If the pipe is still clogged or effective cleaning methods

Pipe cleaning methods depend directly on the material from which the pipe is made. Steel pipes can be protected. Water pipes are protected from corrosion by hot-dip galvanizing, as a result of which steel pipes become almost eternal. The only places that can suffer greatly are pipe joints.

For all types of pipes used in everyday life, we will try to consider the main methods of cleaning pipelines. Basically, we will talk about mechanical methods.

Steel pipes without internal coating

Steel pipes are the scourge of every water pipe. Initially, they are rough, and not only are they

Protection of water pipes from corrosion is galvanizing, which was mentioned above. It is better to immediately purchase such pipes, but if some special diameter is needed, then they can be galvanized. Some companies provide this service.

In general, it is better to completely get rid of steel in the water supply. Replace steel pipes with analogues from any other material, fortunately, the choice now allows you to do this.

If the pipe is overgrown, then it will gradually lose pressure. This is the surest sign of an impending plumbing collapse in your home. Now is the time to act.

The best and most effective method is to clean the water pipe from steel pipes. It all starts with a complete analysis of the system. Usually, pipes are added in mass by 2-3 times due to the formed growths. Disassembly must be carried out very carefully, because this system becomes fragile, especially at the joints

Therefore, if you do not want to go to the welder once again, handle the pipes very carefully.

It is possible to clean the pipe alignment both with acid and mechanically. This requires a steel pipe. A kind of small bullet or ball can be screwed onto its end so that it can go through bends. Also, such a string can be clamped into the chuck of an electric drill and then things will go faster.

Plastic pipes and metal-plastic pipes

Cleaning these pipes is also not easy. Cleaning of water pipes from the inside is necessary in any case. Metal-plastic pipes are the easiest to clean, because they are, in fact, a constructor. If the number of identical parts is large, then they must be numbered, and the direction of fastening, if it is indefinite, must also be indicated. For the rest, everything is simple.

Plastic plumbing can be welded, so try to clean it with a flexible string from any available fork in the pipeline. Anyway, in any pipeline there must be removable fittings, through which you can easily reach almost any section with a string.

Whatever the pipes, this is a real engineering structure, which also needs to be kept in order. Not only the good condition of your equipment, but also the health of the whole family depends on the cleanliness of the pipeline.

Elimination of leaks at the junction of other types of pipes

To eliminate leaks at the joints of a pipe made of metal, plastic or metal-plastic, you can use one of the following methods:

- fitting replacement;

- cold cooking;

- adhesive bandage.

Fitting replacement

On pipelines can be installed:

weld fittings.Mainly used for connecting plastic pipes;

Welded connector

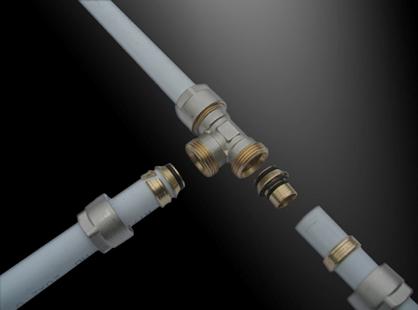

compression fittings. Can be used for joining both plastic and metal-plastic pipes. Unlike a welded fitting, the connection is more reliable and durable;

Element for forming a permanent connection

threaded fittings. They are used for various types of pipes if it is necessary to arrange a detachable connection.

Element for creating a detachable connection

If a pipe connection is leaking and it is necessary to replace the welded fitting, proceed as follows:

- disconnect the pipeline from the water supply;

- cut the connecting element with special scissors;

When cutting the connecting element, it is important to take into account that the overall length of the pipeline is reduced.

- prepare a pipe cut of the required length and two new fittings;

- sequentially weld the elements with special equipment.

Installation of a new fitting by welding

You can use the finished pipe after the pipes have completely cooled. This time is required to strengthen the newly created connection.

If it flows at the junction of pipes with compression fittings, then the replacement of the connecting element occurs according to the following scheme:

- the connecting element that has become unusable is removed;

- the pipes to be connected are chamfered and calibrated;

- compression rings and nuts, which are clamps, are put on the ends of the pipes;

- the pipe is inserted into the fitting until it stops and the fixing elements are tightened.

Compression Fitting Installation Diagram

You can use the repaired pipeline immediately after replacing the compression fitting.

The process of correctly installing a compression fitting is shown in the video.

https://youtube.com/watch?v=c2QhvEbmqbc

If a pipe leaks at a joint equipped with a threaded fitting, then it is necessary to act in the following order:

- first of all, you can try to simply tighten the thread with a key, since in some cases there is an elementary loosening of the tightening;

- if the tightening does not help, then the connecting fitting is removed completely;

- the thread is processed with FUM tape or any other insulating material;

Sealing the threaded connection before fixing

The insulating tape is wound along the thread in the direction of twisting.

- the new fitting is tightened into place.

Fixing the connecting element on the pipes

Cold welding

If a leak is detected in pipe joints that are not equipped with a fitting, then the pipeline can be repaired using the cold welding method. To fix the joint, you must purchase a special composition.

Quick fix leak mix

This tool must be used in the following way:

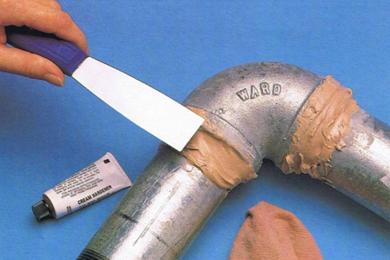

- a fragment of the pipeline in which a leak has formed is cleaned of contamination. If the composition must be applied to a metal pipe, then the damaged area is pre-cleaned with sandpaper;

- the mixture in the package is mixed until homogeneous and applied to the damaged area and gently leveled.

Application of cold welding to eliminate leaks

Until complete drying, which occurs after about 3 hours, the pipeline cannot be used.

Adhesive bandage

If the joints of plastic pipes are flowing, made without the use of special connecting elements, then the leak can be eliminated with the help of an adhesive bandage. To equip the bandage you will need to purchase:

- piece of fiberglass;

- special two-component adhesive.

You can organize the bandage as follows:

- the pipe joint is cleaned of dust, dirt and foreign particles;

- fiberglass is impregnated with glue;

- the impregnated material wraps around the place of the leak several times;

- expected until the material is completely dry.

Arrangement of an adhesive bandage at the site of a leak

There are a lot of ways for self-sealing of pipe joints in the event of a leak. Each master can independently choose the most optimal solution to the problem.

Why did water appear

Condensation is negligible. Motorists don't pay attention to it until it becomes a big, obvious problem. In the cold season, this phenomenon is very dangerous, because water is either gaseous vapor or liquid due to temperature changes. In summer, this phenomenon is also not a guarantee of the correct operation of the exhaust system of the car.

Condensate is the collected water with a small admixture of other substances, which is obtained during the transition from vapor to liquid. This is a normal natural phenomenon that does not cause negative consequences. As a rule, condensate forms both in the muffler and in other working systems of the car: oil, fuel or in the cooling system. Fluid may accumulate in closed parts of the body or interior. There is some degree of harm in any case.

Condensation forms in the exhaust pipe when the car is plugged. This natural phenomenon is not affected by either the age of the machine or its level of serviceability. Inside, the muffler is covered with an ice crust due to accumulated moisture, which freezes after a couple of tens of minutes. Many motorists are afraid of such phenomena, although experts from auto repair shops are sure that it does no harm.

Since a small accumulation of moisture in the muffler occurs naturally, its occurrence can guarantee the serviceability and proper functioning of the car.

Condensation can form for various reasons:

- constant use of the vehicle. In this case, condensation always forms. Especially often and a lot when driving a car in winter;

- Because of the auto start of the car. It should take about 20 minutes for the pipe to warm up. At this time, the condensate, which had time to freeze, melts, but, without having time to evaporate, goes outside with exhaust gases;

- High pressure in the exhaust pipe. When the gas pedal is pressed sharply, water comes out of the pipe also intensively.

How to fix a pipe body leak

How to close a leak in a pipe, provided there is a crack formed on the body? To troubleshoot the problem, you can use one of the following methods:

- install clamp;

- put on a bandage;

- apply cold welding.

Clamp installation

The easiest way to fix a leak on a pipe body is to install a repair clamp. The special device consists of:

- metal case;

- rubber seal located inside the case;

- fixing bolts.

Special device for fixing pipe leaks

You can install the clamp with your own hands in the following way:

- the place of leakage is cleaned of dust and rust;

- the pipe is wrapped with a clamp;

- the device is fixed.

Stopping a leak with a clamp

Clamp selection should be based on the size of the crack. To completely eliminate the malfunction, the clamp must be 1.5 - 2 times the size of the leak.

bandage

How to fix a leaking pipe if there is no clamp? To eliminate the leak, you can use a rubber, adhesive or cement bandage.

The rubber band is:

- a piece of rubber. A cut from a bicycle tube or a medical tourniquet used to stop bleeding is optimal. It is necessary to wrap the cracked section of the pipe with a rubber cut;

- small tie-down straps, wire or other fixing straps for attaching the rubber to the pipe.

Bandage for a pipe from improvised materials

The adhesive bandage is installed according to the following scheme:

- the section of the pipe on which the leak has formed is cleaned of dirt with a solvent;

- fiberglass or medical bandage is impregnated with special glue;

Special composition for elimination of leaks

-

the pipe is wrapped with prepared material in several layers;

- complete drying of the applied composition is expected.

Instead of special glue, you can use epoxy resin or, when using metal pipes, ordinary table salt.

How to cover the current pipe with epoxy, see the video.

Cement bandage is an analogue of adhesive bandage. The bandage or fiberglass is impregnated with a cement mortar prepared in a ratio of 1:10.

Cold welding of pipes

A relatively new way to eliminate leaks is the use of a composition of the so-called cold welding. How to cover the pipe so that it does not flow? For different types of pipes (metal, plastic, metal-plastic, and so on), different compositions of cold welding are used.

Composition for plastic pipes of various types

Detailed instructions for using the mixture are given on the bottle with the active substance. Here is a general algorithm:

- before applying the mixture, the damaged section of the pipeline is cleaned of dirt. If the composition must be applied to a metal pipe, then the crack is additionally cleaned of paint and rust;

Stripping the pipe before applying cold welding

- a special compound is applied to the damaged area. If liquid cold welding in the form of glue is used, then it is desirable to apply it with a brush. If a plasticine-like composition is used, then before application it is necessary to knead it thoroughly until a homogeneous mixture is obtained;

- the substance for cold welding is evenly distributed over the entire section of the cracked pipeline, capturing 3–4 cm more than the crack itself;

Coating the damaged area with a cold welding agent

- the composition is left to dry completely, which takes an average of 2.5 - 3 hours.

So that the area restored by cold welding does not stand out, the dried composition can be cleaned with sandpaper and painted.

All the methods given in the article to eliminate leakage on the pipe body, except for the use of cold welding, are only a temporary measure. To completely get rid of the problem that has arisen, it is necessary to completely replace the damaged section of the pipeline. To perform this operation, it is desirable to involve qualified specialists.

How to fix a leaking fitting

The liquidation of the leakage of the connecting fitting is carried out according to the following scheme:

- First of all, it is necessary to tighten the threaded connection. For this:

- you will need a wrench and an adjustable wrench;

- the pipe is fixed with an adjustable wrench;

- a wrench tightens the fixing nut;

Tightening a threaded connection on a fitting

Tighten the thread very carefully and slowly. Overtightening may cause cracking of the fitting.

- if tightening the thread does not help, then with a high degree of probability the problem lies in the wear of the thread or sealing material. You can fix the problem by replacing the insulating material. For this:

- the water supply must be turned off. The disconnection is made by a tap located in the apartment (if a leak has formed on a pipe that is part of the distribution of the living quarters) or a tap of a common house riser (the tap is located in the basement);

- the thread is unscrewed completely or up to half, depending on the complexity of the situation;

- the old sealing layer is removed;

- a new insulating material is wound up;

The imposition of linen thread on the thread

the fitting is installed in its original place;

- if the listed measures do not allow to close the leak in the pipe, then the fitting will need to be replaced. The replacement of the connecting element is carried out as follows:

- the old fitting is removed. If the connection is threaded, then it is enough to unscrew the thread. If a non-removable fitting (weld or compression) is used, then the connecting element must be cut off;

- a new element of the plumbing system is installed. The threaded fitting is screwed into the old place. To install a weld or compression fitting, you will need special equipment (welding machine or press device).

Installing the compression connector

When replacing one-piece fittings, it should be noted that an increase in the total length of the pipeline will be required, which is done by inserting an additional pipe cut. It is better to entrust the replacement of welded and compression fittings to professionals.

Should I fight with water in the muffler and how to do it

Consider several ways that will help you quickly expel accumulated moisture from the muffler:

- Use the auto warm-up feature, which will warm up your car's engine several times during the night. If, despite this, moisture still accumulates in large quantities and flows out of the exhaust pipe, increase the warm-up time. Just the muffler must be heated to a certain temperature. If there is no automatic heating function, an additional heater can be used.

- To avoid temperature fluctuations, if possible, leave the car in the garage.

- Replace real fuel with more expensive one. Maybe the one you're using now is half water.

- Change the shape of the condensate. Let it be steam, not a simple liquid. To do this, let the engine run for a couple of minutes, then put the front down at a slight slope. This option is only a couple of percent effective, but the corrosion of the muffler metal due to moisture will decrease.

- Try to insulate the muffler. To do this, you can use liquid heating or a non-combustible heat insulator.

Temperature fluctuations happen all the time. Therefore, even the above procedures will not become an obstacle to the formation of condensate in winter. They will affect the amount of his education, but will not solve the problems. As a rule, in such conditions, the muffler will work properly for five to ten years. Next - to the new one. In this case, you do not need to skimp, so it is better to buy a muffler from a quality manufacturer with metal corrosion protection.

Not condensate, but the external environment and exhaust gases lead to the formation of muffler corrosion. Moisture in the muffler slightly increases the rate and stage of corrosion processes. In this case, it is not necessary to deal with the formation of condensate. This waste of time. But if thick white smoke comes out of the muffler along with the water, worry. It is urgent to install a new cylinder block gasket. Only on the condition that this also affected the decrease in the level of antifreeze.

Because of the release of water from the muffler, motorists begin to worry only when they find out that this is a threat to their car. Indeed, in most cases this is a harmless phenomenon. To prevent the development of problems, it is better to constantly inspect other internal systems of the car, check their functioning.

When, together with water of an unusual color, then you need to sound the alarm. This is a direct indication of a malfunction of the engine and fuel systems. Otherwise, don't worry.

Periods of the most intensive formation of moisture

Most often, water appears at the stage of warming up the engine. This is due to the use of an enriched mixture, which is designed to speed up the warm-up time of the catalyst, because it works most effectively in the region of +300°C. As a result, rich in carbon monoxide, unburned hydrocarbons, it is intensively converted into steam and water.

Constant and frequent accumulation of water in the muffler will inevitably lead to corrosion of this element of the exhaust system. To avoid such a nuisance, it is recommended to make long, active trips, which will contribute to better heating of the muffler and prevent the formation of moisture.Another way is to completely warm up the engine; driving with a cold engine only contributes to the formation of condensate.

Winter is the most unpleasant time of the year for a motorist living in the middle lane (there is nothing to say about the north). Very often, in the cold, the car simply refuses to start, even if it has stood on the street for only a couple of nights. This can be caused by bad or dirty spark plugs, oxidized battery terminals, bad oil, or a buildup of frozen condensation in the muffler. The best way to avoid such situations is, of course, prevention and proper operation. But if trouble does happen, there are many ways to solve your particular problem. Let us dwell in more detail on the accumulation of frozen condensate in the muffler. The way out of such an unpleasant situation is to warm it up.

Instruction

You can try to drive it to a service station, where for a nominal sum the masters will do all the work in the best possible way. You can get it to take it to a car service if you unscrew the exhaust pipe of the muffler (or simply) below, which is used for additional purification of exhaust gases. The car will start. But there is a small "but". The car will make a lot of noise, even roar, which is not surprising, because you removed part of the muffler.

If there is no desire or opportunity to tow the vehicle, you will have to act on your own. Before warming up, you need to know where, in fact, to start warming up. Condensation tends to accumulate further away from the engine. Therefore, you need to start heating from the can under the bumper.

Moisture in the internal components of the car is a sign of the proper functioning of its main components. At the same time, there is no need to grab your head and rush to the nearest service station. After all, there can be no question of any defect here. Although novice motorists are sometimes shocked when this moisture accumulates in a decent puddle. Reasonable question: why is there a lot of water in the muffler? This already depends on the ambient temperature, operating mode and fuel quality.

Causes of water in the muffler

The main "culprit" of the phenomenon is condensate. It is formed due to the fact that the inside of the exhaust pipe is not cooled as intensively as the outside. The condensation process begins immediately after the engine is stopped; inside the muffler, dewdrops immediately appear, which later freeze. As soon as the engine is started again, the ice begins to melt and moisture begins to drip from the pipe.

In modern cars equipped with a catalyst, water can drip during the operation of the car. This is primarily due to the principle of operation of the purifier of harmful emissions. A whole “bouquet” of various chemical elements and their compounds is supplied to the exhaust manifold from the cylinders, including carbon dioxide, oxygen, carbon monoxide, nitrogen oxides, unburned hydrocarbons, and water. Of these components, oxygen, carbon dioxide, and water are harmless. All other compounds enter the catalyst and are oxidized due to the presence of platinum and palladium in the design of the purifier. They are located on the longitudinal cells of the catalyst through which the exhaust gases pass. The result is carbon dioxide and water vapor. The latter condenses on the inner surface of the muffler and appears as water droplets.

Condensation is dangerous for cars

Having accumulated in the muffler, the condensate is almost harmless. Most often, it simply causes metal corrosion, which occurs faster in warm weather than in the cold season. In winter, you need to warm up the car regularly, because frozen condensate accumulated in the exhaust pipe can exaggerate the permissible levels, causing the car to stop starting after a few days of inactivity.To avoid such situations, you can make a small hole in the resonator, then the side moisture will drain. But that won't solve the problem. A drilled hole will accumulate even more corrosion around it. Such a temporary solution will in any case require the replacement of the entire exhaust pipe. Agree, auto parts manufacturers would implement this method on their own if it were effective.

Condensation can also accumulate in other automotive systems:

- Condensation accumulates in the gas tank due to the poor quality of gasoline. It may contain water. Most often, such a “mixture” can be found at an old gas station. Competent motorists, in order to avoid problems with the gas tank, always leave it full and leave the car warm. Due to the overfilled tank, there is no place for condensate to accumulate. Otherwise, moisture quickly accumulates. There is no accumulation of moisture in the cold season, when the temperature in the fuel tank and outside air is approximately the same. In a warm garage, everything happens the other way around.

- In the engine, the cover where the oil is poured may become covered with a white coating on the neck. This is due to the lack of water, which also entails a large number of other problems. If the gasket is damaged, then such a plaque may appear near its valves or in other areas. It can accidentally get into the exhaust pipe, from where it will fly out. Plaque can form due to antifreeze, which can also accidentally enter the oil system of the machine. Such cases lead to the fact that the engine starts to warm up several times faster. If you did not find either one or the other in your car, then there is nothing to worry about. When oil and water mix, the top of the engine becomes covered with moisture. It can only be detected under the hood, and water does not penetrate into the exhaust pipe. To prevent plaque from accumulating, you just need to regularly warm up the engine. In this case, it will not pose a threat. The reason for the appearance of a white coating may lie in a small amount of water in the oil. Then you can just add it a little and mix. And it is absolutely not necessary to refill or change the oil completely.

It's bad when water gets into the muffler tank. This can lead to a malfunction of the fuel pump or the functioning of the candles. It can also enter the engine system. This is especially dangerous for diesel engines, in which the fine film or fuel lines can freeze. Today, universal water removers have been invented. In it, they cause chemical transformations, due to which water becomes a substance that quickly burns together with fuel and does not disrupt the functioning of other systems.

The problem can only be that the moisture accumulated in the exhaust pipe is invisible for a very long time. However, if too much fluid is draining from the exhaust systems, then a thorough diagnosis of the car should be carried out by checking all systems for the accumulation of condensate.