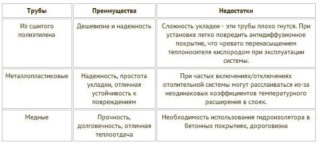

Types of metal-plastic pipes for water supply

All metal-plastic tubes are conditionally divided into two types according to the type of product composition:

- elements marked PEX (cross-linked polyethylene);

- PE-RT pipes (heat-resistant polymer).

In turn, all PEX products with crosslinked molecular chains are additionally classified as follows:

- PEX-A. They have a maximum firmware step of 85%. Extremely strong and elastic.

- PEX-B. The degree of firmware 65%. The layers are processed using silane. Pipes are less elastic, which means that there are restrictions on the allowable bend.

- PEX-C. The main advantage of such a tube is the favorable cost. PEX-C products are ideal for straight runs without the need for material bending.

There are PEX-D tubes. Their production has been reduced because the products cannot compete with more advanced models.

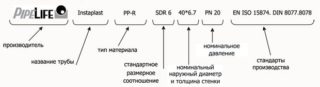

All tubes, without exception, are marked with a special marking. It is written in this order:

- manufacturer;

- certificate or GOST according to which the products are manufactured;

- type of material and stitching method (PP-R, PE-R, PE-X);

- the diameter of the product plus the thickness of its wall (the cross section is indicated in mm, in rare cases in inches);

- nominal pressure in bar;

- type of transported medium (water pipes are not suitable for sending aggressive compounds through them);

- batch number and date of manufacture of the product.

All markings are applied to the tube in continuous type.

Mounting and connection

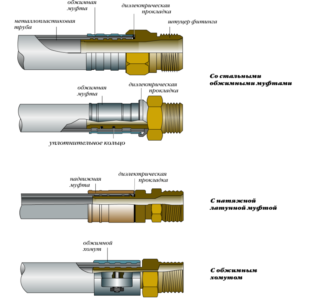

When installing a heating / water supply system, the master can join the pipes in two ways:

- using press fittings;

- using a screw compression fitting.

Work with the use of the press is performed as follows:

- cut off the desired piece of tuba with special scissors;

- using a calibrator, an internal chamfer is cut off from the prepared element (one of its ends);

- the same is done on the outside of the pipe;

- the calibrator aligns possible crumpled places in the lumen of the product;

- drive the shank of the press fitting to the stop;

- insert the sleeve into the press and reduce its handles to the stop.

This method of connecting metal-polymer tubes is considered the most reliable.

If the master uses a screw compression fitting, the joining of the two elements takes place in the following sequence:

cut off the desired section of the product;

remove the inner and outer chamfers;

a crimp ring and a tightening nut are mounted on the prepared end;

the end of the second pipe is driven into the joining element;

tighten the compression ring and the tightening nut to the fitting until it stops so that it covers the ring; here it is important not to make critical efforts so as not to break the thread; the connection can be sealed with fum-tape.

Do-it-yourself installation of metal-plastic pipes

Installation of metal-plastic pipes can be done by hand. There is no fundamental difference from the installation of plastic. Installation of systems made of PE-X or polypropylene does not require expensive tools or equipment.

Necessary tools and materials

For cutting and stripping pipes, you will need a special pipe cutter or grinder, a round file.

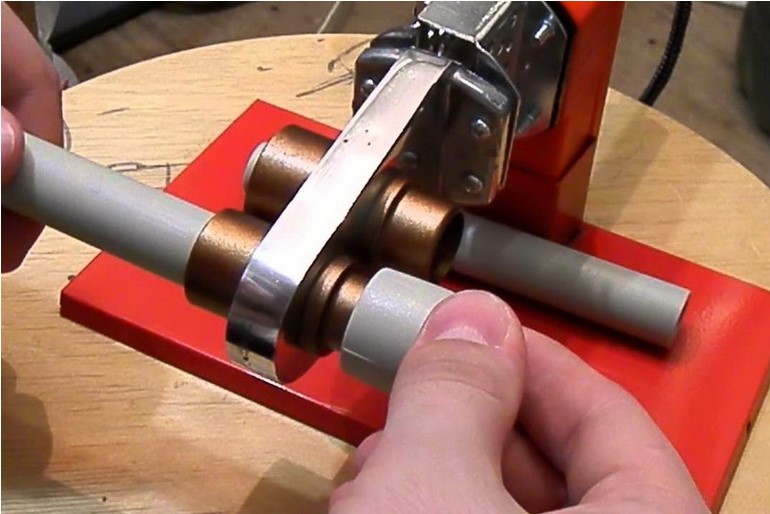

To weld polypropylene, you will need a special soldering iron with nozzles (see photo):

For mounting the system using fittings - two adjustable wrenches and press tongs (manual mechanical press).

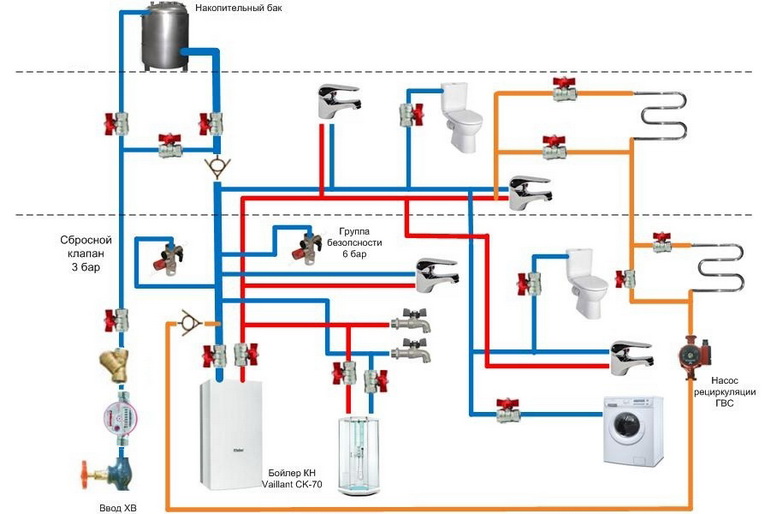

Drawings and diagrams

Any work must begin with a drawing or diagram. First, draw the layout of the plumbing system, calculate the amount of all materials, and only then buy them. This will help not to buy too much and lay the wiring in the most optimal way.

Mounting technology

Before installation, it is necessary to cut the workpieces of the desired size, clean the burrs.

Compression fittings are connected to the workpiece very simply:

- the unscrewed crimp nut is put on the workpiece;

- the workpiece is inserted into the fitting;

- the nut is tightened by hand; then tighten with wrenches about a turn and a quarter.

Press fittings are mounted as follows:

- put a sleeve on the end of the workpiece, insert the inner liner into the workpiece until it stops;

- insert the fitting with the workpiece into the press tongs and squeeze the press handles to the stop. There will be clear imprints from the press clamps on the sleeve.

Work progress

Before diffusion welding, carefully wipe the end of the workpiece from dust, dirt, sand, burrs and degrease with alcohol.

The desired nozzle is installed on the welding machine, the heating temperature is set to 260 ° C. The soldering iron is heated for about 6-8 minutes, then it maintains the desired temperature by itself.

The desired fitting and the end of the workpiece are inserted into the nozzles, heated for 6 seconds for a pipe diameter of 20 mm, for a diameter of 25 mm - 7 seconds, for a diameter of 32 mm - 8 seconds.

Very quickly insert the workpiece into the fitting until it stops, press it for at least 10 seconds. Then the connection is not touched for 7-8-10 minutes - the plastic is allowed to cool and polymerize.

You can see the progress of the work in detail on our video:

Mounting Features

If, after crimping with pressing tongs, there are no clear ring marks from the tongs on the sleeve, the connection should be cut and assembled using a new fitting and a new workpiece. A new fitting cannot be mounted on a damaged tube tip.

Bending of polyethylene blanks is carried out using a pipe bender or a Volnov machine. You can bend the workpiece by hand - but the bending radius is large.

Every 0.5-0.8 m, the pipeline must be fixed in special clip holders - this will help maintain its shape.

Plumbing check

After assembling the entire system, it is necessary to fill it with water from the network, release air and inspect all connections. You can wrap all the connecting nodes in toilet paper - droplets of moisture will be very clearly visible on it.

Specifications

- low level of thermal conductivity - 1300 times lower than that of copper, and 175 times less than steel;

- wall thickness of 2 mm or more, depending on the size of metal-plastic water pipes (section);

- good antistatic - no conduction of stray currents;

- weight of a running meter of a product with a diameter of 16 mm. - 115 gr.;

- throughput - 0.113 l / linear meter for a product with a cross section of 16 mm;

- strength at transverse rupture - 2880 n;

- roughness coefficient of the inner walls - 0.07;

- the expansion index of metal-plastic is 0.26x10-4 per ºs;

- the minimum allowable bending of the product is from 45 mm.

Installation of metal-plastic pipes

Step by step instructions with photo

- Prepare pipes and tools - cut metal-plastic according to the plumbing scheme, select fittings. Compression or press fittings are ideal for connection. Mounting tool:

- hacksaw or special pipe scissors;

- slicer calibrator;

- measuring tape or tape measure;

- knife;

- wrench.

- Process pipe sections with a calibrator.

- Remove the nut and ring from the fitting, put it on the machined pipe section. After processing, the cut should be even, smooth, without burrs. To do this, use a round file.

- Put a fitting on the pipe and align it with the fitting on the fitting.

- Install the previously removed nut and clamping ring on the fitting, tighten until a specific crackle is heard. Control the tension of the nut - too much load can strip the threads and then a complete replacement of the connection will be required.

Springs and other pipe bending methods

Often the pipes are bent to take advantage of the surface that conducts heat.

Here are a few methods: Manual bending.

- Pipe bending.

- Spring for bending.

Bending pipes by hand is the most affordable way, which involves the following steps:

Gently bend the pipe to a bending radius of no more than 20 degrees.

- Bend it a little higher again.

- Make such bends several times (about 15) until the pipe turns to the desired angle.

With the same smooth and accurate movements, you can straighten the pipe.

Maria Korol, expert

With the help of a spring or wire, the metal-plastic pipe is quite evenly and accurately bent:

Place the spring or wire inside the pipe.

- Bend the pipe with your hands to the required angle.

- Carefully remove the spring or wire.

Typical errors in the installation of metal-plastic pipes

The consequence of incorrect actions during installation is depressurization or leakage at the joints. The most common mistake is overtightening the fitting nut, resulting in stripped threads or ruptured pipe. Another common mistake is skimping on a specialized tool such as a beveler and calibrator. This often leads to damage to the sealing rings, which does not improve the quality of the connection. At the same time, it is possible to check the level of tightness and strength of the connection, to detect leaks and flaws by pressure testing.

Pressure testing of water supply pipes

The main part of the pressure tester is a hydraulic pump that sets the pressure required for a correct test. There are two types of pressurizers:

- Manual - used to check the water supply of a small length.

- An electric tool is easy to operate, reliable, durable, but expensive. Therefore, it is used only for professional installation.

The price of pipes made of metal-plastic

The cost of products varies depending on the manufacturer and diameter. Average prices for pipes for water pipes made of metal-plastic in Moscow:

| Manufacturer | The country | Price m/linear ($) |

| Valtec | Russia, Italy | from 1.5 |

| Oventrop | Germany | from 1.2 |

| Henko | Belgium | from 0.8 |

| Nanoplast | Russia | from 0.7 |

| Comap | France | from 1.6 |

Prices are given for pipes with a diameter of 16 mm. The larger the cross section of the product, the higher its cost per linear meter. In addition, prices may vary slightly depending on the region of sale.

Progress gradually simplifies our lives and makes our work easier. With the advent of all kinds of modern durable plastics, they began to be used for pipelines, the methods of installing plumbing systems in our housing have also changed - now we can easily do the installation ourselves without involving complex equipment and specialists. The era of steel pipelines is over.

We welcome our regular reader! In this article we will talk about what metal-plastic pipes for plumbing are - the best material for home plumbing systems.

Advantages and disadvantages

Important positive aspects of metal-polymer products are:

- ideal smoothness of the inner walls, which prevents silting of the system;

- durability - the service life of a metal-polymer multilayer pipe for hot water supply is about 50 years;

- inertness to corrosion and aggressive environments;

- good plasticity;

- light weight, which facilitates the transportation of products and their installation;

- simple installation of cold or hot water supply systems that do not require complex tools;

- soundproofing characteristics - the transportation of water through such systems is almost inaudible;

- aesthetics.

With their positive characteristics, pipes made of metal-plastic are not without disadvantages. The main disadvantage is the different expansion coefficients of the polymer and the metal layer at temperature differences. As a result, joints can loosen over time, leading to leaks.

Tubes are afraid of the sun, so they are used for laying internal communications in an apartment, bathhouse, country house. Sunlight provokes heating and further expansion of the tube.At the same time, cold water causes the polymer to shrink. Temperature fluctuations are undesirable for such a material.

Performance characteristics of pipes made of metal-plastic

Service life of plastic pipes

Metal-plastic is distinguished by increased resistance to corrosion, inertness to most active chemical and biological substances. Products of this type have a reduced expansion coefficient when heated, so they are less prone to deformation than other analogues. Manufacturers provide a guarantee for installed products:

- at a temperature of 95 C˚ - the warranty period is 25 years;

- at a temperature of 20 C˚ - the warranty period is 50 years.

The best manufacturers of metal-plastic pipes

Below are the best manufacturers of metal-plastic pipes:

- Henco (Henko), Belgian corporation. Their pipes are one of the multifunctional, modernized, highly reliable products available on the market today;

- Oventrop - manufacturer of plastic pipes Oventrop is one of the biggest innovators solving the old problems of heating and water supply;

- pex. Molecularly cross-linked polyethylene is suitable both for water supply systems (hot and cold), "warm floors", and for centralized heating;

- Rehau. Rehau products are of high quality and durable, which is the main advantage in choosing a material for plumbing and heating;

- Unipipe. Unipipe pipe structures are known for their attractive price and reliable performance, so the use of these products will be economical and safe.

- Valtec. Pipes manufactured by Valtec meet all kinds of requirements for the construction and installation of plumbing and heating systems, representing a high quality product.

What temperature and pressure can plastic pipes withstand

A pipe made of metal-plastic, in relation to other types of materials, has a number of advantages:

- Withstands high temperature loads up to 95 C˚.

- Working pressure from 10 atm.

- Oxygen diffusion 0 g/m³ per day.

Regulations and certificates

In our country, the market is filled with goods from various manufacturers of metal-plastic pipes. Most firms guarantee quality, but each company puts forward a condition for consumers: to comply with factory instructions.

In Russia, there are documents to control the quality of metal-plastic pipes:

- SP 41-102-98 - rules for the design and installation of metal-plastic pipelines for heating systems;

- SP 40-103-98 - rules for the design and installation of hot and cold water supply.

Pipeline marking

Numbers, letters and other designations on the surface of a metal-plastic pipe hide product data. Manufacturers have the right to make their designations in the marking, but the main data must carry the following information:

- manufacturer's name;

- certificate of conformity;

- grades of polyethylene (PP-R - polypropylene, PE-R - polyethylene, PE-X - cross-linked polyethylene);

- pipe diameter and necessarily wall thickness;

- nominal pressure at a content temperature of +20 degrees;

- then there are signs that make it clear whether this pipe is suitable for water that will be used for drinking;

- the last inscription on the pipe indicates the batch and date of production.

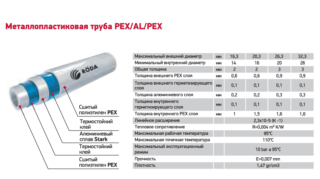

Technical characteristics of metal-plastic pipes

Firstly, pipes for water supply and heating made of metal-plastic are distinguished by excellent strength, which is achieved by the correct sequence of layers of plastic and metal. Secondly, such pipes withstand high pressure and temperature.

The following are specific specifications for pipes of various diameters.

| Name of indicator/Diameter (mm) | 16 | 20 | 26 |

| Inner layer material | PEX-B | ||

| Outer layer material | PEX-B | ||

| Internal diameter, (mm) | 16 | 20 | 26 |

| Aluminum layer thickness (mm) | 0,23 | 0,23 | 0,23 |

| Coil length (m) | 100 | 100 | 100 |

| Weight of 1 running meter of pipe (kg/m) | 0,115 | 0,14 | 0,25 |

| Temperature at 10 bar operating pressure | 0-95 | 0-95 | 0-95 |

| Temperature at 25 bar operating pressure | 0-25 | 0-25 | 0-25 |

| Maximum short-term load | 130 | 130 | 130 |

| Maximum pressure at t=20C, bar | 94 | 73 | 86 |

| Pipe deformation during heating to a temperature (120-3С) during (60 + 1),% | 0,81 | 0,81 | 0,81 |

| Roughness | 0,006 | 0,006 | 0,006 |

| The largest possible radius when bending manually, mm | 80 | 100 | 130 |

| The largest possible radius when bending with a pipe bender, mm | 45 | 60 | 95 |