What is a well filter and its device

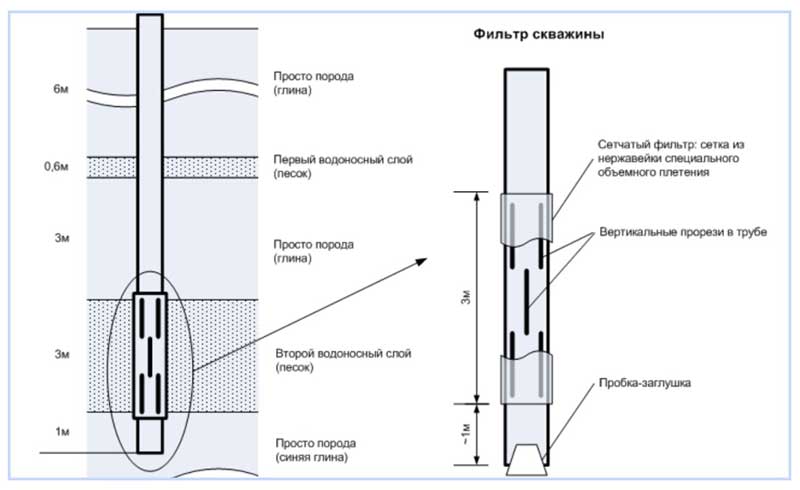

Well water is purified in two stages - by a well filter and surface filtration systems built into the water main. At the same time, the well filter has a structure consisting of three main elements:

- Overfilter section. Part that plays the role of fittings when mounted on a column.

- filter elements. Includes holes in the pipe of the desired size and external materials that are attached to it.

- Sump. The space for placing soil particles that got inside the source or sifted out by filter elements is the lower part of the filter without perforation. The sump for water from the well has a length of about 0.5 m.

Rice. 2 Filter design

Materials for filtration equipment

The efficiency of cleaning depends on the quality of the material for filtration, a limited number of them are used in wells, the main of which are:

Stainless steel. In addition to strength, the material has flexibility and excellent corrosion resistance; the durability of stainless steel is decades. Durable nets and wire are made from it, which are mounted on top of pipes. The disadvantages include the high cost of stainless products.

Plastic. Plastic is another common material for making filters in water sources, and it is cheaper to make meshes and cords than stainless steel. Plastic is corrosion resistant and inert to most chemicals, easy to install and has a long service life. The disadvantages of plastics include low physical strength, which does not allow them to withstand heavy loads at considerable depths.

Nonferrous metals. Copper, brass, bronze can be used in the manufacture of water filters without any restrictions, they have high corrosion resistance and a long service life. Soft alloys with a high copper content are recommended for use at shallow depths to avoid deformation from strong water pressure. In the manufacture of filter elements, a brass mesh and thick brass or copper wire are used.

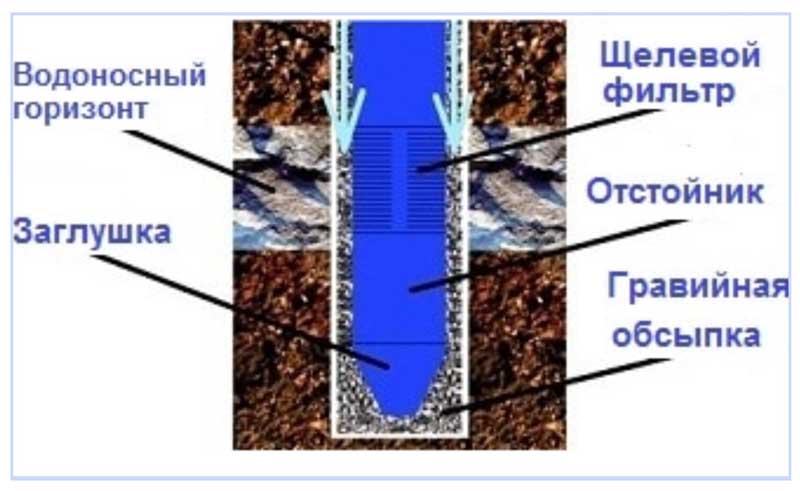

Rice. 4 Casing Filter - Downhole Installation

Steel. Steel filters are susceptible to corrosion, and can be used as a budget option in water intake sources intended for technical needs. The increased content of iron oxide in water as a result of iron corrosion is more than 0.3 mg. per liter leaves a yellow residue on plumbing equipment and plumbing fixtures. Galvanized steel also rusts over time with the formation of zinc oxides that are harmful to human health - this material is not recommended for use in the construction of water filter elements.

What is a downhole filter for?

The need for filtration inside the well is caused by the following circumstances:

- Purified well water, in contrast to contaminated water, increases the life of submersible and surface pumps for wells - impellers, membranes and other moving parts wear out less.

- Filtered water, when further passing through the pipeline, less pollutes the filters in water purification systems located in the water supply system - this saves money on the purchase of new cartridges and increases their durability.

- Filtration increases the service life of automatic control systems for pumping equipment - pressure and idle speed switches, hydraulic accumulators.

- Purified water contributes to better patency of the water main, increases the life of plumbing units (check valves, ball valves, faucets).

- Additional well cleaning contributes to a better quality of drinking water used in the household.

Rice. 3 Filter element arrangement

Making a filter with your own hands

For this you will need:

- Grid with fine perforation, or special material;

- Thick wire.

"Is that all?" - you ask. “Yes,” I tell you. So, after you have found all the necessary materials, take the pipe, securely fix it on a solid surface so that it does not sway, and perforate the end of the pipe with a drill, at a distance of up to 20 cm of the end. Holes should be made at a close distance from each other, a step of about 0.7-1 cm.

Drill for as long as you can. Remember that the area on which the holes will be located must be completely covered by the filter, so be careful. Once the holes are drilled, wire must be wound around them. Just take a thick aluminum wire, and wind it around the pipe to the end of the holes. This is necessary in order to create a frame on which the filter material will lie. Distance from turn to turn (step) = 2.5 -3 cm.

As for the filter material. There are options here. You can use it as a metal mesh with a very fine mesh, or try to find filter material in specialized stores. It will be a tight fabric or plastic. Perhaps in such stores you will also find reinforcing rings of a suitable diameter for your pipe. When buying a plastic filter, choose a thicker material so that it does not sag and break when put into place.

So, when you have decided on the material, you need to carefully wrap it in one layer around the wire on the pipe and secure it well. It is best to fasten with a welding machine if it is a metal mesh, or with a special, moisture-resistant glue if it is an insulating material. Do not use toxic glue, the water that has passed through this filter will still be drinkable.

Sewing the material securely and fixing it at the end of the pipe is a very important point. If this is not done, there is a chance that the filter may slip, which means that either it will not filter at all, or it may block access to water. Believe me, both options are not at all good and the Russian “maybe” will not work here, otherwise, at best, you will have to drink water with sand, and at worst, you will not see it at all.

By the way, I recommend that you prepare the pipe before you start drilling the well. A newly made well tends to quickly drag on, which means that if you do not install a pipe with an attached filter immediately after it has been drilled, you will have to do the work again, because. groundwater will do its job, and the well will fill with water and sand.

And one more piece of advice, keep in mind that there are no eternal things, and filters for a well sometimes fail or simply get clogged, which means that you will sometimes have to get it out and clean it, perhaps change some parts, a grid, for example. Therefore, when installing the pipe, it is not necessary to fill everything around tightly with cement, because over time, you still need to get the pipe out of the ground and carry out preventive work.

I sincerely hope that the above tips will help you when digging a well and installing a filter yourself. Everything that is done by you personally is a guarantee of environmental friendliness and reliability.

Dear readers, comment on the article, ask questions, subscribe to new publications - we are interested in your opinion 🙂

Articles that will be of interest to you:

How to make a filter for a well with your own hands

Downhole filters are installed on the bottom pipe and lowered into the source along with the casing string, their independent production is pointless if you are not engaged in downhole drilling.The task is relevant for drilling organizations and individual drillers who want to make an inexpensive high-quality filter with high characteristics and parameters that are most suitable for a particular well (depth of occurrence, soil composition).

gravel

For a gravel filter device, do it yourself as follows:

- First, the size of the gravel backfill is selected, taking into account the granulometric composition of the water-bearing sand. To do this, contaminated water is extracted to the surface, and after its filtration, the size of the sand particles is determined.

- The gravel pack should have a granule size of approximately 8 times the minimum sand particle diameter or 5 times their maximum diameter. For example, if the dimensional parameters of water-bearing sand are 0.5 - 1 mm, the backfill should have dimensions of 4 - 5 mm, with grains of sand 0.25 - 0.5 mm. gravel sizes are 2 - 2.5 mm.

- The sized gravel fraction is immersed to the well bottom by the method of free fall in the water flow, its minimum thickness is 50 mm.

- Multi-layer filling is allowed, starting with larger fractions and moving to fine particles.

Rice. 11 Backfilling the casing

Perforated perforated well filter

A perforated filter can be made by yourself without much effort with a simple tool (drill with a suitable drill bit). When installing a perforated filter from 125 HDPE casing, proceed as follows:

- The markup is made, marking the distance from the bottom plug to the end of the sump about 50 cm, the length of the filtering part with perforation is 110 cm.

- 4 equidistant lines are drawn along the pipe, 4 rows of holes are drilled with a diameter of 20 - 22 mm. pen drill on wood - they must be performed in a checkerboard pattern. The distance between them should be about 10 cm.

- The burrs formed during the drilling process are cleaned with sandpaper, you can singe them with a gas burner.

If the source is shallow, the number of holes can be increased to 8 rows, and perforated holes can be made almost the entire length of a 3-meter pipe, their number will be about 20 - 25 pieces in a row.

Rice. 12 Do-it-yourself perforated filter

slotted

The manufacture of a slotted filter is rarely carried out independently - the process is laborious and time-consuming, when it is constructed, the following is done:

- Markings are made along the pipe surface, dividing it into 8 equal-sized sectors, drawing 8 lines and retreating from the ends by 50 cm.

- To cut slots, they take a grinder with a disc for metal or concrete, while it should be borne in mind that the slots from the disc for metal will have a smaller width.

- Cutting is done in 10 mm increments. to the width of the sector between the two lines, alternating free longitudinal sections with cut ones. At the same time, stiffening ribs 20 mm wide are left between the slots. through 10 - 20 lines.

- After cutting out 4 longitudinal segments with slotted areas, their surface is cleaned of burrs with sandpaper.

Rice. 13 Plastic pipe with slots

Wire Mesh Filter Systems

Making a wire filter at home is not possible - to ensure a gap between the turns of the V-shaped wire of about 0.5 mm. it needs to be welded onto a rigid frame from the inside at thousands of points.

At home, mesh filters are most often made by doing the following:

- They take as a basis a casing pipe with round holes made according to the technology described above. A nylon cord or stainless steel wire is wound onto its surface with a circumference of about 2 - 5 mm. with a distance between turns of 50 - 100 mm. The ends of the winding are fixed with brackets, screws or screwed with adhesive tape.

- A metal or synthetic mesh is put on top of the winding; a second outer winding with wire or synthetic cord is used to fix it.

Rice. 14 Manufacture of the strainer