Back to manometers

I don’t know about you, but for me the main characteristic of a pressure gauge is accuracy. In second place is reliability. The size of the dial is important, but secondary. If I have an extremely accurate, but small pressure gauge, I will not be too lazy to look at it through a magnifying glass. It's not a problem.

The problem is different. Perhaps I will tell you something new, but any analog pointer device has a measurement error. Moreover, this error is uneven. This error is spread over the scale in such a way that it is maximum at the edges of the scale, and minimum in the middle. This error is so uneven that the values in the first and last quarter of the scale are very inaccurate, and the values in the first and last fifth of the scale can not even be looked at. They most likely will not have anything to do with reality.

And now back to the issue of maximum working pressure. Obviously, pressure gauges for heating and plumbing must be different! For the heating system, the maximum pressure, the end of the scale should be at 4 atmospheres, and for the water supply at 8.

In reality, we see a completely different picture. The vast majority of pressure gauges are designed for a maximum of 10 atmospheres, you can find them at 8. Very rarely, if you look for good suppliers for a long time, you can find them at 6. You can also see pressure gauges for 4 atmospheres, but this is already exclusive.

Why is there such a picture? Again, I express my personal opinion. I suspect making a pressure gauge for a higher maximum pressure is easier and cheaper. It is very possible that the membranes, springs that are used in pressure gauges are easier to make more rigid. That is, we again become a kind of hostages of the economy and marketing. That is, we use not what we need, but what is given. Or you need to understand, search, consult, overpay.

Safety devices

Each OKN to ensure safe

operating conditions is supplied with PU from

increase in pressure above the allowable.

As PU are used: spring

PC; lever-cargo PC; impulse launchers;

membrane PU; other PU, application

which are agreed with RTN.

Spring valves: design

should exclude the possibility of tightening

springs in excess of the established value;

spring must be protected from

unacceptable heating (cooling) and

direct impact of working

environment. Device provided

to check the correct operation

valve in working order

short-term forced

undermining. When the valve is located above

2.5 m remote

drive unit.

Lever weight valves: installation

on mobile objects is not allowed.

The weight is indicated on the load. Cargo motionless

attached to the lever.

The diameter of the passage of the lever-cargo and

spring valves at least 20 mm.

Membrane PU: need

installation and design determines

project organization. Installed:

– instead of lever-load and spring

valves when those valves are in service

conditions of a particular environment cannot be

applied due to their inertness or

other reasons;

– in front of the PC in cases where the PC cannot

work reliably due to harmful

exposure to the working environment (corrosion,

erosion, sticking, freezing. T.

etc.) or possible leaks through a closed

valve of dangerous and harmful substances;

– in parallel with PKPK to increase

throughput of discharge systems

pressure;

– on the output side of the PKPK for

prevent harmful effects

working media from the waste system

and to eliminate the influence of fluctuations

backpressure of this system on accuracy

operation of the PKPK.

On every steam and hot water boiler

must have at least two

PU.

The total throughput of PU,

installed on the steam boiler must

be at least nominal

boiler steam output. Checkpoint

the ability of the launcher is indicated in its

passport.

PU must protect against exceeding

pressure:

Vessels: with pressure up to 3 kgf/cm2 no more than 0.5 kgf/cm2 calculated;

from 3 to 60 kgf/cm2 15% of the calculated value;

over 60 kgf / cm2 10% of the calculated.

When the PC is running, it is allowed to exceed

pressure in the vessel by more than 25% of the working

provided that this is an excess

envisaged by the project and reflected in

passport.

Boilers - no more than 10% of the calculated

(allowed).

Pipelines - no more than 10%

design, at design pressure up to

5 kgf / cm2 - no more than 0.5

kgf/cm2.

For boilers and pipelines

pressure at the full opening of the PC is higher

than 10% of the calculated can be allowed,

if provided for by the

strength.

Vessels and pipelines, design pressure

which are lower than the pressure supplying them

source must have a reducing

device with pressure gauge and safety

valve, which are installed with

side of lower pressure after

reducing device.

If the operation of the object is allowed

at reduced pressure, then the adjustment

PU is produced according to this pressure,

throughput should be

verified by calculation.

Methodology and frequency of regulation

PU and the pressure of the beginning of their opening should

be specified by the manufacturer

in the installation and operating instructions

object.

PU is delivered to the customer with a passport,

including a characteristic of its throughput

capabilities. Attached to the passport

user manual.

PU is installed on nozzles or

pipelines, directly

attached to the object.

The selection of the working medium from the nozzles on

which are installed PU is not allowed.

Installation of shutoff valves between

objects and PU, as well as behind it is not allowed.

PU must have discharge pipelines,

equipped with drains

condensate. Installation of locking devices

drains are not allowed.

Examination:

The correctness of the action is checked

short-term forced detonation.

Staff:

– for boilers and pipelines – as for

pressure gauges;

- for vessels - the order and terms in

depending on the technological process

specified in the instruction manual.

PU approved by the owner in the established

okay.

Test results, information about them

setting are recorded in the shift log

persons performing these operations.

GOST 12.2.085–82 “Safety valves.

Safety requirements".

Gauge scale units

I suggest everyone to focus on bars. This is a non-systemic unit of pressure. It shows the value closely approximated to the physical and technical atmosphere and is the most convenient. Consider a bar (0.1 MPa) as an abstract atmosphere and don't worry. Why are physical and technical atmospheres different? Because getting attached to a water column is dangerous. The real water column also depends on atmospheric pressure. But, I repeat, approximately all three units are equal to each other. If the pressure gauge scale is graduated in kgf/cm2, then it must be borne in mind that 1 kgf/cm2 is exactly equal to one technical atmosphere, or 10 m of water column. More information about pressure units can be found in a special article about plumbing.

I strongly advise against paying attention to such a unit as Psi, or pounds per square inch. This is not our unit and you should not even try to get used to it

Although, if desired, of course, you can get used to inches and pounds and feet. But you need a great desire and a lot of practice.

Briefly speaking

- Technical atmosphere (1 at) \u003d 10 m of water column \u003d 1 kgf / cm2

- bar - has an intermediate value = 10.197 m of water column = 0.1 MPa

- Physical atmosphere (1 atm) = 10.33 m of water column

For the purposes of determining the pressure in the water supply, all these pressures (5 different units of measurement) are approximately equal. The extreme differences are 33 cm of water column or somewhere a bucket of water. Not by weight, mind you, but by height. Since we measure in meters, we neglect 30 centimeters.

Thermomanometer

thermomanometer in 3d

We had places where we needed local instruments for measuring temperature and pressure, in order to save space, it was decided to put a thermomanometer instead of a thermometer and a manometer. The delivery set of the thermomanometer includes a valve so that it can be dismantled without depressurization of the system.

The price of a manometer and a thermometer at the same ROSMA 350 + 685 = 1035 rubles, the price of a thermomanometer = 1110 rubles. Considering that fittings will be required 2 times more, I see no reason to put a thermometer and a pressure gauge separately.

Were ordered:

- Thermomanometer ROSMA TMBR - 31P2 (0-140 ° C) (0-0.25 MPa) G1 / 2

- Boss No. 2 BP-BT-30-G½ (for BT thermometer)

Conclusion

Manometer with a convenient scale and an additional pointer arrow

This pressure gauge would be ideal for plumbing. And there is only one scale. And in bars. It is possible that the creators were thinking about the end consumer. The red arrow pointer is useful for marking the turn-on pressure of the pump.

Two devices in one

It is not very convenient to have both a manometer and a thermometer in one device. In addition, the versatility of the device may degrade other characteristics of the device. This pressure gauge is clearly for the heating system.

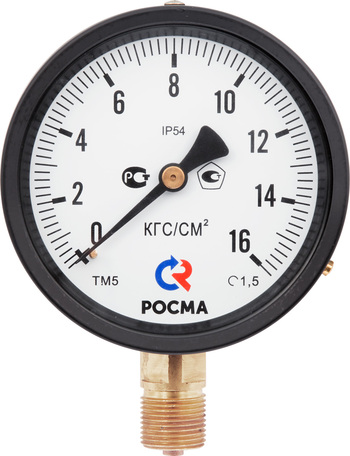

Looks like a device for industrial use

The scale is graduated in kgf / m2 and the upper limit of the scale is 16. This is frankly a lot for a private house.

Manometer with a convenient scale

There she is! The ideal scale for the heating system. Try it, buy one in the store!

Be careful with the choice of pressure gauge. The measured pressure should be as close to the middle of the scale as possible. The pressure gauge must be rated for liquid operation. It is better to choose such pressure gauges that are produced by well-known manufacturers and have indications of measurement error or accuracy class. Under generally equal conditions, a large pressure gauge is better than a small one. The scale should be graduated either in atmospheres or in kgf / cm2, and even better in bars (bar). At worst, MPa will do. All three of these units mean roughly the same thing. The difference between them is insignificant. Probably, it is better to embed the pressure gauge in heating on the return line, because additional heating can introduce an error into the rigidity of the materials that work in the pressure gauge, and the measurement error may increase. But there are pressure gauges designed for high temperatures. Even up to 150 degrees Celsius! I would not install a device in my system that, in addition to measuring pressure, measures something else. Versatility has never been in favor of either instruments or tools.

Big lover of precision instruments Dmitry Belkin

Article created 25.09.2015