The main reason for the leakage of ceramic faucets

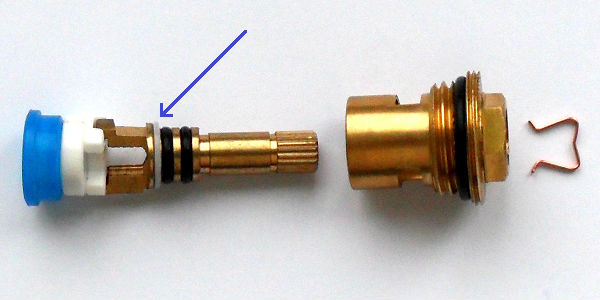

The most common cause of leakage of ceramic faucet-box water faucets and the need to repair them is the wear of a plastic pressure washer (marked with an arrow in the image), which can be made of polypropylene, caprolon or fluoroplastic.

Clamping washers made of polypropylene and caprolon, unlike fluoroplastic ones, are not sufficiently resistant to elevated temperatures, therefore, more often due to their wear, they fail and require repair of the valve box that regulates the supply of hot water to the mixer. The wear of the plastic washers of these products is also enhanced by the fact that, as a rule, the hot water tap is used more often.

When the pressure washer during the operation of the water faucet is significantly worn out or completely destroyed, a gap appears between the ceramic plates and the faucet box begins to pass water in the closed position.

The thickness of the new plastic washer from the photo is 1 mm, the inner diameter is 10 mm, the outer diameter is 12 mm. You can buy one if you can find one, or make one yourself, but there is a way that will greatly increase the life of a ceramic faucet until the next repair, which consists in making a pressure washer from a piece of copper wire.

Common Problems

The design of a single-lever mixer has only three typical problems.

| Malfunction | Cause |

| Sticky handle, high adjustment force | Lubrication washout (usually occurs after 5-8 years of operation) |

| Breakage of the rod (the handle is completely separated from the body) | Excessive force applied to the handle |

| Inability to turn off the water, leak when the handle is in the lower position | Chips of plates due to debris, breakage of plastic clips with excessive force on the lever |

Sticking of the handle can be eliminated by re-lubricating the friction plates. Special grease for the faucet cartridge and ceramic bushings is sold in branded plumbing stores; the price of a small tube is 400 - 600 rubles. A more affordable option is silicone lubricants used for domestic purposes: a 30-gram tube will cost only 120 - 140 rubles.

In all other cases, the repair instruction comes down to replacing the entire cartridge.

cartridge device

The device of a mixer with a cartridge is somewhat reminiscent of the operation of a ceramic crane box: in both cases, the water is blocked by the mutual displacement of ground-in ceramic plates with through holes.

There are, of course, differences:

- There are three holes in the bottom plate. Two correspond to cold and hot water; the third, of larger diameter, supplies water to the spout (gander) of the mixer.

- The upper plate can not only rotate relative to the lower one, thereby ensuring the predominance of cold and hot water in the mixture, but also move up and down, adjusting the pressure.

The device of the kitchen faucet with a cartridge assumes its easy replacement. Cartridges differ in diameter (28.35 and 46 mm) and length. In order not to make a mistake when buying, the easiest way is to take a sample with you - a faulty part.

Faucet Mounting Problems and Solutions

Let's touch on a couple of problems associated with the installation of mixers of different types.

How to rigidly fix the onboard faucet on a thin sink?

- A plywood insert 15-18 mm thick is cut out on the back side of the sink. Width - the maximum that the shape of the sink allows

- The liner is impregnated with drying oil for 2-3 times. It is better to preheat it in a water bath for deeper penetration: the liner will have to come into contact with the inevitable summer condensate on cold water.

- The faucet is attracted through the plywood lining.

How to fix the faucet on drywall or wall panels?

In principle, for this purpose, there are water outlets - press-angles for a metal-plastic pipe, which allow you to clamp the sheet with wide nuts on both sides.

However, several less exotic solutions can be proposed.

- On the back side of the GKL sheet from profile to profile, glue a sheet of varnish-impregnated or waterproof plywood onto liquid nails or sealant. Thickness - the same 15-18 mm. Water sockets can be pulled to it through a tile laid on drywall with ordinary galvanized self-tapping screws.

- If a main wall is hidden under the GKL, water sockets are attached to it. The threads for the eccentrics are brought to the level of the finish coating by extension pipes - branch pipes of the appropriate length with male-female threads.

Teflon grease

Recently, when lubricating the plates, RAVAK Teflon paste is used - it cannot dissolve in water, but it is washed out sooner or later, which necessitates frequent lubrication.

Although so, but such a "filling" is wildly popular. It has a number of its advantages:

- large temperature range compared to other lubricants - withstands where others fail;

- it is enough to apply one drop, on the face - ergonomics;

- its property does not allow it to turn yellow over time, as is usually the case with pastes;

- it can also be used to lubricate door hinges and shower enclosures, shower stall gliders, door handles.

The above information should help you when choosing and using a paste.

It does not matter whether it is in the kitchen, or whether it will have another purpose - the main thing is its quality and longevity. Now you are more aware of the functions and overall appearance, and this knowledge will come in handy when choosing one or another paste.

Good luck in this business and let everything go smoothly and without problems.

Silicone Grease

This type of consumable for the mixer is necessary for the cartridge to fill the space between its plates - there is too little distance in the gap, and without it you could not even move the handle from its place, there is an effect of the force of intermolecular interaction.

Simply put, it softens the turn of the handle and gives you the freedom to turn it. As soon as you feel that it seems to stick when turning, it is a sign that it is time to change it, since it was washed out with water.

For a good cartridge, this will happen after 50 thousand times of turning the water on and off - in this case, you can buy a new one, or you can lubricate it. You need to fertilize with a silicone lubricant - it looks like a paste with a white tint, only half transparent.

But not everything is as good as we would like. Its price varies from 8 dollars, and it is problematic to find it. In search of her, visit stores that avid motorists will advise you and visit the car market - she is more often found there as a spray.

When applying our material to the top plate, hold the cartridge upside down for convenience, but note that in this position it will be the bottom plate - you do not need to fill it into the holes. Do not leave the job unfinished - the consistency has been applied, but now it needs to be evenly distributed, to do this, scroll the rod in the cartridge.

You can apply a little more if needed. If you were previously tormented by the following question - “Maybe you should still buy a new cartridge,” then here’s the answer: if sand or rust gets between the plates after applying the consistency, then go to the store to buy.

How to lubricate the mixer cartridge

The service life of a ceramic cartridge in a kitchen or bathroom faucet can be significantly extended. To do this, from time to time you should use a special lubricant that reduces friction and greatly facilitates the movement of the lever. How to lubricate the mixer cartridge to avoid frequent replacement procedures?

There are three main types of lubricant:

- Ciatim-221.

- Sanitary silicone grease.

- Teflon grease.

The first option is a universal composition that is used not only in plumbing work, but also for lubricating bearings, as well as any friction units. The plastic composition does not dissolve in water and works at temperatures from -60 to +150 degrees.

Silicone lubricants perfectly fill the space between the plates of the cartridge, which prolongs its life and allows you to easily turn the mixer lever. Over time, this lubricant is washed out, so it must be updated regularly.

As for Teflon lubricants, today they are the most popular due to their properties and affordable cost. For high-quality lubrication of cartridge discs, one drop is enough, which allows you to use one tube for a very long time. The lubricant does not dissolve in water, but is slowly washed out over time, so it must be reapplied.

If you are from Chelyabinsk, then on our website you can find qualified craftsmen who can not only change the cartridge in the faucet in the kitchen or bathroom, but also perform any work on heating and water supply at a professional level. A large selection of workers of various construction specialties registered on the portal will allow you to quickly find suitable craftsmen to perform specialized work. To facilitate the search for specialists, the site menu is divided into relevant sections, where there are ads from private craftsmen and work teams. Online ratings of masters, a photo gallery of finished works and reviews from other customers will also help in choosing the right specialist.

Stroy-Tekhnika.ru

Construction machines and equipment, reference book

TOCategory:

Operation, maintenance of cranes and equipment

In gear, worm, chain and other gears, in bearings and wheels, friction occurs during operation of the machine, which, in addition to the main load (lifting the load, boom, rotation of the turntable), creates harmful resistance to the drive. The higher the resistance from friction, the more power is required to perform the same useful work. In addition, the higher the resistance, the greater the wear of rubbing parts.

Harmful resistance can be reduced if the rubbing parts are lubricated with oil or grease. Oil, grease, graphite and other similar substances have the ability to firmly cover the rubbing parts with a film. The force of friction between these films is much less than the force of friction between the dry surfaces of rubbing parts. Films are not destroyed even if two rubbing parts act on each other with great force. Thus, the purpose of the lubricant is to reduce the friction force in the gears of mechanisms, with a decrease in which the energy consumption decreases, i.e., the efficiency of the machine increases, and the wear of rubbing parts decreases. The lubricant also prevents rusting of the metal, therefore, when preserving the machine or storing parts, they are abundantly lubricated.

Two types of lubricants are used for crane mechanisms: the so-called greases (greases, graphite ointment) and liquid ones (nigrols, industrial lubricating oils).

All lubricating oils used in industry are obtained from petroleum by distillation. Oils are classified into groups depending on their field of application, and within each group - by grades and brands, making up the so-called range of oils.

Greases are oils thickened with calcium or sodium fatty acids. The fat content in greases ranges from 10-20%, the rest of the lubricant content is machine or spindle oils.

Depending on the specific pressure between the rubbing surfaces, their temperature, rotational speed, as well as the lubrication system, various conditions are created for the operation of lubricants.So, for example, liquid oils are easily squeezed out from the surfaces of moving parts at high pressure and high temperature, thick lubricants do not work well at high speeds. The grades of lubricants are assigned depending on the operating conditions of the rubbing surfaces.

Lubricant Ciatim-221

You can start with Ciatim-221. Behind this name lies a plastic composition approved by GOST standards and which can be used to lubricate both metal and rubber, not to mention their combinations; it is also excellent for friction points.

Ciatim-221 has a wide range of applications, it can be not only a choice for a faucet in the bathroom or in the kitchen, but also:

- for bearings in electric machines;

- in aircraft there are aggregate bearings - this consistency can also be applied here.

Plus, Ciatim-221 has some remarkable features that you need to know in case of use - you need to understand what you are dealing with, right? As a lubricant, it is insoluble in water. Resistant chemical composition - the lubricant is of good quality. At a pressure of 666Pa, it will continue to work, and the temperature is also not a hindrance to it - from -60 degrees Celsius to +150.

The only problem is demand. Ciatim-221 is very difficult to find on the market, unlike its "brother" - Ciatim-201. This is such a nasty downside.