Varieties of sealing rings

Such rings can have a rectangular, round and x-shaped section and their characteristics must comply with certain standards, for example, rubber sealing rings of round section are produced in accordance with GOST 9833-73.

Depending on the purpose for which it is planned to use a set of sealing products, their physical characteristics vary. They can be rigid or elastic resistant to low and high temperatures, as well as to aggressive environments and various chemical compounds.

Materials used to make seals

The choice of a particular variety depends on what properties the working fluid has, which is in direct contact with the sealing ring. O-rings are:

- Rubber.

- Silicone.

- Rubber.

- Leather.

If the working fluid can adversely affect the material from which the sealing product is made, as, for example, can be the case with rubber seals and oil products, it is necessary to install a rubber seal that does not deteriorate from contact with oil.

In turn, the shape of the products is oval and rectangular, round and chevron, it all depends on what they are intended for. The main advantages of using sealing rings are ease of installation, high functionality and durability, which plays a big role for the same sewer.

In addition, such products do not lose their best qualities even after a large number of assemblies and disassemblies of the structure. In turn, products with a circular cross section have a special seat and the same silicone or rubber rings are installed very quickly.

Types and differences

Most often, rings are sold as a set. The so-called set of seals contains blanks with different sizes and properties. Each set focuses on certain tasks.

There are kits for sealing full-sized sewers, water pipes, replacing seals on fittings, servicing pumps, etc.

We suggest that you pay attention to the division of seals into several main groups.

The most important influence on the scope and cost of the sealant is its material. There are o-rings:

- Rubber.

- Silicone.

- Rubber.

Ordinary rubber blanks are universal. They are equally suitable for both sewerage and drinking water supply.

Silicone rings differ much more impressively in price. This is due to the scope of their application. Unlike rubber or rubber, silicone products are recommended for sealing in domestic water systems intended for humans. They do not affect the quality of drinking water, its level of hardness, etc. in any way.

Rubber samples are very cheap, but are not suitable for service in mechanical engineering, as they are subject to destruction upon contact with substances containing derivatives of petroleum products.

Seal form

The shape of the seal affects where it should be used, for what purposes and in what equipment.

Forms of sealing rings are more than enough. Each area has its own product range. There are rings

- round;

- square;

- cuffs;

- flat;

- special.

Round rings are seals for water pipes. Unlike cuffs or flat rings, these samples are universal, they can be easily mounted on pipes of any size, as long as the diameter is suitable.

Square rings mean exactly the type of section of the seal. Rectangular and square shapes are used on flanges, where the grooves cut under the seal just correspond to it.

The cuff is a seal of a new sample.Cuffs also belong to the class of sealing rings, only the cuff from the ring is very different in shape. It is a molded rubber nozzle of arbitrary shape.

The width of the cuff sometimes reaches several centimeters; an expansion is formed on its outer part, covering the edges of the pipes. That's why the cuff is called that.

Flat o-rings are rarely sold separately. Their task is to seal pipes at the production stage. We are talking, of course, about socket joints, where rubber or rubber rings are glued inside or outside the pipe right at the factory.

Varieties of sealing rings

Such rings can have a rectangular, round and x-shaped section and their characteristics must comply with certain standards, for example, rubber sealing rings of round section are produced in accordance with GOST 9833-73.

Depending on the purpose for which it is planned to use a set of sealing products, their physical characteristics vary. They can be rigid or elastic resistant to low and high temperatures, as well as to aggressive environments and various chemical compounds.

Materials used to make seals

The choice of a particular variety depends on what properties the working fluid has, which is in direct contact with the sealing ring. Sealing rings are

:

- Rubber.

- Silicone.

- Rubber.

- Leather.

If the working fluid can adversely affect the material from which the sealing product is made, as, for example, can be the case with rubber seals and oil products, it is necessary to install a rubber seal that does not deteriorate from contact with oil.

In turn, the shape of the products is oval and rectangular, round and chevron, it all depends on what they are intended for. The main advantages of using sealing rings are ease of installation, high functionality and durability, which plays a big role for the same sewer.

In addition, such products do not lose their best qualities even after a large number of assemblies and disassemblies of the structure. In turn, products with a circular cross section have a special seat and the same silicone or rubber rings are installed very quickly.

J-Section O-Rings

Website : http://hydraulicseal4u.ru

English

Russian

Featuring a unique J-section profile, this o-ring consists of a PTFE-filled seal and an O-ring in accordance with GB/T3452.1-2005. It is used as a dynamic seal for reciprocating rods in hydraulic or pneumatic cylinders, but can also be used as a static seal.

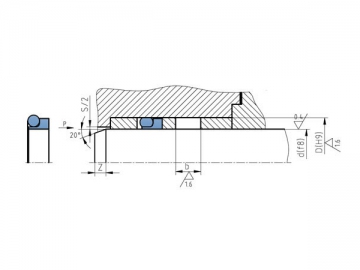

Sealing ring JK5-IA

Working conditions

Working pressure: 0~300MPa

Operating temperature: -55~250℃ (Depends on O-ring material)

Piston stroke speed: ≤6m/s

Working medium: air, ethylene glycol aqueous solutions, mineral oils, acids, alkalis, sludge, etc.

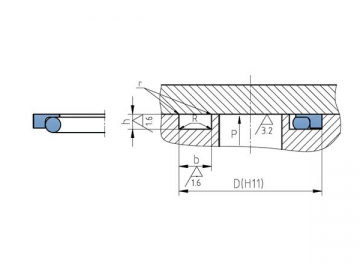

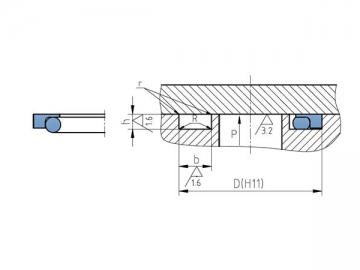

O-ring installation diagram

Parameters

| Rod diameter d(f8) |

Groove diameter D(H9) |

Groove width b 0.2 |

O-ring diameter d2 |

Radial Clearance S≤ |

Chamfer Z≥ |

| 6~17 | d5.4 | 6.0 | 2.65 | 0.2 | 3 |

| 18~39 | d6.8 | 7.0 | 3.55 | 0.2 | |

| 40~106 | d 10.2 | 10.0 | 5.30 | 0.3 | 5 |

| 107~670 | d 13.4 | 12.7 | 7.00 | 0.4 | 7 |

contact form

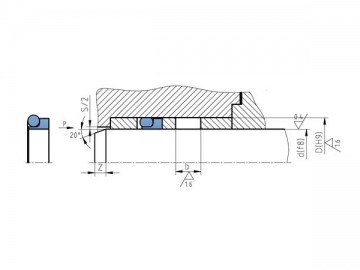

Sealing ring JK5-IB

Working conditions

Working pressure: 0~300MPa

Operating temperature: -55~250℃ (Depends on O-ring material)

Piston stroke speed: ≤6m/s

Working medium: air, ethylene glycol aqueous solutions, mineral oils, acids, alkalis, sludge, etc.

O-ring installation diagram

Parameters

| Rod diameter d(f8) |

Groove diameter D(H9) |

Groove width b 0.2 |

O-ring diameter d2 |

Radial Clearance S≤ |

Chamfer Z≥ |

| 22~39 | d6.7 | 7.0 | 3.5 | 0.2 | 3 |

| 40~154 | d 10.9 | 10.2 | 5.7 | 0.3 | 5 |

| 155~1000 | d 16.0 | 14.5 | 8.6 | 0.4 | 7 |

contact form

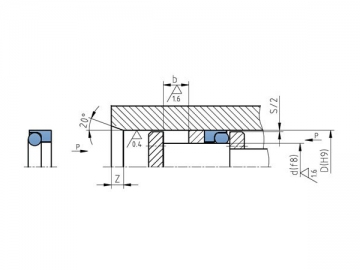

Sealing ring JK5-IIA

Working conditions

Working pressure: 0~300MPa

Operating temperature: -55~250℃ (Depends on O-ring material)

Piston stroke speed: ≤6m/s

Working medium: air, ethylene glycol aqueous solutions, mineral oils, acids, alkalis, sludge, etc.

O-ring installation diagram

Parameters

| Rod diameter D(H9) |

Groove diameter d(f8) |

Groove width b 0.2 |

O-ring diameter d2 |

Radial Clearance S≤ |

Chamfer Z≥ |

| 14~25 | D-5.6 | 5.8 | 2.65 | 0.2 | 2 |

| 26~49 | D-7.1 | 6.8 | 3.55 | 0.3 | 3 |

| 50~121 | D-10.8 | 9.6 | 5.30 | 0.4 | 5 |

| 122~900 | D-14.3 | 12.4 | 7.00 | 0.4~0.6 | 7 |

contact form

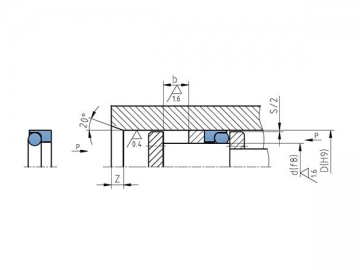

Sealing ring JK5-IIB

Working conditions

Working pressure: 0~300MPa

Operating temperature: -55~250℃ (Depends on O-ring material)

Piston stroke speed: ≤6m/s

Working medium: air, ethylene glycol aqueous solutions, mineral oils, acids, alkalis, sludge, etc.

O-ring installation diagram

Parameters

| Cylinder diameter D(H9) |

Groove diameter d(f8) |

Groove width b 0.2 |

O-ring diameter d2 |

Burtik R |

rounded edge r |

Radial Clearance S≤ |

Chamfer Z≥ |

| 14~26 | D-4.6 | 4.5 | 2.4 | 0.2~0.3 | 0.1~0.3 | 0.3 | 2 |

| 28~165 | D-6.0 | 5.6 | 3.1 | 0.3~0.4 | 0.4 | 3 | |

| 28~56 | D-6.8 | 6.2 | 3.5 | 0.3~0.4 | 0.3 | 3 | |

| 60~300 | D-10.8 | 9.8 | 5.7 | 0.4~0.6 | 0.4~0.6 | 5 | |

| 170~500 | D-16.0 | 13.6 | 8.6 | 0.4~0.6 | 0.4~0.6 | 7 |

contact form

Sealing ring JK5-IIIA

Working conditions

Working pressure: 0~300MPa

Operating temperature: -55~250℃ (Depends on O-ring material)

Piston stroke speed: ≤6m/s

Working medium: air, ethylene glycol aqueous solutions, mineral oils, acids, alkalis, sludge, etc.

O-ring installation diagram

Parameters

| Groove diameter D(H11) |

O-ring diameter d2 |

Groove width b 0.25 |

Groove depth h 0.1 |

Burtik R |

rounded edge r |

| 13~28 | 2.65 | 6.0 | 2.8 | 0.3~0.5 | 0.1~0.3 |

| 29~54 | 3.55 | 6.6 | 3.6 | 0.3~0.5 | |

| 55~128 | 5.30 | 9.1 | 5.3 | 0.4~0.6 | |

| 129~900 | 7.00 | 11.8 | 7.2 | 0.6~1.0 |

contact form

Sealing ring JK5-III B

Working conditions

Working pressure: 0~300MPa

Operating temperature: -55~250℃ (Depends on O-ring material)

Piston stroke speed: ≤6m/s

Working medium: air, ethylene glycol aqueous solutions, mineral oils, acids, alkalis, sludge, etc.

O-ring installation diagram

Parameters

| Groove diameter D(H11) |

O-ring diameter d2 |

Groove width b 0.25 |

Groove depth h 0.1 |

Burtik R |

rounded edge r |

| 30~60 | 3.5 | 6.6 | 3.5 | 0.3~0.5 | 0.1~0.3 |

| 61~305 | 5.7 | 9.5 | 5.7 | 0.4~0.6 | |

| 176~1000 | 8.6 | 13.7 | 8.5 | 0.6~1.0 |

contact form

Feedback

Characteristics and scopes of sealing collars

In those joints that use a movable structure of axes and rods, making translational or rotational movements, so-called cuffs are used. The cuff has inner and outer diameters, and special reinforcement is used to increase its strength.

Rubber cuffs can have various scopes and design features. On these grounds, they can be divided into the following groups:

- Reinforced cuffs, which comply with GOST 8752-79, can be used in cases where diesel fuel, mineral oil, and water act as a working medium. Non-reinforced cuffs that comply with GOST 6678-72 are used in pneumatic units, compressors and other devices. Non-reinforced cuffs corresponding to GOST 14896-84 can be used in hydraulic devices. Cuffs corresponding to TU 38-1051725-86 are used to seal progressively moving units. Sealing ring for nozzles

The use of rectangular sealing products

A set of square-shaped rings can be used to seal a static connection, or a movable, but with a small amplitude. In particular, this applies to the sealing of a flange connection, or the installation of shut-off valves.

A set of rubber rings with a rectangular cross section can be used when laying a pipeline for various purposes, since such products can provide optimal sealing.

The working fluid can be water, both hot and cold, acids and alkalis, various types of gases and steam. In the process of installing rectangular seals, compression from 0.1 to 0.2 mm is allowed, especially since the tightness of the joint can be achieved as a result of displacement of the seal by means of the pressure of the working medium.

Rectangular seals

A set of rectangular cross-section rings has special designations that allow you to determine the possibility of using each product in a particular situation. The first number in this case indicates the diameter of the rod, the second - the diameter of the cylinder and the third height of the ring itself. Each product of rectangular section must comply with GOST 15180-86.

Imported o-rings - main characteristics

Among the main characteristics of the O-Ring is its size, which is determined by the inner diameter d1 and the thickness of the ring d2. These values characterize imported O-rings, allowing you to make a choice for installation in a particular equipment. In addition, no less important for the specific application of O-Rings are the materials from which they are made. Imported o-rings are made of NBR oil and petrol resistant rubber, silicone rubber, fluororubber, chloroprene rubber, ethylene-propylene rubber and other materials. All this provides wide scope

O-rings. In the company's outlets, for sealing rods and cylinders, you can buy a sealing element GOST 22704 77 chevron cuff, and to protect your equipment from various contaminants - GOST 24811-81 wipers.

Sealing elements of this type are sufficient easy to install

to the place of their installation. Before installation, surfaces on which imported O-rings are to be installed must be thoroughly cleaned of various contaminants, such as dirt or processing residues. O-rings are not recommended to be worn on parts with sharp edges, on threaded connections, and so on. In order to avoid damage during installation in such places, cover dangerous areas with any protective materials. When installing an imported O-ring into the groove, it must not be twisted or stretched. During installation, short-term tension of the sealing element is allowed. After installation work, the O-Ring must be given time to return to its original state.

O-rings of this type must be changed during each scheduled repair of the device, because during the disassembly of components and mechanisms, these seals can get scratched, chipped, torn, and so on.

O-rings and cuffs are widely used to seal the connection of fixed and moving parts of the structure of various pneumatic and hydraulic devices.

These can be sanitary ware, or internal combustion engines, sewer parts, pumps and: the scope is quite wide.

Article content

Imported o-rings - main characteristics

Among the main characteristics of the O-Ring is its size, which is determined by the inner diameter d1 and the thickness of the ring d2. These values characterize imported O-rings, allowing you to make a choice for installation in a particular equipment. In addition, no less important for the specific application of O-Rings are the materials from which they are made. Imported o-rings are made of NBR oil and petrol resistant rubber, silicone rubber, fluororubber, chloroprene rubber, ethylene-propylene rubber and other materials. All this provides wide scope

O-Rings. In the company's outlets, for sealing rods and cylinders, you can buy a sealing element GOST 22704 77 chevron cuff, and to protect your equipment from various contaminants - GOST 24811-81 wipers.

Sealing elements of this type are sufficient easy to install

to the place of their installation.Before installation, surfaces on which imported O-rings are to be installed must be thoroughly cleaned of various contaminants, such as dirt or processing residues. O-rings are not recommended to be worn on parts with sharp edges, on threaded connections, and so on. In order to avoid damage during installation in such places, cover dangerous areas with any protective materials. When installing an imported O-ring into the groove, it must not be twisted or stretched. During installation, short-term tension of the sealing element is allowed. After installation work, the O-Ring must be given time to return to its original state.

O-rings of this type must be changed during each scheduled repair of the device, because during the disassembly of components and mechanisms, these seals can get scratched, chipped, torn, and so on.

O-rings and cuffs are widely used to seal the connection of fixed and moving parts of the structure of various pneumatic and hydraulic devices.

These can be sanitary ware, or internal combustion engines, sewer parts, pumps and: the scope is quite wide.

Article content

Classification and Applications of Rubber O-Rings

The set of rubber o-rings is used mainly in static connections, but in some cases it can also be dynamic connections, if there is an oscillatory, rotational or reciprocating movement. Depending on the type of rubber, seals are divided into:

- A set of rings corresponding to GOST 18829-73 can be used in fuel, hydraulic, pneumatic installations. in the food industry, and be in direct contact with products. MBS or oil and petrol resistant in units using gasoline and oil in their work;

The inner diameters of such rings vary from one millimeter to 2000 mm, and their cross sections can range from 0.5 millimeters to 20 mm. In order to be able to distinguish the size and characteristics of the ring, the corresponding designations are applied to it.

If we consider a set of rings for internal sewage, then the first three digits in the designation of each product show what the diameter of the rod should be, on which it will be put on, and the next three digits are the diameter of the cylinder into which the ring is inserted.

The seventh and eighth digits in the product marking indicate what its thickness is, the ninth is the accuracy class, and the tenth is the type of rubber. In some cases, slight deviations of the actual dimensions from those indicated in the marking are allowed.

Sealing ring at the junction of pipes

According to the operating conditions, rubber seals can be used at temperatures from -60º to +250º, specific parameters depend on the type of rubber used. With regard to pressure limitation, if the connection is static, the pressure should not exceed 500 atmospheres.

With a dynamic connection, especially if the rings are in contact with oil, water, fuel, or grease, the pressure should be no more than 350 atmospheres. If a set of rubber O-rings is used to seal dynamic connections in air installations, the pressure should not exceed one hundred atmospheres.

Varieties of sealing rings

Such rings can have a rectangular, round and x-shaped section and their characteristics must comply with certain standards, for example, rubber sealing rings of round section are produced in accordance with GOST 9833-73.

Depending on the purpose for which it is planned to use a set of sealing products, their physical characteristics vary. They can be rigid or elastic resistant to low and high temperatures, as well as to aggressive environments and various chemical compounds.

Materials used to make seals

The choice of a particular variety depends on what properties the working fluid has, which is in direct contact with the sealing ring. Sealing rings are

:

- Rubber.

- Silicone.

- Rubber.

- Leather.

If the working fluid can adversely affect the material from which the sealing product is made, as, for example, can be the case with rubber seals and oil products, it is necessary to install a rubber seal that does not deteriorate from contact with oil.

In turn, the shape of the products is oval and rectangular, round and chevron, it all depends on what they are intended for. The main advantages of using sealing rings are ease of installation, high functionality and durability, which plays a big role for the same sewer.

In addition, such products do not lose their best qualities even after a large number of assemblies and disassemblies of the structure. In turn, products with a circular cross section have a special seat and the same silicone or rubber rings are installed very quickly.

Hardness and wear resistance

O-rings are polyurethane, have such unique properties as elasticity, strength and excellent wear resistance. The use of such rings as sealing elements for many branches of modern industry is expedient and cost-effective.

The hardness of rubber is divided depending on the hardness index, which varies from 0 to 100 (Shore index, A):

from 30 to 50 - the hardness of soft rubbers.

from 50 to 75 - rubber of medium hardness.

from 76 to 86 - hard rubbers.

more than 88 - very hard rubber.

wear resistance is one of the defining characteristics of rubber used for o-rings. This parameter is one of the main ones for O-rings subjected to gas-abrasive and water-abrasive effects, as well as for rings of movable joints;

the sealing properties of rings of any section are affected by a decrease in the sealing properties of rubber. This occurs due to a decrease in internal stress over time (stress relaxation). This parameter is measured by the reduction in the initial value of the sealing properties and the maximum time for which they decrease by the specified number of times;

Since O-rings are subjected to compressive and tensile loads, the ability to restore their original properties after removal of compressive and tensile stresses is very important for them. Relaxation determines the recovery time of properties;

rubber rings must have rigidity (the indicator is determined by the ratio of impact force and permanent deformation) and the ability to dissipate mechanical energy after dynamic impact (load damping).

O-rings and cuffs are widely used to seal the connection of fixed and moving parts of the structure of various pneumatic and hydraulic devices.

Ring sealing

These can be sanitary ware, or internal combustion engines, sewer parts, pumps and gas pipelines: the scope is quite wide.

Materials used to make seals

The choice of a particular variety depends on what properties the working fluid has, which is in direct contact with the sealing ring. O-rings are:

- Rubber.Silicone.Rubber.Leather.

If the working fluid can adversely affect the material from which the sealing product is made, as, for example, can be the case with rubber seals and oil products, it is necessary to install a rubber seal that does not deteriorate from contact with oil.

In turn, the shape of the products is oval and rectangular, round and chevron, it all depends on what they are intended for. The main advantages of using sealing rings are ease of installation, high functionality and durability, which plays a big role for the same sewer.

In addition, such products do not lose their best qualities even after a large number of assemblies and disassemblies of the structure. In turn, products with a circular cross section have a special seat and the same silicone or rubber rings are installed very quickly.

Features and purpose

Any connection, whether it is a plumbing connection or pipes in an engine, needs high-quality sealing. Otherwise, there is a high risk of leakage.

Leaks are always a big problem. In some cases, they cause more harm than inconvenience. In others, the appearance of a leak can lead to catastrophic consequences.

Previously, leaks were eliminated in two ways:

- welding;

- coating the joint with sealants.

You are probably familiar with welding. The assembly of pipelines by welding is extremely popular. This method allows you to create a completely monolithic system from any number of particles. Welded pipes do not leak, are not afraid of pressure drops. Once connected, you can forget about their maintenance.

However, it was not without obvious disadvantages either. Welding metal, so to speak, we cut off our escape routes. Once welded pipes can no longer be disassembled. They cannot be modified, altered or repaired.

If such a need arises, you will have to literally cut out part of the pipe, and then repeat the whole process again.

The second way is external sealing. It is a little more convenient than welding due to the fact that the connection can still be disassembled in the end, however, the sealant layer is destroyed. That is, it was not possible to get away from the unnecessary repetition of the working stages.

Another thing is the use of sealing rings. Their appearance on the market created a real sensation. After all, the ring made the work of plumbers easier and faster, and also completely solved the problem of preparing the future pipe connection for sealing.

The sealing ring, no matter where we mount it, protects pipes well from leakage. By and large, having installed rubber or silicone rings once, you no longer have to remember them.

The process of disassembling the connection is also simplified to the point of impossibility. At the right time, the ring is easy enough to remove.

It is not damaged (with the exception of instances that have been in an aggressive environment for a long time, such as a sewer, but even in this case, the destruction coefficient is minimal), that is, it can be used again and again, as many times as necessary.

Applications

The scope of application of sealing rings is very wide. Do not be mistaken, give preference to sewerage or water supply systems alone. Mobile seals, which rings are, are also necessary in mechanical engineering, the aviation industry, etc.

Seals are indispensable when building tools that work on fluid transfer systems. The most obvious example is hydraulics.

Hydraulic power transmission systems are known to all. They are found in various tools, especially common in construction.

Here, hydraulic pumps are used for bending pipes, lifting weights, drilling, crimping, etc.

The hydraulic pump must also be sealed, but this is done in such a way that at any time a person has the opportunity to disassemble the pump, clean it, change the fluid, etc. The same is true in mechanical engineering.

However, an ordinary person practically does not encounter modifications to an internal combustion engine or a hydraulic pump. What can not be said about sewerage and water supply systems. But in them a set of sealing rings performs no less important functions.

They are glued inside on the socket joints. Thus, the principle of sewer fastening is simplified to the point of impossibility.

For sewerage, it is also recommended to buy a set of rings made of a material that is not susceptible to aggressive environments. At the same time, there is no need to overpay for seals that are harmless to humans, for example, silicone. Ordinary industrial rubber will also work.

With water supply systems, the situation is slightly different. Here, by themselves, sealing cuffs and rings are not so popular.

A plumber won't buy a set of rings separately, as most of them are already built into the finished fittings. In particular, almost all compression and compression fittings contain rubber or silicone seals.

In industrial pipelines, a set of seals is used when assembling flange connections. By and large, in flanges one cannot do without rings at all, because the usual tightening with bolts does not provide the desired quality of tightness.

To seal the flanges, a set of rings of a special size is bought. It is necessary to choose a seal that fits exactly under the groove or slot inside the flange. All dimensions of grooves and seals are easily determined through GOSTs.