Advantages of the pumping system and its disadvantages

-

Ease of installation

. This advantage is significant in comparison with the natural system. The fact is that when installing a circulation pump, there is no need for a complex installation of the upper pipeline, there is no need to weld pipes, maintaining an angle of 300 and installing large diameter main risers. -

Uniform and fast heating of housing

. Unlike natural circulation, in which the heating of radiators depends on the distance to the boiler, in the case of using the pump version, the coolant enters all batteries at the same time, and if there is any dissonance, then it can be adjusted. -

Heating a large area

. This can be done if you choose the manifold-type piping. It ensures uniform heating of the radiators, no matter how far they are from the boiler. Therefore, it is possible to extend the piping system to the desired length without fear of losing heat during transportation due to its large length. -

Possibility of using antifreeze

. It will provide the system with frost protection. -

Heating control

. It is carried out on separate sections of the network. By means of the provided adjusting cranes it is possible to block the whole sections of the highway. Due to which you can change the layout of the network and redo the scheme of its connection. -

Extending equipment life

. Boiler appliances in a closed system practically do not suffer from temperature differences, it is less noticeable at the inlet and outlet of the boiler. -

The possibility of introducing additional elements into the system.

The presence of a circulating pump makes it possible to build in "warm floors". -

No need to adjust the water in the system.

By including a pump and an expansion tank with a membrane in the heating circuit, and making it closed, it was possible to reduce the evaporation of liquid from the system.

-

Work from electricity

. The dependence of the system on the presence of an extraneous resource results in the failure of all heating equipment in the absence of energy. -

The cost of the pump and its components

. The device itself is inexpensive, but for its operation you need to purchase special adapters, taps and other parts.

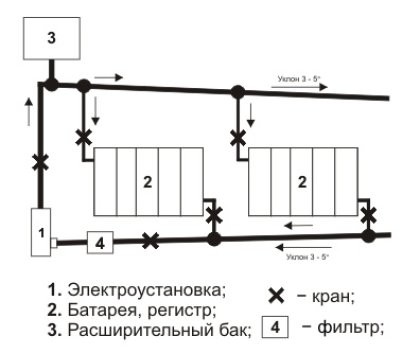

One-pipe and two-pipe system open and closed loop

In addition to the type of wiring and the location of the riser, variations in heating schemes are also divided into single-pipe and two-pipe. Single-pipe schemes are quite rare: they are used mainly in the design of large areas. In residential buildings, they are almost never found.

In a single-pipe system, there is no supply and return pipeline, the coolant circulates through one single pipe, which is only mentally divided in half, counting the first part that delivers water from the boiler as the supply, and the remaining half of the pipe as the return. In a single-pipe system, hot water heated in the boiler rises, displaced by a cold return flow and enters the heating devices through the wiring, flowing from one to another, cooling down and returning to the boiler for heating. Pumping circulation helps the correct flow of fluid through the circuit.

The main problem of the circuit is the loss of heat by the coolant: the water reaches the last battery barely warm. This problem is solved by installing a pump and more radiators as they move away from the boiler. It helps to save heat by installing pipes in such a way that the first radiators where the water from the heating element that has not yet cooled down are the batteries located in the coolest rooms, which require a lot of energy for heating.

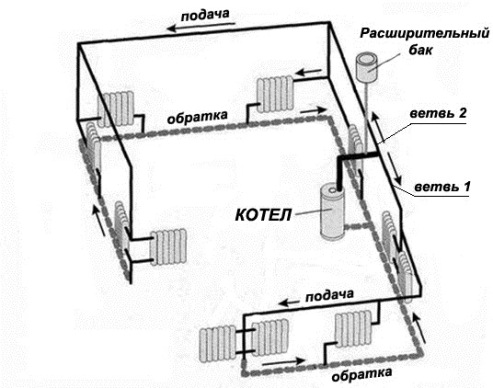

Although single-pipe systems are cheaper, two-pipe systems are more popular.One delivers hot water from the boiler to the radiators, and the second collects the return flow of the cooled coolant and transports it back to the boiler. , differ in that water enters all heating radiators with the same temperature, the problem of uneven heating does not arise. A thermostat can be installed on each heating element and the heat supply can be regulated, which allows additional savings on space heating. Pipes for installation are thinner and look more neat, neater fitting into the interior.

Weaknesses include the need to install shut-off valves and a Mayevsky crane on each heating element. Dead-end and associated schemes They divide the heating circuits and according to the principle of movement of the coolant in them. An associated heating system implies the movement of water in the supply and return lines in the same direction. A dead-end heating system assumes that the water in the return line moves in the opposite direction to the supply.

The dead-end circuit is not characterized by the same length of the contour rings of the heating radiators. The farther the radiator is located from the riser, the more water travels, moving from the boiler to the radiator and back. The farther the heating element is from the heating element, the longer its contour. Associated heating circuit - a circuit where the maximum identity of the material resistance value is realized, and the length of the heating pipes forming the contour rings is the same. The voltage in the circuits is also the same, which makes the distribution of resistance over the heating system. Minus associated pumping circulation - a more tangible cost, because you need to buy more pipes. In conclusion, it is worth remembering all the positive aspects of the schemes with the pump, because of which they are preferred:

-

- Such a system is launched in a short time

- The circuit with the pump works without losses, providing efficient heating of the room

- Pumps are durable and work without repair for a long time

- The pump makes no noise and consumes little electricity

WATCH VIDEO

Pumped circulation heating systems are very efficient. The advantages of heating systems with a pump outweigh the disadvantages.

Advantages and disadvantages

The use of a heating system with natural circulation of the coolant has many advantages, the main of which include:

- simple installation, commissioning and maintenance;

- maximum efficiency - the gravitational heating network has a high efficiency and makes it possible to regulate the temperature regime of each room separately;

- efficiency - a gravity heating network is one of the least expensive among existing home heating systems (if measures are taken to reduce the thermal conductivity of walls, floors and roofs);

- noiselessness - the absence of working electrical equipment minimizes the noise that accompanies the operation of the climate system;

- energy independence - the gravitational heating network put into operation will work even in the event of a temporary interruption in the supply of electricity, which would otherwise be needed to power the pumps;

- long service life - with proper installation and proper maintenance, heating equipment will work for more than 35 years without the need for major reconstruction.

Gravity heating system - a guarantee of warmth and comfort in the house

The main disadvantage of heating with natural circulation is the inability to use it for large buildings. Due to the low pressure of the liquid, the length of the horizontal sections of pipelines should not exceed 30-35 meters, otherwise the efficiency of the system will decrease significantly.

In addition, it is necessary to have a technical floor in the upper part of the building, where the expansion tank is mounted.

Also, due to the low inertia, it is recommended to avoid laying pipes in unheated rooms, as there is a risk of freezing of the coolant and, as a result, violation of the integrity of the pipelines.

A natural circulation system is perhaps the best solution for arranging heating for a small country house. However, it is absolutely not suitable for a city apartment, a summer residence, where year-round living of people and a cottage with an area of more than 100 square meters is not expected. meters. In this case, it is better to dwell on other heating methods, which are described in the video below.

Scheme of installation of gravity heating systems

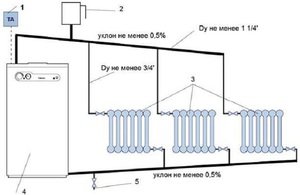

Since the circulation of water in the heating system occurs without the participation of a pump, for the unhindered flow of fluid through the lines, they must have a diameter larger than in the scheme where water circulation is forced. The gravity system functions by reducing the resistance that water has to overcome: the farther the pipe from the boiler, the wider it is.

Water heating with natural circulation can have an upper or lower wiring. When the wiring is designed as two-pipe, heated water enters directly into each battery, and does not pass through them one by one, as in a single-pipe scheme.

The upper wiring, in which the coolant first rises to the ceiling, and from there descends to the batteries, is best suited to install such a design. If the wiring is planned lower. then an accelerating circuit is being built: a height difference at which water from the boiler first goes up, where it enters the expansion tank at the upper point of the pipeline, and then goes down to the heating radiators.

The higher the heating device is located, the higher the pressure inside the pipeline. Therefore, the batteries of the upper floors often warm up better than those on the lower ones. Accordingly, if you make heating with natural circulation two-pipe, the batteries placed on the same level as the boiler or below do not warm up enough.

To avoid such a situation, the boiler room is thoroughly buried, providing a sufficiently high pressure for the coolant to pass through the pipes at the required speed. The boiler is placed in the basement, approximately 3 meters below the center of the lowest heating element. Pipes with hot water, on the contrary, are raised as high as possible, placing an expansion tank at the highest point of the structure, and then the water from the supply pipe descends to the radiators.

The choice of the design of the riser

There are two main options:

- Vertical stand. In this case, all pipes from heating radiators are joined to the central element passing through each floor of the house. The advantages of its use include the absence of the risk of air locks, the disadvantages are the high cost (more pipes are needed connecting the central pipe to the radiators).

Heating scheme with vertical risers

- Horizontal stand. All heating panels on each floor are connected to one supply line. More economical option. However, in this case, it is necessary to additionally install special air valves that will prevent the “airing” of the heating network, which affects its efficiency.

Heating scheme with horizontal risers

Important points during installation

In order for forced circulation heating to function without problems for a long time, it is necessary to correctly install important components on which the efficiency of the entire system depends.

To increase the life of the circulation pump, it is cut into the return line. It is explained simply. The water moves through the return pipeline in a chilled form, since the heat has already been given to the heating devices.In the design of the pump, manufacturers use cuffs and seals made of rubber, which can change properties when under constant exposure to high temperatures. The cooled coolant entering the return does not have a significant effect on rubber parts, which allows them to retain their original properties longer.

For the installation of a forced heating system, pipes with a minimum diameter can be used. At the same time, it is possible to reduce the cost of work on the device of the heating system at home. After all, the volume of coolant that fills the system is reduced. This, in turn, affects the choice of an expansion tank of a suitable volume and power of the purchased heating boiler.

In heating systems with forced circulation, it is recommended to use modern heating boilers, the design of which provides for the presence of automation. These devices provide control and regulation of all processes with minimal human intervention in the operation of the equipment. Fuel is used more efficiently and the temperature inside the room is regulated, taking into account various factors that affect the course of the home heating process.

Heating system diagrams

The scheme of the heating system depends on several criteria:

- method of connecting batteries to supply risers. There are one-pipe and two-pipe systems;

- places for laying a line that supplies hot water. It is necessary to choose between the upper and lower wiring;

- line laying schemes: dead-end system or passing water movement in the routes;

- risers can be located horizontally or vertically.

What is the difference between forced and natural circulation?

Forced movement of the coolant implies the circulation of fluid through the line due to the working force of the pump. The natural system does not need to use any equipment, here the coolant moves due to the difference in the weight of the hot and already cooled liquid.

One-pipe scheme: how to regulate the temperature?

provides temperature difference

To ensure the same temperature in rooms on different floors, the surface of the heating appliances on the lower floor should be slightly larger than on the upper floors. Hot and cooled liquid in the upper heating devices enters the lower radiators.

In a single-pipe system, there can be two versions of fluid movement: in the first case, part goes to the battery, the other part goes further down the riser to the lower radiators.

In the second case, the entire coolant passes through each device, starting from the top. The peculiarity of this wiring is that the batteries on the lower floors receive only a cooled coolant.

And if in the first option it is possible to regulate the temperature in the rooms with the help of taps, then in the second one they cannot be used, since this will lead to a decrease in the supply of coolant to all subsequent batteries. In addition, the complete shutdown of the tap will stop the circulation of fluid in the system.

When installing a single-pipe system, it is better to choose a wiring that makes it possible to regulate the water supply to each battery. This will allow you to adjust the temperature in individual rooms and make the heating system more flexible and, therefore, more efficient.

Since a single-pipe system can only be top, its installation is possible only in structures with an attic. That's where the supply line should be. The main disadvantage is that heating can only be started immediately throughout the house. The main advantages of the system are ease of installation and lower cost.

How to choose a circulation pump model

When choosing pumping equipment, attention is paid to the simplicity and reliability of its operation, as well as to energy consumption. In addition to these important qualities, pump power and pressure are important.

These characteristics are determined by the size of the heated room. You can refer to the following examples:

- for houses with an area of 250 sq. meters, acquire pumps with a pressure of 0.4 atmospheres and a capacity of 3.5 cubic meters. meters per hour;

- for houses whose area is in the range of 250-350 sq. meters, acquire pumps with a pressure of 0.6 atmospheres and a capacity of 4.5 cubic meters. m/h;

- for houses with an area exceeding 350 sq. meters up to 800 sq. meters, purchase pumps with a pressure of 0.8 atm. And with a capacity of 11 cu. m/h

With a more accurate selection of the circulation pump for a particular facility, calculations are carried out by specialists, taking into account the length of the entire system, the number of installed radiators and their type, the shut-off valves used, the diameter of the pipes, as well as the material of their manufacture, the type of fuel. See the article "Selection and nuances of installing a circulation pump for heating" for more details.

Interfering with the normal circulation of the coolant in the heating system can be air pockets that form in each radiator and in places where the pipeline rises vertically. You can deal with air accumulations by installing Mayevsky taps on each radiator or special automatic air vents. The installation of these devices will prevent the “airing” of individual sections of the system and violations in the heating operation that affect the microclimate in the room.

Types of open systems

Such water heating schemes are divided into types depending on the method of circulation and delivery of the coolant to the radiators with its subsequent return back to the boiler. Heated water can move along the highways in two ways:

- with the help of natural circulation;

- artificial impulse from the pump.

Due to the design features, there is practically no excess pressure in an open heating system. At the highest point, it is equal to atmospheric, and at the lowest point it rises slightly due to the hydrostatic effect of the water column. The value of this pressure is small, which makes it possible to organize the natural circulation of the coolant. The principle is based on the fact that a coolant with different temperatures has a different density, and hence mass. Example: 1 m3 of water at t = 40 ° C weighs 992 kg, after the temperature rises to 60 ° C, the mass of 1 m3 drops to 983 kg.

It would seem that the difference is insignificant. Nevertheless, it allows the cooled coolant with a low temperature to displace lighter hot water from the boiler. Natural (convective) circulation occurs in pipelines, and such systems are called gravity or gravity, because the movement in them occurs due to gravity. Therefore, the speed of the coolant flow in the mains and radiators is low, only 0.1–0.3 m/s. But such schemes are completely non-volatile, provided that boilers for an open heating system that do not require electricity work together with them.

Note. In gravity systems, lines are made with increased slopes and pipe diameters.

In order to increase the rate of water flow through the pipes and reduce the heating time of the premises, a pump is built into the line coming from the boiler. It forces the coolant to move at a speed of 0.3–0.7 m/s, due to which the heat transfer is more intense, and all branches are heated more evenly. Due to the presence of the pump, the distance between the heat source and the batteries can be increased both in length and in height.

The installation of a pumping unit allows you to create a slight overpressure in the heating system, which allows the coolant to flow well into the radiators. This clearly improves the efficiency of the system as a whole, although it makes it dependent on the availability of electricity.

Note.So that the heating of a private house does not stop along with a power outage, it is customary to install a circulation pump on a parallel bypass line.

Horizontal and vertical risers

If the pipes connecting all the heating devices to each other are located in a horizontal plane, this is with a horizontal riser. This approach is more economical, because requires fewer pipes and requires less installation costs. A horizontal heating riser - a hot water supply line, is more common in one-story buildings with a long length, because. with such a layout, it is more reasonable to connect the radiators in series one after the other.

Such a design makes it possible to set separate temperature conditions for rooms, use heat meters. The disadvantage of the design is the occurrence of air jams in the pipes. To eliminate this problem, Mayevsky cranes are installed to release the resulting excess air.

If the heating scheme with a pump involves connecting radiators located on different floors to a common line, then this is a vertical riser heating system. With this installation scheme, radiators that heat one apartment are fed from different risers, which makes it difficult to account for heat consumption in a single apartment. In a vertical heating circuit, the supply line runs under the ceiling of the upper floor or in the attic, and all heaters are connected in series to the main riser, which is located vertically and passes through all floors. Schemes of this type are used in multi-storey residential buildings. Each floor can be connected to a vertical riser separately, this will come in handy if the house is put into operation gradually. A vertical riser solves the problems of air accumulation in pipes, but the installation of such a design is more expensive.

The riser can run right through the apartment: penetrating the floor and ceiling in every room or located outside the living quarters. In the second option, it carries large heat losses, so it is “dressed” with a heat-insulating coating or placed in an insulated shaft. In a circuit with a vertical riser, it is impossible to build underfloor heating, it is difficult to maintain the required air temperature in different rooms. The upper floors are warmer than the lower ones, and the risers that are located further from the supply line are colder than those that are closer.

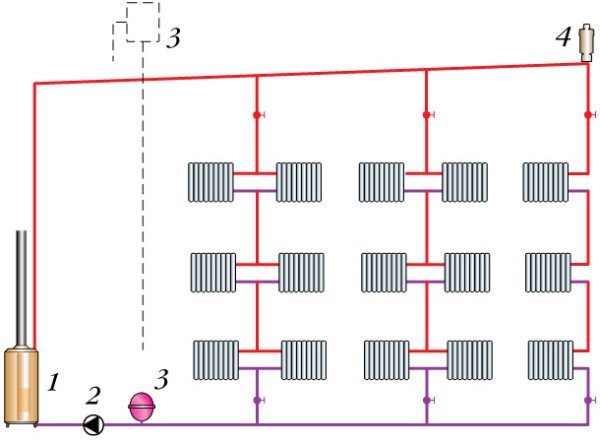

If directly to the distribution manifold, and each of them has a supply pipe and a return pipe, such a scheme is called a collector or beam. This approach is more expensive than the previous options, but is used in the installation, because. makes it possible to reduce the use of shaped elements and make the coolant velocity the same in all circuits.

Installation of the heating system

The approximate cost of construction can range from 4,000 to 4,500 thousand dollars, but if you wish, you can find cheaper or more expensive options.

It is important to remember that a design that is too cheap may not provide the house with the necessary amount of heat, and too expensive options often do not live up to expectations.

Conclusion

What conclusions can be drawn from all of the above? A closed-circuit heating system with forced circulation is quite reliable and durable, and this design will serve the house for many years. If necessary, natural circulation can also be used in a closed circuit, but this option will create some inconvenience, without which it would be quite possible to do without.

With pump circulation - a convenient and practical option for solving the issue of heat supply for the home.

Unlike designs in which the circulation is natural, the pressure in the circuit with a forced fluid flow pattern is stable and strong enough. This makes it possible to use smaller diameter pipes without reducing the flow rate in the heating system, makes it easier to choose radiators and saves money.

The main structural part of the heating circuit is the circulation pump. He is responsible for the water supply of the boiler, pushes the heated water through the pipes from the boiler to the radiators. The already cooled water is returned to the boiler through the return pipes. An expansion tank is necessarily present in the scheme, which normalizes the pressure in the pipes and takes on the excess volume of water expanding when heated. Thanks to the pump, which provides a sufficient speed of water movement, it is possible to connect not only horizontal, but also heating to the main. Low horizontal heating radiators look good in niches under large windows, and a vertical radiator is suitable for a vertical opening, a room without windows.

Disadvantages and advantages

Let's talk about the disadvantages first. This approach will help determine whether such a heating system is right for you.

- If there is no pump in the system, then you need to wait quite a long time until the hot water reaches the batteries and passes through them.

- Uneven heating of radiators. This is due to the same nuance - hot water from above, and cold from below.

- Installation is carried out with more expensive pipes of large diameter.

- It is necessary to install an open expansion tank, as a result of which the water evaporates and it must be periodically added to the system. Installing an expansion tank of a closed type may degrade the performance of the system.

- The design of the room suffers.

- You can not violate the slope of the pipes, even if you need to bypass the doors.

- The system should have as few turns as possible.

- When planning a heating system without a pump, it is necessary to correctly determine the level of the batteries, the expansion tank and the boiler, which should be installed at the lowest point.

Advantages

- Electronic independence. Even if a pump is installed, in the event of a power outage (or if the pump fails), the heating system continues to work.

- Installation and further maintenance does not require special skills.

- Quiet operation.

The principle of operation of the system with natural circulation

The heating scheme of a private house with natural circulation is popular due to the following advantages:

- Easy installation and maintenance.

- No need to install additional equipment.

- Energy independence - no additional electricity costs are required during operation. In the event of a power outage, the heating system continues to operate.

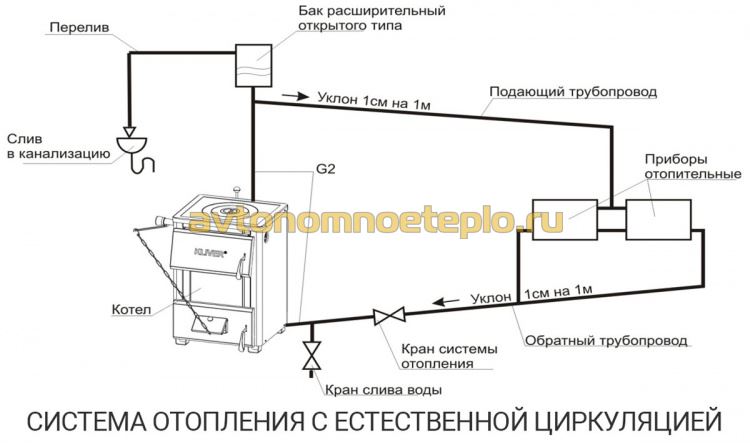

The principle of operation of water heating, using gravity circulation, is based on physical laws. When heated, the density and weight of the liquid decrease, and when the liquid medium cools, the parameters return to their original state.

At the same time, there is practically no pressure in the heating system. In thermotechnical formulas, the ratio is 1 atm. for every 10 m of water column pressure. The calculation of the heating system of a 2-storey building will show that the hydrostatic pressure does not exceed 1 atm. in one-story buildings 0.5-0.7 atm.

Since the liquid increases in volume when heated, for natural circulation, an expansion tank will be required. The water passing through the water circuit of the boiler is heated, which leads to an increase in volume. The expansion tank must be located on the coolant supply, at the very top of the heating system. The task of the buffer tank is to compensate for the increase in liquid volume.

The self-circulating heating system can be used in private houses, making the following connections possible:

- Connection to underfloor heating - requires the installation of a circulation pump, only on a water circuit laid in the floor. The rest of the system will continue to operate with natural circulation. After a power outage, the room will continue to be heated using installed radiators.

- Work with an indirect water heating boiler - connection to a system with natural circulation is possible, without the need to connect pumping equipment. To do this, the boiler is installed at the top of the system, just below the air expansion tank of a closed or open type. If this is not possible, then the pump is installed directly on the storage tank, additionally installing a check valve to avoid recirculation of the coolant.

In systems with gravitational circulation, the movement of the coolant is carried out by gravity. Due to natural expansion, the heated liquid rises up the accelerating section, and then, under a slope, “flows down” through the pipes connected to the radiators back to the boiler.

Wiring lower and upper scheme of autonomous circulation

According to the types of wiring, heating circuits are divided into structures where the wiring is lower and upper. With the lower wiring, the supply line is laid in the lower part of the coolant flow pattern, as is the return pipe. Both lines are located below the heaters. This design has a high hydraulic stability, it is convenient in that it allows you to take out the vertical pipes of the risers outside the rooms. All circuit regulators (valves, locking mechanisms) with this arrangement are located in the same room, as a rule, this is a basement or a technical floor.

Lower wiring of heating pipes saves heat, because. they are not laid in attic spaces or interceiling spaces. The disadvantage of this type of heating is the need to install air bleed valves for each battery, as well as constant air plugs.

With the upper type of wiring, the pipeline with the coolant passes in the upper part of the heating circuit. As a rule, it is located in the attic or in the space between the ceiling and the roof. Return pipes are mounted below the heating radiators. An expansion tank is placed at the highest point of the circuit. It regulates the pressure inside the structure and eliminates the appearance of air congestion. This type of heating cannot be installed in a house where there is no slope at the roof. The minus of the upper wiring is the negative gravitational pressure in vertical pipes. This interferes with the flow of water and reduces hydraulic stability. With the upper wiring, it is impossible to drain the risers centrally.

In addition to the lower and upper wiring, there is also a mixed one: the supply line runs from above, and the return pipeline runs at the bottom of the heating structure. This approach is reasonable if a multi-storey building has its own autonomous boiler located under the roof.

natural circulation

Approximate system diagram

The main issue of the natural circulation system is the issue that determines the force of movement of the coolant to the heating devices and back to the boiler. The force of movement of the heated coolant appears due to the fact that the coolant is heated in a heat generator, while in heating devices this coolant cools down and the heated coolant squeezes it out. In other words, the coolant, which has heated up in the heat generator to a certain temperature, has a smaller mass than the coolant in the cold state.

So, water heated to the desired temperature rises in a certain direction in the main riser and is distributed by piping to all heating appliances, that is, radiators. After a while, the coolant in the radiators cools down, giving up its heat to the metal, which makes it heavy. Through specially laid pipes in the opposite direction, the cooled coolant is transported back to the heating boiler, where it displaces hot water from the heat generator with its mass.

Such a cycle of movement of the coolant in the heating system will be repeated until the heating boiler is in operation, as a result of which the coolant will circulate through the pipe line.Heating systems with natural circulation have different pressure forces, which leads to different intensity of circulation and heating of heating devices. The force of movement of the coolant in the heating system depends on the different densities and weights of the cold and hot coolant.

From this we can conclude that the pressure in the heating system and the force of water movement depends on the total difference between hot and cold coolant. In other words, the greater this difference, the greater the force of movement of the coolant in the heating system, in which the coolant circulates naturally. Among other things, the pressure in the heating system and the force of movement of the heated coolant depends on the height at which the heater is located relative to the heat generator.

As a rule, the coolant in a simple water-type heating system heats up to 95 degrees, while the cooled coolant has a temperature of no higher than 70 degrees. From these indicators, it is possible to determine the total pressure in the heating system and the force of movement of the coolant to the upper and lower heaters. In order to visually imagine the distribution between the upper and lower radiators in the heating system, it is necessary to draw a kind of diagram.

In the center we denote the heating boiler, from which the wiring goes to the upper and lower radiators, closing opposite the boiler itself. By drawing a line between the upper and lower heating devices (radiators), we will get the temperature difference limit from 95 to 70 degrees. Next, consider the heating process.

System Diagram

The heating boiler heats the coolant, in our case water, which, due to the pressure formed, begins to move from one heater to another. When the coolant crosses the line we have drawn and goes to the heating devices of the lower floor, its temperature will be much lower, and the coolant will come out of the last radiator with a temperature of only 70 degrees. When carrying out the movement of the coolant from the radiator to the radiator, one should not forget that part of the temperature is given to the pipes themselves, as a result of which the temperature of the coolant is constantly decreasing.

From this we can boldly conclude that the heaters that are located above the system separation line will heat up more than those located on the lower floor.

All this leads to the fact that the use of this heating system for two-story houses is irrelevant, because the first floor will be constantly colder than the second. In addition, when using a two-pipe heating scheme, when the radiators are located below the boiler itself or at the same level as it, it is almost impossible to achieve proper circulation of the coolant without the use of auxiliary mechanisms.

For these obvious reasons, the location of the heating boiler must be such that the heating appliances are at a level above the boiler itself. To do this, the heating boilers are placed in a small recess, and the heating system is slightly raised at a certain angle in order to achieve the proper pressure and proper natural circulation of the coolant. Such obvious shortcomings are deprived of standard single-pipe heating schemes.