Why are pipes of different colors

The choice of sewer pipes is an important step in the wiring of the internal sewerage system

For high-quality work of the entire pipe system, attention is paid to such elements: fittings, connection methods, material of manufacture

It is also important to choose the diameter and length of the pipes, and this is where the color scheme of the pipes will help. The manufacturer has specially created different colors so that the buyer can choose the right pipe for the intended use.

So, the color of the pipes indicates its classification. Until recently, sewer pipes were of two colors: gray and black. Now there is such a color variety: gray, red, black, green, blue, white. This complicates the choice to some extent, but you just need to know the purpose of pipes of a certain color.

The manufacturer has specially created different colors so that the buyer can choose the right pipe for the intended purpose. So, the color of the pipes indicates its classification. Until recently, sewer pipes were of two colors: gray and black. Now there is such a color variety: gray, red, black, green, blue, white. This complicates the choice to some extent, but you just need to know the purpose of pipes of a certain color.

Manufacturers cannot paint pipes at their own discretion, for this there are standards by which production is carried out and these rules are mandatory for all companies involved in the production of these products.

If the sewer pipes do not fit into the interior of the room in color, then choosing the right color scheme, you need to thoroughly study the parameters of the product, they may not be suitable for other indicators. Only then make purchasing decisions. A wide variety introduces a buyer into a stupor, since he does not know the elementary purpose of a particular pipe.

Product varieties

The classification of fan pipes into types is carried out according to the materials of manufacture, according to which polymer and cast iron products are distinguished. Cast iron, by and large, is now practically not used - it is a relic of the Soviet era, such solutions can be found in multi-storey buildings that have not been overhauled sewers.

The cast-iron fan pipe has a number of serious disadvantages, the main of which are heavy weight, high cost, labor-intensive installation. In terms of performance, it completely loses to plastic products, its only advantage is durability and high mechanical strength.

A plastic sewer pipe can be made from two types of polymers - low-pressure polyethylene (HDPE) and polypropylene (PP). We recommend using products made of HDPE - this is one of the most rigid types of plastic, which has high crack resistance and resistance to deformation.

Consider the advantages of plastic pipes:

- minimum cost;

- low weight and, as a result, ease of installation;

- durability - service life over 50 years;

- resistance to chemically aggressive substances;

- resistance to corrosion.

Note that due to the perfectly smooth inner surface of the pipe, with rare exceptions, it does not need sound insulation, since the sound of the air circulating through the system is not audible.

Basic noise isolation is carried out by mounting the line using damping clamps with a rubberized fixing ring that dampens vibration. If practice shows that the fan pipe produces a lot of noise, sound insulation can be made using polyethylene foam or mineral wool sleeves.

Installation and replacement

The fan pipe is installed so that the lower part of the riser is placed in a heated room and the upper cut is led out into the open air.In this case, the pressure drop due to the temperature difference will ensure the effective removal of sewer gases.

When installing a fan pipe, the following rules must be followed:

- you can not use a fan pipe, the diameter of which is less than the diameter of the sewer riser (standard - 110 mm);

- if a plastic pipe is connected to the old cast-iron riser, a rubber adapter must be installed at the junction to ensure the tightness of the entire system;

- several risers of an apartment building can be connected to one fan ventilation channel by means of adapters and bends; in this case, the horizontal parts of the line must be laid with a slope of 2% from plumbing fixtures;

- the minimum distance between the roof of the building and the upper opening of the fan pipe is 30 cm, if the attic of the building is used as a living space, the distance increases to 3 meters;

- the outlet point of the sewer pipe should be 4 meters away from the nearest balcony;

- when installing plastic products in places from passing through the concrete floors of the house, steel sleeves must be installed;

- it is strictly forbidden to combine fan ventilation and chimney into one channel;

- a fan fungus must be installed on the outlet, which will prevent insects and leaves from entering the system.

Fan pipe on the roof of the house

The replacement of fan pipes in multi-storey buildings is carried out by responsible representatives of the housing and communal services, since the fan part of the sewerage system is located outside the residents' apartments.

The riser is repaired independently, the cast-iron parts of which can rot during operation and cause serious problems in the apartment. Repairs must be coordinated with neighbors upstairs, who should not use bathrooms for the period of site replacement.

Sewer riser replacement technology:

- The water supply to the toilet is blocked, the drain hose of the bathroom is removed.

- The toilet bowl is dismantled, the room is cleared of foreign objects.

- With the help of a hammer, a chisel and a grinder, the damaged part of the riser is dismantled - this is an extremely time-consuming process that can take more than one hour of work.

- Rubber cuffs are installed on the end parts of the old riser, fixed with a sealant.

- A new riser is assembled from plastic segments with a diameter of 110 mm, which is equipped with an additional socket for connecting drain pipes from the toilet, bath and sinks.

- Plumbing fixtures are brought to the riser by means of corrugated plastic pipes installed with a slope of 5 towards the drain.

Pipe colors and scope

Due to the aggressiveness of the environment that carry wastewater through sewer pipes, they are subject to serious requirements: the material of manufacture is cast iron, PE (polyethylene), PP (polypropylene), PVC (polyvinyl chloride), ceramic, asbestos-cement. All of them must be strong and durable, and each type of pipe has its own purpose. In order to facilitate the choice, manufacturers have designated sewer pipes in different colors.

gray

The gray pipe is made of PVC, is not afraid of corrosion, is not heavy in weight, is easy to install, and has a completely neutral color in terms of aesthetics. The pipes are different in size, but they have limitations in diameter.

redheads

This type of pipe is designed for external sewerage, made of PVC (polyvinyl chloride), in diameter there are 110, 125, 150 mm - the standard for such pipes. They can be 500, 1000, 2000, 6000 mm in length.Large pipe sizes are designed to create sewerage systems with a large flow area, storm sewers and culverts. The thickness of such a pipe is 3.2 mm. Such a pipe can be laid to a depth of up to 4 m. The temperature range is from -10 to + 60. The pipe is smooth with a socket, according to the stiffness class SN 4, consists of several layers. It is ideal for outdoor sewerage.

The material from which the pipe is made is strong, durable, resistant to corrosion and is not afraid of exposure to harmful microorganisms. Such a pipe inside has a smooth structure, which helps to pass various drains without delay. Despite the rigidity and strength, it is not laid under the highways, as it will not withstand pressure, bend and cause blockage and subsequent breakdown. Although the ribbed surface and many layers gives an additional chance to withstand a large amount of soil.

This pipe is more expensive, but it also has a high service life - about 50 years.

black

Black HDPE pipes can be used both indoors and outdoors. More often they find applications as pipes in which communication cables are laid to protect against moisture. Black pipes are not suitable for plumbing, as they cannot withstand high pressure. If water is carried out without pressure, then it can be used. It is mainly used for sewage from domestic sewers. It happens in bays of 40-50 m and a diameter of 110, 160 and 200 mm. There are also special black perforated pipes designed for underground drainage.

Black HDPE pipes can be used both indoors and outdoors. More often they find applications as pipes in which communication cables are laid to protect against moisture. Black pipes are not suitable for plumbing, as they cannot withstand high pressure. If water is carried out without pressure, then it can be used. It is mainly used for sewage from domestic sewers. It happens in bays of 40-50 m and a diameter of 110, 160 and 200 mm. There are also special black perforated pipes designed for underground drainage.

Greens

Such pipes are often made of cast iron, as this material is distinguished by high strength and durability. There are pipes and plastic ones. The walls of such pipes are strong, designed to withstand a large layer of soil, and have perforations (drainage holes). Such products are used for underground drainage - they collect groundwater, withstand temperature extremes.

Blue

Blue pipes are often used for laying a system for discharging rain and melt water inside heated residential and industrial buildings. These pipes are incredibly strong, as risers and drain pipes need to withstand the pressure of the water flow in the event of blockages and overflows in the system.

White

White sewer products are not used as often, even less often than black ones. If it is not possible to hide the internal pipeline, then white pipes are taken, since gray ones are difficult to fit into the interior of a bathroom or kitchen. There is no need to worry about the quality of these pipes, they also meet the parameters of the interior installation of the premises, like gray ones.

White sewer products are not used as often, even less often than black ones. If it is not possible to hide the internal pipeline, then white pipes are taken, since gray ones are difficult to fit into the interior of a bathroom or kitchen. There is no need to worry about the quality of these pipes, they also meet the parameters of the interior installation of the premises, like gray ones.

Temperature heating can withstand up to 950, when choosing such a pipe, you should not worry about its safety. Noise isolation at a height, the diameter of the pipe is varied in assortment: from 32 mm to 150 mm. In length from 150 to 5000 mm. The layer thickness is about 2.7 mm and of course the pipe has a socket with a rubber ring, which makes the installation of the docking hermetic. Various fittings and connections are easily selected for such pipes.

When it is known for what purposes a sewer pipe is needed, whether it be internal or external wiring, and the required diameter and size are known, it will not be difficult to assemble and bring pipes, especially since no special tools and devices are required for this.

Scope of application

- Sewerage network.

- External sewerage network.

- Wastewater treatment.

An internal wiring network is used inside buildings, as a rule, it is connected to water inlets: baths, sinks, toilets, urinals, bidets, showers - this is a system for collecting wastewater inside the building and delivering it to the external sewer.

External sewerage network - collection of effluents from the building and their discharge to treatment facilities or discharge into a water intake. External sewerage can be central, from which effluents go to special treatment facilities or domestic, where there can be a water treatment collector. There may also be a household pit into which dirty water is discharged, and then, as it fills up, it is pumped out by a sewer machine.

Wastewater treatment - serve to collect storm water and quickly remove precipitation, as well as melt water or discharge water from technological enterprises. Water flows into special ditches (ditch system) of an open type and enters underground pipelines, and from there it can flow either to treatment facilities or directly to water bodies. Sometimes such water is diverted directly to sparsely populated places, to forests, to plantings.

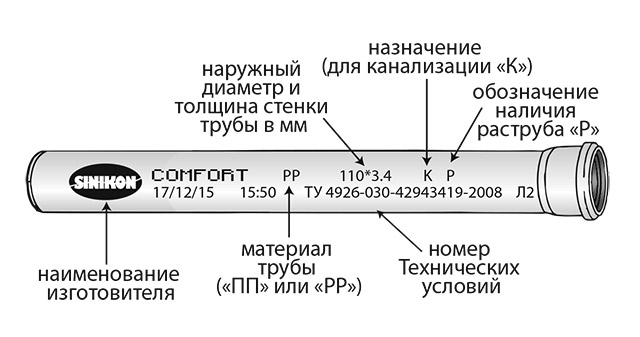

Marking sewer pipes with color

It is easy for an uninitiated person to get confused in the existing variety of polymeric materials. Plastic pipes are a variety of polymeric materials that differ in the nature of the polymer, the conditions for their production, and technical characteristics. Color marking of polymer pipes is a convenient way to inform the consumer about their purpose.

Marking sewer pipes with color is not arbitrary. Uniform international standards have been established, which bona fide manufacturers must follow.

Color coding shows:

- What material are the pipes made from?

- their purpose, depending on the location - indoor, outdoor, for outdoor or underground operation.

Manufacturers offer the following types of pipes, which differ in color:

- Gray (or white), color tone depends on the manufacturer. Polypropylene pipes intended for laying communications inside a heated room.

- Orange (or brown, red) - here the tone depends on the manufacturer, and the name often depends on the vocabulary accepted among workers. Pipes for external drainage.

- Green (or blue) - perforated pipe materials. The materials are intended for laying underground drainage systems.

- Black - polyethylene sewer pipes. Perfectly suited for the installation of an individual sewer system, which is operated by gravity.

All listed sewer pipes differ in resistance to temperature, pressure, external influences.

What determines the color of sewer pipes

A buyer who does not have sufficient information in this area may be confused by the existing variety of colors. How can you figure it out if products made from the same material can have different colors? Why are pipes of several colors made for laying sewers in a private house, because there is only one system? And what determines what color is painted?

Despite the apparent complexity, the answers to these questions are quite simple: manufacturers have made life easier for consumers by giving their products a different shade, depending on their purpose. The owner of the house, who came to buy, say, pipes for internal sewerage, can no longer strain his eyes, studying the information on the labels, but immediately go to the racks where gray sewer pipes are displayed.

An exception to this rule is when the use of a pipe of a particular color is not aesthetically pleasing, then you can buy a pipe that is more suitable in color, for example, white, and eliminate the existing contradictions.

Mounting Features

The laying of the internal sewerage is carried out from gray pipes without the use of additional materials or tools, using a socket connection. The divergent end of the gray pipes is equipped with seals initially.

Pipe size varies from 25 to 300 mm

Since the installation of gray pipes is carried out in a socket, it is important to select the components of the right size so that you do not have to spend extra money and then cut the material

Features of the installation of sewer pipes:

- Horizontal sections must be mounted with a slope towards the drain. The steepness of the slope varies depending on the diameter of the pipe used. The norms are as follows: D 50 - slope per 1 running meter of at least 3 cm; D 110 - 2 cm; D 160 - 0.8 cm is enough.

- When changing the direction of the pipe, the angle of rotation should not be straight, as a sharp turn contributes to the rapid formation of blockage. Installation is planned with several obtuse angles of rotation, instead of one sharp one.

- Communications that are laid in unheated areas of the building should be protected from freezing with thermal insulation.

Laying pipes of external communications is carried out below the freezing point of the soil. For each region, this is a separate depth. Additionally, pipes can be insulated if winters in your area are unstable. If communications pass under the parking area or traffic, then the pipe must be placed in a special protective casing

Before digging a trench, it is important to make sure that the pipes do not sag, and that the base under them is sufficiently solid.