Auger drilling

Well drilling by auger method is used mainly for sandy and gravel-sandy soils. It is produced by an installation that has a drill head, followed by augers that divert the soil. Auger drilling has a distinct advantage in penetration rate.

In addition, simultaneously with drilling, the walls of the well are pressed and laid, which hold the rock and prevent its collapse. Installed well walls can be both concrete and steel.

With auger drilling, there is no need to flush the well during drilling.

An auger is a drill pipe, the entire length of which is wrapped with steel tape. Drilling by the auger method is carried out by drilling mechanisms with a movable rotator. The augers are connected by thread or elements having a figured section.

The feed stroke when drilling with the auger method is from 1.9-15 m.

Hollow sealed augers are equipped with reversible locks with different bits. Due to the high-quality steel of tool joints, which have high wear resistance, drilling time is significantly reduced. At the same time, work productivity increases.

When auger drilling wells on soft and loose soils, the blades of the bit should be at an angle of 30-60o with respect to the bottom. On dense soils or gravel-pebble deposits, the blades of the bit should have an angle of 90o with respect to the bottom. Setting the angle when drilling depends on the hardness of the drilled soil.

The cutting elements of the drill are cooled by the destroyed soil. In this case, the destroyed rock rises along the spiral of the auger.

For screws up to 100 mm in size, the speed should not exceed 500 rpm.

When drilling wells using the auger method, augers with a central channel are considered the most effective. Air or water is supplied through it using a hydraulic pump, which reduces friction during drilling. Usually, auger drilling of wells is carried out to a depth of up to 50 m. In exceptional cases, drilling with an auger tool can be carried out to a depth of 100-120 m.

When drilling deep wells, auger drilling is usually combined with some other types.

In the production of auger drilling of wells, technology can be applied using casing pipes or plugging the walls of the well with concrete under pressure from the surface. With this type of drilling, the speed of ground passage per day can reach up to 30 meters.

In machines for auger drilling of wells, cast drill heads with cutting blades and a shank are used. The cutting edge of the blades usually needs to be hardfaced. In the case of drilling in particularly hard rocks, the drill head must be equipped with technical diamonds.

The depth of auger drilling of a well is carried out to the size of one rod, then the machine is turned off, the rod must be disconnected from the spindle, lifted up and extended with a new rod. After that drilling can be continued.

Features of augers for drilling water wells

The augers of the drilling rig are cooled by the destructible soil.

In this case, the soil rises along the spiral of the cutting tool:

- The volume of soil at an average speed of movement should be no more than 0.2-0.4 of the total. In this case, the number of rotations of the drill should be 150-200 rpm.

- For cutting elements that are up to 10 cm in size, the rotation speed cannot be more than 500 rpm.

- When drilling wells with augers, cutting elements that have a central channel are more effective. Air or water passes through it with the help of hydraulics, which reduces friction when drilling the soil.

Before auger drilling, a soil analysis should be performed

Before auger drilling, a soil analysis should be performed

Traditionally, drilling with augers is carried out to a depth of up to 50 m. As an exception, drilling with equipment can be carried out to a depth of 120 m.

Stages of work

The auger drilling method is used to form wells in a vertical or horizontal direction. In the latter case, the following stages of work are present:

- The equipment is being prepared and installed on a special stable platform.

- They dig a pit to remove loose and loose soils.

- With the help of laser measuring devices determine the direction of drilling.

- All necessary equipment and casing are being installed.

- The deepening of the drill occurs until it stops until the maximum depth is reached.

- The working tool is removed to the surface.

- A new section is connected to the drill, which allows you to reach the required depth.

Vertical drilling also occurs, but this method does not require the use of a casing pipe.

Related video: The first drilling of a well broke off an auger of 16 meters of clay

A selection of questions

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

Advantages of using auger

The process of drilling wells for water by using a cutting element eliminates the need for grinding and erasing the soil separated from the bottom. The slaughter is carried out in a continuous mode, in parallel is the destruction of the soil. When separating from the bottom of the earth, it is sent to the screw, which rotates at the highest speed. The centrifugal forces that accompany the process press the soil against the walls of the well, while the continuously moving belt pushes the earth up. Part of the soil remains on the walls of the well. These techniques provide the speed of work up to the 4th category of rocks according to the drill.

The advantages of a rotary drill are as follows:

- High penetration rate;

- Transportation of soil without lifting equipment;

- Continuous supply of soil to the surface;

- No rinsing required.

Auger drilling equipment is quite expensive

Auger drilling equipment is quite expensive

With all the advantages, the tool also has disadvantages. To create a well in the auger way, the insignificant depth of the drill is important

Also taken into account is the rotation of the massive auger string, which requires considerable effort. To increase the resource of the bit, it must be reinforced with hard alloy cutters

The chisel should have a section larger than the auger by 2 cm.

The most popular bits used for auger drilling are those that have 2-3 blades in the configuration. The 3-blade tool has a body made of a metal material by casting. When a well is being made, the rotation of the tool on the drilling equipment is carried out using special machines.

Attention! Without knowledge of the rules, it will not be possible to perform drilling work where an auger tool is used

The first condition before starting the equipment is soil analysis on the site, the second is how far the water goes. Thus, work with the help of the LBU-50 machine tool is performed by a special rotator, which eliminates the use of rotary and spindle elements. This will be required to ensure a large rotation and create axial translational movement of the screw.

If the well needs to be made as quickly as possible, then powerful machines must be used that can guarantee the highest productivity. To do this, they are installed on the chassis of the car. Drilling can be carried out with SO-2 machines.In such a situation, a modern excavator is used in tandem with the equipment.

Drilling wells is not an easy task, but if you have the necessary tools at hand and follow the technology, then you can drill a well yourself.

Technology Description

This technology is used only for wells with low debit.

When auger drilling, safety regulations must be observed

When auger drilling, safety regulations must be observed

Standard auger drilling of a well under water is carried out in the ground:

- frozen;

- Loose;

- Soft.

With the help of an auger-screw, the earth selected during the storm is removed from the face. The auger is a drill pipe, the entire length of which is sealed with a steel tape. The work of the auger is performed by drilling mechanisms that have a movable rotator. The auger is connected by a thread or elements that have a special section. The feed stroke with auger is from 1.9-15 m. Hollow sealed auger elements have special locking mechanisms. Due to the high-grade steel of the lock, which has high wear resistance, the drilling time is significantly reduced. At the same time, productivity, on the contrary, grows.

Advantages and disadvantages of the method

The technology of auger drilling of wells has many advantages:

- high drilling speed is ensured without additional grinding of the waste rock;

- cleaning of the recess in the ground is carried out continuously;

- provides drilling depth from 1.5 to 70 m;

- simplicity of technology;

- no need to attract high-tech machinery and equipment;

- no need to supply drilling fluid, which simplifies the work process;

- if necessary, the well can be placed at a slight angle;

- a wide range of applications in various industries - for drilling drinking wells, for the formation of pile foundations;

- the possibility of carrying out geological exploration of the territory.

Auger drilling is not without its drawbacks. This method cannot be used in clay soils or in the presence of soil with a high density. When a cutting tool hits a stone (even a small one), work can be stopped. Further movement becomes impossible. Also, when deepening the screw to a considerable depth, it is necessary to make a lot of effort.

Auger drilling technology

It is believed that auger drilling is the cheapest and easiest method of drilling wells. Indeed, auger drilling is characterized by a high penetration rate (up to 100-300 m per shift).

If it is quite simple to explain the principle of operation of auger drilling, we can recall an ice drill, which fishermen use in winter to make a hole. The ice drill is installed vertically and, due to rotation and pressure, crashes into the ice.

If we talk about technology, then when drilling a well, in theory, it is not much more difficult.

Where is auger drilling used?

Auger drilling is mainly used in drilling sandy and sandy-gravel soils, as well as medium-hard rocks for blast holes, engineering and hydrogeological surveys, geological surveys, mineral exploration, mapping, etc. popular for water well drilling.

The depth of the well is usually up to 50 meters, but depending on the soil, it can be up to 100-120 meters. Drilling diameter by auger, usually from 60 mm to 600-800 mm. In some cases, screws with a diameter of 1500 mm or more are used.

Auger technology

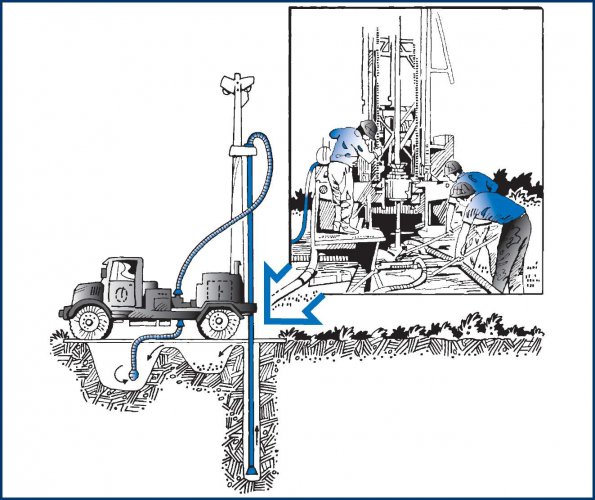

Auger drilling is one of the methods of rotary drilling and is carried out by an installation that has a drill head, followed by augers, with the help of which the destroyed rock (sludge) is transported to the surface.

The destruction of the rock occurs due to the rotation of the drill head, which is understood as a bladed bit or drill. The tool is varied and is selected based on the properties of the rock.

Left to right: Blade drill; Two-bladed chisel; Three-bladed chisel.

The drill head and auger can be separate or one piece, the latter is called an auger.

Then the sludge is transported along the spiral (flange) of the screw to the surface.

Auger drilling

Moreover, the auger is selected based on the fact that the interturn space should be occupied by the transported rock by 0.2-0.4 volume.

This must be taken into account because in this case normal cooling of the auger occurs due to rapid deepening and a constant flow of rock of different temperatures. Heating occurs due to rapid rotation and friction against the walls of the well.

The auger flange serves only for transporting destroyed soil, which means that the destructive tool (chisel or drill) must be of a larger diameter.

pros

- Continuous process of lifting soil to the surface;

- The auger string does not require lifting while drilling;

- High deepening speed (Up to 100-300 meters per shift).

Minuses

- A large and heavy screw string needs to rotate quickly, so the drilling rig needs to be powerful;

- Relatively shallow drilling depth, usually up to 50 meters;

- If you hit a boulder, further penetration can be a problem, most likely you will have to drill nearby;

- Drilling in rocks of high hardness is not possible;

- In sticky and viscous soils, sticking is possible.

Drilling technology

For drilling wells by auger, the working tool with blades constantly rotates. This ensures uninterrupted supply of waste rock to the surface, which is very convenient. The augers, which carry out all the operations foreseen by the technology, consist of a central pipe, which is also called a drill rod. A steel strip is placed along its entire length at a certain angle along its surface. It is she who transports the destruction of the soil to the surface.

The design of the auger has a sharp tip that cuts into the ground. Most often it is made removable. This allows you to change the tip, depending on the type of cultivated soil. In auger drilling, the following types of tips are most often used:

- chisel equipped with three blades;

- paddle drill;

- chisel with two blades.

During the drilling of wells for water, the formation and strengthening of its walls simultaneously occurs. For this, concrete or metal can be used. It should also be remembered that this method is rarely used for the production of deep wells. But if necessary, the penetration length can reach 50 m. Therefore, the drilling auger is equipped with additional sections.

Auger drilling rules

The process of drilling wells for water in the manner described above has many advantages, one of which is the speed of passage. At the same time, with the production of drilling, there is a punching and installation of the walls of the well, which helps in holding the soil, excluding its shedding. Arranged walls can be metal or concrete.

This method is used only for water wells that have a small debit. Thanks to the screw, soil is taken from the face. The device is a special pipe, which is completely wrapped in a metal tape. The process involves the use of drilling units, which are arranged with a movable rotator. The cutters are in contact with threads or parts that have a figured section. The feed step has a limit of up to 15 m.

Auger drilling requires a minimum of 2 people

Auger drilling requires a minimum of 2 people

Screws:

- Included in the design of the cavity;

- Have reverse locks;

- Equipped with different chisels.

The steel surface is resistant to wear, which makes it possible to reduce the period of work by several times. If the drill is carried out on a site with soft and loose soils, then the blades of the bit should be arranged at an angle of approximately 30-60 ° to the bottom.If drilling by this method is necessary on dense soil or in soil with the inclusion of gravel and pebbles, then the blades of the bit should be located at right angles to the bottom. The angle is determined depending on the hardness of the soil with which the work is being carried out.

When a well is arranged, the cutting elements of the equipment release a high temperature regime due to the destroyed soil. The waste land goes up the screw. The volume of mining while maintaining the average speed of movement is approximately 0.2-0.4 of the volume of space. The technique provides for maintaining the frequency of torsion of the drill 150-200 rpm. If an auger is used in the work, which has dimensions up to 10 cm, then the torsion frequency should not exceed 500 rpm.

When constructing a well using this technology, the most effective are screw screws that come with a channel in the center. It is he who transmits air masses or water by means of a hydraulic pump, which makes it possible to make friction during the performance of work as low as possible.