Why do you need a non-return valve for ventilation

During normal operation of the exhaust ventilation, air moves from the room to the street. Exhaust openings are located "in dirty or damp" rooms - a bathroom, a kitchen. The task of this part of the ventilation system is to remove odors and excessive moisture to the street. But sometimes a situation arises when air goes in the opposite direction through the exhaust ventilation - it enters the premises. This moment is called thrust overturning and they try to fight this phenomenon.

The check valve for ventilation is necessary for the normal operation of the system

Why fight backlash? In the case of apartments, this is fraught with odors from neighbors, which is very unpleasant. If we consider private houses, portions of outside air in them reduce the temperature in winter. The second point is more dangerous and unpleasant - with reverse draft, the boiler may go out, combustion products (and carbon monoxide too) can return to the room from the chimney. In any case, the reverse movement of the air flow is an incorrect operation of the ventilation system and this phenomenon must be fought. The check valve for ventilation is just set to block the movement of air in the wrong direction.

Additional Information

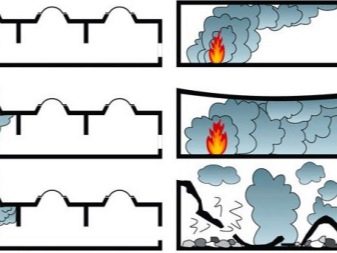

The principle of operation of the fire damper is also completely determined at the design stage. In this case, the static method is simpler than dynamic isolation. In the first case, the operation of the ventilation system simply stops. Because of this, the smoke cannot reach neighboring rooms, and that part of it that has already penetrated the outside gradually dissipates and does not pose a particular threat. At the same time, blocking the oxygen supply to the flame from the outside slows down the growth of the fire.

In dynamic systems, valves are assisted by fans that turn on at the command of sensors. With the natural method of removing burning, smoke is drawn out through the lanterns and smoke hatches

Attention: according to official requirements, smoke can only be removed from one source, that is, valves in other rooms will remain in their original position

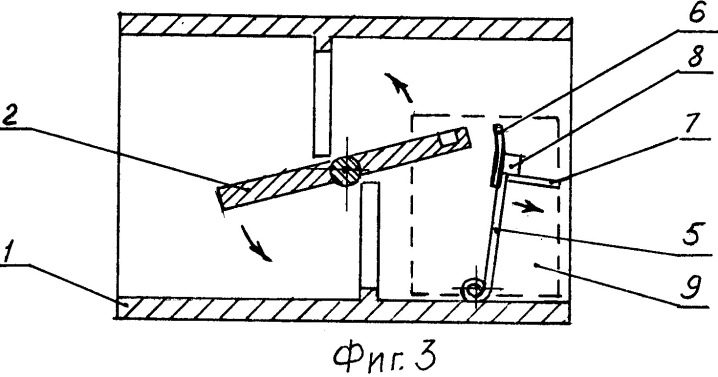

The valve itself is not very complex. A shutter is hidden in the metal case, blocking the clearance if necessary. Its start is carried out using the drive. As for the grilles that some models are equipped with, their role is limited to just external design. Valves are divided into those mounted inside the wall, as well as duct valves, which are placed in the ventilation shaft.

Drives are varied in execution. In addition to electromagnetic and electromechanical devices, standard solutions based on spring action are often used. After connecting the installed valves, it is mandatory to check the performance of the system as a whole. Commissioning work is completed by aerodynamic tests, the results of which are recorded in a protocol drawn up in a special form. It is quite reasonable to combine such tests with a fire drill.

Depending on the design, the type of drive used also differs. So, with a reversible electric drive, flange devices that remove smoke are usually supplied. But the systems that restrain the spread of fire are for the most part equipped with return springs. When selecting engines for torque, it is necessary to focus on the area that the air damper has according to the standard. Most developers prefer to make the voltage disappearance as a control signal, which provokes the movement of the shutter of the electromechanical apparatus from the initial state to the working position.

To hold the sash in its initial position, very little electricity is consumed. For your information: some of the actuators are equipped with thermal indicators, thanks to which the system is triggered if the heating inside the valve has reached a critical value. And in reversible models, the movement of the valves occurs due to changes in the circuit of the supply circuit. The undoubted superiority of reversible systems is due to the fact that they cannot accidentally work if the power is suddenly turned off for any reason. That is why such blocks are recommended for supply and exhaust devices.

A visual demonstration of the operation of the smoke exhaust valve is in the video below.

Troubles that may arise

Everything seems to be clear and logical: extraneous smells in the apartment are very unpleasant. Traction overturning in a private house is no less unpleasant, but also dangerous. In principle, with a properly calculated system, such phenomena should not occur, and the causes of occurrence must be dealt with. But not everyone has the opportunity and resources. It is easier to put a check valve for ventilation. This is true, but there are nuances that are worth knowing.

- A valve installed in the vent prevents natural ventilation. If you want natural exhaust to work, you need to think about the connection so that the valves do not interfere.

- Even the "quiet" valves made of plastic, when closed, slam, sometimes making quite loud sounds. These pops are stronger, the stronger the pull. With a variable wind, they are very annoying. So it will be necessary to think of something to make the valve "quieter".

- Some fans or cooker hoods have a built-in non-return valve. If the regular one does not suit you for some reason, it must be removed. Then you can put a separate one. Two valves on the same channel may not get along. Rather, the exhaust channel is unlikely to work.

- For normal operation, the check valve must be regularly serviced - cleaned, checked, lubricated axles. Given the fact that it is not always easy to get close to him, this is at least inconvenient. So consider the possibility of access for cleaning and revision.

As you can see, putting a check valve on ventilation does not mean solving the problem once and for all. You will have to monitor the state of the system and put up with the shortcomings of this solution.

Peculiarities

For any kind of technical systems related to fire safety, strict compliance with norms and standards is very important - even more stringent than for “ordinary” things. All major technical standards are aimed at ensuring that the ventilation system remains free of gaseous and solid combustion products for longer.

Related to this is another important task that the developers of fire-retardant complexes solve - how to increase the resistance of products to strong heat.

Therefore, quite a lot of attention is paid to the selection of materials and verification of their thermophysical properties. The duration of preservation of qualities at a certain temperature is also officially fixed.

The state standard for fire ventilation installations was developed back in 1969.

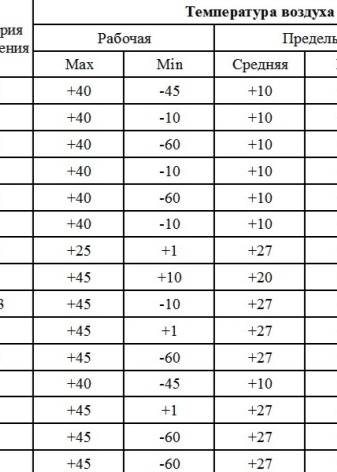

The requirements of GOST 15150 indicate that when using such devices:

- the design thermal regime must be strictly maintained;

- contact of dampers with moisture, whether condensing or otherwise coming in, is unacceptable;

- it is also necessary to prevent dampening of the control units and the outer part.

It is strictly forbidden to use devices that do not have proper protection for pipeline complexes that remove aggressive and caustic substances. Also, such devices cannot be placed where the concentration of corrosive reagents in the air leads to a loss of corrosion resistance of the housings.

It is customary to single out:

- normally open valves;

- normally closed valves;

- smoke devices;

- open and sealed explosion-proof units.

Channel types

There are 3 types of ventilation valves in total. Slot type valves. Such valves, in turn, are automatic and mechanical. The air flow in the slotted valves is regulated using a small hole, which is usually located in the upper part of the window. The advantages of such a valve include ease of installation, as well as a large air exchange.

Rebated valves. The operation of the valve is carried out through the seam cutouts in the window. They have low air permeability, but at the same time they have a low cost and do not require the window to be dismantled during installation. The distinctive features of the seam valve also include excellent sound insulation.

Overhead valves. Overhead valves have excellent air permeability, but this is perhaps their only advantage. They significantly worsen the heat and sound insulation in the room, and also do not have the ability to install on existing plastic windows. They are usually used in manufacturing plants. When choosing a particular type of valve, you need to take into account the characteristics of the room, as well as the amount of funds allocated for the device.

Advantages and design features

Manufacturers of ventilation valves call their devices ideal. All due to the fact that the ventilation valves provide the room with good ventilation, but at the same time they do not create drafts and do not reduce the temperature. Also, ventilation valves do not violate one of the most important properties of plastic windows - sound insulation. In addition, in the room where the ventilation valve is installed, there will always be a good microclimate. When airing, it will not be possible to achieve a normal microclimate, since the temperature inside the room will constantly jump.

Externally, the ventilation valve is an oblong plastic element. Due to the fact that all the incoming air is directed upwards, there will never be drafts in the room where the device is installed. Installing a ventilation valve is an excellent solution for owners of premises with a large number of plants who need a good microclimate.

Supply valves KIV 125 and KIV Quadro

The design of the valves "KIV-125" and "KIV Quadro" is unified and is distinguished by internal heads of various shapes, which are completely interchangeable. The new “KIV Kvadro” head is made of environmentally friendly materials and fully meets the high European requirements in the field of hygiene and ecology. He also retained the main advantages of the KIV-125, namely:

- Excellent protection against street noise and condensation;

- High air performance;

- High-quality durable filter;

- Ability to adjust the air flow;

- Ease of installation, operation and maintenance;

The shape of the KIV Kvadro head takes into account the wishes of those customers who were completely satisfied with the technical and operational characteristics of the KIV-125 valve, but wanted the inner head to be square.

The appearance of "KIV Quadro" not only expands the range of popular products, but also leaves behind the counterfeit "KIV-125" and reveals the real leaders in the supply valve market.

A bit of history

Back in 1998, Engineering Equipment LLC began introducing the STATVENT ventilation system with natural air inflow to the Russian market, where the main component is the air infiltration valve KIV-125. Over the past 13 years, KIV-125 valves have taken root in Russia and have proven themselves excellently. High-quality, solid and easy to install and operate, the STATVENT ventilation system has become very popular.The reverse side of the popularity was the numerous fakes of the KIV-125 valve of very low quality, because it is not easy to copy well and with understanding. Usually, unscrupulous sellers attach documents to these copies and refer to the technical characteristics of the original KIV-125 valves, convincing the client that this is a “real KIV” or its analogue, only a little cheaper. Naturally, during the operation of a fake, problems arise for end customers, casting a shadow on the reputation of the real KIV-125 valve and its suppliers. A worthy way out of this situation for Engineering Equipment and Systems LLC and its partners was the further development and improvement of their products. As a result of a lot of painstaking work, KIV Kvadro appeared, which is offered to the attention of specialists in the field of ventilation and air conditioning, as well as builders, interior designers and everyone who is interested in ventilation.

When choosing supply devices during the design and installation of a specific object, you can also stop at supply valves of dubious quality and origin "assembled on the knee"

But, if it is important what the project will be embodied in and there is a desire to apply reliable innovative solutions that will be implemented not for show, but for the benefit of people, KIV and KIV Kvadro valves are for you

We are the exclusive supplier

Engineering Equipment and Systems LLC is the exclusive supplier of Finnish inlet valves KIV-125 and Italian valves KIV Quadro

Why you need a vent valve

To begin with, it is worth noting 4 components, which are the basis for creating a good indoor microclimate. They are:

- temperature;

- humidity;

- air flow;

- ventilation.

The ventilation valve primarily provides the room with an influx of dry air from the street. Humid room air is then removed through the valve. After installing the ventilation valve, the temperature in the room will be approximately 23 degrees, while the humidity will drop to 50% (instead of the average of 65%). The inflow of dry air and ventilation will also be at an optimal level. Therefore, we can say that thanks to the ventilation valve, it will be possible to achieve the ideal microclimate at home.