How is a septic tank made of concrete

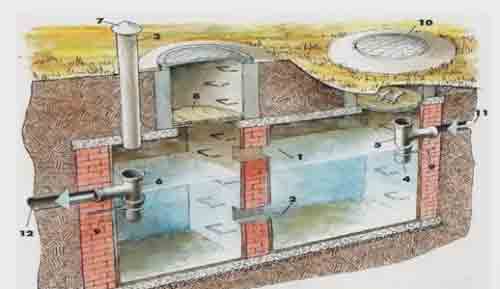

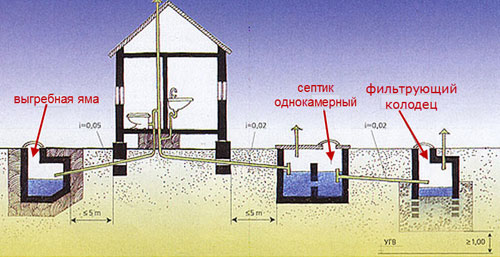

A concrete septic tank is designed in the same way as any other septic tank. But, perhaps, you haven’t read about the construction of septic tanks, so ... a concrete septic tank looks like this schematically:

(I’ll clarify: a brick drain pit is made exactly according to the same scheme, only, obviously, the walls are made of brick, not concrete)

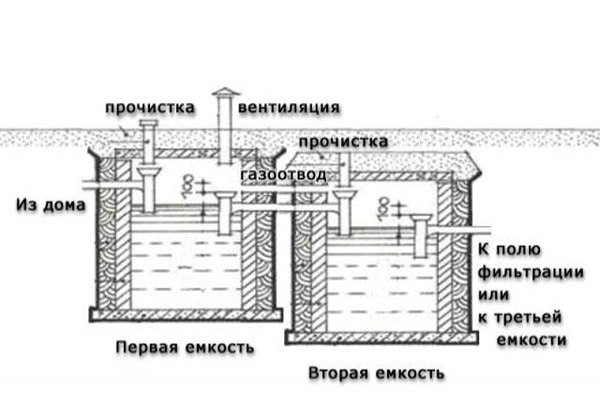

The first compartment (on the right in the diagram) is a sump, it receives wastewater from the house. In the sump you need to put a tee. Drains will be directed down the lower outlet, and the upper outlet for air access.

The second part provides for an exhaust hood that is at least 70 cm from the ground level. (For what this “hood” actually is, read the article about ventilation of septic tanks.)

Between the compartments there is a partition with two openings: the upper one is for ventilation, the lower one is for the passage of water from the first compartment to the second one. Here I’ll immediately clarify: although we are building a septic tank from concrete, however, the partition can be laid out of red brick or blocks, then plastered with cement mortar on both sides.

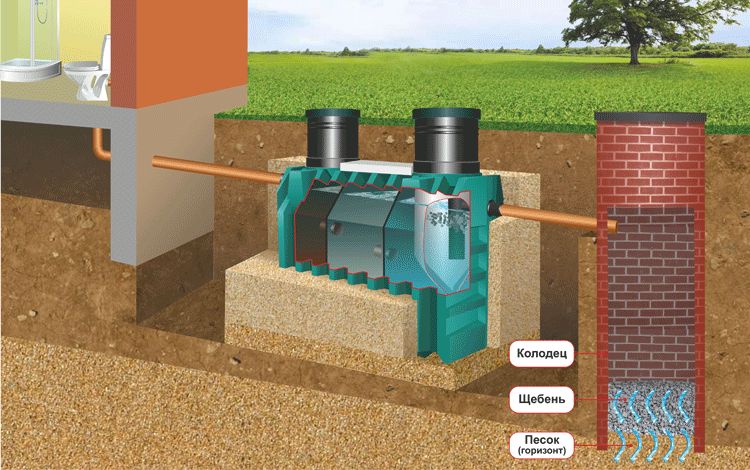

The bottom of the sump MUST be concreted, and preferably in the second compartment. A pipe comes out of the second compartment in the figure to the left, it is understood that water goes through it, but not into the ground, but into some kind of filtration device: into a sand and gravel filter, into a filter well or trench, into an underground filtration field, for example, like this :

Hatches are needed to be able to pump out the contents.

In general, before making a septic tank with your own hands, I strongly recommend reading all the articles on this topic.

Finished plastic septic tanks

The advantages of plastic septic tanks include the following qualities:

- light weight. It immediately becomes clear that the design will be easy to transport and install. The weight of plastic structures allows them to be installed manually, without the use of special equipment.

- Resistance to aggressive environments. Plastic is very well resistant to aggressive environments, which include wastewater.

- tightness. All plastic tanks are sealed, so the likelihood of them breaking through and getting waste into the soil is low. In addition, the lack of contact with the environment prevents plastic septic tanks from flooding with soil water or precipitation.

Making the right choice

First you need to understand what exactly country septic tanks are installed for. How much time can owners spend on construction? What financial costs are they ready for?

A ready-made septic tank made of a durable plastic base is the best solution for many situations. In such septic tanks, designers initially think through a lot of little things so that any bacteria that are inside feel comfortable. The material is completely protected against corrosion.

The main disadvantage is that underground devices can be damaged. For example, under the influence of groundwater with aggressive properties. It is possible to build a protective concrete frame, but this takes quite a lot of time. And the cost will increase, although the design will receive the necessary protection.

Do septic tanks need insulation?

Inside the sump, water cannot freeze on its own. Indeed, during internal fermentation, heat is always released. Wastewater also contributes to an increase in the temperature inside

It is important to take into account the location of the soil below the freezing level.

But putrefactive bacteria reduce their activity if the temperature of the liquid decreases sufficiently. It is best to insulate the septic tank at the top. To do this, use expanded polystyrene plates, or a layer of expanded clay.

How to build septic tanks

Installation work can begin immediately after you have managed to find a suitable plastic container. Step by step:

- First you need to dig a hole where the septic tank will be installed. It must be at least 5 meters from the house, this is required by safety rules. It is better to use small special equipment to create a pit, if possible. Handicrafts are too expensive and time consuming. When the excavated soil is taken out of the territory, it is necessary to leave a small amount of it in order to then fill up the pit with a septic tank.

- Next, proceed to the arrangement of sewer pipes. It is recommended to give preference to corrugated plastic products. The minimum outer diameter is 100 mm. In this case, there is no need to purchase rubber seals, additional plastic fittings.

This means that the reliability of sealing is not in doubt. 1-3 percent of the length is the recommended slope. It is necessary to independently insulate pipes if they lie above the freezing level. Silicone sealant must be treated with sewer pipes, at the joints of which there is concrete.

It is necessary to skip the ropes in the mounting eyes. The body of the septic tank is installed on the boards. Then the boards are removed, and the product itself is gradually lowered.

Septic tanks based on plastic barrels

This option is great for areas where the sewer system is used only from time to time, most actively - in a certain season. It is enough to pick up a few barrels of 220 or 250 liters. They are enough to serve a comfortable stay on the territory of 1-3 people.

Installation work is carried out in the same way as for a conventional septic tank. The main thing is not to forget to make holes in the barrels themselves. So-called couplings are inserted there. On one of the barrels, we will need to make a round hole for the adapter and flange.

At an angle of 90 degrees to each other, it is allowed to create side holes. The main rule is that the first barrels, where the incoming effluents are processed, are installed much higher than the second. Therefore, adapters are needed - to create a reliable connection between containers that are at different levels.

plastic rings

Installation takes place according to the same principle as for plastic barrels. Of the advantages - the same low weight, one container can weigh up to 50 kilograms. It is worth noting the long service life, the absence of serious requirements during installation.

The most common outer diameter for rings is 950 millimeters. Their height is up to one and a half meters, and the wall thickness is 25 millimeters.

Additional articles:

- how to make a septic tank with your own hands;

- garden septic.

Homemade plastic structures

Here it is important to clearly and accurately follow the instructions, then it will be possible to assemble a product that fully meets the requirements in these operating conditions without any problems. You need to start with a thorough study of the scheme according to which the septic tank is arranged

This will help you understand the principle of operation and understand what the assembly process should be like.

Only one plastic container can be used. But then the system will move into a series of accumulative ones. It will require frequent and constant cleaning, otherwise the wastewater will not be suitable for reuse.

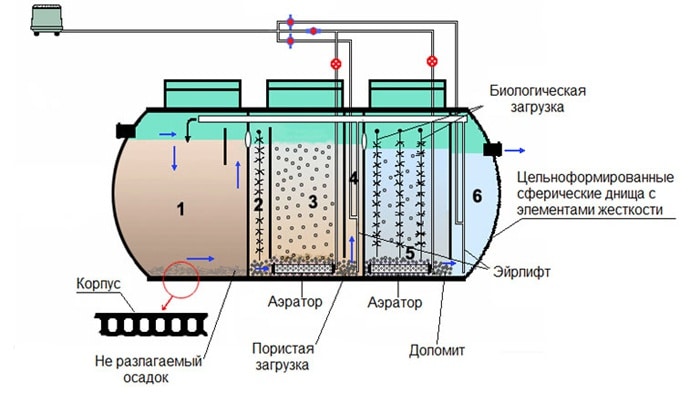

In the first section, wastewater is processed and clarified. It is here that the so-called anaerobic bacteria begin to connect to the process. If effluents are difficult to recycle, they simply settle to the bottom.

The first section is much smaller than the second one. From the entire length of the structure of the treatment plant, it is usually at least 1/6.

The second plastic block is responsible for recycling. You can equip septic tanks with timers and compressors. The latter force air inside so that all the elements are completely mixed in the container.

Common mistakes when installing a septic tank made of polymers

Often, owners who seek to install a plastic sewer sump with their own hands without the help of professionals make annoying mistakes. Those, in turn, lead to a disruption in the operation of the treatment plant and, accordingly, a decrease in its efficiency. But in the worst case scenario, it may be necessary to dismantle the tank and install a new one.

So, common mistakes:

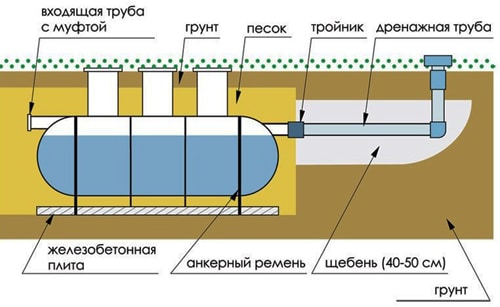

A polymer septic tank is not attached to a concrete slab. It should be borne in mind that too low specific gravity of the tank does not work in favor of the tank if it is not anchored. That is, even a filled sump will feel like a float in the ground. And therefore, it is possible that the container will be washed out of the soil to the surface.

- The absence of a cement-sand sarcophagus. Such neglect can lead to freezing of drains in the tank. Or the septic tank will be pushed out due to seasonal heaving of the soil.

- Use of unsifted coarse sand for sprinkling the tank. Here it is worth considering that large grains of sand under the influence of cold in the ground and possible moisture can behave according to the principle of a cutting mechanism. That is, under the load of soil for compression, coarse sand at low temperatures is able to form microcracks on the walls of the tank, which over time will lead to depressurization of the tank.

Thus, it can be seen that a polymer septic tank is a good solution for creating a private sewerage and wastewater treatment system, but with a competent approach to its installation.

The choice of design which septic tank can be made from plastic containers

If you plan to install a tank as a receiver for a cesspool, then you need to accurately determine the volume of wastewater that will accumulate in the tank between the arrivals of pumping equipment. When installing a multi-chamber structure, the volume of the receiver must exceed three times the value of the water flow rate from all points of water intake in the house, multiplied by the number of family members. It is better to buy a tank with a significant margin in terms of volume, given that the number of drains will increase in summer.

Structure Installation Diagram

To install a plastic septic tank in a cesspool, it is enough to buy an inexpensive plastic tank. This solution is suitable for areas where it is necessary to organize drainage from 1 - 2 seasonally used points: a summer shower and a toilet. Polyethylene can be destroyed under the influence of a large amount of household chemicals, so it is better to choose a polypropylene tank for a septic tank of a private house.

Storage tank: it is important to calculate the volume correctly

The shape of the tank is selected depending on the depth of the planned installation, the quality of the soil and the availability of sufficient space for installation. You can save a few meters by installing a deep square tank, provided that the bottom is above the groundwater level.

Size and volume - no restrictions

It is possible to install the tank only after additional sealing of the pit: it is better to fill the bottom and walls with a solution, and lay insulation between the walls of the tank and the pit

The installation depth is calculated taking into account the limitations on the operation of the equipment: pumping is carried out only to a depth of 3 m

A plastic septic tank with an active filtration capacity is a two-chamber system sufficient for autonomous processing of residential building effluents. After primary settling and stratification of the masses in the receiver, the effluent enters the reservoir, where further purification takes place under the action of microorganisms that process organic compounds.

Active septic tank: design drawing with two tanks

The advantage of organizing an autonomous active system is energy independence. Bacteria process pollution without access to oxygen, so you do not need to connect special equipment. The liquid is in the container for 3 days: it is better to choose a plastic tank with a margin of volume.

Factory containers are equipped with sealed lids and pipe fittings. There are ready-made septic tanks with internal overflow walls - two chambers inside one structure.

With your own hands, you can make an active septic tank from recycled plastic - tanks, tanks, eurocubes. To make an overflow, two separate containers are dug in with a difference in height and connected with an overflow pipe.

Plastic septic tanks that do not require pumping are installed to treat wastewater in private homes. The system consists of 2 - 3 chambers with different types of filtration. Fiberglass or polypropylene containers are used: with a large internal volume, the walls must be especially strong.

Scheme of wastewater treatment in a multi-chamber factory station

There are 2 ways to arrange.

- Installation of the finished structure, selected according to the required volume, with the internal organization of chambers with overflows.

- Sequential installation of several plastic containers.

Ready-made septic tanks can be installed immediately after the preparation of the base: the tanks are equipped with ventilation outlets, sealed manholes, insulated pipes for connecting a sewer pipe.

Septic tank with factory equipment and water outlet to the filtration well

There are factory stations with pre-installed equipment for aerobic treatment: aerators and a drainage pump.

For self-assembly, choose containers of a suitable volume for each of the chambers. Additionally, markings are made for holes for tie-in pipes, inspection hatches, ventilation ducts.

Principles of proper installation of a PVC septic tank

In order to properly install a polymer sewer sump that will work efficiently and for a long time, you need to adhere to several important principles:

- The pit for the installation of the tank should exceed the dimensions of the tank by 40-50 cm in depth, and 30 cm in each direction. This place will subsequently be allocated for concreting the site and creating a sarcophagus for a septic tank.

- At the bottom of the pit, a layer of sand 15-20 cm thick should be poured and compacted well. In this case, the evenness of the base must be checked by level.

- A concrete slab must be laid at the bottom of the pit. It will eliminate the possibility of washing the reservoir during the snowmelt season.

- In order to create a sarcophagus for a plastic settling well, the walls of the pit can be laid out with bricks. In this case, the thickness of the wall can be 12 cm with a cross section of a round-type tank, and 25 cm with a cross section of a rectangular-type septic tank.

- If the septic tank is installed in the ground, where the groundwater level will exceed the bottom of the tank, then you need to make a special "carving" of the tank. To do this, use a mixture of sand and cement at the rate of 4:1. The process of pouring the sarcophagus looks like this: first, the tank is filled with 20 cm of water, and then a solution of cement with sand 15-20 cm high is poured around it. Then water is again added to the tank by 20 cm, and the solution is again loaded into the pit. Thus, they act up to the very top of the settling tank.

- For a septic tank, which is installed to a depth of more than half a meter, a concrete floor must be provided.

- When installing the tank, check the tightness of the connection between the ventilation pipe and the tank.

Installation of plastic septic tanks

Installation of septic tanks - how to install it correctlyConstruction work is carried out in the following way:Upon completion of the preparatory work, pipelines are laid:

- corrugated polyethylene pipes with a brown-orange color are best suited for arranging outdoor pipelines: these pipes demonstrate excellent performance in outdoor conditions;

- pipe installation can be simplified using special reinforced concrete trays. If there is no desire to use ready-made structures, then the pipes are laid on a sand cushion laid directly on top of the ground;

- when laying pipes, you need to remember the need to create a permanent slope.

The installation of a septic tank is the last step and is performed according to the following algorithm:

- a polymer septic tank must be laid to a depth of one and a half meters to prevent the impact of negative temperatures on the structure;

- as the septic tank is instilled, it must be gradually filled with water so that the walls do not sag under the influence of external pressure;

- when the pipeline is connected and the trench is filled with sand, it is necessary to install an electrical cable (if the system requires it) for the compressor. Cable laying is carried out using a corrugated polyethylene pipe, which protects the wire from environmental influences;

- to insulate a plastic septic tank with your own hands, it does not hurt to lay foam sheets or backfill with expanded clay.

Conclusion

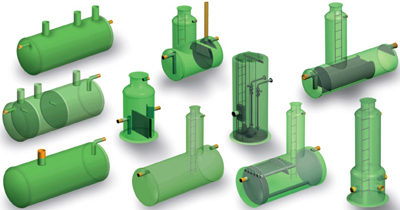

Types of plastic septic tanks

Currently, you can purchase a septic tank made from various types of polymer. Such a septic tank is a worthy alternative to a more traditional septic tank made of concrete. A plastic septic tank is recommended for installation both in houses where people live permanently and in summer cottages.

To date, consumers can purchase a plastic septic tank for a summer residence or a country house from three types of materials:

- fiberglass;

- polypropylene;

- polyethylene.

Now we need to consider each of them in more detail.

Polyethylene septic tank

In difficult conditions, models that are made of durable polyethylene work very well. Modern models of such septic tanks are able to work both with aggressive environments and at fairly large temperature differences.

Modern technologies make it possible to produce seamless models of septic tanks, which have walls that prevent the formation of various deposits.

It is also very important that the septic tank can have almost any shape.

Most often, polyethylene septic tanks for summer cottages are made multi-layered to increase the strength of their walls, which will increase their service life quite significantly. The operating temperature range for polyethylene septic tanks is from -50 to +70 degrees, so they can be used in almost any climate.

Polypropylene septic tanks

The density of polypropylene is less than that of polyethylene, but it has more resistance to abrasion and strength. A polypropylene septic tank for a country house can be used even at higher drain temperatures, as it can withstand heating up to 140 degrees. In addition, it is very resistant to stress corrosion cracking. A septic tank made of polypropylene, due to such qualities, is often used where there is the most aggressive environment, as well as for the treatment of industrial wastewater.

fiberglass septic tank

This type of septic tank is made from a material based on resins. In order to increase the strength of the walls, fiberglass is added to these materials during the manufacturing process.

Such a septic tank is a container divided into chambers. It can be used when working in aggressive environments, since fiberglass is not subject to corrosion at all.

What are sewage treatment plants

- Concrete;

- brick;

- metal

- Plastic.

The first type of cleaning devices is very durable and low cost. Its installation is easy to do if you use special equipment. Concrete treatment facilities may consist of several rings or be monolithic. When installing systems with such a design, it is necessary to carefully waterproof the bottom and side walls so that the contents of the tank do not seep into the ground and pollute the environment.In severe frosts, freezing of water in the soil can lead to the destruction of concrete.

Metal septic tanks are relatively light and strong enough. But the arrangement of such a device requires significant material costs. This is due, first of all, to the fact that under the base of a heavy tank, the construction of a solid concrete base is required. The devices themselves are not durable, since the metal, subject to corrosion, quickly collapses. These factors do not contribute to their particular popularity.

We watch a video on how to choose a septic tank and also types:

Brick cleaning systems are made from cheap building materials and have a very simple design. But they have a number of shortcomings that offset everything previously said. In addition to the fact that the service life of a brick is short, careful sealing is necessary, and this is quite difficult and costly to do.

A plastic septic tank built into the ground differs from the previous options in a number of advantages, which made it popular and widely used in all latitudes of our country. Let's take a closer look at their characteristics.