Preparation of drilling equipment

To carry out such work, you will need the use of a small-sized drilling rig. As a rule, it has a diameter of 1 meter and a height of up to 3 meters.

Hydro drilling equipment includes:

- collapsible frame made of durable steel;

- electric winch;

- a special contour that ensures the sliding of the elements along the frame;

- special drill with rods;

- hydropump and hose for water supply;

- Control block.

Before starting work, you need to take care of the availability of a mains power supply or generator. Also useful: casing pipes, the main filter element and standard working tools.

Step-by-step well drilling technology

It is important to start hydro-drilling a well with your own hands in the morning, taking into account climatic conditions and terrain features. When working on sand - more water will be needed

When extracting the clay, it is necessary to give it time to dissolve, for this you will need to start using water in advance.

Let's take a closer look at the drilling process itself:

- walls are being polished to strengthen the column;

- the liquid used cools the drill, enhances its penetration deep into the ground;

- the spent solution enters the filter tank, where it is cleaned;

- then poured into the next container for subsequent use.

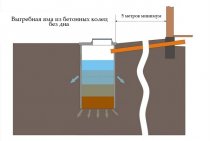

The technology used allows drilling before reaching the aquifer. The efficiency and power of such an installation make it possible to work at a depth of up to 50 meters. Upon completion of the work, the mine is washed with clean water, the drill rods are removed.

Casing pipe laying

Upon completion of drilling wells with a hydraulic drill, the time comes for the installation of casing pipes that prevent the collapse of the walls of the mine. For this purpose, the following can be used:

- steel;

- plastic;

- asbestos cement.

Plastic pipes are the most efficient. They have sufficient strength, are not susceptible to corrosion, and do not collapse when exposed to a humid environment for a long time. It is recommended to use pipes with a diameter of 116 mm for short wells, and 125 mm for deep mines. In addition, modern plastic pipes allow you to avoid unnecessary connections, which greatly enhances the strength of the entire structure.

To achieve high water purification, it is necessary to use special coarse filters. They can be homemade or factory made. In the home-made manufacture of such a filter, small slots are made on the intake pipe, after which they are wrapped with a fine mesh, which is fixed with clamps. After installing the filter, half a bucket of fine gravel is poured onto the bottom of the intake pipe. After that, the final washing of the aquifer is carried out to clean it from the remnants of the drilling fluid.

The technological process of drilling a well with water is considered a responsible job. It requires careful preparation of the tool used and strict adherence to the technical process. However, the positive result obtained, made by oneself, will delight the happy owner of clean tasty water for a long time!