Ceiling installation

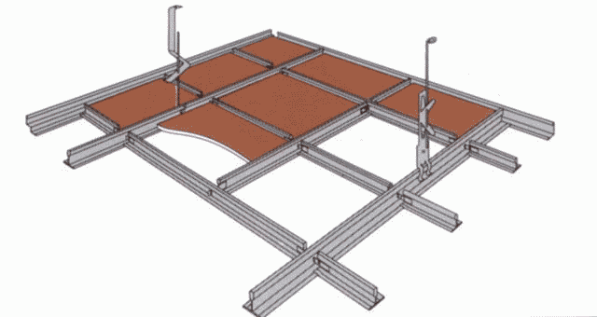

The installation of the fiberglass board structure is carried out using some kind of suspension system. Frames that are arranged according to the principle of rack, panel, plasterboard and other ceilings are perfect.

It is very important that the surface to be treated is horizontal, and the width of the frame cells is from 15 to 24 centimeters. In order to have an idea, it is recommended to additionally view videos on this topic and photos

Installation work should begin with the installation of load-bearing profiles. They need to be fixed around the perimeter of the entire room to the ceiling and walls. Depending on the size of the area of \u200b\u200bthe room, it is necessary to fix the frame with one or two levels to improve the reliability of fastening the profile structure. When drawing the start line for the main guides, use a laser or water level. An ordinary building one is also suitable, but its length should not be less than one meter, but then you need to measure it very carefully.

Metal frame for installation of fiberglass boards

After that, you can proceed to the direct installation of fiberglass plates. I mount this material in the cells of the ceiling profile, screwing it to the base with self-tapping screws. You need to do everything the same as when working with gypsum boards, the only difference is that it is necessary to heat the caps of the self-tapping screws more carefully. For such purposes, it is recommended to pre-drill the hole.

Structures made of fiberglass plates are used to decorate the ceiling of not only residential premises, but also public institutions, medical institutions, and swimming pools.

Fiberglass is a completely safe material, which is considered a plus to everything and environmentally friendly. Thanks to this characteristic, it is more than allowed to decorate ceilings in children's rooms with it. In addition, the cost of this material is moderate, which makes fiberglass trim affordable and widely applicable in everyday life.

Proper care of polystyrene tiles

In addition, a number of precautions must be observed:

- it is advisable to place lighting fixtures open from the side of the ceiling at a distance of at least 30 centimeters from the tiles, since polystyrene foam can deform when heated (it is thermoplastic);

- when the chandelier is purchased and already installed in place, you can simply change ordinary incandescent bulbs to energy-saving bulbs that heat up much less;

- to wipe laminated tiles, it is better to use a damp sponge, which should be moistened with soapy water or detergent (without abrasive particles). If the surface of the material is grainy, then it is advisable to wipe it with a dry cloth;

- small contaminants can be easily removed with an ordinary eraser, while you should not press it hard, polystyrene foam can be easily pushed through.

Plexiglas ceiling

The material has excellent light transmission and excellent light scattering performance when properly processed, so it is used in the construction of many illuminated objects - podiums, advertising signs, light panels, and so on.

-

The most familiar solution is the Armstrong cassette system. It is a rigid metal frame mounted on the base ceiling surface. Designed primarily for use in large office and retail premises, it has a number of advantages.

-

Between the base floor and the ceiling, a large distance can be maintained, designed specifically for the installation of utilities and lighting fixtures.

-

Installation is very simple and quite do-it-yourself.

-

Plates are laid on the frame, and not hemmed onto it.If necessary, the panel is simply removed from the cell, providing access to communication.

-

-

There is another, more decorative way to mount a backlit ceiling. The cassette system strictly regulates the size of the ceiling tiles, the shape - square, rectangular or round, does not change. However, curved plexiglass elements can be made and fixed not on a metal frame, but on a wooden hanging crate. Typically, this solution is used not for the entire ceiling surface, but for a part, and it looks very impressive. In the photo - an acrylic ceiling with a painting.

-

Another option is the traditional sheathing of the crate from below or even installation on suspensions. It is used much less frequently, as it makes it difficult to access the backlight mounted on the base floor.

Plexiglas is produced with various light scattering parameters. Accordingly, acrylic ceilings can have different properties.

-

Transparent - has a high light transmission, so it is rarely used to make a backlit ceiling. But its color variants are used much more often, especially when organizing exhibitions and shows.

-

Matte - from opaque to translucent. The most popular option for a backlit ceiling, as the matte surface has excellent light diffusion and creates a light screen when illuminated. Very impressive frosted colored glass.

-

Corrugated - corrugation is applied on one side of the sheet - “honeycomb”, “prism”, “chipped ice” and so on, the other side remains smooth. When light is refracted in a convex pattern, original lighting effects are formed. Fluted glass is available in clear, frosted and colored glass to create a striking impression. In the photo - a colored acrylic corrugated ceiling.

In addition to the above features, the acrylic ceiling allows you to implement photo printing.

The material, being a polymer, perfectly interacts with paints of a similar origin, so the manufacture of ceiling tiles with photo printing is even easier than drawing a picture on a mirror or ordinary quartz glass.

There is no restriction on the choice of image

However, when developing a composition, you should pay attention to the fact that the drawing will be divided into separate fragments. As a rule, this does not significantly reduce the aesthetic impression.

In the photo - a variant with photo printing and backlight.

Ceiling installation

Acrylic suspended ceilings, as well as rack ceilings, are sold as a set from the manufacturer. This is very convenient if the pattern on the glasses must be joined when assembling in fragments in order to obtain a complete pattern.

The method of assembling the frame does not differ much from other types of suspended structures; instructions must be attached to the kit, with which you can assemble the ceiling with your own hands. If this is your first time doing this kind of work, watch a video on this topic. The frame is mounted from guide profiles of a T-shaped section, with a step adequate to the size of the module. This is done after all electrical wiring has been completed and conclusions for the lamps have been left, and markings have been applied to the supporting structures. When the frame is mounted, acrylic panels are simply laid into each section. If the lighting fixtures are hidden inside the ceiling space, they are mounted immediately, before the cassettes are laid. Outdoor lights and chandeliers are hung last (see How to Hang a Ceiling Chandelier - Do's and Don'ts).

Plexiglas cutting

You will have to make holes and cut acrylic glass yourself. The manufacturer, offering the ceiling as a set, cannot foresee how many lamps you will have and what size holes you will need.

https://youtube.com/watch?v=DjPcRSAreIM

So:

- The surface of the glass is covered with a film, which does not need to be removed until the installation work is completed. It will not interfere with cutting holes.If for some reason there is no protection on the glass, instead of it you need to use improvised material - cloth or even food-grade cellophane film.

- So, before you start cutting, you need to draw a notch line with a pencil. Having made a straight or curved incision, press on the cassette, breaking off the separated part. This work is done in the same way as cutting tiles or ordinary glass.

- A round hole can be cut with a circular saw, marking its center with a drill. For drilling Plexiglas, a drill with a double angle (60 ° - 90 °) is used. Only it will help to avoid the formation of chips around the hole.

- When drilling glass thicker than five millimeters, so that it does not crack, you need to use a cooling emulsion lubricant. For a thin sheet, any hard and smooth gasket is sufficient.

- If you need to cut a large sheet, any fine-toothed saw, hacksaw or jigsaw will do. If the break turned out to be not very neat, its edges are polished with cycles, or with fine sandpaper.

How acrylic ceilings compare favorably with, for example, a plasterboard ceiling - they do not require any additional processing in the form of puttying and painting after assembly. After installation, they have a finished look and make the room very bright even without additional lights. Such a design will serve indefinitely. Removable modules provide access to interior lights and wires. They are easy to remove, wash and reinstall - all you need is a stepladder.

Preparation of the base surface for gluing

To stick ceiling tiles made of expanded polystyrene, you need a base surface, cleared of whitewash and uneven plaster. To do this, use a steel spatula. To facilitate the process of gluing ceiling tiles and prevent the appearance of a large amount of dust, the floor surface is treated several times with water from a spray bottle. But, when there is no desire to clean the ceiling or there is no way to free the room from furnishings, tiles, due to their low weight, can be glued directly to whitewash or plaster (for more details: “How to glue ceiling tiles to whitewash”). Therefore, they prefer polystyrene tiles as a finish, in which case the repair will be completed quickly enough. But the ceiling in this case should be treated with a penetrating primer, which will improve the adhesion of the finishing material to the base surface. Also, the primer will impregnate the whitewash and plaster, after which they form a monolithic, very durable layer.

The appearance of the canvases and the range of ready-made solutions

The appearance of fabric and PVC sheets has significant differences.

Film ceilings are always smooth, have a glossy, matte or satin surface. Matte white ceilings are a classic, they look exactly like a whitewashed or water-based paint ceiling, but with a perfectly smooth surface. Glossy stretch ceilings made of PVC fabric are able to reflect light and objects, visually expanding the room, giving it additional depth and increasing illumination.

Satin - the most popular - is a kind of compromise between a dull matte surface and a slightly intrusive gloss. The reflections in them are blurred, and the lighting becomes diffuse and soft. If the glossy surface of the ceiling is good for the front, hall, bathroom and kitchen, then satin is ideal for the bedroom.

The structure of the fabric web can remind someone of a high-quality plastered surface. This effect occurs due to the interweaving of the polyurethane thread in the canvas. Fabric ceilings can only be matte, but at the same time imitate suede, satin, or have a two-layer effect when an embossed fabric is applied to the inner mesh base.

Stretch PVC ceilings can be made in any color, manufacturers offer more than 200 shades of film, including metallic.In addition, PVC canvas can be mother-of-pearl, lacquer, translucent, like tinted glass, mirrored and even perforated. It can be applied to images by photo printing, including 3D paintings.

The fabric does not have such an abundance of colors, but this disadvantage is fully compensated by the possibility of painting by hand and applying various patterns. You can even say that the fabric in certain cases looks more respectable and luxurious.

Fabric canvases can be painted with acrylic paints up to 4 times, while PVC ceilings cannot be painted, but they are easier to wash.

The dimensions of PVC sheets, density and weight, tensile strength and light fastness coefficient also differ. The standard roll width is 120, 150, 255, 270, 300, 320, 350, 410, 450, 500 cm, etc.

n. Density - from 180 to 320 g / m², thickness - from 0.15 to 0.20 mm. Tensile strength: in longitudinal tension - at a load of 12 N/mm², in width tension - at 10 N/mm².

Light resistance coefficient (resistance to fading) - from 1 (low) to 10 (maximum). These indicators largely depend on the manufacturing technology used by a particular manufacturer, and, accordingly, on the brand.

Therefore, it is important to clarify all the technical nuances in advance, in particular, whether the ceilings will be seam (welded from two or more sheets) or seamless, especially when it comes to spacious rooms or when a film pattern is required for a ceiling of complex geometry, such as L-shaped or U- figurative

The width of a fabric roll usually ranges from 300 to 510 cm, so seamless installation of fabric-based ceilings is possible in rooms of almost any size.

Fabric panels must have a light resistance coefficient of at least 6!

So, PVC ceilings are more affordable in price, color, texture, they are suitable for almost any room, while fabric ceilings are nobility and elegance, they are more appropriate in elegant rooms with appropriate furniture and accessories.

Polystyrene ceiling tiles general information

Expanded polystyrene is used to make polystyrene ceiling tiles. In addition, various mineral supplements are used in the composition:

• for polystyrene ceiling tiles - wood fibers;

• for polystyrene wall tiles, gypsum and chalk are added;

• various mineral fillers.

Where is Styrofoam Ceiling Tiles Used?

Ceiling polystyrene tiles are suitable for any indoor space and can be glued to a variety of surfaces. It can be concrete, and drywall, any plaster. That's just for the kitchen, it is recommended to take tiles with a protective laminated film.

For interior decoration of restaurants, offices, bathrooms, bedrooms, they began to use a novelty - mirror polystyrene tiles. If you want to visually increase the space, this design option is the best. In addition, care for mirror polystyrene tiles is easy and simple - you can clean it with a damp cloth. The installation of this tile is the same as that of the usual one.

Advantages and disadvantages of polystyrene tiles for ceilings and walls

Pros:

- a variety of tiles in texture, color and ornaments;

- the price is accessible to many;

- installation of ceiling polystyrene tiles can be done independently;

- can be glued to any surface;

- sound insulation and heat insulation - small;

- hiding surface defects;

- by weight - light;

- the interior will be unique and cozy.

Minuses:

- melting at high temperature;

- lamps cannot be built in;

- fragility;

- installation only indoors;

- yellow over time.

How to glue tiles to the ceiling and walls yourself?

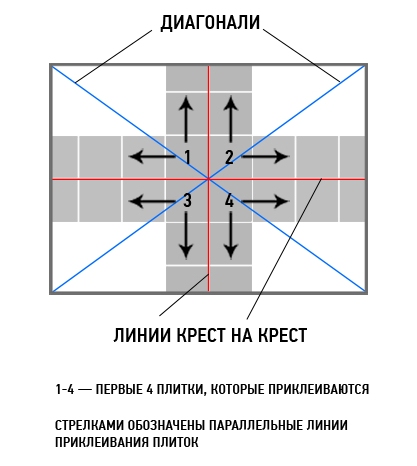

Before installing polystyrene tiles, you need to clean the ceiling (walls) from dirt, sand holes and cracks, you can prime them for better adhesion. After cleaning the surface, it is necessary to mark the surface to be glued.A guide line is drawn through the center of the ceiling and you can start pasting the ceiling and walls with polystyrene ceiling tiles from the center to the edges.

Glue for such tiles is used differently: most often "Titan", less often - PVA, "liquid nails", special mastic. Glue is applied along the edges of the back side of the tile and in the center (the places where the adhesive composition is applied are shown on the package). Give the glue a little “grab”, then the tile is pressed to the right place, smoothed and released after a while.

What do experts recommend?

1. If the tile has turned yellow over time, paint it with water-based paint, adding the desired color ...

2. If you take a tile with wavy edges and ornaments, the seams will not be so noticeable.

Tips for working with polystyrene ceiling tiles

Ceiling pasting

The ceiling tiles are glued with a special adhesive called moment-mounting.

It can be replaced with polymer universal adhesives such as Dragon or Titan, or liquid nails. The boards also hold well on acrylic putty. She can then cover up the seams.

In rooms with a small area, professionals recommend gluing tiles parallel to the walls, starting at the corner opposite the entrance.

Entering the room, we pay attention to this particular corner, so it is so important to maintain parallelism there. But in spacious rooms it is better to start gluing tiles from the center, and not parallel to the walls, but in a diagonal way. A chandelier is taken as the center of the room

A chandelier is taken as the center of the room.

The second option of pasting is more expensive, but in view of the fact that the tile is very cheap, it will not hit your pocket hard.

Sometimes methods are combined. For example, they begin to glue from the center, keeping parallel with one of the walls. And it happens that the tile is glued diagonally from the wall.

To make the design of the ceiling more interesting will help the use of two types of tiles of different colors. By choosing a contrasting combination, you can turn the ceiling surface into a checkerboard or make a pattern in the form of a snake or spiral. Having spent a minimum of funds, at the exit you will receive an original ceiling.

To cut tiles, use the most common, well-sharpened knife.

If there is a distance of one to one and a half centimeters between the wall and the tile, it is not necessary to glue it with tile fragments. A ceiling plinth will look much more advantageous and logical.

When the glue is completely dry, you can begin to cover the seams. White silicone sealants work well for this task.

As you can see, there is nothing complicated in pasting the ceiling with polystyrene plates.

With minimal experience and a little patience, you can transform the ceiling in the room on your own. The key to success in this business is thorough preparation for work and attention to detail. For those who value their time and save money, adhesive tiles are just what the doctor ordered.

https://youtube.com/watch?v=ikLWLLz0UcArel%3D0%26controls%3D0%26showinfo%3D0

- http://skosr.ru/sovet/akrilove-podvesne-potolki.html

- https://www.pravda.ru/navigator/natjazhnye-potolki-pvkh-ili-tkanevye.html

- http://fortstroi.com.ua/stroitelstvo/stati/item/2167-podvesnye-potolki-iz-orgstekla-dostoinstva-nedostatki-osobennosti-montazha-praktichnye-sovety

- https://vodaidom.com/plitka-iz-polistirola-dlya-potolka-plyusy-minusy-osobennosti-montazha/

Reliability, durability and insulation properties

If we talk about reliability, durability and insulating properties, then each type of stretch ceiling has its pros and cons. To make the right choice, consider them briefly.

PVC ceilings

Advantages:

- durability - up to 12 years;

- the ability to withstand pressure up to 100 kg / m2 (when the apartment is flooded by neighbors from above, the PVC film stretches, but does not tear, while the water can be drained through the hole for the chandelier);

- practicality and low cost;

- variety of colors and textures;

- the possibility of using a more reliable, "harpoon" installation system;

- the possibility of multiple replacement of panels;

- antifungal coating.

Flaws:

- the likelihood of damage by sharp objects;

- intolerance to sub-zero temperatures (not suitable for unheated cottages);

- low sound and heat insulation properties.

fabric ceilings

Advantages:

- strength, the fabric ceiling is difficult to damage with sharp objects or scratch;

- durability: warranty - up to 12 years, probable service life - up to 20–25 years;

- antistatic effect (does not magnetize dust);

- resistance to temperature fluctuations from -40 to +80 oС;

- simpler installation technology (without heating the panels);

- seamlessness (web width - up to 5.1 m);

- the fabric provides additional sound and heat insulation, when installing special substrates in the room, you can create good acoustics (sound absorption coefficient - 0.4 at a frequency of 1000 Hz).

Flaws:

- only matte textures;

- the impossibility of removing the canvas and reinstalling it;

- lower water resistance - due to porosity, water seeps out during flooding and can spoil the appearance of the canvas itself;

- low elasticity;

- with a strong impact of water, the canvas can break off the fasteners (profile, baguette).

With all this, the price of fabric ceilings is higher.

Types of polystyrene tiles

According to the manufacturing method, the following types of tiles are distinguished:

- Injection tiles - characterized by low density and affordable price. It is often referred to as foam, which, in general, is true, since all foamed plastics are called that, and it appears just by baking the foam. The thickness of such a tile is on average from nine to fourteen millimeters.

- Stamped tiles - obtained by pressing at high temperatures. It is denser than injection, despite the fact that its thickness is less: from six to eight millimeters.

- Extruded tiles, also known as extruded tiles, have a smooth and easy to clean surface, which allows them to be used in the bathroom and kitchen. The densest of all of the above with a thickness of two and a half, three millimeters. The surface of this tile is often laminated, which explains the wide range of colors.

Types of tiles

Material characteristics

The composition of the fiberglass panel contains a large number of unidirectional threads, no more than six microns thick. They are fastened together with polyester resin, so that the material has a uniform structure, and the finished product is highly durable.

This structure of fiberglass provided him with a number of features:

- Sound absorption, which is achieved by the parallel alignment of the fibers of the plates. This contributes to the absorption of the sound wave, rather than reflection, which reduces the effect of echo in the room;

- Moisture resistant. The material does not absorb water due to the fact that it does not have capillaries. This property of fiberglass can be called unique, since such a structure is inherent only to it. Therefore, the liquid that enters the surface of the structure or inside during cleaning will instantly evaporate without leaving any traces;

- Fire resistance. In order to further improve this property of the product, it is coated with special compounds;

- Dust proof. Caring for a fiberglass ceiling is not difficult. Cleaning is done with a vacuum cleaner. Also. The surface can be wiped with a damp cloth using a synthetic detergent. If there is a need for mechanical cleaning, then it is quite possible.

Preparatory work before installation

The ceiling must be prepared before the installation of fiberglass boards on its surface.

It is very important to follow the instructions carefully during these works. For the process to be successful, you can not show any independence

The plane to be formed must be cleaned of various parts that are loosely attached to it. Seams that are painted should be cleaned, and cracks with an opening exceeding a centimeter should be plastered.

As for the space above the ceiling, there absolutely all types of work must be completed and communication elements firmly fixed.All this is necessary in order for the structure to be reliably protected from the fall of these objects.

So which stretch ceiling to choose PVC or fabric

The answer to this question depends on many factors. First of all, from the budget of the planned event.

If there is no limitation in funds, then you can choose a fabric ceiling. The interior with it looks more refined and elegant if the room is furnished with appropriate furniture and lighting fixtures: for example, in the Empire style, Baroque or traditional calm classics. But for rooms with high humidity, a fabric ceiling is not suitable; it is also better to install a PVC film in the kitchen, because, even if there is a good hood over the stove, fats, soot and dirt settle on the walls and ceiling.

PVC ceilings are more democratic.

At a low cost, they are distinguished by a variety of colors, and they can be installed indoors in any style - from hi-tech to rococo. The only inconvenience during their installation is the need to remove objects from the room that high temperatures can damage. So, if the room has expensive furniture that has nowhere to rearrange, preference should be given to fabric ceilings.

Often, organic glass, also known as polymethyl methacrylate, is used to install a suspended ceiling. Let's take a closer look at its pros and cons, installation features, characteristics.

Acrylic Glass Specifications

Speaking about how acrylic suspended ceilings should be mounted, it should be noted that the glass used in the process of work can be translucent matte, which allows you to equip acrylic matte ceilings, as well as with a reflective surface, which makes it possible to mount a glossy ceiling with backlight

But more often, those ceilings that are planned to be equipped with decorative lighting are still made of frosted plexiglass, which visually gives the surface a kind of depth and increases the room in size, raising the ceiling.

It is extremely important to know that the plexiglass ceiling is completely resistant to moisture, thanks to which it will not be difficult to mount, for example, an acrylic ceiling for a bathroom, shower room, kitchen or other room with a high level of humidity. In addition, the material tolerates sudden temperature changes well, so it can be used both in unheated and hot rooms.

Plexiglas tolerates mechanical loads well, so it will not be possible to damage it with any slight blow or careless touch.

Due to the ability of the material to interact with inkjet printing, it becomes possible to install stained-glass windows on the ceiling. Another positive property of acrylic glass is that it is very easy to cut, which also has a positive effect on the comfort of installation.