter comes out with combustion products. Carbon monoxide and a mixture of other wood derivatives in the upper part of the chamber ignite, as secondary, heated air is supplied there. The temperature of the upper part of the Butakov furnace furnace is much higher compared to the lower part, and therefore is often used for cooking.

Air convection passes through the pipes.They are located in the upper part of the furnace at a certain distance from each other and at the right angle. Such a device device provides the fastest possible passage of cold air from the lower part of the room and its maximum heating. Air convection also occurs through the appliance door. There you can see the corresponding holes.

Butakov's long-burning metal furnace has a significant advantage over other models of similar devices. Its chimney is located in such a way that condensate does not accumulate in the tank, but flows down the walls of the pipe, falling into the combustion chamber, where it burns.

The principle of operation of the Buleryan long-burning furnace.

What is a Buleryan oven. If we compare Butakov's and Buleryan's long-burning furnaces, then the second one has two chambers in the furnace section, which improves its efficiency. Thus, the efficiency of Buleryan heating equipment reaches 85-90%. In addition, today there is a Buleryan-Aqua furnace for sale, which is suitable for servicing a water heating system.

The device has the following structure:

- oval body made of steel or cast iron;

- collectors;

- injectors;

- upper combustion chamber;

- lower combustion chamber;

- chimney with damper;

- door with gate;

- ash pan.

These are the most efficient long-burning stoves, since their original design allows you to blow air into the convector with injectors without the help of an electric fan. Natural air circulation occurs due to a noticeable temperature difference at the inlet and outlet of the tubes. It is about 120°C.

Tying the furnace Buleryan-Aqua with a water jacket.

Air ducts can be connected to the oven convectors. This makes it possible to heat adjacent rooms. In conditions of elevated air temperature, which circulates through the pipes, it is recommended to use aluminum ducts. However, no one has canceled heat loss, and therefore the consumer, wanting to increase the efficiency of heat transfer, is obliged to insulate the ventilation wiring.

Another feature that characterizes the Buleryan-Aqua cast-iron long-burning heating furnace is the ability to connect a water heating circuit to it. The furnace is mounted in the heating system of both open and closed type. To do this, the pipes are connected to the convectors of the heating equipment. And now it is not air that circulates through the pipes inside the furnace, but the water of the heating circuit. Such wiring has one significant disadvantage - cold water cools the combustion chamber. As a result, the efficiency of the furnace also decreases, as a result of which the amount of energy carrier used increases.

The disadvantage of the device is the accumulation of condensate in a special container. Also, when using an energy carrier with a high percentage of moisture, oily deposits form on the inner surface of the chimney. They harden over time, making cleaning difficult.

In addition to the above options, experts advise to build long-burning stone stoves for a summer residence or a country house. How it works and how it works are described in the video:

Do-it-yourself installation according to the drawing, calculation of power 2.5 MW

Given the fact that factory gas-generating boilers are expensive, and the design is simple, owners increasingly prefer to make the unit with their own hands. It is not difficult, but the work requires the following steps:

Schema creation. Device and drawing are inseparable concepts

Calculate the capacity of the generator, thermal power, the presence of a second circuit or supply to the heating pipes - it is extremely important.

The right choice of metal for construction. Considering that the combustion temperature is high, thin tin barrels from fuel and lubricants will not work

Heat-resistant steel and cast iron are ideal, but the latter is brittle during sudden cooling or mechanical damage.

Welding skills.The do-it-yourself wood-burning unit must be airtight, so welds are required, without flaws. Bolted and threaded connections are not allowed.

If the conditions are met and the components - grate bars, asbestos gaskets, branch pipes - are purchased, proceed to assembly. Instruction:

Case assembly. A ready-made container is adapted for it or boiled from metal. The volume is calculated individually.

Inside the future wood-burning generator, a combustion chamber is being built, occupying a third of the body volume. The grates are immediately installed, a hole for air inflow is cut out and a blower and furnace door is installed.

The combustion chamber is connected to the gas combustion tank - the second third of the body - through a pipe

The gases cool naturally, so it is important to make this connection outside the generator.

An air distribution system is arranged in the upper part of the body. It also has an entrance to the gas combustion chamber, but is equipped with a check valve.

It remains to weld a water jacket to the second third of the body - a heat exchanger for the water circuit, weld a cover with a chimney pipe and equip the finished gas generator for the house with supply openings in the air distributor system and a fuel combustion chamber. The latter is equipped with a low power fan.

So, with his own hands at home, the master will create a very useful and economical design - a fuel boiler that works on any garbage.

Alternative application: homemade version for a car

WATCH VIDEO

Now a car on firewood is a rare phenomenon. Once upon a time at the turn of the 30s and 40s, the use of firewood energy was popular, however, personal cars looked like bulky rattles - you had to carry a whole generator station with you if you wanted to drive fast and a lot. Nevertheless, the owners of subsidiary plots, for cultivating their own lands, the design would be very useful - you should think about it and use a wood-burning gas generator with your own hands, not only for heating. A wood burning gas generator is a great option for heating a room!

Flaws

- The main disadvantage can be considered the high cost of a solid fuel gas-generating boiler, but you need to remember that operation and maintenance are cheap, and you will buy a boiler for many years.

- Increased requirements for quality and, especially, for fuel moisture.

- To remove burnt substances after pyrolysis, smoke removal is required. This means that the use of solid fuel gas-generating boilers is possible only in houses where it is possible to bring the pipe into the atmosphere, while not causing inconvenience to neighbors. Therefore, it is hardly applicable in high-rise buildings.

- Some temperature limitation. To prevent condensation, the temperature of the water coming from the heating system should be about 60 degrees.

- It is impossible to automate the supply of solid fuel to the furnace.

- High requirements for tightness of solid fuel gas-generating boilers. An explosion or fire may occur due to leakage of flammable gas.

Possibility of self-manufacturing of the unit

The high prices for pyrolysis-type solid fuel equipment explain the desire of many consumers to make a gas-generating boiler with their own hands, drawings and a detailed description for it are usually provided in a paid version.

One of the schemes was developed by designer Belyaev and involves the creation of a unit capable of providing a thermal power of about 40 kW. Air acts as a heat carrier in this system.

For the manufacture of a pyrolysis-type unit, you will need: a sheet 4 mm thick and pipes, the wall thickness of which must also be at least 4 mm, shaped pipes, a rod with a diameter of 20 mm, asbestos cord, fasteners. For the manufacture of the lining of the heating installation, fireclay bricks are needed.To ensure the efficient operation of the unit and its convenient operation, it is necessary to purchase thermostatic automation and a centrifugal fan.

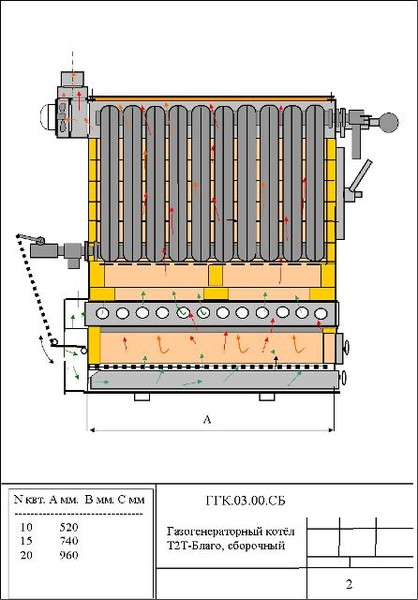

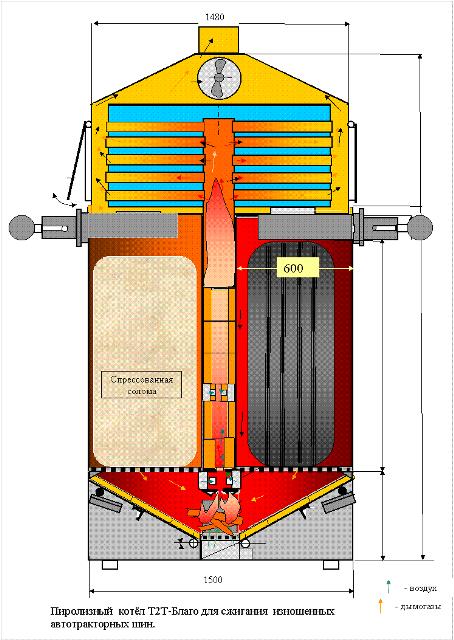

A do-it-yourself gas-generating boiler can be created using the scheme of the inventor Yu.P. The unit is called Blago.

This heating installation ensures long-term combustion of wood fuel with the formation of the maximum amount of heat.

Important advantages of the Blago boiler are its non-volatility and ensuring complete combustion of compounds of phenolic groups - resins, alcohols, essential oils.

The rails installed in the combustion chamber serve as excellent heat accumulators. Firewood, coal, sawdust, peat briquettes are used as fuel for Blagodarov's heating installations.

Advantages and disadvantages

To understand the full benefits of a long-burning unit, consider the advantages that the device will bring to its owner:

High efficiency - up to 95%. This means that the consumption of formed fuel is justified - the gas burns completely, without losing extra calories to the atmosphere.

- Long burning time. This feature frees owners from the constant loading of fuel, and with automatic settings, from constant monitoring. However, handicraft wood-fired boilers are no different and care is needed. In the case of a bright head of the owner, arranging security automation is not so difficult.

- Use of any kind of fuel. Only the material used in the construction of the unit will depend on it - home-made long-burning boilers on wood are made of thick iron, on coals alloyed steel or cast iron is already required.

- The amount of harmful substances entering the atmosphere of the house is minimized due to the tightness of the structure and the rare loading of fuel - the latter is put into the gas-generating boiler only after the previous portion has completely burned out.

The main criterion for choosing a unit for heating by owners of private houses is obvious efficiency. Benefit is derived from any garbage that has the ability to burn, firewood may not be needed. Infrequent loadings allow saving on wood fuel, which is required 3-4 times less than a standard stove. Thanks to stable operation, the heat of the house is kept at the same level - there is no need to heat the frozen rooms and, accordingly, spend a certain amount of raw materials on heating.

Cons: schematic

Unfortunately, gas generation is not possible without forced ventilation, therefore, a wood-burning boiler for heating is considered energy-dependent, since a fan is used. During power surges, it is impossible to leave the boiler unattended, so the problem is solved by connecting an uninterruptible power supply - a device that supplies the accumulated electricity.

It is important to maintain a working wood-burning gas generator in a given mode in a timely manner - a decrease in power leads to the formation of tar that settles on the walls of chambers, gas ducts and furnace doors. Therefore, when choosing a factory unit or assembling your own design, it is important to take into account the needs and not purchase an overly powerful boiler for use.

DIY drawing

According to the previous paragraph, the temperature of home heating should not be less than 60⁰С. If this becomes a problem for the owners - a small room, a summer house, intolerance to heat - you should purchase a different solid fuel boiler, and not a wood-burning generator.

Features of the operation of wood boilers with long burning

The burning time of one bookmark of firewood is from 8 to 24 hours. The battery life depends on several factors:

- Boiler type.

- Fuel quality.

- Proper operation.

Learning how to heat a boiler correctly is much easier than it might seem at first glance.During kindling and further operation, adhere to the requirements specified by the manufacturer in the technical documentation. After a few fires, the process becomes habitual.

How to achieve long burning wood

The consumption of firewood, subject to the use of the long burning mode, is 30-40% less than in conventional boilers. The efficiency reaches 92%. Not all consumers manage to get the boiler to work in the long burning mode the first time. Some complain about the copious release of resin during the burning of wood.

You can achieve long-term burning of firewood by carefully following the manufacturer's recommendations:

- Firewood is kindled with a fully open damper.

- In the mode of long burning, the boiler is transferred only after reaching a temperature of 600 ° C.

- The humidity of firewood should not exceed 20%. Heating with coniferous wood is not recommended.

Violations of the rules of operation leads to the fact that tar is formed from firewood in the boiler. Most often, the following conditions are not met:

- The minimum outlet temperature of the coolant must not fall below 65°C.

- It is correct to heat the boiler with hard wood: aspen, beech, acacia, oak, etc.

- The high humidity of firewood leads to an abundant release of resin.

Proper operation of long-burning boilers extends the life of the equipment and increases heat transfer.

How to properly load firewood

Stacking firewood in the boiler is carried out in accordance with the following rules:

The logs are split into large pieces.

Stacking firewood in the firebox is carried out as tightly as possible

It is important to avoid voids between logs.

The length of the logs should be less than the size of the loading chamber, at least 5 cm.

Ignition is carried out exclusively with dry splinters. It is forbidden to use gasoline or kerosene to kindle firewood. From time to time, it is recommended to use special chemical briquettes that remove tar deposits on the walls.

How much firewood do you need for the winter season

The device of a long-burning boiler allows you to save on fuel, approximately 15-30%, depending on the model chosen. The approximate consumption of firewood is calculated as follows:

- It is generally accepted that for heating every 100 m², 3 Gcal / month will be required.

- When burning a kilogram of firewood, 3200 kcal is released.

- To get 1 Gcal, long-burning boilers burn 312 kg of firewood.

- To obtain 3 Gcal, approximately a ton of wood is required.

During the heating season, 7-8 tons of firewood are needed to heat a house of 100 m².

Rules and regulations for the installation of a long-burning wood-burning boiler

The installation of a long-burning boiler is carried out in compliance with the standards applicable to all wood-fired boilers. During installation work, the existing requirements of PPB and SNiP are taken into account:

- Installation is carried out on a solid non-combustible base. The walls and floor are lined with non-combustible building materials.

- The chimney is carried out in compliance with fire safety cuts. At the junction with the wall of combustible material, fire-resistant insulation is laid. The material is lined with steel sheet.

Water heating from a long-burning wood-fired boiler is connected to special outlets located on the boiler body. The instructions indicate in detail which pipe goes to the supply and return of the water circuit.

A boiler with a capacity of more than 40 kW is installed in a separate room.

Volatile boilers are connected to the power supply through a stabilizer and an uninterruptible power supply. Be sure to use the machines. The connection is made directly from the switchboard.

In the room used for the boiler room, it is necessary to have supply and exhaust ventilation and natural lighting. If necessary, it is allowed to place the boiler in the basement.

How to DIY

- a thick sheet of metal or an iron pipe (you can use a barrel);

- corners made of steel (5 × 5);

- hinges, door latches;

- chimney pipe;

- rebar bars.

The number of materials and various additional elements depends on the size of the room and the tasks assigned to the heating equipment.

The oven has two compartments. The afterburning chamber will be a special labyrinth located at the top of the device. It is made of metal plates, placing them parallel to each other.

It is made in a rectangular shape, while several metal sheets are welded together. You can use a ready-made barrel or a piece of thick-walled pipe.

Preparing Work Items

First you need to mark and then cut out the details of the future furnace: sides, top, panel for the grate, plates for the gas labyrinth (3 pcs.). The edges of such elements must be cleaned with a grinder.

A round hole is cut out in the upper element of the furnace, a chimney will be connected there. In the front wall of the body, hatches are made in the form of rectangles (for firewood and a blower).

Metal pieces that act as doors are ground and hinges are attached to them. The edges of such structures must be scalded to ensure a snug fit.

Plates for gas labyrinth

At 10 cm from the top of the facade, perpendicular to it, a plate is installed. It should be 7 cm shorter than the length of the entire heating device. Behind it, two more plates of the same size are attached to it. The indent from the top is 15 cm. After the complete assembly of the furnace, this design will become a gas labyrinth that slows down the movement of gas.

Installation of grate

Corners (2 pieces) must be welded to the sides of the body at the same height. A grate will be installed on them. It is made from reinforcement rods or from a metal sheet with a large number of slots.

final assembly

All parts are connected with a corner by welding. The edges are cleaned with a grinder and painted with a refractory compound.

Such a home-made stove can heat small utility rooms. After assembly, it must be tested. If everything is done correctly, the device will start heating the room quickly enough (within 30 minutes).

Precautionary measures

It is impossible to convert a conventional furnace into a gas-generating one. Such manipulations will only lead to smoke building. In order to fully use the gas generating device, it is necessary to take into account its shortcomings.

At the outlet of such equipment, cold gas is formed. If the chimney is not properly insulated, condensation will form. Moisture will drain back into the appliance. Therefore, experts recommend the use of insulated sandwich structures. They consist of 2 pipes nested in each other, between which there is a heater.

In order for the gas generator to work as efficiently as possible, it is necessary to install an economizer (optional equipment).