Approximate cost of work

Work on connecting any water heater to a gas boiler should be entrusted to professionals.

The cost of their services will depend on the required actions. For example, the design of a boiler room costs from 300 rubles, for the installation of a boiler you need to pay from 3,000 rubles, and for the installation of a pumping group - at least 3,300 rubles.

Hello, my reader or reader! I dedicate this post to an interesting question that different people periodically ask me. This question sounds like this: “I heard that you can connect a storage water heater to a double-circuit boiler and not buy an indirect heating boiler. Is it true?" I will say right away that such a scheme exists. Let's figure out together why this is all necessary.

Common mistakes when tying a gas boiler

A large boiler heats water faster, which means it consumes more fuel. This is also worth keeping in mind when buying and connecting gas equipment.

Pay special attention to controlling the pressure level in the expansion tank. An incorrectly selected tank size can also adversely affect the operation of the entire system as a whole.

The piping scheme for a double-circuit boiler is not an easy task. The best solution would be to contact a specialized gas service, whose employees will quickly connect the unit to the gas supply system.

More and more owners of not only private houses, but also city apartments, not wanting to depend on communal structures, are installing autonomous heating systems in their homes, the “heart” of which is a boiler - a heat generator. But on its own, it cannot work. The heating boiler piping scheme is a set of all auxiliary devices and pipes that are connected according to a certain scheme and represent a single circuit.

Why is it necessary

- Ensuring the circulation of fluid through the system and the transfer of thermal energy to the premises in which heating devices - radiators are installed.

- Protection of the boiler from overheating, as well as protection of the home from the penetration of natural or carbon monoxide gases into it in case of emergency situations. For example, the loss of a burner flame, water leakage, and the like.

- Maintaining the pressure in the system at the required level (expansion tank).

- A properly installed gas boiler connection diagram (piping) allows it to operate stably in the optimal mode, which significantly reduces fuel consumption and saves on heating.

Main elements of the circuit

- Heat generator - boiler.

- Membrane (expansion) tank - expandomat.

- Pressure regulator.

- Pipeline.

- Stop valves (faucets, valves).

- Coarse filter - "mud".

- Connecting (fittings) and fasteners.

Depending on the type of the selected heating circuit (and boiler), there may be other components in it.

The piping scheme of a double-circuit heating boiler, as well as a single-circuit one, depends on many factors. These are the capabilities of the unit itself (including its equipment), and operating conditions, and features of the system design. But there are also differences, which are determined by the principle of movement of the coolant. Since private dwellings use boilers that provide both heat and hot water, consider an example of a classic piping of a double-circuit device with forced circulation of the coolant.

The piping scheme of a double-circuit heating boiler, as well as a single-circuit one, depends on many factors. These are the capabilities of the unit itself (including its equipment), and operating conditions, and features of the system design. But there are also differences, which are determined by the principle of movement of the coolant. Since private dwellings use boilers that provide both heat and hot water, consider an example of a classic piping of a double-circuit device with forced circulation of the coolant.

Heating circuit

The water, heated in the heat exchanger to the desired temperature, “leaves” from the boiler outlet through pipes to radiators, to which it transfers thermal energy. The cooled liquid is returned back to the inlet of the heat generator. Its movement is controlled by a circulation pump, which is equipped with almost every unit.

An expansion tank is installed between the last radiator in the chain and the boiler to compensate for possible pressure drops. Here is also a “mud collector” that protects the heat exchanger from small fractions that can get into the coolant from batteries and pipes (rust particles and salt deposits).

A pipe insert for supplying cold water (feed) is made in the area between the boiler and the first radiator. If it is equipped on the "return", then this can cause deformation of the heat exchanger due to the temperature difference between it and the "feed" liquid.

DHW circuit

Works just like a gas stove. Cold water from the water supply system is supplied to the DHW inlet of the boiler, and from the outlet, the heated water goes through pipes to the points of water intake.

The piping scheme for wall-mounted boilers is similar.

There are a number of other types as well.

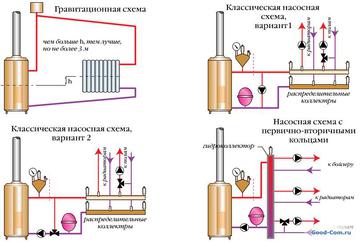

Gravity

It does not have a water pump, and the circulation of the liquid occurs due to the temperature difference at the inlet and outlet of the circuit. Such systems do not depend on the power supply. Membrane tank of open type (placed at the very top of the route).

With primary-secondary rings

In principle, this is an analogue of the already mentioned comb (collector). Such a scheme is used if it is necessary to heat a large number of rooms and connect the "warm floors" system.

There are others that do not apply to private houses. In addition, there may be some additions to the listed ones. For example, a mixer with a servo.

| Articles |

Wall-mounted boiler piping schemes

Tying a floor-standing gas boiler and other types of heaters can be simplified by using primary-secondary rings. There will be fewer all kinds of devices designed to control the operation of the system if you make several rings of the heating system and install your own circulation pump for each of them. Thanks to such measures, a uniform supply of hot coolant to the end consumer is ensured.

The piping scheme for a dual-circuit device is complex. A reasonable solution is to contact a specialized gas organization. Its employees will quickly connect the equipment to the gas supply system.

Rules for tying a gas unit

Before you start purchasing equipment, you need to obtain the Technical Conditions and permits for connecting to the gas pipeline. The gas service determines whether the installation of a gas boiler is in principle possible, as well as the gas parameters at the tie-in point. Further, the owners carry out a heat supply project with the involvement of a specialized organization, in which the piping scheme will be indicated without fail. This project is coordinated with the gas service. Usually it takes from 2 weeks to 3 months, only after that you can buy gas equipment.

Fundamental rules:

- Before starting to piping a gas boiler for heating, it is installed in a room that must have minimum parameters: an area of at least 4 m, a height of 2.5 m, and a doorway width of at least 0.8 m.

- The room should have natural ventilation and windows, the dimensions of which depend on the area: 0.3 m2 of a window per 10 m2.

- All gas pipelines must be made of steel.

- The flue pipe must have a diameter, depending on the power of the boiler: 30 kW - 13 cm, 40 kW - 17 cm, but it must not be smaller than the flue outlet from the boiler.

- The outer part of the chimney must be at least 50 cm higher than the roof.

- In the boiler room, a gas sensor and a gas cut-off valve are installed.

- The boiler equipment must be properly grounded.

- The power supply system is equipped with current protection and thermal insulation.

- The piping of the elements of the working circuit is carried out using pipelines, which can be made of galvanized steel, cast iron, copper and plastic.

- Pipe sections at the outlet of the boiler are made only of metal, with a length of at least 1.0 m.

Recently, metal-plastic pipes with press fittings and polypropylene pipes with aluminum reinforcement have gained the greatest popularity. Their advantage is undeniable, both in terms of reliable quick assembly and in terms of cost, in addition, such a pipeline can withstand pressures up to 25 bar and ambient temperatures up to 95 C. Nevertheless, the options also have disadvantages that must be taken into account when starting installation. Press fittings are very sensitive to assembly quality, water leakage can occur at the slightest misalignment, and polypropylene has a high elongation factor at temperatures above 50C.

Features of tying gas boilers with polypropylene:

- Heating and hot water circuits are performed: with pipes PN 25 (2.5 atm, 95 C) and PN 20 (2.0 atm, 80 C).

- The connection of pipes and fittings is carried out by cold or hot welding; threaded connections are used to connect to metal sections.

- To avoid the destruction of polypropylene pipes, compensation loops are installed.

- Multilayer pipes have internal reinforcement to compensate. Foil reduces elongation by 2 times, and fiberglass by 5 times.

- Before welding, the foil is removed from the reinforced pipelines.

How is the gas boiler piping

How is the gas boiler piping

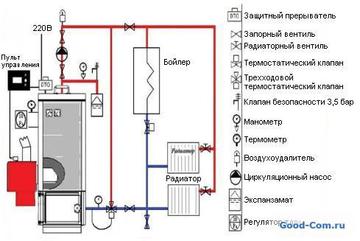

Schemes for connecting a water heater to a gas boiler.

Now let's move on to considering the connection diagram of the water heater to the DHW circuit of the boiler. So let's look at the picture below:

It can be seen from the figure that the storage water heater is connected separately to the boiler and to consumers. Separation is done by two 3-way valves with servomotors. Switching the servos and turning on the circulation pump is carried out by a certain device called the “power management circuit”. This device is connected to the water heater thermostat. There are no standard solutions here and this device will have to be invented from scratch.

For comparison, I will give you another diagram from the technical document:

There are no three-way valves in this circuit and no power management circuitry. The circulation pump is powered directly via the water heater thermostat. This is done according to the following scheme:

The upper diagram has one important feature - the water heater there has three connection pipes. This is a non-standard option for electric water heaters, but indirect heating boilers have a recirculation inlet and outlet, through which it is quite possible to organize a similar connection scheme. Well, for ordinary electric water heaters, you will again have to invent something. Sometimes, such a "collective farm" takes a lot of time, effort and money.

Now let's look at how the water circulates in the upper diagram. To do this, I will give two more pictures:

The arrows in the upper figures indicate the direction of water circulation in each operating mode. In this scheme, heating and water intake can occur simultaneously.

Strapping scheme options

The classic version of piping a gas boiler is when the coolant rises along the supply, enters the risers and further to the radiators. The degree of space heating depends on the number of installed radiators equipped with chokes and jumpers. The return of the cold coolant to the boiler is carried out along the lower return line.

The most common strapping schemes currently are:

- Gravity system;

- forced with a circulation pump;

- single-circuit;

- double-circuit;

- wall location of the boiler;

- outdoor installation of the unit.

Strapping in gravity systems

The gravitational heating scheme is allowed for the implementation of heat supply for objects with an area of \u200b\u200bno more than 100 m2 and must be carried out exactly with the project. If there are errors in the selection of pipes, or the slopes are not maintained, the system will not work.

The principle of operation of the system is based on the difference in the specific gravity of hot and cold water. The hot one rises to the radiators, where it gives off heat to the surrounding air, then the cooled cold coolant goes down and enters the heating boiler through the return line. The main condition for piping is to ensure pipe slopes of at least 3 degrees.

Benefits of the scheme:

- Simplicity of design;

- availability of installation;

- noiseless operation of the boiler;

- long service life.

As disadvantages, users note:

- Long heating period;

- the inability to accurately adjust the temperature inside the room air;

- rough appearance of the installation of pipes with slopes that interfere with the interior of the premises.

Tying systems with a circulation pump

Circulation pumps are included in the circuit in a system with high resistance when they cannot be overcome using natural circulation or in double-circuit boilers, where the coolant alternately steps into the heating or hot water circuit. The pump increases the circulation rate of the medium through the boiler system, in connection with which the efficiency of the heat supply system is increased by 30%. In addition, the positive fact is that such a scheme is easier to automate and performs finer adjustment of the thermal regime in the premises.

The installation of the pump on the network pipe is carried out using union nuts, most often they are included with the boiler, but can also be purchased in the distribution network. When installing the unit for pumping network water, it must not be subjected to forces when tightening the nuts. A strainer is installed at the pump inlet to protect the impeller of the unit from dirt and deposits. The pump is cut off from the main equipment by ball valves for repair and maintenance.

Strapping schemes

Do-it-yourself piping of a gas heating boiler is most often performed according to the classical method. That is, at first the water begins to move upwards through the supply pipeline. Further, the coolant enters the risers, where special devices are installed that do not completely open the riser.

The heat level is regulated by radiators, which incorporate a choke and jumpers. Be sure to install a shut-off valve on the second supply line, and place an air vent in the upper part of the expansion tank circuit. The coolant is already returning back along the lower level of the supply.

To perform the piping of a double-circuit boiler yourself, you need to prepare some devices that will be needed during the work:

- thermal head or valve for distribution;

- pump for internal circulation;

- taps: drain and ball;

- expansion tank;

- balancing crane;

- inline filter;

- fasteners;

- valves: check and air.

- tee and corners.

Usually this method is used in simple heating systems of small apartments and houses.

The peculiarity of such heating units is that the control is automatic. For individual rooms, you can choose an individual temperature regime, the sensors of the system fully control this process.

However, such a strapping scheme also has its negative sides, namely:

- high cost of components;

- a complex strapping scheme that is beyond the power of an ordinary person - a non-professional;

- high service costs;

- constant balancing of parts.

If your house has a very complex heating system, for example, there is a “warm floor” and radiators, then there is some kind of inconsistency in the movement of the coolant. Therefore, hydraulic decoupling is necessarily included in the piping scheme. It forms several circuits of water movement - general and boiler.

To waterproof the circuits with each other, an additional heat exchanger is used. This is necessary if you combine closed and open systems.Such separate type installations must have their own circulation pump, feed and drain valves, and a security system.