Selection of pipes for laying in the ground

External sewer pipes experience more serious loads than those located inside the building. In internal networks, pipes are laid along the walls, in extreme cases, sewer pipes are laid under the floor. External sewage pipes are laid in deep trenches, they have to experience ground pressure.

Advice! If it is necessary to lay a sewerage pipeline under a road, it is necessary to use pipes of the highest strength class.

Sewer pipes for laying in trenches

For external networks, a special type of pipe is produced. So that the consumer is not confused with the choice, manufacturers paint such pipes in brown-orange or red. While the pipes intended for the installation of internal sewerage are usually dark gray.

For the assembly of external sewerage, the following types of pipes are used:

- Smooth polymeric - made of PVC or polypropylene.

- Corrugated polymer - made of polyethylene or polypropylene.

- Cast iron.

- Asbestos-cement.

It must be said that polymer pipes are most often used. Moreover, corrugated products are recommended to be used where the load is especially high - if deep laying is necessary or when a pipeline is placed under a highway.

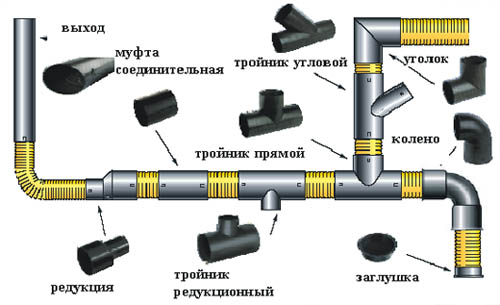

Advice! The most common pipe size used for the construction of external sewerage in a private house is 110 mm. In addition to pipes for assembling the pipeline, it is necessary to purchase fittings - bends, crosses, revisions, etc.

Stages of laying external sewerage

Many people, thinking about sewerage into the house, are wondering how to lay sewer pipes? The whole process can be divided into several stages:

- Drawing up a plan for future sewage and calculating all the necessary materials that will be needed to mount the system. This takes into account not only the required length of the pipes, but also calculates all the necessary corners, transitions and branches that may be needed.

- Performing all earthworks.

- Installation of the entire pipeline.

- Implementation of backfilling.

This instruction helps to lay a sewer in a country house or cottage without any unpleasant surprises, since all possible cases have already been calculated at the planning stage, and thus you have nothing to fear.

The main types of autonomous sewage for a country house

Despite the fact that cesspools are considered by many to be the “last century”, this type of autonomous sewerage is the easiest to build with your own hands.

An equally important argument in defense of cesspools is the fact that their internal arrangement has now changed.

Before you make a sewer in your house like a cesspool, you need to find out the engineering and geological features of your site.

The easiest way to build cesspool walls is with masonry, with ceramic red brick being the most viable option.

If it is possible to use additional equipment, then it is possible to build a cesspool from reinforced concrete rings. Experts recommend concreted the bottom of the cesspool, cover the pit with a slab with equipped ventilation and a special inspection hatch.

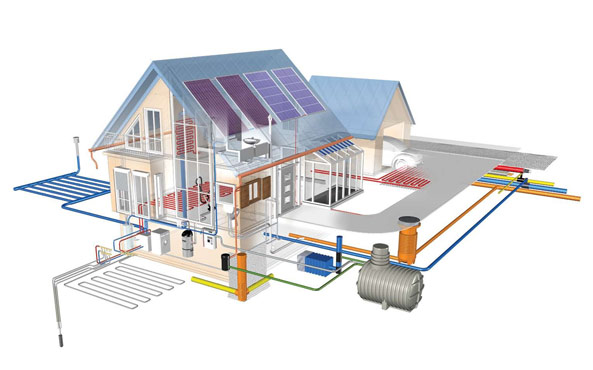

Polypropylene septic tank

You still have not decided how to make a sewer in a private house yourself?

We recommend installing a local autonomous sewage system, for example, a septic tank.

This type of sewerage is especially relevant in those houses where people constantly live, and has gained particular popularity among Russians.

The septic tank is quite simple and reliable in operation, it is easy to install it on your own by following the step-by-step installation guide (it is included when buying a septic tank, for example, their polypropylene).

In addition, septic tanks do not require frequent cleaning, so you will spend less money on calling a vacuum truck.

Modern septic tanks are even three-chamber, they have a very high degree of purification of wastewater and domestic water due to the elements of the aeration system and biofilters.

Deciding which type of autonomous sewerage is most suitable for your home and site will help sewerage in a private house video.

The sequence of actions in the construction of an individual sewer system

Before you make a sewer in the house, you need to decide on a pan of initial actions:

Determine on the ground where the sewer well (cesspool or septic tank) will be located

Important: the drain well must be located below the level of the house.

Determine the exit point of the sewer from the house.

Carefully inspect the exit point of the collector pipe. Keep in mind that at this point all drains and used water from all plumbing fixtures in your house (sinks in the kitchen, toilet, bath, boiler) will accumulate. to make sure that the collector is mounted correctly (there should be no distortions and deviations).

Only after a preliminary inspection has been made, it is possible to draw up a preliminary sewerage project for a private house. Please note: the external sewer system is usually straight, the internal sewer system usually has many bends and corners. Therefore, it is very important when drawing up its project to calculate all pipe sizes, their bends, and so on.

Only after everything is thought out and calculated, you can start buying the necessary materials.

We proceed to the installation of external and internal sewerage systems.

Carrying out internal sewerage

Recently, pipes made of polypropylene have been especially popular. They do not corrode, so their service life is much longer than steel and cast iron pipes.

And the installation of polypropylene pipes is not so difficult. However, one must take into account such a fact: how many drain sources are in the house.

For those houses where many plumbing fixtures are installed, a pipe with a diameter of at least 100 mm is required. Consider this fact: when leaving the washbasin, the pipe has a diameter of 50 mm, so pipes of different diameters will have to be joined.

But today this is not a problem - there are special adapters. Therefore, you don’t have to worry about sealing the joints - it will be reliable.

It is not superfluous to check the quality of the gaskets: they must not be damaged. Then there will be no leaks at the joints.

Connecting plumbing fixtures

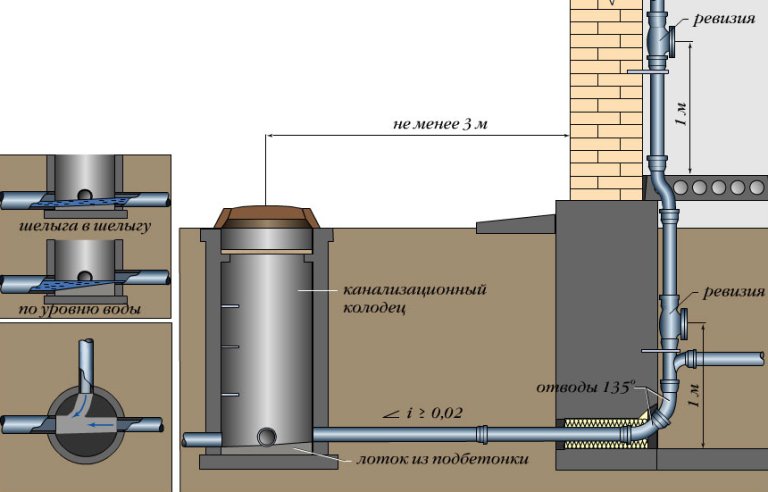

As a rule, the riser is equipped with a revision (it is installed from the floor at a height of at least 1 m) and a special exhaust pipe (it is installed 0.7 m above the roof of the house).

Why do we need such a complex structure of the riser?

Connecting a private house to the sewer involves the formation of gases and an unpleasant odor.

If the riser is equipped with reliable ventilation, then this is a guarantee of ventilation of the entire sewerage system in a private house.

In fact, polluted air is forced out through the riser. And the people living in the house do not suffer from an unpleasant smell at all.

Important: insulate the riser if it is located in an unheated room. In order to connect the riser to the external sewer, you need to use a special outlet, its diameter must be less than the diameter of the pipe on the riser

Experts recommend installing an outlet to the riser according to the movement of dirty water at an angle of 90 degrees or more. To connect the risers, two bends with an angle of 135 degrees are used.

In the event that another additional riser is required, then you need to use a 45 degree angled tee and another additional bend.

Therefore, it is much easier to connect to the sewerage of a private house on your own if there is one riser or one collector pipe.

For laying external sewerage, a polypropylene pipe with a diameter of 150 mm is best suited.

sewer fittings

For those who still doubt their own abilities, we recommend watching: how to make a sewer in a private house video. We hope that all your doubts will disappear and you will get down to work with enthusiasm.

Factors that determine the depth of laying

When choosing the pipe laying depth, it is necessary to take into account a number of factors that have a significant impact on this value, and, accordingly, determine the cost of installation work.

- The purpose of the sewer network.

- Way of laying sewers.

- climatic conditions in the region.

- The possibility of additional load on the sewer pipe.

Let's consider these criteria in more detail.

Varieties of sewer networks

For most residents, sewerage is associated only with the removal of sewage from residential premises, but in fact the concept of sewerage is more extensive and includes various networks.

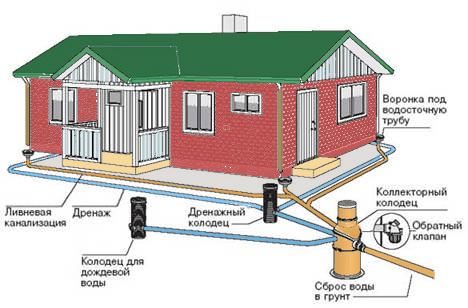

Storm sewer device

- The device of the storm sewerage, is intended for collecting and removal of an atmospheric precipitation. The depth of the storm sewer should not be less than the depth of soil freezing. When insulating the system, it is possible to reduce the depth to 0.7 meters.

- Cable ducting is designed to ensure the safety and possibility of replacing electrical lines. Laying electrical cables in special pipes greatly simplifies the installation process. The depth of the cable duct is determined mainly by the material of the pipes from which it is made. When using plastic pipes, it should be at least 0.4 m, and with steel sewerage - 0.2 meters.

The depth of laying domestic sewage depends on a whole range of factors, which we will consider below.

Construction of an external sewer system

If the internal sewerage system of a private house practically does not differ from the sewerage system in an apartment, then the scope of work in the first and second cases differs significantly.

There is much less work to be done if the house already has an old sewage system. In this case, you just need to dismantle the old pipes and use the same sewer routes as before.

But it may happen that you have to completely redo everything. In this case, there is a lot of work to be done: you need to raise the floor (spread it out) and in the event that the depth of the sewer exit from the house is not sufficient, we deepen it.

To do this, we dig a hole under the foundation, after which we measure the distance from the lower edge of the foundation to its upper edge.

This distance should be 1 meter or more, then the drains in the collector pipe at the exit from the house will not freeze even in the conditions of the Russian winter.

From the outside of the house, we also dig a trench to the drain well. Moreover, experts recommend digging a trench on the street deeper than inside the house, and ensuring its constant slope.

Such a measure is necessary in order to ensure the unimpeded flow of water and wastewater.

How to properly lay sewer pipes in a trench

The sewerage system in a private house with your own hands involves laying pipes both inside and outside the house. Let us dwell in more detail on the laying of external pipes.

Connection of sewer pipes

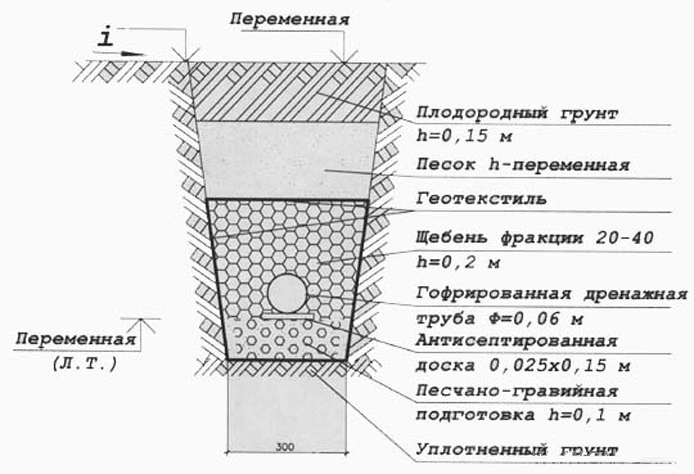

Experts recommend pouring a layer of ordinary sand (about 15-20 cm thick) at the bottom of the trench. Such a measure will save sewer pipes, including those made of polypropylene, from excessive pressure.

On the sand, the pipes will sag slightly and take a comfortable position.This will save them from excessive pressure of the filled soil.

An important issue when laying sewer pipes is their connection and sealing of joints.

An audit is needed so that in case of clogging of the pipe, it can be cleaned. We advise you not to save on the installation of revisions, the money spent will pay off during the operation of the entire system.

It is desirable to install a revision after every 4 m, it is advisable to close the pipe outlet with a special plug from the outside.

Pipe laying features

- For an autonomous sewer system, pipes with a diameter of at least 110 mm are used.

- Plumbing equipment can be connected to the system with pipes having a diameter of 50 mm.

- The horizontal angle of adapters and outlets must be equal to 45 degrees.

- Make a slope of the sewer pipe from the drain point to the septic tank. The slope must be at least 2 cm per linear meter of the pipe.

- For sewerage passing through the site, inspection and revision wells are installed.

- The pipeline of the sewer system is insulated if it is laid above the freezing level of the soil.

- To seal the joints, silicone or a special sealant is used.

- The sewerage system starts from the point of discharge and ends with a sewage treatment plant or wastewater receiver.

- To remove gas accumulations, the entire system is equipped with ventilation openings.

- For laying a cast-iron pipe, special equipment is needed.

- The installation of the sewer pipe begins after marking the entire system on the site.

You can independently make a sewerage system without the use of heavy equipment if you choose polymer or plastic pipes.

Pipe laying

Removal of the sewer pipe from the house

The pipe laying process can be divided into three stages:

- Excavation.

- Pipeline assembly.

- Backfilling.

Excavation work

Before laying sewer pipes, it is necessary to properly prepare the trenches. Rules for excavation:

- Trenches can be dug by hand or with earthmoving equipment.

- The width of the trench should allow the installer to work with the pipe from the bottom.

Advice! If the pipes have a diameter of 110 mm, then the width of the trench should be 60 cm.

Outdoor pipes laid in trenches

- It is more difficult to determine what is the optimal depth for laying sewer pipes. According to the regulations, it should exceed the depth of soil freezing in the area by half a meter. However, this condition is not always met in practice. If the pipes are laid at a shallower depth, then care should be taken to insulate them.

- Trenches need to be dug with a certain slope. As a rule, a slope of 2 cm per meter of pipeline is laid in the project.

- When digging trenches, they are made deeper than the designed pipe laying depth by 10 cm. This depth will be used to create a shock-absorbing cushion.

- The bottom of the dug trench should be well rammed, if there are large boulders or frozen clods of earth on it, then they will need to be removed, the resulting holes should be covered with earth and tamped there.

- Sand or fine gravel is poured at the bottom of the trenches. Sealing the pad along the entire length of the trench is not required. But in the places of the planned installation of revision wells, the poured sand will need to be compacted at a distance of two meters in each direction from the installation site of the well.

- In those places where the sockets of the pipes will be located, pits are arranged.

Pipe laying and assembly

Laying external sewer pipes in trenches

Consider the basic rules for laying sewer pipes:

- Installation of the pipeline begins from the place where the pipe exits the foundation of the house.

- Pipes should be laid along the trench, while the sockets of the pipes should be directed in the direction opposite to the flow of drains.

- We carry out pipe connections. To do this, you need to clean the bell well and make sure that the rubber o-ring is installed in it.The smooth end of the pipe, which will be inserted into the socket, is also cleaned no less thoroughly. A preliminary measurement is made of the entry of the pipe into the socket until it stops, putting a mark on the smooth pipe. To facilitate the introduction of the pipe into the socket, silicone grease is applied to the smooth end. If there is no lubrication, then you can use liquid soap or dishwashing liquid. The pipe is inserted into the socket, and in order to compensate for the linear deformations of the pipeline, the pipe is not inserted all the way, but a centimeter gap is left (when inserting the pipe, they are guided by the mark set earlier).

- If it is necessary to make a turn of the pipeline, it is necessary to use bends with an angle of 15 or 30. Use of bends with an angle of 90 degrees is prohibited.

- In addition, the technology for laying sewer pipes provides for the installation of revision wells. These devices are necessary to control the operation of the pipeline and carry out cleaning in the event of a blockage.

- If it is provided for by the project, then the pipes are insulated. For this purpose, it is recommended to use a heater based on foamed polyethylene.

Backfilling

Preparation for backfilling pipes in trenches

- After the pipeline has been assembled and the slope of the pipes has been checked again, it will be possible to proceed with backfilling.

- The first 10-15 cm of the backfill height is recommended to be filled with sand. At the same time, it is necessary to carefully compact the sand along the edges of the pipe, but it is strictly forbidden to ram the backfill on the pipe itself.

- Further, the pipeline can be covered with ordinary soil, which was taken out when digging trenches. You just need to make sure that there are no large stones in the ground.

The process of laying pipes in trenches is a simple job, but it requires accuracy and patience.

It is very important to follow the rules for preparing trenches and installing the pipeline, only in this case, the work carried out will be effective.

http://kanalizaciyam.ru

Scheme of the sewer line to the house

As you know, there are three types of schemes for arranging sewer networks, namely:

Scheme of the sewer line to the house

- Centralized type, involving the connection of a branch from the house to a common highway.

- Autonomous type without pumping, involving the connection of the house to a septic tank for collecting solid waste and subsequent wiring of the drainage system for settled water. The soil of the site is responsible for filtering the drained waters, in this case.

- Autonomous type with pumping, involving the collection of effluents in the overall storage, released by periodically pumping out the settled waters. Moreover, a special company providing sewage services should deal with the pumping of such waters.

And all sewer arrangement schemes involve an original plan for laying and connecting sewers to the house.

Sewerage scheme

So, in the case of a centralized scheme for collecting wastewater, the laying of sewer pipes in the ground is carried out from the central outlet of the fan pipe of the internal network to the input into the collector of the central network. Such a pipeline is laid in one line and is complemented by manholes, where dampers and revisions are mounted to facilitate system maintenance.

In the case of installation of an autonomous system without pumping out, the laying of external sewage networks is carried out in one line from the outlet of the vent pipe to the input to the storage. The pipeline is completed with revisions and dampers.

In the case of installing an autonomous system without pumping out, the sewer pipe is pulled from the outlet to the septic tank, from which the drainage pipes are diverted. This is the most time-consuming liner option, but also the cheapest to maintain.

Unloading and storage of PVC sewer pipes

The installation of PVC sewer pipes begins with the unloading of the received pipes and fittings and the organization of their careful storage. Any pipe after transportation must be checked for defects.

The unloading of pipes, either by hand or by machinery, must be done with great care so as not to damage them.

When unloading, it is unacceptable to throw frozen PVC pipes on the cold ground or floor. The pipe should never be thrown at all, despite the fact that the PVC pipe is quite elastic, if handled incorrectly, it can crack even in warm weather. Moreover, the crack may not be noticeable, but during the operation of the pipeline, it can cause leaks.

What pipes can be used

The material and profile is selected in accordance with the existing project of the waste system.

Cast iron products do not lose their relevance due to their low price and durability.

They are resistant to loads and temperature extremes, but are subject to corrosion. Modern technologies create anti-corrosion coatings that increase the life of the product. Cast iron pipes are heavy, so the trenchless laying of the sewerage system will require special equipment and support personnel to create an engineering structure. When performing external sewerage, cast iron products must be provided with thermal insulation.

In recent decades, sanitary products made of PVP and PVC have appeared, which are not inferior in their properties to metal ones. They are much lighter, so installation with such products is easier. When installing an internal system in a bathroom or bathroom, it is better to use PVC pipes. Polyethylene and polypropylene pipes are more suitable for outdoor systems. The advantage of plastic is that they practically do not accumulate deposits.

Asbestos pipes are resistant to aggressive environments. In the aquatic environment, asbestos only gets stronger over time. In addition, under the influence of the flow of water on the inner surface of the pipes there is no overgrowth. Installation of the asbestos system is not difficult, but it is sensitive to mechanical stress. You need to be careful when transporting and installing them. Protection must be provided to prevent subsidence and fractures. Asbestos products are not recommended for use in sandy soil, as they have low resistance to sand.

Pipe selection

Scheme of a trench for a sewer pipe.

External sewer pipes, like water pipes, experience much more serious impacts and loads than those laid inside the building. In addition to its own, dynamic loads, water hammer, the pipeline laid outside also experiences a static external load - the pressure of soil masses. The values of these influences are especially critical in sections of the pipeline located under the carriageway - roads, especially unpaved ones.

Therefore, it is important to make the right choice of the type of pipes used to equip the external pipeline.

Today, the following products are used as sewer pipes:

- smooth polymer pipes - PVC or polypropylene;

- polyethylene or polypropylene corrugated pipes;

- cast iron;

- asbestos-cement.

The most technologically advanced, reliable, easy to install are the first 2 varieties. The cast-iron pipeline, although it is considered very reliable, durable, has significant drawbacks, the main of which is the high cost.

Scheme of wiring of sewer polymer pipes.

In addition, cast-iron pipe products are distinguished by a significant mass, so the production of a pipeline with a diameter of more than 200 mm is very difficult and practically impossible without the involvement of special equipment - an assembly crane (or a pipe-laying crane).

Asbestos-cement pipeline is used even less frequently today.The reason for this is the low manufacturability of installation work, the need for coupling joints, and most importantly, low mechanical strength, high fragility of asbestos-cement products, low maintainability of the pipeline from such pipes.

Laying of external sewerage process overview

The very procedure for laying a sewer network of any type involves the consistent implementation of the following work plan:

Choosing sewer pipes for laying in the ground

Plastic sewer pipes

At this stage, you need to choose the diameter and length of the pipe. Everything is simple with the length - it is equal to the distance from the fan outlet to the input to the collector or septic tank. The diameter of the pipe is selected based on the estimated volume of effluents. However, in reality, you will have to choose between 110 millimeters and 150 (160) millimeters. These are typical sizes of household sewer pipes. If you plan to build an industrial highway, then the diameter will start from 400 millimeters.

In addition, you need to select the type of "pipe" material. Usually it is polyvinyl chloride (smooth pipes) or polypropylene (corrugated pipes). PVC products are less durable, but will cost less than PP pipes.

Determine the slope of the sewer pipe

Such a slope guarantees the flow of liquid through the pipeline under the influence of gravitational forces. That is, the system will divert effluents in a non-pressure mode.

We carry out earthworks

The depth of the trench for the sewer must correspond to the level of soil freezing. Otherwise, the system will freeze in the winter.

Laying sewer pipes in the ground

Therefore, the input to the sewer main (outlet from the fan pipe) is immersed in the ground by 1.2-1.5 meters. The withdrawal depth is determined based on a 2-centimeter slope (per linear meter of the pipeline).

As a result, at this stage, a trench is being dug, the bottom of which goes to the catchment point under a slope. Moreover, the width of the trench is 50-100 millimeters. And its walls, after deepening to the level of one meter, are reinforced with shields and struts. The selected soil is stored in a special area, it will come in handy for filling the trench after the installation of the pipeline.

sewer well

Long sections of the sewer line are equipped with wells, the walls of which are reinforced with concrete rings. The bottom of the well coincides with the depth of the trench or falls below this mark (the missing part of the soil can be poured).

At the same stage, a pit is dug for a septic tank or a waste storage bin. The selected soil is removed from the site and disposed of. It will not be used for bedding. After all, the selected volume will fill the design of a septic tank or bunker.

In addition, at the same stage, you can start laying trenches for the drainage system of an autonomous sewer.

Laying sewer pipes in a trench

Laying sewer pipes

The installation of the pipeline is carried out in measured segments (4, 6 or 12 meters each), which are connected into a socket. Moreover, it is better to lay a layer of sand at the bottom of the trench, 10-15 centimeters thick, it will save the line from possible ground vibrations provoked by heaving deformation.

Laying is carried out with bells upwards, that is, the bell should be the first on the flow path, and the smooth end should be located under a slope. Therefore, the assembly is carried out from the outlet of the fan pipe towards the septic tank.

After completing the assembly, the pipe is covered with coarse sand, after which the trench is filled with selected soil, leaving a tubercle on the surface, which will “sag” next spring, after the soil “settles down”. The rest of the soil is disposed of.

Commissioning

Before backfilling the trench, it would be a good idea to check the tightness of the joints and the throughput of the pipeline. To do this, you can wrap the socket sections with newspaper and drain several buckets of water into the toilet.

If there are no wet spots on the newspapers, the system functions without compromising the tightness of the pipeline.Well, the throughput can be estimated by comparing the volumes of "introduced" and "discharged" fluid. If the same bucket of water “reached” the exit, then there are no stagnations in the sewer, and you will not have problems with system maintenance.

The choice of material for laying external sewerage

Before proceeding with the installation of the sewer system, it is necessary to select pipes that can withstand the effects of the environment, since the impact on them in the house is much less than on the street. Since the pipes are laid in deep trenches, they must accordingly withstand significant ground pressure, which makes it necessary to use stronger materials than for internal sewage. Today, the store for laying external sewerage offers pipes such as:

- smooth pipes made of polypropylene or PVC;

- corrugated pipes made of PVC or polypropylene;

- asbestos pipes;

- cast iron pipes.

Smooth PVC pipes for outdoor sewerage

In order for buyers not to get confused which pipes are intended for internal and which for external work, manufacturers paint them in different colors. Pipes intended for indoor use are dark gray, while pipes for outdoor sewerage are painted red or brown-orange.

Today, as a rule, smooth and corrugated PVC pipes are used for sewage. This is due to the fact that, firstly, they are much cheaper than others, and secondly, they are very easy to install without additional equipment.