The pump pumps jerkily, turns on and off very often

To fix this problem, you need to do the following:

Pay attention to the pressure gauge, which is located on the automation unit. If the pressure gauge needle rises to the pressure that the station was set to (the pump will turn off), then drops sharply until it is turned on, then there may be the following reasons: there is no air pressure in the hydraulic tank

At the factory, nitrogen is pumped into the tank to a pressure of 1.5 atm. Sometimes, due to corrosion, cracks appear in the tank body, and the pressure does not hold for a long time. It is necessary to find a leak and repair the crack (for example, with “cold welding”). You can check the air pressure in the hydraulic tank by connecting a pressure gauge (at least a car one) to the nipple. The pressure in the tank may not necessarily be due to the appearance of a crack, but simply for some unknown reason, the air has left. Then you don’t need to bring yourself to a brain twist in search of non-existent cracks, but simply pump the air with a pump (in fact, you should start with this); rupture of the diaphragm separating air and water in the tank. You can check this through the nipple: if water flows from the nipple, then the diaphragm is damaged; pressure switch not working. which controls the activation of the pump.

The pump does not draw water

When it turned out that the pump does not pump water, one of the reasons may be that the pressure in it is not adjusted correctly. Troubleshooting is carried out according to the scheme:

- the pumping station is turned off from the mains;

- water is drained from the water tank;

- the air pressure in the tank is measured through the nipple with a car pump with a pressure gauge or a compressor, its optimal value is 90-95%;

- air is pumped into the water supply system.

- water is poured into the station;

- joins the network with pressure control.

The air in the water supply system is pumped as follows. The cover from the pressure switch is removed by removing the plastic screw and changing the tightening force of the existing assembly springs. Turning one nut turns on the lower value of the pump. Clockwise rotation causes the pressure to increase and counterclockwise rotation causes the pressure to decrease.

Turning the other nut adjusts the pressure range between the lower and upper limits. The range limits are changed by rotating the element clockwise to expand it, counter-clockwise to decrease it. After the steps taken, the pumping station is connected to the mains, and its performance is checked.

Common causes of breakdowns of the pumping station

In the world, as the classics justifiably assert, nothing lasts forever, this also applies to equipment. Unexpected malfunctions in the operation of pumping equipment, its stop or incorrect functioning can be caused by a number of reasons, such as:

- lack of electricity;

- lack of water in the system;

- pump breakdown;

- breakage of the membrane tank;

- damage to the automatic unit, etc.

The device of household pumping units is not particularly difficult, and this allows you to do repairs yourself. In some cases, you need to disassemble the pump and replace the damaged part. Sometimes it is required to seal a crack in the tank, and sometimes it is enough just to check the availability of electricity. In each case, you need to determine why the pump does not pump water, and find a "recipe" for solving the problem. If you can not find an acceptable solution to the problem, you need to contact the experts.

Solving problems associated with the lack of water in the system

The first step is to check the tightness of the pipelines and the presence of water in the system.When there is no water, the cause could be a malfunction of the check valve located between the head of the well and the inlet pipe of the pumping station. This part stops working as a result of clogging of the valve with foreign objects. The unsuitability of the spring that controls the operation of this element is also being considered.

Clogging of the valve is eliminated by cleaning it after removal, and in the event of a breakdown, a complete replacement of the check valve must be made, but this will require a significant amount. With a long idle time of the pumping station, a situation arises when water disappears at the junction of the well and the pump. A special filling hole eliminates the problem.

If there is a problem with seasonal low water levels, the solution is to place the pump inlet loop deeper into the well shaft. When the inlet circuit is deeply immersed, the likelihood of clogging increases; a filter is installed to prevent this.

Insufficient voltage in the network is also the reason for the lack of water supply when the supply system is running. This is determined by the power supply tester. The wear of the pump blades is eliminated according to the following plan:

- disassembly of the pumping device using a special tool to facilitate the removal;

- inspection of the condition of the impeller, if necessary - replacement of a broken blade;

- if it is impossible to replace a broken part (it all depends on the manufacturer), the pump is completely changed.

The pump hums but does not turn

The reasons for this malfunction of the pumping station are as follows:

- it happens that the pump has lain somewhere in the barn for the winter, and in the spring they got it and try to start it. But it starts to buzz ... Due to the fact that the pump remained without water and without movement for a long time, the pump impeller "glued" to the housing. It is necessary to manually twist the impeller from the back side, and then plug it into the network;

- the capacitor has failed (located in the branded box of the engine);

- you need to check the voltage in the mains, it may just be low.

That's all (or almost all) that can be said about malfunctions of the pumping station for home water supply systems and about repairing the pumping station with your own hands.

pumping station malfunctions

2013-2017 Copyright Use of site materials is allowed with reference to vodoprovod-doma.ru

The pressure device turns on more often than usual

Why does a serviceable pumping station often turn on? The reason is primitive - there is insufficient pressure in the air chamber of the storage tank. The lower the air pressure, the more often the pump turns on and the period of its continuous operation decreases. To make sure of this, an automobile device is taken to determine the pressure value and the pressure is measured on the nipple inserted into the tank. In many models of water pressure installations, 1.5 atm is considered normal pressure. If, after testing on a pressure gauge of 0.5 atm or 0.9 atm, air is pumped into the tank to the recommended value using a familiar car pump.

It is worse if, when monitoring the pressure in the air compartment of the tank, its complete absence is detected. This may be due to air leakage through the rusted tank metal body, which may well occur after 3-4 years of operation if the tank is made of ordinary rusting steel. A leak will be detected when trying to inflate the air chamber. In many cases, the tank cannot be repaired, so you will have to replace it.

At the moment, new storage tanks are sold in a set (tank, membrane fabric, connecting flange), so its replacement is not difficult. It is necessary to disconnect the nut of the pump pipe section from the old flange and release the two threaded fasteners that connect the tank with the devices installed on top

The used tank is carefully removed, a new one is put in its place.The fasteners are tightened, the pipe section is attached to the new flange - the station is ready for operation

What else can be associated with the regular inclusion of equipment? This happens when a rubber pear becomes unusable (torn). Diagnosing such a malfunction is the easiest - when you press the nipple, water actively flows out of it. In such a situation, it is necessary to change the "breathing" film. How to do it?

It is necessary to prepare containers (dishes) to drain the water (the tank is fully filled with liquid). First, the nut is released little by little, connecting the pipe section with the flange so that water begins to flow. When the liquid has completely drained from the inlet, the bolts connecting the flange with the tank body are unscrewed and the remaining contents of the tank are drained. Now it is necessary to pull out the expired "breathing" film, dry the tank as much as possible inside (if it is made of ordinary steel) and place a new pear in it. The flange is installed in place, being gradually attracted by bolts to the body, a pipe segment is attached. The replacement of the rubber membrane fabric is completed. It remains to pump air through the nipple to the previously indicated pressure and pour water into the pump cavity. Can be included.

Adjustment of the pressure switch of the pumping station

The considered breakdowns of water-pressure installations are considered very popular, they can be easily removed by the owners of the equipment themselves. Interruptions in operation are also possible due to a malfunction of the automatic control system. This happens quite rarely and requires the intervention of a professional master. It is better not to touch the relays and sensors with your own hands.

Principle of operation

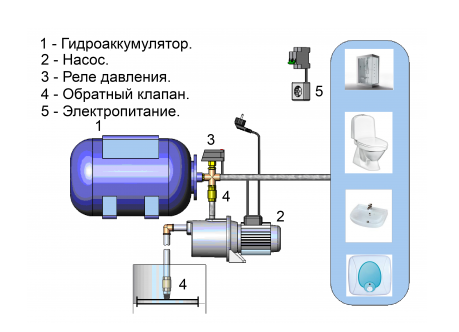

The main difference between a pump and a pumping station is the automatic maintenance of water pressure in the central water supply system. The main factors supporting the full operation of the pumping station are the availability of electricity and the required amount of water in the well.

Pumping station

The principle of operation and the device of the pump with a storage tank

A pumping station with a storage tank is considered an old model, although today such options are still found. The reason is that the tank itself is a very bulky structure. The presence of water and pressure in it is controlled by a float, and when the level drops, the sensor is triggered, starting its pumping. Such a system has a number of disadvantages:

1. Large dimensions;

2. If the water level sensor fails, water may overflow into the room;

3. Complexity of installation;

4. Low pressure due to the fact that the water flows by gravity;

5. The installation of the tank must be carried out above the level of the station.

The principle of operation and the device of the pump with a hydraulic accumulator

A pumping station with a hydraulic accumulator is considered the best option in autonomous water supply. Such a system contains a relay, through which the maximum air index is controlled. In this case, in the accumulator, it decreases in volume due to water pressure.

The pumping station, after being put into operation, begins to take water from the well and, due to pressure, sends it to the accumulator. As soon as the user of the house turns on the water, the pressure in the system gradually decreases. When the pressure drops to a certain level, the relay will turn on the pump, which will pump water into the tank and thereby increase the pressure to the required level. The relay then turns off the pump. If the water demand is small, then the pump itself will not turn on, so liquid from the tank will begin to flow into the tap.

General completeness

Regardless of the type of station - with a battery or with a tank, it is additionally equipped with:

1. By cable;

2. Pump unit;

3. Pressure gauge;

4. Terminals for grounding;

5. Membrane pressure tank;

6. Connector for connection.

Basic information about the operation of the pumping station

The operation of the pumping station is carried out according to the following scheme: receiving power from the source, the suction pump begins to draw water, the water goes into the tank, filling it to a certain level, after which the pressure switch stops the suction device. When a person consumes water, the liquid level in the membrane tank drops, the pressure switch gives a command to implement the water intake process again.

Usually, when buying a pumping station, the warranty period is indicated. But what to do when the pump does not pump water after the expiration of such a period? There are certain approaches to performing work related to the failure of the station, allowing you to find the cause of the breakdown, and ways to repair the pumping station with your own hands. In many cases, this does not take as much time as it might seem at first glance.

How to ensure the stable operation of the water supply system

In order for the plumbing system to function successfully, it is necessary to provide a certain level of pressure and water pressure. When there is no access to centralized water supply, this problem is easily solved with the help of a pumping station. It usually consists of:

- pump;

- membrane storage tank;

- automatic control unit (pressure switch, pressure gauge, etc.).

The pump pumps water, which enters the tank. When the pressure in the tank reaches a certain maximum level, the pump is switched off. Gradually, the water from the tank is consumed for various needs and the pressure drops. At a minimum pressure level, the pump turns on again and water enters the tank. The process is controlled automatically.

With the help of such a unit, it is possible to provide water supply to a house, a bathhouse and other buildings located on the site. Having studied the principle of operation, you need to start studying possible breakdowns and ways to eliminate them.

Having studied the principle of operation and the device of the pumping station, you can do it yourself repair

Checking the charge pump

The pumping station will often turn on even if the pump is not supplied with sufficient power. The pump impeller will not be able to develop the required power. In this case, the pump will not be able to create the maximum pressure in the pipeline, in order to fill the pipes with water, it will have to work almost without interruption.

Power deficiency can be the result of a malfunction in the operation of individual parts of the pump - electrical or mechanical.

Contribute to this problem and faulty power supply.

The main reasons for the lack of power:

- Salting of the inlet and outlet pipes of the pump: eliminated by mechanical cleaning or flushing with cleaning solutions.

- Oxidation of the contact surfaces of the terminal box: they should be cleaned with fine sandpaper, after disconnecting the pump from the power source.

- Unstable voltage in the mains: checking its fluctuations is carried out with the pumping station running. You can eliminate this drawback by connecting a voltage stabilizer.

Over time, the individual components of the mechanical part of the pump wear out, which leads to a decrease in the maximum possible pressure level in the system. You can check the ability of the pump visually by disconnecting it from the outlet water supply.

A weak jet of water at the outlet of the pump indicates a high degree of wear of its parts. Most of them cannot be repaired, so you will have to replace the entire worn-out assembly.

Have you decided to equip the water supply system in a private house on your own? Then the following topic will be interesting for you:. Do-it-yourself step-by-step setting of the pumping station pressure switch.

Malfunctions of the pumping station, or How to repair a pumping station with your own hands

No device, no matter how reliable, lasts forever. Alas! This also applies to pumps for water supply systems.Therefore, at the end of the topic on pumping equipment, we will figure out what malfunctions of the pumping station occur and how to do the repair of the pumping station with your own hands. If you were looking for: malfunctions of the water supply pumping station, malfunctions of pumping stations for the home, malfunctions of the water pumping station, malfunctions of the pressure switch of the pumping station. then this article is for you. Further I will simply list possible malfunctions and “fix” them.

The pump does not want to turn off what to do

If the pump does not turn off for a long time, this indicates that the pumping station is not gaining the pressure necessary to trigger the relay. There can be several reasons for this, specifically:

- lack of pump power;

- no water in the voids of the gas ring pump;

- large leak in the water wiring.

Consider any of these circumstances. In which cases the pump does not provide the required pressure? The reasons for this phenomenon are:

- installation of low-power equipment (the pump cannot cope with the task in specific operating conditions);

- pump wear.

The first situation occurs when the power of the equipment is incorrectly calculated, when such an indicator of operation as pressure does not meet these conditions. In other words, the pump is weak, due to this it is not able to overcome the resistance of water (which must be raised from a certain depth) and compressed air in the storage tank. This problem manifests itself immediately after the installation of the purchased station and the first attempts to start it. The problem is solved by replacing the equipment much more powerful.

During the long-term operation of the water pressure device, one of the parts of the gas ring pump may fail. Sometimes it happens to be an impeller that wears out and is not able to provide the necessary water pressure. In this situation, it is necessary to replace the worn part or pump assembly. For mutual cases, the presence of water in the water supply system will be characteristic, in other words, the station pumps water, but its pressure is not enough for the relay to work.

The specificity of the gas ring pump is its inability to create pressure without the presence of water in its voids. Before starting a newly installed pumping station, the cavity of the pumping device and the supply pipe should be completely filled with water through a special hole on the pump housing (top), closed with a screw plug. If this is not done, the pump will run in vain without stopping. To prevent water from flowing into the water intake tank, a check valve is first placed at the end of the supply pipe.

Water for gas ring pumps is considered not only as an object of transportation, but also as a coolant, due to this, it is impossible to leave the pumping device on for a long time if it is not filled. This can lead to overheating and failure.

How can there be a situation with the lack of water in the voids of the pump during operation? It's simple - the check valve stopped working, and the water left the supply pipe. It is necessary to change the valve (if it has been in operation for a long time) or inspect it. It may well be that a grain of sand or another small object that interferes with a snug fit has got between its body and the membrane tissue. To prevent this from happening, the valve is equipped with a strainer that prevents contamination. If the station is not switched off for a long time due to lack of water in the pump, nothing will flow from the open mixer. In such a situation, immediately turn off the equipment and look for the cause.

Equipment installation

Why isn't the pumping station shutting down? This happens with volumetric water intake at points of use or with a significant breakthrough of the pipeline in the domestic water supply system.The pressure gained by the pump is regularly spent, due to which the pumping device may not turn off for a long time. In such a situation, the possibility of a breakthrough in communications should be of concern. To establish the presence/absence of a leak, the valve closest to the station on the discharge pipe is closed. If then the equipment began to work at normal intervals (gained pressure and turned off), you must immediately look for a breakthrough or just someone forgotten an open tap.

The device of a complex of pumping equipment

In order to understand what malfunctions can occur in the complex of pumping equipment during the organization of pumping water supply, how to fix them, it is necessary to know the composition of the devices and the procedure for their operation.

Pumping stations consist of the following units:

- actually pumping equipment

. Depending on the characteristics of the water supply source, pumps can be submersible or surface. They can have different modes of operation and power; -

hydraulic pressure accumulator

. This knot is a container, which is divided into two parts by a flexible but durable rubber partition. During the operation of the pumping device, the container is filled with water and the rubber partition is stretched. When the pump stops, the partition tends to return to its original position and returns the water accumulated in the tank to the pipes, maintaining the pressure in the water supply pipelines at a constant level; -

control block

. This assembly consists of a manometer that measures the pressure in the system. The mechanical parts in the control unit set the minimum and maximum pressure values. When the minimum indicators are reached, the unit gives a command to turn on the pump, and when the maximum indicators are reached, the pumping equipment is turned off.

Clogged inlet filter

The liquid entering the water supply system of your own house from an autonomous well is saturated with mechanical impurities. Solid particles of silt, clay, sand, freely circulating through the main pipes, can damage the equipment, causing premature wear of parts. To extend the life of the pumping station, a special filter is mounted on the inlet pipe, blocking the path of debris.

Clogging of the screening device or a break in the supply pipeline leads to the incessant operation of the pump system. As a result, a sufficient amount of water ceases to flow into the unit. To solve the problem, it is recommended to clean the protective device or replace the damaged section of the line.

How to ensure the stable operation of the water supply system

In order for the plumbing system to function successfully, it is necessary to provide a certain level of pressure and water pressure. When there is no access to centralized water supply, this problem is easily solved with the help of a pumping station. It usually consists of:

- pump;

- membrane storage tank;

- automatic control unit (pressure switch, pressure gauge, etc.).

The pump pumps water, which enters the tank. When the pressure in the tank reaches a certain maximum level, the pump is switched off. Gradually, the water from the tank is consumed for various needs and the pressure drops. At a minimum pressure level, the pump turns on again and water enters the tank. The process is controlled automatically.

With the help of such a unit, it is possible to provide water supply to a house, a bathhouse and other buildings located on the site. Having studied the principle of operation, you need to start studying possible breakdowns and ways to eliminate them.

Types of pumping stations

With built-in ejector

Pumping stations are divided according to the type of workflow, they come with and without an ejector.The basic principle of operation of the internal ejector is that the volume of liquid rises due to the created vacuum. True, such models have a very high price, but due to their design they can supply liquid from a depth of 20 to 45 m.

Pump station with built-in ejector

This equipment has high performance, but because of this, a much higher noise level. Therefore, it should be installed in a utility room or, if possible, outside the house.

With remote ejector

Such pumps are immersed in the well along with two pipes. Through the first pipe, water is supplied to the ejector, which leads to the formation of a suction jet. This unit significantly loses in its characteristics to classic ejector pumps. In addition, they are afraid of air and sand in the system. Their main advantage is that this pump can be installed at home without any problems, even if the nearest well is located at a distance of 10-30 m.

Ejectorless designs

In a pumping station without an ejector, water is taken in due to a special multi-stage design related to the hydraulic part. This equipment is able to operate almost silently and with significantly lower power consumption.

The pumping station is running, the pump is spinning, but there is no water

The steps to troubleshoot this issue are as follows:

- First of all, you need to check the check valve, which is located in the water in the well or well. It often happens that sand or debris gets into it, and the valve does not close. In this case, the water does not rise through the pipes to the pump.

- Secondly, check for water in the pipeline between the well and the pump. The pump must also be filled with water; if there is no water, fill it through the filler hole.

- Very large output between impeller and pump housing. The pump just works for itself. The reason for this may be the high content of abrasive substances in the water, such as sand. In this case, you should change the housing and impeller, if they are on sale, or the entire pump (but not the entire station!).

- The well/well ran out of water. The way out is to try to lower the suction pipe or hose deeper. But remember: the distance from the water level in the well to the pump should not exceed that indicated on the pump, usually 8-9 m.