Why the faucet is buzzing, and how to fix a leak in the faucet in the kitchen and bathroom tips from masters for repairing faucets

Unfortunately, plumbing devices do not have a very good property to sometimes break. This applies primarily to faucets and faucets. The most common malfunctions can be various leaks and leaks, the presence of noise when opening, low water pressure even when the valve is fully open, turning the valve or the impossibility of completely closing it, as well as difficulty in rotating the faucet spout or the same valve head. If the faucet is leaking in the bathroom or in the kitchen, then, first of all, you need to find out the cause of the malfunction, and then try to repair it.

How to unscrew a broken screw

If your attempts to unscrew the screw have not been successful, and the edges of the screw head have already been torn off, you should saw off two edges of the bolt with a hacksaw in order to make a smaller turnkey head. Then do the previous procedure: fill the old bolt with kerosene or turpentine and leave everything for a while. After waiting a bit, try to unscrew the screw.

A hammer and a chisel will become faithful helpers in the fight against a naughty screw if all the previous methods have been ineffective. In order to break off the old screw, it is necessary to substitute the chisel directly to the head of the screw and hit the chisel with a hammer several times. In most cases, this method solves the problem of a stubborn screw.

After such operations, the bolt can be easily unscrewed with a wrench.

The main rule for easy handling of screws is their timely treatment with graphite grease.

Ceramics take over

All hot and cold water faucets fail after a while. Their design provides for fast-wearing elements - a bushing crane for a mixer. In mixers made in the old Soviet times, these are rubber gaskets. Time does not stand still and mixers began to improve, replacing rubber or bronze wear parts with ceramic ones.

Ceramics is not the clay from which dishes are made. These are powder mixtures of various metals sintered at high temperatures. They possess qualities exceeding modern steels. Due to their increased hardness, ceramic parts are ten times more durable than rubber parts.

Bush faucet in the mixer - Photo 02

Ceramic products have such useful properties.

- mechanical strength,

- hardness,

- chemical and thermal resistance,

- do not rust.

high cost compared to rubber.

What to do if the faucet faucet is hard to turn

First of all, it is necessary to remove the mixer and disassemble it in order to eliminate the cause of the breakdown. After that, clean all the parts - first of all, the cartridge. Next, the mixer must be assembled and checked for operability.

Consider an important nuance - all these manipulations should be done only if you are versed in plumbing and have the skills of such work. Otherwise, an attempt to repair may result in another breakdown, and worst of all, the complete inoperability of the plumbing fixture.

If the problem arose due to dirty water, then a thorough flushing and cleaning of all elements of the device will help to correct the situation. After cleaning, all mechanisms begin to work correctly. For flushing, 2 main methods are best suited:

- With detergent. Mix hot water and mild detergent in a small bowl. Place all elements in it and rinse.If you find old dirt, then they can be wiped with a paste using a toothbrush. After that, rinse all the elements under warm running water.

- With the help of chemicals. Put on gloves and take a special chemical limescale remover. It will take care of any dirt. If it is not there, then ordinary table vinegar will help, but it cannot be used on iron parts. Moisten a cloth and lightly apply it to the elements of the mixer. After that, leave all the details for 30 minutes, and after this time, rinse everything thoroughly under running water.

In the second case, the main thing is not to use a large amount of chemicals or vinegar, as they can damage the parts and elements of the faucet.

If the mixer’s performance problem is associated with mechanical malfunctions, then it is important to understand which element needs to be repaired. To do this, you will also have to disassemble the crane and examine in detail all the nodes and components, and then replace the faulty one with a new one.

During the operation of the mixer, the lubricant may dry out, which helps to make the crane turns smoother. If for this reason it has become difficult to turn, then the problem can be solved in just a couple of minutes by re-lubricating all the necessary elements.

Use only quality lubricant. Products of unknown origin can only harm the elements or dry out quickly, clogging all the holes, and thereby completely render the plumbing fixture unusable.

Construction of a ceramic crane box

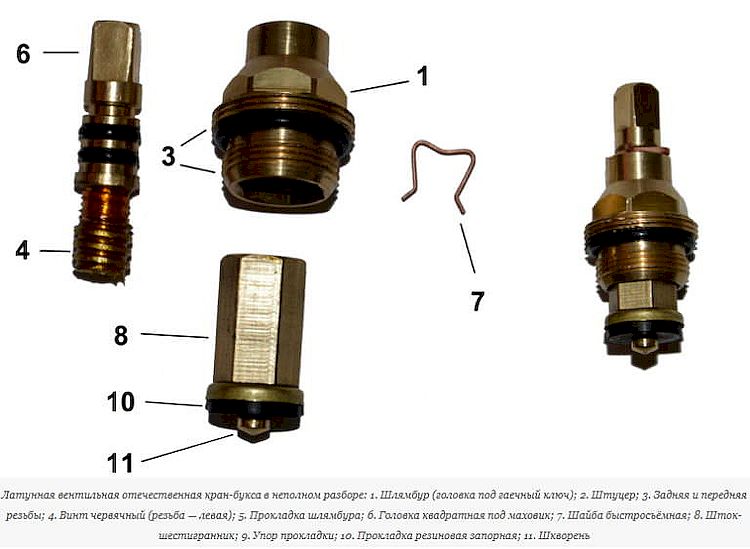

The part consists of a body, which in plumbing is called a jumper, a connecting part of the components of the crane box - a fitting and a hollow hexagon - a rod. The body of the crane box has a thread with a gasket for easy connection to the mixer. The front part of the jumper looks like a hexagon for a wrench. The fitting is attached to the body with a washer, which also plays the role of a bearing and protects against falling out of the mixer.

In ceramic faucet boxes, the body has the shape of a cylinder with holes on the sides. The fitting has two protrusions that will connect to one of the polished discs - movable.

Both disks have water supply holes. When the flywheel is turned, the discs either overlap each other (then water does not flow) or open at the same time (then water flows).

The tightness of the ceramic crane box is achieved due to the fact that a rubber gasket is located between the disks. If the gasket becomes unusable, a characteristic noise appears.

Crane box replacement

Mount the crane box in the same way.

It must be remembered that when mounting a ceramic axle box, it must not be overtightened, otherwise rather fragile ceramic plates can be deformed. It is only necessary to screw it tightly into the tap hole and secure it with a lock nut.

That's all, if something is not clear to you, then we are waiting for your comments below.

2013-2017 Do-it-yourself apartment renovation. Construction portal about apartment renovation. Everything about design, interior, decoration.

Copying entire articles or quoting part of the materials is allowed only with an active indexed link to the article page of the PostRemont.ru portal. Any other use of texts and images requires the approval of the editors. Unsolicited use of materials is punishable by law.

Repair crane boxes of different types

The main node of most mixers is a faucet - bushing. This device performs the function of opening / shutting off the water flow and adjusting its supply. In modern mixers, two types of faucet boxes are used: “worm-driven” (with a rubber cuff) and ceramic.

The main failure of the first is the wear of the gasket, as a result of which the valve has to be clamped more and more each time. It is not difficult to make a gasket and replace it on your own.To do this, you need to perform a number of the following steps:

Pry with something sharp and remove the plastic plug from the valve, then unscrew the bolt located inside.

Remove valve.

Using the appropriate open-end wrenches, remove the crane - axle box. According to the model of the old gasket made of thick rubber or leather, cut and install a new cuff.

Install the repaired device on the mixer

It is important to check the presence of the sealing ring.

Reassemble the removed parts.

The failure of the rubber cuff may also be indicated by the presence of hum in the pipes at high pressure in the water supply system. Noises result from the resonance of a worn gasket.

The disadvantage of ceramic faucet - bushings - high sensitivity to water clogging.