First steps in an emergency

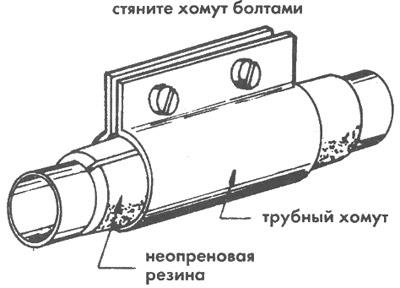

How to wrap a heating pipe? If you have a couple of clamps with rubber seals in stock at home, you can prevent some emergencies. In the event of an accident, the most important thing to do is to shut off the coolant supply to the area where the heating pipe leaked.

It will be necessary to stop the operation of the heating boiler, turn off the pump and close the necessary taps and valves. The clamp will solve the problem for a while, so repairs will still be inevitable. Before proceeding with the repair, you will need to prepare the necessary materials and tools, turn off the heating, turn off all the taps and drain the water from the system. Depending on the material from which the pipes are made, repairs can be carried out in various ways.

How to find a leak in a heating pipe

One of the "symptoms" of a violation of the correct operation of the system is extraneous noise. Vibration, whistling or clicking usually indicate that either the tightness is broken or the pressure in the system has changed.

In any case, you should pay attention to the noises that have arisen and, having examined the entire system, determine the place where the noises are most audible. Most likely, this is the area where the problem arose.

Having established the causes of noise in the heating pipes, you must immediately begin to eliminate it.

However, these signs are clearly visible only on metal pipes. On plastic or metal-plastic that is not subject to corrosion, water droplets evaporate quickly, leaving virtually no traces. What to do if the heating pipe drips? How to fix a fistula in a heating pipe? Of course, the first step is to try to stop the leak. On different pipes, repair work is carried out using different technologies. But there are also some common points. Let us dwell in more detail on the methods of repairing heating pipes from different materials. Indeed, in some cases, the problem can be solved independently, or, in any case, stop the leak until the repair team is called.

Polypropylene

Causes

Polypropylene pipes sag and go in waves when heated for the sole reason - due to a significant coefficient of thermal elongation.

This is what the deformation of polypropylene looks like when heated.

elimination

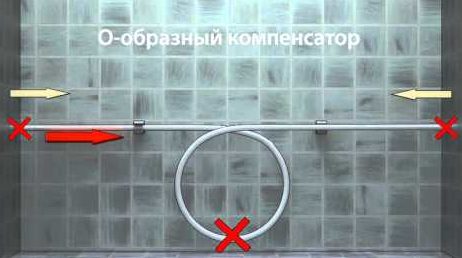

Expansion joints are welded into long straight sections - ring or U-shaped bends. Along the entire length, the pipe is fixed movably, so that it can move in the clamps.

Causes

Leaks can be caused by:

- Water hammer;

- Exceeding the recommended temperature;

- Welding with an aluminum-reinforced pipe fitting without first cleaning it with a shaver. Aluminum comes into contact with water and is gradually destroyed by electrochemical processes, after which the pipe delaminates.

elimination

Seven troubles - one answer: the damaged area is completely cut out, after which a new assembly is welded in its place.

The defective section must be replaced.

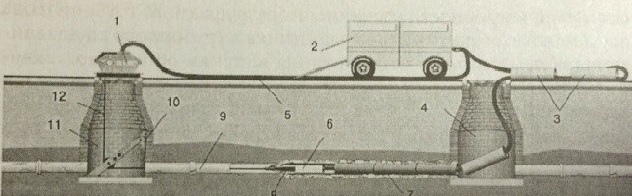

Destruction of the old pipeline and pulling the new one from separate modules using a pneumatic impact machine

1 - pneumatic winch; 2 - compressor; 3 - sections (modules) of the new pipeline; 4 - working well; 5 - air outlet hose; 6 - pneumatic percussion machine; 7 - new pipeline; 8 - expander; 9 - replaceable pipeline; 10 - anchor; 11 - receiving well; 12 - winch cable

Pulling a new pipeline with parallel destruction of the old one can be carried out using pneumatic impact machines or pneumatic punches equipped with destructive sleeves with appropriate knives (Fig. below). The energy required to move the device along the route of the old pipeline is supplied from the compressor.The cracking knife destroys the old pipe and compacts the fragments into the surrounding natural soil. The expander creates an enlarged profile for the new pipe, which is pulled into the vacant space at the same time as the destruction process.

all materials

Let's start with problems that do not depend on the material with which the heating system is diluted.

Causes

If you are bothered by uniform noise in the heating pipes, the reasons for this may be as follows:

- A significant difference between the supply and return pipelines with partially covered shutoff valves;

- Operation of a riser or elevator assembly for discharge;

- Leaks;

- In an autonomous circuit - excessive performance of the circulation pump, which creates hydraulic noise.

elimination

- Make sure that the screw, ball or plug valves on the connections to the radiator and the corresponding heating risers are fully open. If they are covered, open all the way;

Valves and taps have two operating positions - "fully open" and fully closed. There are throttles for adjustment.

- Check risers and heating beds for leaks. If available, submit an application to the service organization whose area of responsibility includes your house;

- Look into the elevator node of the house. If the water from the heating system is continuously drained into the sewer, again notify the service organization. The reasons for starting a house for discharge can be quite convincing, so it’s not worth interfering with the operation of the general house heating;

- Set the pump to a lower capacity or replace the single-mode pump with a stepped or, more conveniently, smooth adjustment.

Our choice is a variable displacement pump.

clicks

Why does the heating riser click?

Cause

As a rule, it becomes a semi-closed valve or a screw valve valve detachment on the heating riser when it is installed against the arrow (when water enters the seat not from below, but from above) The valve moves freely in a turbulent water flow and from time to time clogs the seat, causing a series of weak water hammers .

Opened screw valve. The valve is movably held on the stem and can come off in case of counterflow.

elimination

Strictly speaking, the knock in the riser must also be eliminated by the managing organization. However, in winter, it may refuse to service the application, since the repair requires a reset of the heating system, which in cold weather can lead to defrosting of the access heating and its other most vulnerable areas.

What can you do yourself?

In the general case, just open the valves on your riser all the way. This will help if the valve is not torn off the stem: it will rise and will not interfere with the passage of water.

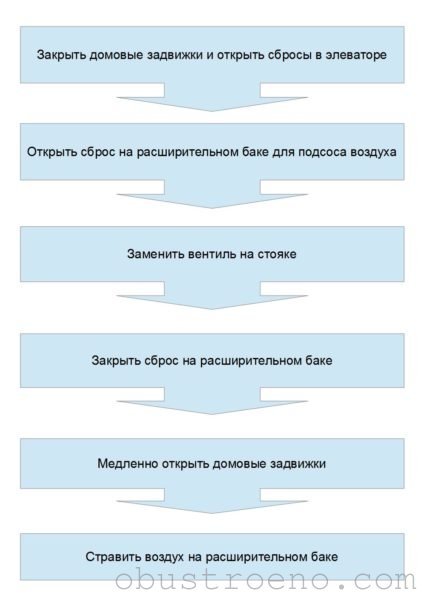

If you are friends with plumbing and your house is equipped with a top filling system (with heating supply in the attic), you can try to fix the problem during the heating season:

Instructions for replacing the valve on the riser in a system with top filling.

- It is not worth dumping a system with a bottom filling during the heating season. Really not worth it. Air risers cannot be launched without residents of the upper floors, and they tend to go to work or leave somewhere for a long time;

- It will be necessary to bleed the air at the expansion tank outlet at least twice with an interval of 10 minutes. As circulation is restored, new portions of air will enter it;

- The screw valve is replaced by a modern ball valve with the replacement of the drive: their length is different. If you don’t have the opportunity to order a squeegee of the required length, replace the valve with a similar one, or simply turn the old one over (unless, of course, its valve is destroyed and torn off).

You may need an extended squeegee to replace the valve.

The following methods of restoring water supply and drainage networks using trenchless methods are the most common

- application of cement-sand coatings (CPP) on the inner surface of the restored pipeline;

- pulling a new pipeline into the damaged old one (with and without destruction) using special devices, such as pneumatic punches;

- dragging a flexible polymer pipe (pre-compressed or folded U-shaped) into the repaired pipeline;

- pulling through continuous protective coatings from various polymeric materials;

- the use of flexible elements made of sheet material with a toothed fastening structure;

- the use of a flexible combined sleeve (stocking), which makes it possible to form a new composite pipe inside the old one;

- use of roll winding (endless profile tape) on the inner surface of the old pipeline;

- application of spot (local) coatings, etc.

Each of the listed recovery methods has specific features and has its own advantages that determine the scope of its application. The expediency of using one or another method is specified after detailed diagnostic examinations and the conclusion of technical expertise. In each case, the condition of the pipeline, its dimensions, the type of transported medium, the surrounding underground infrastructure, the type of soil, the presence of groundwater and a number of other factors that can affect the choice of restoration method are subject to consideration.

Let us present a brief description of some methods of trenchless restoration of water supply and drainage networks.

Application of cement-sand coatings on the inner surface of pipelines (spray method).

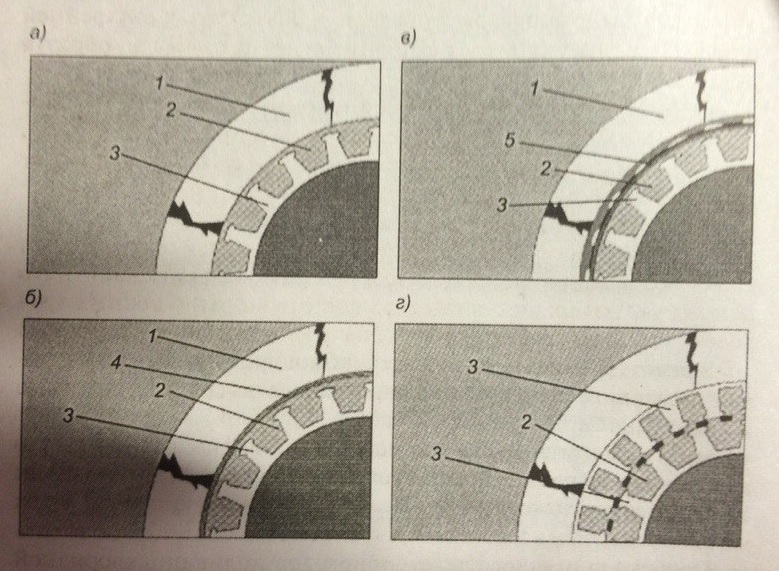

Installation of sheet polymer toothed sections using Trolining technology

a - the basic installation system (with one toothed section and filling the voids between the inner surface of the pipe and the toothed elements); b - the same with the use of an intermediate protective layer; c - the same with the use of an additional elastic element around the toothed section; d - installation system with two gear sections; 1 - damaged pipe; 2 - injector firm "Trolining"; 3 - toothed section; 4 - protective layer; 5 - elastic element

The “Trolining” system of internal flexible segments allows the use of various types of sections that differ from each other in the surface structure (single-layer, multi-layer and combined with protective layers).

Use of a flexible combined sleeve (stocking). The essence of this recovery method is the formation of a new composite thin-walled pipe inside the repair section of the pipeline, which has a fairly independent bearing capacity with a minimum decrease in the diameter of the existing pipeline.

To implement the method, a combined sleeve is passed inside the dilapidated pipeline through manholes, which is a reinforcing material impregnated with a thermosetting binder (fiberglass, synthetic felt). Then, a coolant (steam, hot water) is supplied to the inner hermetic shell of the combined hose under pressure, which straightens the hose, presses it against the inner surface of the pipeline and polymerizes the binder, forming a new composite pipe.

The eversion and advancement of the combined sleeve in the pipeline can be carried out using a flexible element (cable), a liquid or gaseous medium supplied under pressure, as well as the combined use of both methods.

Use of roll winding (endless profile tape) on the inner surface of the old pipeline. Ribloc and Expanda-Pipe methods can be used for renovation of non-pressure drainage pipelines. They allow lining the inner surface of pipelines with PVC tape.To do this, a special machine is installed in the well, which performs several functions: applying (winding) an endless tape along the inner diameter of the pipeline, its fastening; pouring adhesive resin; pushing the resulting PVC frame into the repair section of the pipeline, expanding the frame to fix it on the structure being restored. After the winding process, the remaining free annular space between the restored pipe and the new frame is filled with a special solution and compacted with a rammer to increase the static strength.

Damage to polypropylene pipes

Detecting a leak in such pipes is more difficult than in metal pipes. Since polypropylene products are not subject to corrosion, only droplets appear on their surface, which quickly disappear under the influence of high temperature.

Steps to take if leaks are found:

- Before you fix a heating pipe leak, you must turn off the area where a small leak has appeared or a breakthrough has occurred.

- Drain water from the disconnected area.

- Carefully dismantle the pipe insulation if the area is insulated.

Polypropylene pipe leak

Often, the insulation is fixed with foil tape, which is not recommended to be reused - its adhesive qualities are lost.

- Dismantle the pipeline. It is desirable to do this, in the case of an extended section, at the soldering point or between the nearest fittings. When a breakthrough occurs at the location of the fitting or welding, it is recommended to replace the soldering place with a piece of a new pipe, and replace the fitting with a new one.

- Installation of a new fitting or section. When brazing pipes, it is necessary to observe the normalized soldering, heating and cooling times. Violations of the installation technology can be the cause of the existing defect. When replacing heating pipes, products of the same type and diameter must be used.

- Let water into this area again, bleed off excess air and start the system again.

After completion of work on the repair of the heating system within 2-3 days, to control the work performed, it is not necessary to mount the thermal insulation back.

- After repairing a separate connection or installing heating pipes, periodic control is required over this section. The first hours after starting the system, you need to check the repaired area every hour for the appearance of new smudges. This will reduce the risk of a new emergency.

Experts say that leaks or breakthroughs occurring in the same places indicate an incorrect balancing of the system - different pressures are in different areas. In this case, it is required to perform a verification detailed calculation of the heating system and determine a method for eliminating the problem. In most cases, the diameter of the pipes in the problem area is changed.

Polypropylene pipe repair

Leaks can occur even in such heating systems. Sometimes it can be quite difficult to determine the location of the leak, especially if it is minor:

- If the heating pipe (its threaded connection) is leaking, then the seals will need to be replaced.

- If a problem situation is observed on a welded joint or a straight section, then pipe repair will consist solely in replacing the entire damaged section.

- Soldering polypropylene pipes must be carried out strictly according to certain technologies. The required temperature and heating time must be observed. Any mistake can cause the joint to collapse after a short period of time.

- When replacing a pipe section, it is not allowed to change the wiring diagram.

Polypropylene pipe repair

After all repairs have been completed, it is still too early to turn on the boiler. First you need to fill the system with water. You also need to make sure that the pumping equipment is also turned off.In addition, you will need to remove air from the pipes. We turn on the boiler equipment and look after the area that has been restored. The first day, you can check every hour or two how the joint behaves.

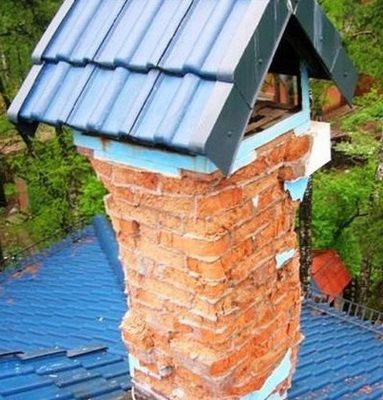

Causes and consequences of the destruction of the chimney pipe

It is possible to carry to artificial destructions: poor-quality illiterate masonry; low-grade materials used in the work; improper operation; low qualification of the stove-maker; non-compliance with the rules and schemes for the construction of the structure.

This chimney is in need of repair.

If the work is not carried out correctly, condensation may form in the chimney, and if the temperature changes and the water freezes, the ice will break the mortar in the masonry and destroy the bricks. After such processes, a violation of traction is not ruled out, which means that it will be impossible to heat a fireplace or stove, since the smoke will not go into the chimney, but will go into the room.

Explicit delamination of low-quality bricks

When using low-quality or unhardened bricks, it can be damaged by sparks or ignition of gases emanating from the firebox. In the future, these destructions can lead to damage to the entire furnace heating system or even to a fire.

Repair of a brick chimney is carried out in cases of its damage for other reasons - for example, due to the consequences of natural manifestations or mechanical impact, which led to a violation of the integrity and solidity of the masonry.

The fatal impact of time and nature

The natural causes of destruction include the aforementioned long-term use, and, as a result, the general aging of the structure.

Troubleshooting metal pipes

Leakage at joints

Fitting leak

At the moment, metal pipes for heating are used little. But in old houses, the wear of metal heating pipes is catastrophic. When a heating pipe flows at the points of connection to heaters, fittings, taps, it will be necessary to disassemble the mount, replace the seal and reassemble the connection.

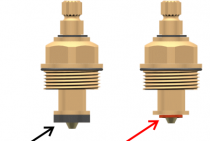

If a leak occurs in the place where the pipe is connected to the stop valves, it is advisable to change it to a new one

Since there is a high chance of breakage of valves and fittings, old connections must be disassembled with care.

Seal replacement

Leak in the body of a metal pipe

When fixing a leak in a heating pipe, one must keep in mind the fundamental difference between the plumbing and the heating system - it consists in the temperature of the liquid contained in them.

What to do if a metal heating pipe leaks:

- In some cases, it is enough to rub salt into a small damaged area several times - after that the leak will drag on.

- For larger leaks, the leak needs to be bandaged, generously sprinkling salt on each layer of gauze. The use of salt is a temporary solution to the problem, as the leak will resume when the water in the pipes cools down.

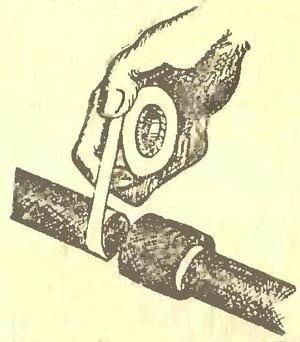

- If possible, it is necessary to install a clamp in place of the leak. This method is more durable and reliable.

- Since the action of the clamp is short enough, a complete replacement of the pipe section is required. To do this, when the heating pipe has broken through, the damaged area is cut out and a new one is welded in its place.

- The dismantled section of the metal pipe can be replaced with polypropylene.

Clamp installation

Troubleshooting copper pipes is done in much the same way as any other metal pipes. The difference is that other materials and equipment are used for welding (usually semi-automatic).

A fragment of the application of a tape protective coating using the Ribloc technology from a well

According to the “Panel Lok” technology, developed by the company “Camit Ltd” (Australia), a special profiled PVC tape is used for winding, which has T-shaped corrugations on the outside.The corrugations increase the structural surface and provide mechanical adhesion to the cement mortar injected between the lining and the wall of the pipeline being restored. Profiled tape can be used for round, oval and rectangular sections of pipelines with a diameter of 900 mm or more, with sufficient bearing capacity.

Spot (local) protective coatings. This type of coating is typical for the elimination of single (point) through, including peripheral, cracks caused by soil movement (for example, when carrying out earthworks near routes, exposing pipelines to excess loads from traffic, earthquakes, etc.), and as well as local corrosion of pipeline walls. Spot repair coatings can also be used as seals between individual pipes in various trenchless network rehabilitation applications.

Local damage that caused chemical erosion of the walls of pipelines can develop very quickly and lead to premature failure of the pipeline. Statistics show that this kind of damage is about 10% of the length of the pipeline.

Local repair coatings can be supplied in the form of: liquid solutions that harden after application operations on damaged surfaces; solutions of semi-liquid consistency; fibrous materials impregnated with resins (polyester, epoxy and polyurethane); profiled rubber seals; stainless steel sleeves; elastic sleeve blanks; tubular liners, etc.

Before the implementation of any of the methods described above for the repair of existing networks and facilities for water supply or sanitation, it is necessary to lay temporary external bypass pipelines. For example, in cases of restoration of water supply networks, bypass pipelines must ensure the supply of domestic and drinking water to the consumer in the required quantity and of the appropriate quality for the period of repair. In addition, bypass pipelines must meet certain requirements set out in the technical conditions for the production of repair work, they must be quickly assembled and dismantled and ensure the appropriate sanitary and hygienic indicators of the transported water. Since these pipelines are laid outside along sidewalk curbs, they must withstand the impact of vehicle tires and also be designed to withstand the full hydrodynamic pressure of the water. At the same time, it is very important to adapt bypass pipelines to standard fittings, control and adjustment and shut-off valves.

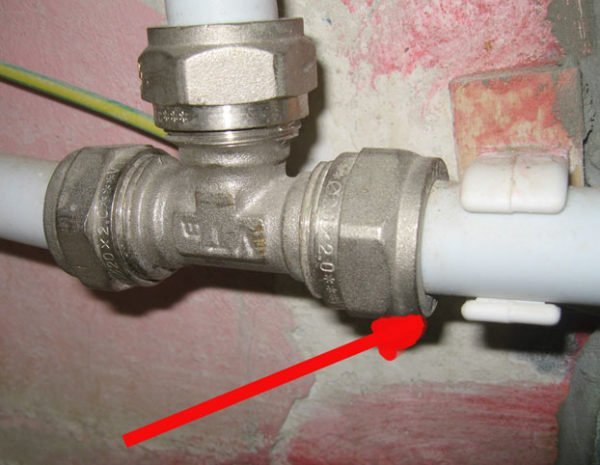

Metal pipes leak

Cause

Their typical problem is leaking compression fittings. If the leak resumes after one or two tightening of the union nut, then the reason is most likely the incorrect assembly of the connection: the sealing rubber rings of the fitting are torn out of their grooves, and the pipe compresses the fitting itself.

The photo shows a typical leak.

elimination

The problem is solved like this:

- The connection is disassembled;

- The pipe is shortened by 2-3 centimeters. If necessary, it can be shortened more and built up with an additional tube on the coupling;

- The end of the pipe is deburred;

- The inner chamfer is removed from it;

- The pipe is being calibrated. The price of a calibrator rarely exceeds 150 rubles, while a simple tool can save you a lot of trouble;

The universal calibrator from Valtec is equipped with knives for internal chamfering.

- The end of the pipe with a nut and a split ring is put on a fitting lubricated with silicone grease - without distortion, so as not to displace the sealing rings;

- The nut is tightened.

Conclusion

I hope that my material will help the reader in eliminating minor household troubles.To learn more about what a heating pipe repair might look like, the video in this article will help you. I look forward to your comments and additions. Good luck, comrades!

Any communications need periodic maintenance and repair.

All communications are subject to wear and tear. Both pipelines made of "budget" plastic, and systems made of expensive copper pipes sometimes need preventive inspection and repair. Their service life largely depends on the material and quality of installation. If high-quality materials and components were purchased, if the installation of the system was carried out according to a competent project and all technological standards were observed during installation, then the probability of an emergency leak is minimized. But still, it exists. A fistula on the heating pipe may occur even in this case. There can be several reasons for a leak:

- change in operating mode: if the heating system, designed for periodic or temporary use, suddenly began to work in a constant mode;

- changing the coolant to a more aggressive one;

- a sharp change in pressure in the system;

- wear of pipes or components;

- water hammer;

- frequent significant temperature drops inside the system, “defrosting”;

- use of low quality materials;

- errors in the installation of the system;

- mechanical damage as a result of external influences (for example, a blow or a heavy object falling onto a pipe).

And if some of the causes are more dependent on the owner and, accordingly, can be prevented, then the likelihood of others, such as wear or an emergency change in pressure, still remains. Therefore, you need to know how to repair the heating pipe in the event of an emergency.