Getting ready for installation

Before installing structures on suspensions, it is necessary to prepare the planes that are in contact with the structure: walls and ceiling. Work, as the instructions indicate, do not need independence.

Pretty good preparation for the base. It would be possible to manage even more with little blood

The surface of the ceiling must be cleaned of loose parts. Paintable joints must be cleaned, cracks with the detection of more than one centimeter must be plastered.

If the installation is carried out on a draft ceiling, then it must be primed, painted, joints must be sealed in it, finished and removed on the plane of significant flaws. In the ceiling space, all types of work must be completed, and the communication details are perfectly attached to protect the system from falling and resting on the frame of these parts. The walls are prepared like the ceiling.

Ease of installation

Zierer

In the manufacture of materials, the manufacturer processes both parts of the products, so they are even and smooth. This allows you to create beautiful and aesthetic facades without any additional effort. No special tools are required for installation.

Panels are a material that will even help hide serious wall defects, which is why they are so in demand. Moreover, the materials themselves are not affected by most natural factors. They are resistant to moisture, cold, mold, fungus and mechanical stress. The service life of products is calculated in decades.

VOX façade panels are a modern façade, impact-resistant, resistant to changes in weather conditions, and correct installation ensures proper façade ventilation.

, ,

1. ������� ����������� �������� ��������� � ����� ������, ������� ������������� ������� �� ���������� ������� ������ ����� ������.

2. ���������� �������� ��������� �����. ��� ��������� ������ ����� ����� �� ������������ �� ������ �����������, ������������ � ����������� ����� ������������� �������, ������ �� ��������� � ������ ���� ����� ���.

����� �����������3. ��� ����� ����������� ���������� ������������ ����������, ����� ���������� ������� ������ ��� ������� �� ������ � ������.

4. �������� ���������� ������ ����� ������� ���������� ������������� ����.

5. ������ �������� �� ����.

6. ������� �������� �������� ����. ��� ����� �� ���� ��������� ����������, ������ ������ �����, � � ������� ������ (���������� �����, ������������� �� �����) ��� ������������� ������ ��� ����� 90� �������� ������������ �����.

��������� ��������

7. ������� �������� ������������� �� ����������, � ������ �����. �������� ��� ������� �������� ������� ��� ������� ������.

�����! ��� ��� ��� ��������� ���������� ������������ � ����� ������, ������ ����� ������� ����� ������. �� ��������� ���������� ���������, � ���� ����� ��������� �� �����.

8. ���������� ������������ ������ ����� � ������� ������� ����� ����������.

9. ����� ���� �� �������� � �����, ���������� ��������� �������� ������� ����� �������, ����� ������������ ������� ����� �������.

10.

��� ��� ����� ������� �� ������ �������� �������, ���������� ������� ��������� ������� �� ����� � ���. � ���������� ������� ����� �������. ��� ��������� ������� ����� � ������� ������������ �������, ������ ��� ��������� � �����, � ����� ���� �������� �������� �����.

11. ����������� ���� �������� ����� ����� �� ������ ������� � �����.

12. ������� ������������ �����, � ����� ������� ����������� �������� ��� ������� �������� ���������� ����������� �������� ������� � ����� � ������ �������.������������� �����������13. ������� �������� ������� ������� ����� �������.

14. � ����� ���������� �� ��������� ������� ������� ����������� ���������. ��� ����� �� ����������� � ��������� ��������� � 1 ��, � �����, �������� �������, ����� ����� ����� ��� �������.

����� �� ����� ��������� ��� �������

15.

������ ���������� ������. ������ ��� ������� ��������� �������. ��� ���� � ������� ����������� ������ ������ �� ����� 2 �����.

16. ���������� �������� ������ ��������� ������. ��� �������� �� ������� � ��������� ��������� ����� ��������� �� �������� ������ ������� �����.

17. �� ��������� ��������� �������� ��������� ��� ��������� ������� ������� ������, ������ ��� �����������, � ����� �������������.

18. ��� ������� �� ����� ������������� ��������� ������� � ������� ���������� ��� ����������� �������.

One way to make a beautiful ceiling is to hang wallpaper. This material can have a different structure, color, pattern.

The glassware looks very nice. Pasting the ceiling with glass wallpaper decorates the interior, gives it expressiveness - you can see this by looking at the photo.

The material is almost impossible to set on fire, it belongs to

Choosing the best stretch ceilings

Choice by manufacturer

Now we will try to explain which manufacturer is better. The main suppliers of stretch ceilings are traditionally French and Asian manufacturers. And if the cost when choosing is of secondary importance, then it is undoubtedly better to prefer French stretch ceilings, which, according to experts, are of better quality. These are considered to be German stretch ceilings, and canvases of other European manufacturers, not so widely known in comparison with French ones (see Production of stretch ceilings, types of technologies).

As for Asian stretch ceilings, the cost is, of course, in the first place, but after installing such a system, you will certainly feel the plastic smell characteristic of Chinese films, which will most likely disappear over time. Outwardly, Chinese films are practically no different from European ones, so the best ceiling manufacturers are those whose canvases are able to satisfy your basic selection criteria.

The choice depending on the material and texture of stretch ceilings

Otherwise, it is difficult to find an unambiguous answer, since everything here comes down to materials and external characteristics, which gives rise, rather, to subjective opinions. But in order, again, to make it easier for you to understand which of them may be closer to you personally, we will describe their main types and give a brief description of each of the types of stretch ceilings.

Depending on the material from which the stretch fabric is made, the ceilings are of the following types:

- Film or PVC stretch ceilings. Such structures are mounted using high-strength PVC film by heating, followed by fastening under the ceiling to the baguette and tension during cooling. 90% of modern stretch ceiling structures are film due, as a rule, to a variety of colors and textures. What is better - glossy, matte or semi-gloss stretch ceiling? If you rely on dry statistics, then it is glossy, since it is it that is installed in more than 80% of cases when installing stretch ceilings - its semi-mirror texture in combination with competent lighting looks just great.

- Fabric. These ceilings are also called seamless, since there are no seams on such ceilings. They are usually made of polyester fiber and are mounted using a cold method. Fabric stretch ceilings are more durable than film ones, but their main disadvantage is the limited textures - they are only matte, but also in various colors (see Which fabric or PVC stretch ceilings are better: selection tips). Matte stretch ceilings are somewhat reminiscent of a plastered surface and are an excellent option for decorating strict classic interiors.

From all of the above, we can conclude that ideal stretch ceilings do not exist, since even experts often judge them based on subjective considerations. But judging by their general opinion, as well as guided by the results of statistics, the best and most popular stretch ceilings are film ceilings made in France with a glossy texture, multi-level configuration and competent lighting.

Advantages of stretch fabric ceilings

The main advantages of fabric stretch ceilings are:

- environmental cleanliness and safety for human life and health;

- high level of heat and sound insulation;

- aesthetics;

- the possibility of covering a large ceiling without seams;

- the ability to "breathe";

- lack of response to sudden changes in temperature without stretching and modification;

- the possibility of changing color during operation by means of staining;

- high strength, which makes the coating resistant to damage, sagging, cracks;

- no need to heat the room during installation, and, therefore, the removal of the most expensive furniture;

- the simplicity of the device, which in some cases allows you to carry out installation work yourself.

- resistance to high temperatures and fire safety;

- durability;

- the ability to hide all defects in the original ceiling and existing communications.

However, with all the significant advantages, the material also has some disadvantages.

Cons of fabrics

- due to pores, with prolonged direct contact of the canvas with water, leakage and color changes of the canvas may occur;

- the cost of such a coating is much higher than the PVC analogue;

- delicacy in service;

- a limited selection of models that cannot be glossy or mirror;

- the inability to re-mount the fabric web.

It is worth noting that for many consumers, it is the haze of the material and the high cost that are arguments for abandoning a reliable ceiling coating in favor of PVC.

Material for stretch ceilings

Stretch ceiling structures are currently gaining immense popularity due to ease of operation and the ability to create a wide variety of design options. Below we will consider which material for stretch ceilings is better and how to choose the perfect option for yourself.

Stretch ceilings - material composition

All existing types of stretch ceilings are conditionally divided into three categories according to materials.We will look at the pros and cons of each in the following list.

- Stretch ceilings made of natural materials are usually called fabric. The design of such structures is more restrained and traditional. As a rule, this option is chosen for children's and bedrooms. For kitchens or bathrooms, fabric stretch ceilings are not suitable, since the composition of the material does not tolerate increased moisture. Of the advantages, it is worth noting a higher resistance to scratches, sub-zero temperatures (you can safely use it for unheated rooms). Fabric material for stretch ceilings is approximately 5 m wide, so you can get a seamless coverage even in a spacious room.

- When deciding which material for stretch ceilings is better, many also start from the price category. In this regard, PVC structures are superior in demand to fabric counterparts due to their low price. In addition, you can choose matte or glossy coatings of any color and with any image.

- A little less often they use material for stretch ceilings made of fiberglass. The installation principle is slightly different and more like installing a suspended structure. But this option is chosen quite rarely due to the complexity of installation and about half the service life.

So, as a result, you have some idea about the choice of material for the stretch ceiling. If you want to experiment a little and create an original design, it is better to use PVC film. For large rooms and classic designs, fabric types are more suitable, since as a result you will get a seamless ceiling and the ability to choose a complex multi-level design.

Installing a self-leveling floor is not an easy task, but it is quite possible to cope with it yourself. Our article will help you correctly and efficiently fill the self-leveling floor.

The ceiling plinth plays the final role in interior design, beautifully outlining the contours of the room. How to glue the ceiling plinth correctly, we will show in the master class.

Ceiling decoration with polystyrene plates is becoming increasingly popular, however, the quality of such a coating primarily depends on the correct pasting. How to glue ceiling tiles, we will show in the master class.

To level the floor under parquet, laminate or linoleum flooring, chipboard is often used. What are the advantages of such flooring and what are its characteristics, the article will tell.

Stages of work with fiberglass

Scheme of fiberglass production.

So, what is the whole process of working with fiberglass? The following is a short example to give you an idea of the basic principles of working with fiberglass.

Matrix manufacturing. It is made from polyurethane foam or a sheet of foam plastic. A layer of cling film, foil, or an ordinary newspaper is applied to the finished matrix.

You can fix it on the form using a simple masking tape. Applying a thin layer of epoxy with a brush. The resin should not be completely poured out of the can, as it dries fairly quickly. It is best to use it in parts as the work progresses. Once the resin layer has been applied, you can safely apply fiberglass to it.

This simple procedure, resin-glass fiber-resin, should be repeated 2-3 times. The resulting structure must be thoroughly dried. We grind the surface. First, grinding can be carried out using coarse sandpaper, gradually changing it to a finer one.

In the end, the processing must be completed with “zero” sandpaper. Puttying. For a material such as fiberglass, there is a special putty, which can be purchased at any specialized store. Painting. Paint can also be purchased at any hardware store.

Experienced craftsmen claim that a well-made fiberglass part is stronger than steel.

fiberglass characteristics.

- Workwear set.Respirator.Protective gloves and goggles.Mounting foam or polystyrene.Foil, cling film and old newspapers.Epoxy resin.Fiberglass.Sandpaper.Brushes and masking tape.Scissors and knife.Putty.Paint.

Tip: before you start working with fiberglass, it must be degreased.

To do this, the fabric is impregnated with gasoline, solvent or alcohol. The substances used perfectly dissolve paraffin particles in fiberglass fibers. After this procedure, the fiberglass material must dry completely.

When buying fiberglass, consider its density. The higher the density of the fiber, the more difficult it will be for you to work with fine details. But the lower the density, the more difficult it will be for you to gain the required thickness of the product.

In principle, working with fiberglass is quite simple.

Most importantly, use personal protective equipment. After all, the fiber contains components that are quite harmful to the human body. Remember this, and then work will be given to you easily and without harm to health.

https://youtube.com/watch?v=ux8khRffYjYrel%3D0%26controls%3D0%26showinfo%3D0

- heatmonster.ru

- 1poteply.ru

- vsyaizolyatsiya.ru

Ceiling installation

So:

- It is possible to install a ceiling with fiberglass panels using any suspension system. Frames are suitable here, arranged according to the rule of suspended plasterboard ceilings, slatted, panel and various others.

The most important thing is that the surface is in a horizontal direction, and the frame cells are about 15-24 cm wide. It is better to specifically look at the photo or video of the fiberglass ceiling device in order to have an idea. - The structure must be strong. This can be achieved by the strength of the foundation and the high-quality installation of the system. The truth is capital, it can not be read.

- Work begins with the installation of load-bearing profiles. They are attached along the perimeter of the room to the surface of the walls and ceiling.

Depending on the area of the ceiling, the frame is fastened with one or 2 levels of fasteners, which improves the strength of the installation of the profile system. When drawing the starting line for the main guides, use a water or laser level.

You can use an ordinary repair one, at least one meter long, but then measure it seven times.

Next, proceed to the installation of fiberglass panels. Fiberglass is mounted on the ceiling surface in the profile cells and the material is fixed to the base with screws.

The situation is the same as with Drywall Sheets, but it is necessary to heat the screw heads more carefully. It is best to drill the hole further for this purpose.

Installation according to the design of "Armstrong"

Fiberglass ceiling hinged systems are used in buildings of public importance, in honey. institutions, swimming pools and residential areas.

The material is completely not dangerous from the point of view of ecology, and therefore it can also be used to decorate rooms for children. The cost for it is relatively low, and therefore this type of finish is widely readily available at home.

Advice! It is easy to make curved parts, integrated lighting, relief, edges and moldings from fiberglass panels. This version of the ceiling is suitable for specifics in rooms where silence and comfort are needed: in recording studios, cinema centers and sports centers.

No need to be afraid to use today's materials, the comfort of your home and the health of residents will not suffer from this!

Fiberglass and its history

First of all, I would like to draw the attention of readers to information about why fiberglass is needed. Many consumers mistakenly believe that this decorative material is used exclusively for finishing work inside buildings.

In fact, the scope of fiberglass is much wider.

A fiberglass web is a set of glass threads combined together and impregnated with a modified form of starch. Most often, this material is used to strengthen the corners and surfaces of walls, and in deciding which glue to glue fiberglass on, preference is most often given to compositions intended for vinyl wallpaper.

For the first time, fiberglass appeared on the consumer market in the 30s of the 20th century.Initially, the Germans took up the production of this durable material. The first batch of fiberglass wallpapers made of colored glass was created in the German city of Steinach, at the Koch GmbH factory. Over the next few years, the use of fiberglass in the production of decorative materials for building finishes has gained great popularity. The demand for fiberglass was especially high.

Today it is known that fiberglass is a material with a non-woven base. It consists of glass fibers arranged randomly with respect to each other, and fastened to each other by means of paper and resins of organic origin.

The density of the material is determined in accordance with the number of glass fibers per 1 sq.m. Density indicators in a certain way affect the degree of breaking load, which, in turn, is a determining factor when choosing a place to use fiberglass.

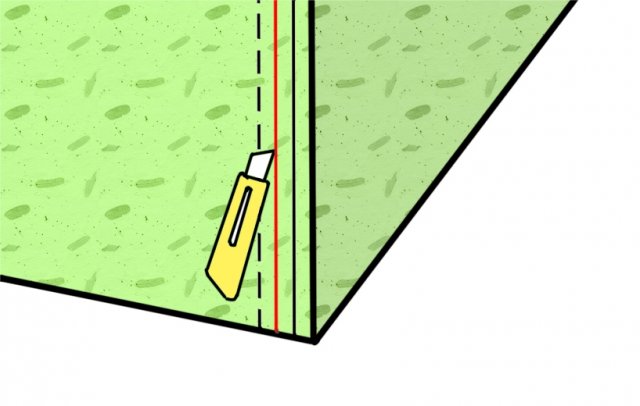

Sticking glass wallpaper

When the canvases are already cut, you need to apply glue to the wall (it is diluted in water at room temperature), while wallpapering should start from the door.

And then, taking into account the height, lean the wallpaper against the wall

It is important to ensure that the canvas is fixed as evenly as possible.

Cut off extra centimeters with a special clerical knife, which must be prepared in advance.

In order for the canvas to be even and not to form air bubbles, it must be smoothed with a plastic spatula.

Next, you need to continue gluing the glass wallpaper in the same way, only with each new segment, the problem of matching the pattern appears. Therefore, carefully monitor not only the evenness of the canvas to the floor, but also the coincidences.

The joints are the most difficult, because there should not be much pressure with a spatula so that the glue does not come out. Such manipulations are carried out with each new piece, until the very completion of the work.

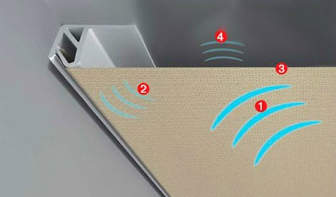

Perforation type

Do not think that all acoustic ceilings are the same.

One of the main differences is the method of perforation.

Due to different methods, a certain effect is achieved.

On sale are:

- Cloth with microperforation. The holes in them are not more than 0.1 millimeters, and they are placed at intervals of 2 mm. They are the most common ones. The thickness of the coating is approximately 0.17 millimeters - it is quite enough to prevent the formation of echoes in the room and improve its acoustic properties.

- Irregular perforation is used less often. The holes are diamond-shaped: nine millimeters wide and ten millimeters long. The thickness of the film is similar to the previous type of coating, but the number of holes is less - only fifteen thousand. Due to this, the canvas is denser and transmits less sound. But its acoustic properties are reduced - it can be a little phony in the room.

- The golden mean is ceilings with a reduced amount of perforation. Holes are applied in a square with a step of eight millimeters. The final density is about 25,000 holes. The coating keeps the sound well, not letting it in or out.

You should choose this option depending on your needs. We recommend that you consult with builders who will suggest the best option in terms of technological characteristics.

Technical qualities and physical and mechanical characteristics

Fiberglass compares favorably with other structural materials, combining high strength characteristics with a low specific gravity, for which they are often called "light metals".

By varying the spatial orientation of the reinforcing glass fibers and the composition of the binder resins, it is possible to regulate the technical characteristics and physical and mechanical properties of fiberglass in the right direction.

The table shows the average strength indicators for SPM on various binder resins.

| Name of indicator | unit of measurement | The value of the indicator for fiberglass based on various resins | ||

| polyester | Epoxy | Phenol-formaldehyde | ||

| Density | g/cm³ | 1,4-1,75 | 1,6-1,9 | 1,5-1,8 |

| Tensile Density | MPa | 140-450 | 400-600 | 300-500 |

| Static bending strength | MPa | 150-500 | 400-800 | 200-600 |

| Compressive strength | MPa | 150-300 | 200-400 | 100-300 |

| Tensile modulus | GPa | 11-25 | 22-32 | 18-25 |

To compare the physical and mechanical characteristics of fiberglass with those of other materials, the table below shows comparative data for SPM, PVC, steel and aluminum.

| Physical and mechanical characteristics | fiberglass | PVC | Steel | Aluminum |

| Density, kg/m³ | 1600-2000 | 1400 | 7800 | 2700 |

| Breaking stress during compression (tensile), MPa | 410 | 41-48 | 410-480 | 80-430 |

| Breaking stress in bending, MPa | 690-1240 | 80-110 | 400 | 275 |

| Tensile modulus, GPa | 21-41 | 2,8 | 210 | 70 |

| Modulus of elasticity in bending, GPa | 27-41 | 2,8 | 210 | 70 |

| Coefficient of linear expansion, * 10-6 m / hail | 5-14 | 57-75 | 11-14 | 140-190 |

| Thermal conductivity coefficient, W/mK | 0,3-0,5 | 0,15-0,16 | 46 | 140-190 |

Advantages and disadvantages of glass wool insulation

Glass wool is an excellent insulation for a number of reasons, it:

- It is elastic, so it is advisable to use it for uneven surfaces, for example, pipes, ventilation shafts.

- Chemically inert.

- It does not shrink during heating and cooling, therefore it is suitable for the water supply system.

- According to reviews, roof insulation with mineral wool adds up to 5 ° C in living rooms and creates additional comfort by protecting against external noise.

- Not subject to mold and does not attract rodents.

- It is durable, does not cake, does not wear out for more than 50 years.

- Helps to maintain optimal temperature conditions at any time of the year without additional energy consumption.

Top Brands

When choosing fiberglass insulation, keep in mind that reputable brands like Izover, Knauf or a little less well-known - Tisma, Ursa, meet the technical requirements and gain the desired thickness within 24 hours. Chinese, on the other hand, practically do not solve the problems of improvement and soundproofing, moreover, they contain untested binders that can be potentially hazardous to health.

1. Knauf glass wool comes from Germany. It has increased elasticity and density up to 60 kg / m3, so it can be used for partitions, ventilated facades, pitched roofs, insulation of frame and wooden houses, for siding. It does not have a strong odor and is not very irritating to the skin.

The line includes rolls designed for insulating pipes, floors between joists, floor slabs. The price of Knauf light yellow glass wool plates is from 980 rubles. It should not be confused with basalt rolls from the same manufacturer - they are more expensive and have a brownish-gray tint.

2. French products Izover deserve special attention. Soft glass wool insulation is designed for those places where the bearing load on the structure is excluded. It can also be used in sandwiches as an internal insulating lining, as its density is only 16 kg/m3.

3. You can buy Izover fiberglass insulation from 620 rubles. It is safe, does not prick, does not cause irritation, due to the fact that its fibers are not so brittle and do not form dust. In addition, the range includes rolls with a protective coating in the form of foil.

How to insulate with your own hands

Installation is carried out in 4 stages:

- frame installation;

- sheet cutting;

- laying segments between stiffeners;

- fixing and sewing up the insulating gasket.

The main thing is to choose products in accordance with its purpose: softer ones should be taken for horizontal surfaces, pipes, and hard ones for pitched roofs and verticals. Thin material is suitable for interior decoration, wide - for outdoor protection, attic spaces.

Safety

Given the harm of glass wool, it is necessary to take precautions during work - be sure to wear a protective suit or overall with gloves and a respirator. If, nevertheless, the fragments get on the skin, you should try to remove them, wash them off without combing the affected areas, so as not to drive the fibers deeper

However, it has been noted that the better the product, the less harmful it is and the easier it is to install.

What is better fabric stretch ceiling or PVC

Considering that PVC stretch ceilings have been successfully used for quite a long time (in the post-Soviet space they first appeared in the mid-90s of the last century under the name French), it looks quite natural to compare the fabric look with them.

Similar features of "competitors"

Many characteristics, as well as installation requirements for the two types of ceiling are identical:

- can be installed on ceilings of any shape and size;

- do not require special preparation of the base;

- it is allowed to install a heat-insulating layer on the ceiling;

- both materials are fire resistant and fireproof;

- do not lose a presentable appearance throughout the entire period of operation;

- have soundproofing characteristics, although, in fairness, in fabric, they are higher;

- operational warranty period - at least 15 years;

- on both types of ceilings, an image or artistic painting can be applied, but it should be borne in mind that only photo printing is suitable for PVC, and painting with paints is also suitable for fabric ones.

Distinctive features of two types of stretch ceilings

The differences begin, first of all, with the price. Depending on the compared specimens, the difference can be from five to ten times.

Another fundamental difference is the installation technique. to install a PVC ceiling, heating the room with a heat gun is required, for fabric ones there is no need for it, since there is no need to stretch the material, and fastening is carried out using skirting boards equipped with a special clamping groove.

The absence of seams on the surface of the ceiling is also a plus of the fabric look, walking this aesthetic defect is not so noticeable on the PVC canvas

But what you should definitely pay attention to is protection against possible flooding.

If the installation of a stretch PVC ceiling is a kind of guarantee against such a nuisance, then for a fabric one, in a similar situation, not everything is so simple.

And although manufacturers guarantee that such ceilings, as well as from a film, can withstand up to 100 liters of water per square meter, this will be a real test for the appearance, as stains will remain on the surface. Simple cleaning will not work to get rid of them, so the ceiling will need to be painted or, in general, replaced.

There are some differences in the installation height: if the installation of a PVC film “eats” an average of 4 to 7 cm, then only 1.5 cm is often enough for fabric ceilings (although on average this figure is 3-4 cm).

Stretch or suspended ceilings

For those who have not yet determined for themselves which is better - a stretch ceiling or a suspended ceiling, let's try to make the task easier through a brief comparative analysis:

- Stretch ceilings are good, first of all, for their irresistible appearance and relatively quick installation, but installation can only be carried out with the involvement of third-party specialists due to the complexity of the technology (see Benefits of stretch ceilings: and again about the good).

- Suspended ceilings can be installed independently, and they have practically no restrictions on complexity. However, at the same time, they cannot boast, for example, of an ideal gloss that is inherent only in film stretch fabrics (see Aluminum suspended ceilings - types, scope, installation features).

- When determining which is better - a suspended or stretch ceiling, in each case, the characteristics of the room should be taken into account.So, for elite modern interiors, stretch ceilings are usually used, but, for example, they are not suitable for outdoor rooms and rooms without heating, because they become brittle at low temperatures, which cannot be said about suspension systems.

- It is advisable to use suspended ceilings in the decoration of large areas - offices and other institutions, besides, such systems look more strict.

Ceiling gluing technology

When figuring out how to glue glass wallpaper on the ceiling, you can understand that the process is practically no different from the same work with standard types of wallpaper. You will need exactly the same set of tools and the usual adhesive composition for heavy wallpaper coatings. For those who do not know how to glue the ceiling with glass wallpaper, below is a brief instruction.

- Prepare the plane by priming it.

- Cut cullets with a margin of about ten centimeters to fit the pattern.

- Lubricate the surface of the overlap with adhesive composition. It is better to spread a not too large area at a time, one that will fit two or three stripes.

- Attach the cut fragment to the area treated with glue and smooth with a rubber spatula or roller.

- Cut off the excess along the edges of the strip with a sharp knife.

- The next strip is glued end-to-end with the previous one, without overlaps. The drawing is customized.

- When the entire plane of the overlap is pasted over, staining can be done.

At the same time, the technique of gluing glass wallpaper onto the plane of a plasterboard ceiling mounted on a frame will not differ in any way from the usual sequence of actions.

�����! ��� �������� ������������� ���������� ���� ��������� � ��������� ������. ����� ������� ������� ����� �������� ����.

���������� ��� ������������ �������� ����������� ������ ���� �� �����������, ������� ������ �������, ������� ����� ���������� �������������� ���������. �� ������� �� ������, �������� ���������� ����������, ��� ������������� ������������, � ����� ��������������. ������ ���� ������� ����� ������� ������� ���������. ����� ������������ ���� ������ �������.

����� ���� ��������� �������, ����� ������ ��������.

��� ����� ������������ ������� ���� ����� ������ ������������ (�� ���������� ���� ����������� 50-70 � ������ ����). ��� ����������� �� ����������� ����� � ����� ��������� ������� ��������, � ���� ����� ��������� ������������ ��������.

�����! ��� ����������� �������� ���� ����� ������������ �� ������� ����, � ����������� ����� ��������� �������������.

Oscar: , ; 10 ; ;

Kleo Ultra: ; 5 , 500 35-50 . ;

Metylan ; ; , , .

�����! ��� ������������ �������� � �������� �� ��������� ����� ������������ ����������� � ��������� ���� ����������. ����� ������� ����� ������ � �� ����� �����.

Oscar 18-25 . . .