Manufacturer rating

Knowledge of the most popular manufacturers of submersible pumps for the well will allow the buyer to purchase a quality product. The rating of manufacturers of these products is based on sales statistics, as well as feedback from users of equipment. The following are companies that have enjoyed the trust of customers for a long time due to the good assembly of the goods:

- Gilex;

- Aquarius;

- Aquario;

- Vortex;

- Patriot;

- Livgidromash.

These manufacturers specialize in the production of different classes of devices, which include:

- deep well pumps of centrifugal type - located in a liquid medium;

- vortex water pumps - submersible devices differ from the previous version in the presence of a tightly fitted wheel and blades to increase the water pressure;

- screw pumping stations - the operation of a volumetric device is based on the launch of an auger that directs water into the supply pipe;

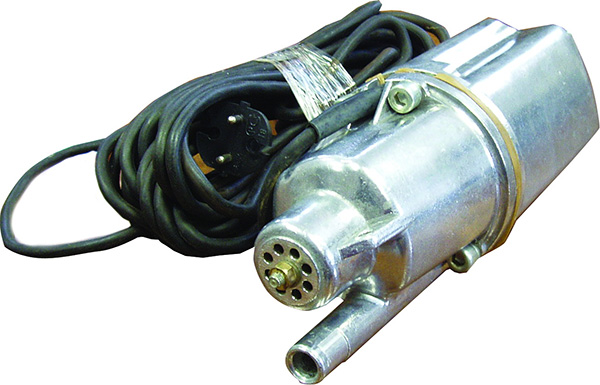

- vibration pumps for wells - during operation, they create reciprocating movements after the electric current is supplied to the winding.

Before you decide which pump is best for a well, you should choose the manufacturer and product series you like the most.

|

Place in the ranking |

Name |

a brief description of |

|

Submersible pumps for wells |

||

|

1 |

The most powerful in pumping water - overtakes more than 3.5 cubic meters per hour. |

|

|

2 |

Grundfos SQ 2-55 |

The most durable of the entire line of equipment is the perpetual motion machine, as users usually call it. |

|

3 |

The most "absorbed" - works at a depth of more than 80 meters. |

|

|

Submersible pumps for wells and open water |

||

|

1 |

The optimal combination of quality, price and features. |

|

|

2 |

Creek-1 |

Reliable, solid, domestic and the cheapest in the line. |

|

3 |

Grundfos SBA 3-45 A |

Grundfos consistently produces the most durable units that can work in any conditions. |

|

Drainage pumps |

||

|

1 |

Grundfos Unilift KP 150-A1 |

Ideal for very dirty liquids – all components are very robust. |

|

2 |

Karcher BP 1 Barrel |

In terms of quality characteristics, it is second only to Grundfos, which does not make it less reliable. Germans, what can I say. |

|

3 |

VORTEX DN-400 |

In Russia, the most popular is inexpensive, repaired in every service center. |

Installation and assembly

You can install a pump with a grinder and a submersible unit, without this device you can do it yourself, observing safety precautions and the technological sequence of the installation process. In this case, the following actions are performed:

- A non-return valve is installed on the pump nozzle to prevent water from draining when the power is turned off.

- A filter is mounted on the suction pipe.

- Then the discharge pipe is connected, through which the water will move upwards.

- A power cable in a waterproofing braid is passed through the discharge hose, securing it with clips.

- A polymer twine is threaded through the brackets in the upper section of the body part, on which the pump will be held.

- The unit is carefully lowered into a well or well.

- The rope is fixed on a bracket located on the outer part of the casing pipe.

The pump installation process is shown in more detail in the video:

The cost of installation and maintenance of equipment:

| Name | price, rub. |

| Replacement of a submersible pump in a well up to 100 m deep with a 133 mm casing | 15000 |

| Replacement of a submersible pump in a well with a depth of 100 to 150 m with a casing string of 159 mm | 20000-25000 |

| Replacement of pumping equipment in the well | 8000 |

| Diagnostics | 3000 |

Start-up, adjustment and verification of the settings of the automatic part of the equipment are included in the total cost of work.

Main selection criteria

The choice of a deep pump can be made according to several criteria. The following are the main recommendations:

- The depth of the well and the water level in it. The pump is often chosen according to the depth of the well, since this indicator determines the amount of load exerted. Almost all manufacturers in the equipment passport indicate for what depth it is designed. When creating a well, this moment will also become known. Pump models should be selected with a margin in terms of the recommended well depth.

- Need for water. When designing a water supply system, it takes into account how much water is needed to meet all needs. In most cases, this figure is taken as an average. Depending on the selected pump model, the performance indicator can be from 20 to 200 liters per minute. One person per day can consume up to 200 liters. For a country house in which 4 people live, a pump with a performance indicator of 30-50 liters per minute will be quite enough. It is worth considering the moment that with an increase in the performance indicator of such equipment, its cost, as well as power consumption, increases significantly.

- The debit of a well is an indicator that determines the maximum amount of water received for a certain period of time. Often this indicator determines how long the equipment can work without stopping. It is rather difficult to determine this indicator, since during prolonged operation there is a possibility of overheating of the structure.

- Cost of equipment. You can solve all possible problems by purchasing expensive devices that will have higher performance. However, they will cost several times more than budget options. It is worth remembering that cheap equipment will not be able to last for a long time and will cause quite a lot of problems.

In general, we can say that in order to purchase the most suitable equipment, it should be selected in terms of well depth and productivity. In this case, the main structural element is an electric motor, which can have a different power rating. The higher the power rating, the greater the cost of paying for electricity.

Choosing a submersible pump depending on water quality

Another important indicator is the presence of impurities in the water. This is due to the fact that some models are very susceptible to the impact of a flow that has an admixture of a large fraction. An example is the following information:

- Some designs can filter water, others can't. This determines whether periodic maintenance is required.

- Vibrating models, due to design features, are less susceptible to impurities, vortex or centrifugal models can quickly be damaged due to the presence of an element called an impeller. Impeller - blades located on the wheel, which capture the flow and ensure its movement in a spiral.

The working chamber of vibration models does not have elements that can be deformed during prolonged operation. In turn, the impeller is made of a soft material, the deformation of which is possible when a large impurity enters.

If it is necessary to ensure a long supply of water, vortex or centrifugal models are installed that have an impeller. This is due to the fact that such designs are more suitable for long-term use.

On sale you can also find versions with a chopper. They are suitable for installation in the event that the pump is installed in a well, in which an admixture of clay or other substance is likely to appear. The grinder is able to reduce the size of the impurity, which increases the service life of the structure.

SQ Series Downhole Pump

Models of this series are widely used due to their reliability, practicality and safety.

Their main advantage is the possibility of application in wells of small diameter.

Specifications:

| Parameters | Indicators |

| Performance | 9 m3/hour |

| Dimensions | 74 x 677…74 x 902 |

| Working voltage | 220 W |

| Permissible temperature of the pumped liquid | Up to +40 degrees |

| Maximum allowable pressure | 150 bar |

| Maximum fluid head | 200 m |

| Noisiness | Less than 70 dB |

| Solid impurities | Not more than 50 g/m3 |

Design features:

- The material of the pump housing is aluminum-cast iron alloy with anti-corrosion coating. Other parts of it are made of polyamide with the addition of fiberglass.

- In the configuration of the electrical part of the engine there are permanent type magnets that increase its performance.

- Due to the presence of an upper thrust bearing, the impeller is protected from "lifting up" as a result of its displacement, in the case of pump operation at low pressure.

Models and prices:

| Varieties | Head, M Hg | Fluid speed | Prices |

| SQ 1 - 35 | Up to 50 | 1.7 m3/hour | 38900 |

| SQ 1 - 50 | Up to 70 | 42100 | |

| SQ 1 - 65 | Up to 85 | 45300 | |

| SQ1 - 80 | Up to 118 | 54700 | |

| SQ 1 - 95 | Up to 140 | 57000 | |

| SQ 1 - 110 | Up to 167 | 59200 | |

| SQ 1 - 125 | Up to 190 | 70500 | |

| SQ 1 - 140 | up to 212 | 72900 | |

| SQ1 - 155 | up to 238 | 75300 | |

| SQ 2 - 35 | Up to 45 | 3.5 m3/hour | 40200 |

| SQ 2 - 55 | Up to 68 | 42800 | |

| SQ 2 - 70 | Up to 88 | 47400 | |

| SQ2-85 | Up to 109 | 53100 | |

| SQ 2 - 100 | Up to 132 | 65800 | |

| SQ2-115 | Up to 155 | 68200 | |

| SQ 5 - 15 | Before 18 | 7.5 m3/hour | 38200 |

| SQ 5 - 25 | Up to 37 | 39900 | |

| SQ 5 - 35 | Up to 54 | 47400 | |

| SQ 5 - 50 | Up to 72 | 53100 | |

| SQ 5 - 60 | Up to 88 | 68200 | |

| SQ 5 - 70 | Up to 107 | 70400 | |

| SQ 7 - 15 | up to 21 | 9 m3/hour | 52500 |

| SQ 7 - 30 | Up to 43 | 57000 | |

| SQ 7 - 40 | Up to 64 | 72900 |

Other advantages of Grundfos SQ units:

- The presence of the "soft start" system, which allows minimizing the load when starting the device, providing additional protection of the engine from wear and damage.

- The presence of a thermal sensor that protects the engine from overheating.

- The presence of fuses to protect the pump from possible drops in the network.

- They are equipped with a “dry running” system that turns off the unit if there is not enough liquid in the source of its intake.

Video with a detailed overview of all the features of the SQ series pumps:

Materials used in the manufacture

On sale you can find a variety of versions of pumps. Their classification is also carried out according to what material is used in the manufacture of the main elements. The body is the main protective element. It can be made from:

- Plastic. This material does not react to the effects of high humidity, corrosion does not appear on the surface, and the main performance characteristics remain unchanged throughout the entire service life. However, plastic has one drawback - low protection against mechanical stress. Therefore, the version with a plastic housing is installed in special rooms that provide the required protection.

- Cast iron. For many years, it was cast iron that was used in the manufacture of the hull and other structural elements. This is due to the fact that such material also does not respond to exposure to high humidity and has a long service life. Also, the price of cast iron is low, it can take a variety of forms. But there are also significant drawbacks: a lot of weight and fragility.

- Stainless steel. Steel has high strength and reliability. At the same time, the material has a low cost and can be used to obtain a wide variety of shapes. However, steel has always had one significant drawback - it was covered with corrosion during prolonged contact with water or when operating at high humidity. They were able to solve this problem by changing the chemical composition of the metal, which increases its resistance to moisture. However, the achievement of corrosion resistance causes an increase in the cost of the alloy.

The remaining elements of the pump design can be made from a wide variety of materials, and, as a rule, the manufacturer does not indicate such information. It is recommended to install models with a cast iron and steel case for long-term use of the pump, but plastic is used mainly in the manufacture of portable models.

In conclusion, we note that another important selection criterion is brand popularity. Popularity is formed on the basis of performance and reliability of the design.If a model quickly breaks down and has problems, then it is not popular and vice versa. In addition, models whose price is higher often have a more advanced design, but not always. On sale there are also fakes that will not last a guaranteed period. Therefore, you should purchase models that are covered by a long warranty.

Grundfos submersible pump automation

To maximize the power and functionality of Grundfos submersible pumps and more convenient work with them, it is necessary to use automatic installations with them to protect the device from voltage surges, sudden temperature fluctuations and dry running.

It consists of:

Pressure switch;

Performs the function of regulating the operation of the pumping unit, that is, turning it on and off at a certain pressure. It can have automatic and manual settings.

Cost: from 400 rubles. up to 5600 rub.

Level sensor;

Designed to protect the device from operation in unnatural conditions. For example, with a sharp shallowing and a critical decrease in the water level in the source of the intake. Can be float and galvanic.

Price: from 1010 rubles. up to 8900 rub.

Pressure meter.

Used to maintain constant pressure. Cost: from 800 rubles. up to 5700 rub.

In addition, additional elements may be included in the package of the automatic unit, for example:

- Dry running sensors;

- pipeline rupture controllers;

- Temperatures, etc.

At the moment, the third generation of automatic systems has been released, which is distinguished by high power and reliability. True, complete with Grundfos pumps, the price of such devices is quite high, but they work out the money spent on their purchase in full.

- After assembling the system, a hydraulic accumulator is installed on it.

- A pressure switch is attached to it.

- All elements are connected.

- If necessary, the unit is connected to the power supply.

- The upper position of the relay is adjusted.

- Sets the difference between the top and bottom positions.

- The system is tested in action, after which, if necessary, the settings are changed in the right direction.

What to choose a deep pump or pumping station

To pump out a liquid medium from a well or a well of great depth, not only submersible pumps can be used, but also pumping stations consisting of a whole set of technical devices. The question of what to use to service a well or a well - such a station or a deep pump, is often faced by owners of country houses and summer cottages who decide to equip an autonomous water supply system.

The composition of the pumping station, in addition to a powerful surface pump, includes a storage tank, which is called a hydraulic accumulator. The liquid medium pumped out from a well or well is first sent to such a tank and only then, when a certain pressure is established in the accumulator, is it fed into the pipeline system.

The pumping station will provide the country house with water supply in automatic mode

If we compare a pumping station with a deep-well pump, then, along with higher productivity, it also differs in significant dimensions, which should be taken into account when choosing a place for its installation. In addition, the construction of a pumping station will require more financial resources than the purchase of a submersible pump.

In any case, when choosing pumping equipment for equipping an autonomous water supply system, one should be guided by the parameters of the well or well from which water is to be pumped out, as well as the required amount of liquid for the needs of water supply and irrigation and its flow parameters.

Main series and their purpose

Depending on the design features and specifics of use, pumping devices of this brand are divided into several series:

SPO

This range includes pumps equipped with a grate in the suction section. Designed for pumping water from wells with a diameter of 5 - 6 inches, as well as from wells, pools and other containers.

SQ

This series is represented by three-stage and centrifugal models that can be operated in wells with different diameters. They are compact in size and easy to use.

KP

Drainage type. They are used for pumping clean and polluted water from reservoirs. Suitable for pumping liquids with solid particles up to 10 mm in diameter. They are light in weight and small in size. Suitable for watering vegetable gardens, orchards and vineyards.

SP

Models of the Grundfos SP series, which are four-inch pumps designed for pumping water with severe pollution (with the presence of sand in the composition up to 50 g / m3). They are distinguished by high power, reaching up to 470 m3/h, and can lift the pumped water to a height of up to 670 m. Absolutely tight due to the use of silicon carbide for mechanical seals. Their only drawback is their high price.