Performance definition

This indicator does not require complex calculations. The consumption of pumping equipment should not exceed the debit of a deep well. For example, if the inflow in the well is 3 m3, a pump capacity of 2.7 m3 per hour will be quite enough. It is not scary if the consumption of the device is, for example, 1.5 m3 per hour.

The main thing is not to purchase equipment whose performance is much higher than the debit of the well. During the operation of such a pump, a situation will constantly arise when the water level drops to the installation position of the suction device. If the latter is equipped with effective automatic protection, it will turn off the equipment. But you need to think that the protection may someday fail, not work, and the pump will burn out in a matter of minutes, running dry. Therefore, it is better not to risk an expensive device by making the right choice of its performance.

In country houses, it is almost impossible to connect to the central water supply. What to do? Conduct your own water supply system, make a well or well. The second option is more convenient, but requires solving a lot of different issues.

Number of pump speeds

Well-known manufacturers of pumping equipment for heating equip their units with shaft speed switches; in some models, the speed of the device is automatically controlled. During operation, this creates additional convenience: since the heating of the liquid takes quite a long time, to quickly warm up the premises, you can set the maximum speed of the electric pump or save electricity by setting the minimum speed of the electric motor when the room is warmed up.

The number of speeds, depending on the manufacturer, can be from 2 to 4 - the more there are, the more efficiently you can use the circular in the heating system, and the most economical option is electronic speed control.

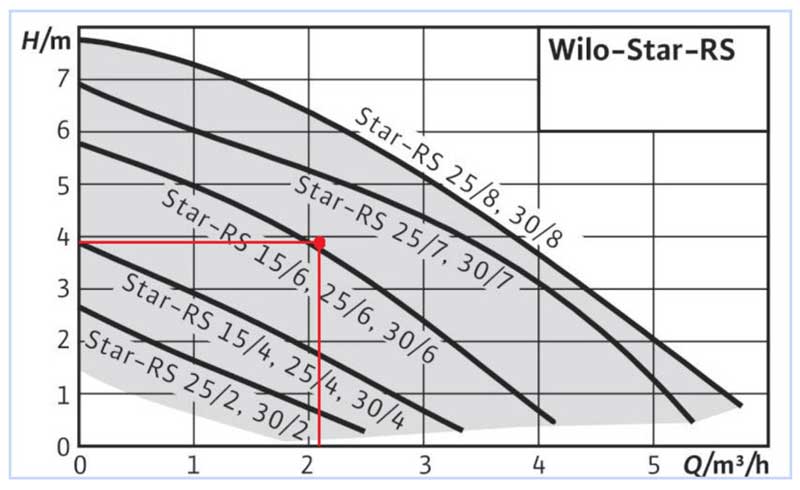

Fig.13 Selection of an electric pump according to pressure characteristics

How to choose the right pumping station for a summer cottage

Efficient water supply for dachas, as well as irrigation of garden plots, filling reservoirs, supplying water to fire-fighting devices, ensuring emergency pumping of excess liquid in the backyard - all these processes are provided throughout the world through the use of pumping stations.

The world famous Italian corporation Pedrollo is recognized as one of the leaders in the development and manufacture of pumping equipment.

A distinctive feature of pumping stations of this brand is the stability of pressure parameters due to the possibility of automatic control of volume flow indicators, minimization of service maintenance and the possibility of achieving significant energy savings in comparison with competitive brands of equipment (up to 10%).

It is possible to achieve a high economic effect from a pumping station purchased for organizing water supply in a country house only as a result of a competent choice. This approach makes it possible to exclude insufficient or excessive volumetric flow, and, consequently, underload or overload of the engine, the occurrence of vibrations, a decrease in efficiency, an increase in electricity consumption, the occurrence of leaks and premature equipment failure.

The purchase of a pumping station, the characteristics of which fully correspond to real conditions and allow solving the technical problems facing the consumer, guarantees its long service life and minimum operating costs.

In the process of choosing a pumping station for a summer residence, the following factors should be taken into account

An example of the selection of equipment for a well

In order for the choice of a pump for a well to be made correctly, you can use the following example.

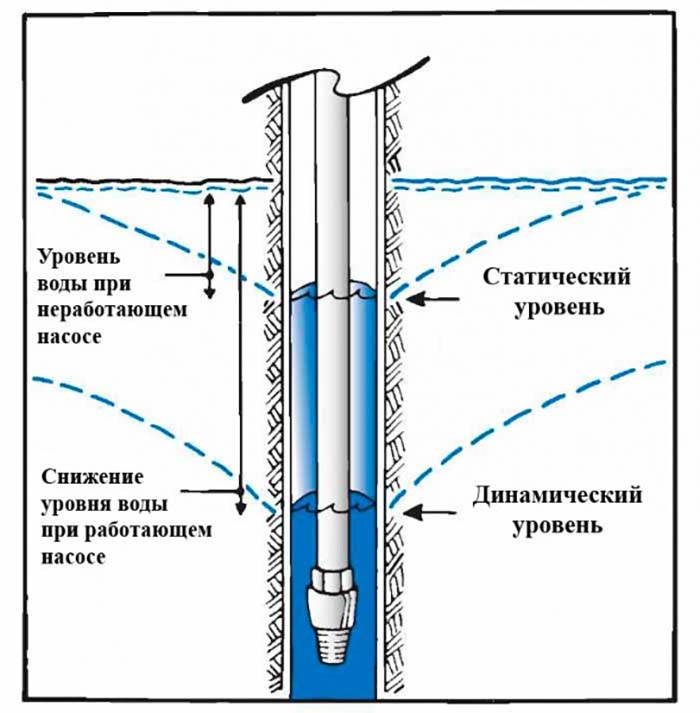

Scheme for determining the height of the pump.

Initial data for the well:

- the total depth is 100 m;

- dynamic water level - 70 m;

- the water static level is 75 m;

- water well diameter is 133 mm;

- flow rate is 3 m³/h;

- filter installation depth - 95 m;

- the equipment control unit is located at a distance of 25 m from the well;

- from the well to the entrance to the house, the distance is 20 m;

- a head is used to design the wellhead;

- the highest point for water intake is 8 m from the ground surface (3rd floor of the house);

- power is supplied from a 220 V network, the system is used single-phase, there is a possibility of drawdowns up to 190 V.

The selection of a pump for a well is carried out in this way:

- First, it is necessary to take into account the number of draw-off points with an allowable flow rate limit of 2.6 m³ / h. This amounts to 5-6 cranes open at the same time, the performance of which is average. Even for a large house, this amount is enough.

- The depth for installing the pump in the well is 72 m.

- For the consumer, a comfortable pressure at the highest point should be 2.5 bar. Given a pressure loss of 1 bar on the rise, a value of 1.5 for the high point is quite acceptable.

- For the riser pipe, the total length in this case will be 92 m, and for the supply cable to the control equipment panel, the length is 97 m.

- The diameter of the cable is 5 mm, its length is - 72 m + 2 m + 4 * 2 m (for cable loops) = 82 m.

- For a plastic water pipe, the diameter is best taken to be 40 mm, while the total loss will be approximately 4 m if the flow velocity is 0.8 m/s.

- Losses during the operation of the filters will be approximately 10 m, that is, about 1 bar.

- The required total head is H=1.5*10.2+70+(10+4) = 99 m.

What pumping equipment should be?

Taking into account all the above data, the well can be equipped with the following pumping equipment:

- Pump for 1.1 kW, power cable for 4 * 6 m³, while the voltage loss will be 2%.

- Pump for 1.5 kW, power cable for 4 * 6 m³, voltage loss will be 3.1%.

- 1.5 kW pump, 3 * 6 m³ power cable, voltage loss will be 2.9% along the entire length.

- Pump for 1.4 kW, power cable for 3 * 6 m³, loss in length will be 2.7%.

For the presented system, it is best to take a 150-liter accumulator for the first 3 options. At home, it is recommended to install a voltage regulator of 5 kW.

The choice of a pump for a well for water is a responsible process. Not only the characteristics of the pumping equipment itself are taken into account, but also numerous parameters. This is the length of the cable, the presence of a hydraulic accumulator and other elements of the system

During the selection, attention should be paid to the flow of water for the house and the site. Only in this case can the pump be considered fully suitable for a particular well.

For an effective water supply device for a country house, it is necessary not only to make a well, but also to equip the underground structure with the necessary equipment, the main component of which is a device for lifting water from depth to the surface. Proper selection of a borehole pump will ensure uninterrupted water supply in the cottage and reliable operation of the equipment itself. What criteria are guided by when choosing a pump for a well, and what characteristics of the device will be decisive in this - these and some related questions will be answered in the article.

Why do you need a pump in the heating system

Circulation pumps for heating private houses are designed to create a forced movement of the coolant in the water circuit. After the installation of the equipment, the natural circulation of the liquid in the system becomes impossible, the pumps will work continuously.For this reason, high demands are placed on circulation equipment regarding:

- performance.

- Noise isolation.

- Reliability.

- Long service life.

A circulation pump is needed for "water floors", as well as two- and one-pipe heating systems. In large buildings it is used for hot water systems.

As practice shows, if you install the station in any system with natural circulation of the coolant, the heating efficiency and uniform heating along the entire length of the water circuit increase.

The only disadvantage of such a solution is the dependence of the operation of pumping equipment on electricity, but the problem is usually solved by connecting an uninterruptible power supply.

Installing a pump in the heating system of a private house is justified both when creating a new one and when modifying an existing heating system.

The principle of operation of the circulation pump

The operation of circulation pumps increases the energy efficiency of the heating system by 40-50%. The principle of operation of devices, regardless of type and design, is as follows:

- The liquid enters the cavity, made in the form of a shell.

- Inside the housing there is an impeller, a flywheel that creates pressure.

- The speed of the coolant increases and, by means of centrifugal force, the liquid is discharged into a spiral channel connected to the water circuit.

- The coolant enters the water heating circuit at a predetermined rate. Due to the swirling of water flows, the hydraulic resistance decreases during fluid circulation.

The principle of operation of a heating system with a circulation pump differs from circuits with natural circulation in that the movement of fluid is forced. The heating efficiency is not affected by compliance with slopes, the number of installed radiators, as well as the diameter of the pipes.

The operation of circulation pumps may differ slightly, depending on the type of construction, but the principle of operation remains the same. Manufacturers offer more than a hundred models of equipment, with various performance and control options. According to the characteristics of pumps, stations can be divided into several groups:

- According to the type of rotor - to enhance the circulation of the coolant, models with a dry and wet rotor can be used. The designs differ in the location of the impeller and moving mechanisms in the housing. So, in models with a dry rotor, only the flywheel, which creates pressure, comes into contact with the coolant fluid. "Dry" models have high performance, but have several drawbacks: a high level of noise is generated from the operation of the pump, regular maintenance is required. For domestic use, it is better to use modules with a wet rotor. All moving parts, including bearings, are completely encased in a coolant medium that serves as a lubricant for the parts that bear the greatest load. The service life of the "wet" type water pump in the heating system is at least 7 years. There is no need for maintenance.

- By type of control - the traditional model of pumping equipment, most often installed in domestic premises of a small area, has a mechanical regulator with three fixed speeds. It is rather inconvenient to regulate the temperature in the house using a mechanical circulation pump. The modules are distinguished by high power consumption. The optimal pump has an electronic control unit. A room thermostat is built into the housing. Automation independently analyzes the temperature indicators in the room, automatically changing the selected mode. At the same time, electricity consumption is reduced by 2-3 times.

There are other parameters that distinguish circulation equipment. But to choose the right model, it will be enough to know about the above nuances.

Downhole pump selection criteria

When selecting a borehole pump, two main criteria should be followed.

the pump must provide the necessary water flow to meet the needs of the consumer, taking into account the depth of the well and the distance to the water intake point (usually this is a membrane accumulator);- at the same time, its average consumption should not be greater than the productivity (debit) of the well.

The second condition is very important, since if the pump flow rate exceeds the well flow rate during its long-term operation, the water level will drop so much that the pump will partially come out of the water and will run “dry”. And that's a direct path to destruction.

Therefore, it is impossible to thoughtlessly select a borehole pump according to the principle of the more powerful, the better. This is the case when you spoil the porridge with butter.

Pump selection

Knowing the main characteristics, you can proceed to the selection of a specific unit.

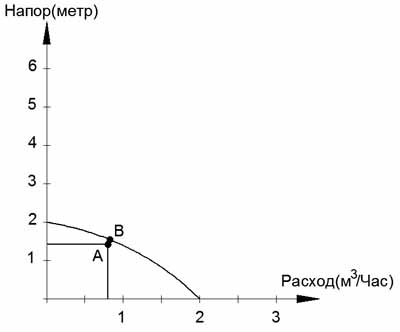

So, we have two quantities - resistance and performance. Let's return to our schedule with the head-flow characteristic.

We plot the resistance value on the Y axis, and the flow rate on the X axis. Then we select the unit, the graph of the pressure-flow dependence of which is located near this point:

It is necessary to choose such an apparatus, the operating point of which will be located as close as possible to the point we noted earlier.

Important! As a rule, the graph shows three lines for different modes of motor operation. It is best to be guided by the second speed, and the operating point should be located in the middle third of the diagram, since it corresponds to the highest efficiency.

The pump must match the pipe diameter.

Of course, it is necessary to select a device designed for high ambient temperatures (95 - 110 ° C), and also know the diameter of the pipe into which the device will be embedded. The price of the device will depend on the manufacturer and quality.

The correct choice of the circulation pump for the heating circuit is made on the basis of calculations. If the material presented seems too complicated for you, watch the video in the article.

Calculation of the pumping station

It should be noted that well pumps come in different sizes, usually 3- and 4-inch. Since drilling "narrower" wells is cheaper, the most common pumps are 3-inch. There are universal three-inch submersible pumps that are also suitable for supplying water to a private house from larger diameter wells.

The "minus" of submersible pumps for the water supply of a private house is their relative sensitivity to voltage drops, which often occur in suburban power networks. Modern pumps for home water supply systems have built-in stabilizers, which means that the owner does not have to install expensive surge protectors. A situation may arise when water, for some reason, stops flowing into the submersible pump - “dry running”. "Dry running" is fraught with serious damage. If there is no water, the pump rotor may burn out. To avoid this, leading pump manufacturers provide dry-running protection that prevents pump breakdowns and subsequent costly repairs. For example, GRUNDFOS SQ borehole pumps are equipped with protection against "dry running", overheating, a check valve, a built-in voltage stabilizer, and a soft start system that eliminates the current surge at the time of start-up, preventing the motor from overheating.

If you decide to dig a well, then it makes sense to use a pumping station or a surface pump. Such pumps are installed in the house and connected to the water source by a pipeline. The length of the pipeline should not exceed 200 - 300 m, otherwise there may be pressure losses along the length. The surface pump used in the water supply system of a private house can deliver water from a source with a depth of no more than 8 m. It is worth remembering that the longer the suction pipe, the smaller the possible suction depth. Unlike its submersible pumps, a surface pump must be regularly serviced by the user himself , therefore, all components and parts that need maintenance should be easily accessible and using a minimum set of conventional tools. Leading manufacturers of pumps for water supply to a private house produce ready-made pumping stations based on self-priming pumps. The kit includes a pump, a membrane expansion tank (from 24 to 50 liters), a control relay and built-in protection systems against dry running and overheating.The pressure switch is triggered when the pressure drops in the network and turns on the pump, the expansion tank eliminates frequent on-off switching of the electric motor and protects the system from water hammer, which cause noise in the pipes and in some cases can even damage the elements of the system. The main disadvantage of surface pumps is increased noise. It makes sense to place such stations in specially equipped warm utility rooms. However, there are also low-noise units equipped with a water-cooled electric motor, such as the GRUNDFOS MQ, which can be installed directly in the kitchen.

High-quality water supply of a private house cannot do without a water purification system. Water purification filters are directly built into the pipeline of the water supply system of a private house, so purified and filtered water provides high-quality water supply to a private house.

The water supply of a private house is always arranged individually in accordance with the needs of the people living there. The water supply system of a private house must take into account the supply of both cold and hot water. And when supplying cold water to a private house or cottage, the need for water for irrigation, a bathhouse and a pool is always taken into account.

The main task of calculating the volume of water consumption in a pipe according to its cross section (diameter) is to select pipes so that the water flow is not too large, but the pressure remains good. In this case, it is necessary to take into account:

- diameters (DN internal section),

- head loss in the calculated section,

- hydroflow rate,

- maximum pressure

- influence of turns and shutters in the system,

- material (characteristics of the pipeline walls) and length, etc..

The selection of the pipe diameter according to the water flow using the table is considered to be a simpler, but less accurate way than measuring and calculating the pressure, water velocity and other parameters in the pipeline, made on site.

Calculation of the pressure of a borehole pump

The pressure is calculated according to the following formula:

Head = (distance from the point of installation of the pump in the well to the surface of the earth + horizontal distance from the well to the nearest draw-off point * + height of the highest draw-off point in the house) × water resistance coefficient **

If the borehole pump will be operated together with a storage tank, then the pressure value in the storage tank must be added to the above formula for calculating the head:

Head = (distance from the pump installation point in the well to the ground surface + horizontal distance from the well to the nearest draw-off point + the height of the highest draw-off point in the house + pressure in the storage tank ***) × water resistance coefficient

Note

* - when calculating, keep in mind that 1 vertical meter equals 10 horizontal; ** - coefficient of water resistance is always equal to 1.15; *** - each atmosphere is equal to 10 vertical meters.

everyday mathematics

For clarity, let's simulate a situation in which a family of four needs to choose a pump for a well 80 meters deep. The dynamic level of the source does not fall below 62 meters, that is, the pump will be installed at a depth of 60 meters. The distance from the well to the house is 80 meters. The height of the highest draw point is 7 meters. The water supply system has a storage tank with a capacity of 300 liters, that is, for the operation of the entire system inside the accumulator, it is necessary to create a pressure of 3.5 atmospheres. We believe:

Pressure \u003d (60 + 80 / 10 + 3.5 × 10) × 1.15 \u003d 126.5 meters.

What pump is needed for the well in this case? - An excellent option would be to purchase Grundfos SQ 3-105, the maximum pressure of which is 147 meters, with a capacity of 4.4 m³ / h.

In this material, we have analyzed in detail how to calculate a pump for a well.We hope that after reading this article, you will be able to calculate and choose a borehole pump without outside help, which, thanks to a competent approach, will last more than one year.

To organize the water supply of a private house, before installing pumping equipment, it is first necessary to calculate its parameters. In this case, it is necessary to take into account the technical characteristics of the source, the distance to the consumer and the volume of water intake. A homeowner who independently mounts a water supply line to the house does not need to calculate the pump for a well using complex formulas - online calculators posted on the network are designed for this.

Rice. 1 Online calculator for determining the volume of delivery - appearance

Their significant drawback is the approximateness of the results obtained - many important parameters that affect the final result are not included in the input data. Almost all online calculators calculate only one of the parameters: lift height, performance, or required line pressure, the rest of the data has to be determined in other ways. Another problem is choosing an accurate and reliable calculator from the many options available online. Therefore, the most correct solution to the question of how to calculate a pump for a well is to calculate its parameters using formulas using loss tables and use calculators as an aid to verify the correctness of the calculations.

Rice. 2 Online - calculator for calculating the pump for water supply

Calculation of water supply of a private house

In order to correctly calculate the water supply system of a private house, it is necessary to determine the required water consumption for household needs. It must be remembered that the need for water in a private house is not constant and depends on the season. Sometimes in the summer, water consumption can increase by 4-5 times compared to other seasons.

With autonomous water supply to houses, 2 water supply schemes are most common:

- The water supply of a private house is carried out from a well using a submersible pump.

- Water supply of a private house from a well is carried out using a pumping station.

When choosing a pump for a private house water supply system, it must be remembered that it must meet certain conditions. You need to know how deep the water will rise. According to the areas of application, all pumps for water supply at home are divided into two groups:

- submersible - with a depth of water rise over 8 m;

- surface - the depth of water rise up to 8 m.

Submersible pumps are used to lift water from artesian wells, and are also used in deep wells. These pumps are located at great depths - up to 200 m, so submersible pumps for the water supply of a private house must be very reliable. The cost of repairing this can reach the cost of acquiring a new one. The water may contain sand, which has strong abrasive properties, so the water supply of a private house should be carried out by a submersible borehole pump made of high-quality stainless steel and modern composite materials.

Types of pumps for lifting water to the surface

Now there are several types of pumps that are used to pump liquids from deep. The main ones among them are:

- superficially installed;

- submersible vibration;

- submersible centrifugal (rotary).

The first type of equipment is characterized by the fact that the mechanism is on the surface, while an attached pipe (hose) is placed in the water, through which water is sucked in. Surface-mounted pumps have a limited liquid lifting depth (up to 9 meters), so they cannot be considered as full-fledged downhole equipment. With the help of such devices, it is possible to raise liquid only from surface aquifers (perch water), where the quality of water is suitable only for irrigation.

Submersible vibration pumps, which work due to the movement of the membrane and the valve system, are structurally simple, inexpensive and can pump water from a depth of up to 30-40 meters (depending on the power of the model). However, it is categorically not recommended to install such equipment in aquifer deep wells for several reasons:

- strong vibration destroys the well structure;

- the strong turbulence that occurs during operation raises silt and sand from the bottom of the water mine, which pollute the water;

- the shape of vibrating pumps is not adapted to use in narrow casing pipes, so the device often gets stuck in them, after which it is necessary to carry out expensive repair and restoration work.

In water-bearing wells of medium and large depth, only rotary type equipment is used. Centrifugal submersible pumps are specifically designed to work in narrow borehole conditions and, if properly maintained, last from 10 to 20 years. What is this type of device, we will consider further.

What indicators characterize the well

For the correct choice of equipment, some data characterizing a deep well should be evaluated. Interested in such well parameters:

- dynamic water level;

- well debit;

- casing inner diameter.

In addition, when choosing a pump, you will need data on the level of the highest point of water consumption in the house and the distance of the main building from the well.

The first two indicators can be found in the passport of the underground structure. The dynamic level indicates the height of the water table in the casing during long-term water intake. The pump is installed at least one meter below the dynamic level. From this it is necessary to proceed, calculating the height of the rise of water to the level of the mouth of the well. The debit indicates the rate of replenishment of fluid in the lumen of the well. These data are needed when choosing the performance of pumping equipment. Knowing the diameter of the casing pipe will help not to make a mistake with the choice of the appropriate pump rating.

Selection of a pumping station according to the type of pump used

The product range of Pedrollo Corporation includes pumping stations equipped with vortex, self-priming and multistage pumps.

For dachas using water supplied to the facility under pressure, pumping stations have been developed, which include vortex devices. The main technical advantages of these devices, which are usually used for supplying clean water, are their economy and high efficiency.

Pedrollo Corporation offers the following series of pumping stations based on vortex pumps: PKm 60-24SF, PKm 60-24CL, PKm 65-24SF, PKm 65-24CL and many others.

For water supply of country houses using water from wells, as well as from natural water bodies, Pedrollo Corporation has developed pumping stations, which include centrifugal self-priming devices. This equipment has high productivity and low hydraulic losses. In the Pedrollo product range, these pumps are represented by the JDW and JSW series: JSWm 1CX-24SF, JSWm 1BX-24SF, JSWm 1AX-24SF, JSWm 10MX-24SF, JSWm 12MX-24SF, JSWm 15MX-24SF.

Stations operating on the basis of multistage pumps guarantee maximum performance, although their suction depth does not exceed 9 m. A key technical advantage is the quietness of the equipment. In the Pedrollo range, this group includes pumps 3CPm 80E-EP I, 3CPm 100E-EP I, 4CPm 80E-EP I, 4CPm 100E-EP I and others.

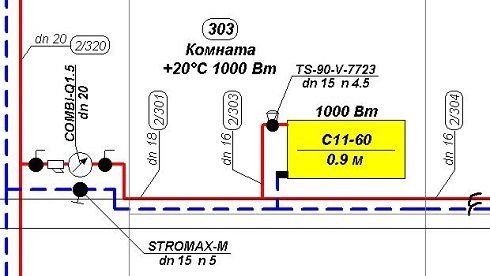

The purpose of the hydraulic calculation is to determine the economical pipe diameters while providing the calculated water flow and the required pressure for all consumers in the building.

Hydraulic calculation is performed in the following order:

1) On the axonometric diagram of the internal water supply, the calculated branch is selected from the most remote and highly located water folding device (dictating point) to the point where the water supply enters the building. Nodal points where the change in the estimated water flow occurs are numbered (Figure 16). Thus, the calculated sections and their lengths are determined on the calculated branch of the axonometric diagram. Each section is numbered 1-2, 2-3, 3-4, etc.

2) Determine the number of devices N in each section.

3) Determine the second water flow rate of the water fittings (device), referred to one device q0.

In the formulas when calculating the water supply for a separate device (in section 1-2), the second flow of cold water is taken according to Appendix 2:

q0 = q0c, (2)

where: q0c is the consumption of cold water by a sanitary appliance.

For various devices serving the same consumers (for all other sections), water consumption rates are taken according to Appendix 3:

- in residential buildings equipped with water heaters

q0 = q0tot , (3)

where q0tot is the total water consumption (cold and hot) by the device.

- in residential buildings with centralized hot water supply

q0 = q0c. (4)

4) Determine the number of residents U using N devices in each area.

You can accept the number of residents in a one-room apartment - 2 people, a two-room apartment - 3 people, a three-room apartment - 4 people.

5) Determine the probability of action of sanitary appliances in the network sections according to the formula:

, (5)

where U is the number of residents using N appliances;

N is the number of devices served by the calculated network section;

q0 - water consumption by a sanitary appliance, l / s;

qhr,us - the rate of consumption of cold water by the consumer at the hour of the highest water consumption (accepted according to Appendix 3), l:

- in residential buildings equipped with water heaters

qhr,uс = qhr,utot; (6)

- in residential buildings with centralized hot water supply

qhr,uc = qhr,utot – qhr,uh, (7)

where qhr,utot is the general rate of water consumption by the consumer at the hour of the highest water consumption, l;

qhr,uh - consumption rate of hot water by the consumer at the hour of the highest water consumption, l;

6) Determine the value of NP.

7) Determine the coefficient a, depending on NP (according to Appendix 4).

8) Calculate the estimated water costs in the areas

q = 5 q0a. (eight)

9) Determine the length of the calculated sections L according to the axonometric projection.

10) According to the calculated estimated costs in the sections and economically advantageous speeds, the diameters of the pipes d of the network sections are determined according to Appendix 5.

Calculation of hydraulic resistance

To calculate the hydraulic resistance, you need to know the performance and head of the circulation pump

The method for calculating the first parameter has already been discussed above, so the main attention should be paid to the head. First you need to determine the hydraulic resistance, since the pressure of the unit is constantly faced with the need to overcome the resistance that occurs during the circulation of water

The more resistance the system has, the more pressure the pump used will require. Its value is determined in pascals (Pa) or meters of water. For example, a water column 10 m high creates a pressure of 100,000 Pa, which also corresponds to the 1st atmosphere.

First of all, the hydraulic resistance is determined in the most unfavorable part of the system. Only after that a pump is selected, the pressure of which should not be less than the result obtained. The total hydraulic resistance value includes the straight section resistances and all available local resistances. Local resistances include bends, tees, reduction transitions and other difficult places. When calculating, it is mandatory to take into account the maximum permissible speed of water movement in pipelines. This will prevent excessive noise during system operation.

Table with parameters having a constant value:

Location of pipeline sections

About complex liquid transfer systems

Each pumping station combines a suction device and a storage tank for water supply. The standard package includes a surface pump, which allows the use of a device for extracting fluid from wells with a small diameter.

The fundamental parameter is the power, which for household models ranges from 600-1500 watts.It is usually selected taking into account the number of water points, the distance from the device to the well and the flow rate of the well itself. As for the volume of the tank, it depends on how much water is consumed per day by all family members.

Pumping equipment is installed in a separate caisson