Device for cleaning wastewater from barrels

The collector can be made from barrels. The principle of its operation is identical to the functioning of treatment facilities built of reinforced concrete rings. The filtration system may have several chambers.

Barrel selection

In order to build an autonomous sewer, you can use plastic or metal barrels. They don't have to be new. It is acceptable to purchase old containers, but they must be intact.

If we compare such barrels with those made of metal, plastic ones have the following advantages:

- You can choose containers of different volumes and sizes.

- Plastic products last longer. They are not afraid of the aggressive environment that sewers represent.

- Low weight for easy installation. All work can be done on your own, you do not have to hire special equipment.

Plastic barrels do not need to be treated with an anti-corrosion compound. Products are highly sealed, so you can not be afraid that the soil will be contaminated with sewage.

To prevent the plastic septic tank from being squeezed out in winter in frost or in spring during floods, the barrels are fixed to the concrete base with a cable. To prevent the plastic from cracking, you need to be careful when filling the collector with earth.

Materials and tools

To make a cleaning system, you need to purchase 2 plastic barrels of 220 liters each, geotextiles. You will need a sewer pipe and 4 sewer tees.

A pit is needed to dig a pit, and a rake is required to level the ground. In order to quickly cut products, you need a jigsaw.

Plastic barrels for a small septic tank in the country.

Features of the installation of plastic containers

Plastic barrels are placed on a concrete slab and then attached to it with cables. Holes for the ventilation riser and for the overflow pipe are made using a jigsaw.

You will need to make 2 more holes. The first is to connect the sewer. It is cut through, stepping back 20 cm from the upper boundary of the tank. The second hole is made on the opposite side, 10 cm below the inlet.

The ventilation riser is made only in the sump, in the second section it is not needed. The same tank must be equipped with a lid, this will allow you to quickly clean the bottom of the collector from accumulated waste.

In the second section, 2 holes are made, drainage pipes are connected to them. The joints must be filled with sealant, a two-component epoxy is best suited for this purpose.

Features of installing metal barrels

When installing metal barrels, the procedure is almost the same, only a welding machine is required to connect the barrels to each other. To make the product more durable, stiffeners are made. Without them, the tank can be deformed under the weight of the earth poured on top.

If the soil is heaving, barrels are anchored. To do this, they are attached with cables to a concrete base. Plastic pipes can be attached to a tank made of metal barrels. But all seams should be coated with sealant. Before filling the collector with earth, all metal parts are coated with bitumen. This will protect the tank from corrosion.

3 Urban sewerage systems

Difference in character

and concentration of contaminants of individual

types of wastewater require different

cleaning methods. In connection with

this creates a need

transportation of certain types

sewage on independent

pipelines. Depending on the

how certain species are assigned

wastewater - jointly or separately,

sewerage systems are divided into

common, separate

complete or separate incomplete and

semi-separate.

At common alloy

sewerage system all

waste water types

to wastewater treatment plants

through a common pipeline network.

|

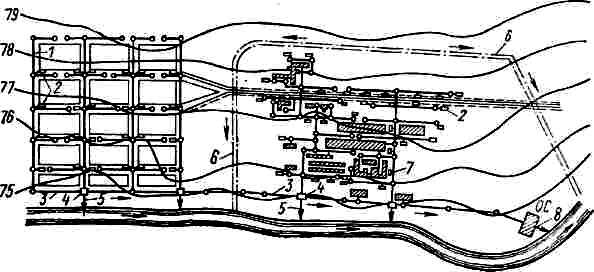

Rice. 4.2. Alloy sewerage system 1-street |

Since during the period

heavy rains sewage flow,

following on

treatment plant, very large and

same time concentration

their pollution is small, part of the mixture of waste

water is dumped

into the reservoir without cleaning through special

devices - downpours

4,

usually located on main

collector

3

near a reservoir.

Complete split system, wherein

all types of wastewater are discharged to

processing over independent networks.

|

|

Rice. 4.3. Complete split system 1— |

Incomplete separatesystemsewer is usually intermediate

under construction of a complete separate

sewer systems. In this system

sewer networks are provided

only for the removal of household and most

contaminated industrial effluents,

atmospheric water flows into water

streams in cuvettes.

Semi-split system sewers

is called a system in which

intersections of independent

sewer networks for drainage

different types of wastewater are available

spillways that allow

bypass the most polluted

rainwater at low flow rates

household network and divert them one by one

collector for treatment facilities, and

during showers, dump relatively

pure rainwater directly

into the reservoir.

|

|

Rice. 4.4. semi-divided a - scheme |

Incomplete split system is different

from complete separate absence

underground sewer network for

removal of atmospheric water, which is discharged

along cuvettes and open trays.

Semi-split system is different

from a complete separate device,

providing partial withdrawal of the first

portions of the most contaminated

surface runoff into household

sewer network, and less polluted

flows enter the reservoir.

Installation of internal sewerage in the country

Installation of internal sewerage is the construction of a network of channels through which wastewater is discharged by gravity into the external sewer system. The internal sewerage of the cottage is an extensive system of pipelines that drain sewage from various plumbing fixtures to the main sewer riser from which wastewater enters the underground pipeline of the external sewer system.

Sewer pipe layout

around the house is carried out under a slope towards the main riser connected by an underground pipeline. Mainly internal sewerage of the cottage

settles in invisible parts of the house, usually laying sewer pipes

carried out underground or in the space between the ceilings.

We carry out installation of internal sewerage using standard sewer pipes produced by Politek. This famous Russian company is a leader in the production of high-quality plumbing fittings.

Sewerage of a country house internal wiring

The internal sewerage, as well as the external one, is mounted quite simply - I’m not afraid to even compare this work with the assembly of a children's designer. The only thing that is required here is to cut the pipes to size, insert rubber seals into their sockets and, having lubricated them with a special silicone-based paste, connect them. Another question is how to connect pipes, or rather, not how, but according to what scheme? Here you will have to turn on all your imagination and arm yourself with the theory kindly provided by our site.

Sewerage system in a private house

First, let's deal with the materials. As a rule, the sewer constructor consists of the following parts.

- Pipes. In addition to the fact that they can be of different diameters (32mm, 50mm and 100mm), they also differ in length - as a rule, these are 300mm, 500mm, 1000mm and 2000mm. Blindly buying everything is not worth it - it should be understood that the longer the pipe, the more expensive it is. At the same time, if you collect sewage from short pipes, it will cost even more. The length of the pipes used will have to be calculated based on the scheme according to which the autonomous sewage system of a private house will be assembled.

- Tees. Everything is simple here - they are installed on almost every plumbing fixture. The only exceptions are the terminal tees, which are the first in the direction of the wastewater flow. Tees are different: straight, oblique and transitional. It is better to use oblique tees, as they are less likely to clog due to the smooth bend.

- Turns. They are used to change the direction of the drainpipe. The sewerage system in a private house provides for the use of both 90˚ and 45˚ turns. Again, instead of one 90˚ turn, it's better to use two 45˚ turns.

- Air valve. In principle, it can be replaced with a drain pipe, which removes the unpleasant sewer smell in a private house and improves the operation of the system as a whole. It is better to give preference to the fan pipe - its diameter should be 100mm. It is mounted with a riser through a tee - you need to install it closer to the toilet, which will improve its performance. The air valve is also best placed closer to the toilet.

Among other things, you will need a pipe mount and, possibly, adapters from a larger to a smaller diameter.

Now about the intricacies of the assembly. You need to start by immediately making a release from home. In a predetermined place (in the wall, below the floor level about 0.5 m), you need to punch a hole into the street. First you will need to dig a trench for laying street sewers and bring it to the place where you plan to arrange it. It should be remembered about the depth of soil freezing - in order for the sewerage in the house, made by oneself, to function normally in winter, the trench must be dug to a depth of at least 600 mm at its highest point (near the exit of pipes from the house).

Installation of sewerage in a private house

We move on, return to the house and continue the installation of sewers in a private house. From the input to we lay a pipe with a diameter of 100 mm - without fail, all turns are performed with bends at 45˚. Do not forget about the fan pipe or air valve, for their installation you will need to provide a tee. After the toilet, you can install an adapter on a pipe with a diameter of 50 and lay the rest of the wiring with a pipe of a smaller caliber.

A very important point is the observance of the slope - it is necessary for the organization of the natural flow of waste water. What is fraught with the absence of a slope or the so-called counter-slope? At best, it will work poorly, and at worst, a month later.The optimal slope at which the sewage system functions normally is a deviation from the horizon level of one and a half to two centimeters per meter of pipeline length.

Aboveground and underground sewerage from Flotenk

One of the main specializations of the company "Flotenk" is the development of complexes of sewer systems, consisting, as a rule, of above-ground and underground parts. By contacting this company, you can either buy ready-made standard systems that have proven themselves in practice, or order specialized ones that best meet the specifics and needs of each specific client. The Flotenk company manufactures almost all elements of these engineering complexes at its own production base from such modern material as fiberglass.

Laying of external sewerage, in the country

Outdoor sewerage in the country

- this is a part of the pipeline system located outside the house, designed to divert wastewater from buildings to a treatment system or to a centralized sewer.

The laying of pipes for external sewerage in the country is carried out underground, usually at a depth of 0.6 to 1 meter. Underground pipelines are laid at a slight slope towards the receiver of sewage from 3 to 1 cm per line. meters, depending on the length.

For laying underground sewerage pipelines, only thick-walled pipes with high ring stiffness are used. Namely, PVC pipes with a wall thickness of at least 3.6 mm, brown or red, in some cases, when laying sewers at great depths, corrugated pipes that can withstand a higher load can be used.

Attention!

For underground laying, only thick-walled PVC pipes with a wall thickness of at least 3.6 mm or even more reinforced corrugated pipes can be used. PVC pipes for underground laying are usually produced in brown or red color.

» rel=»lightbox» href=»assets/cache/directresize-wm/wm_vodosnabgenie_dachi_kiriyanovo_7.jpg»> Laying underground sewer pipes in a country house

in most cases it is done by hand, without the use of any construction equipment

Often this is very important in the country, especially in cases where there are already plantings or a lawn on the site, because when laying sewer pipelines manually, minimal damage to the ground cover occurs.

The process of laying an underground sewer pipeline is as follows:

First of all, a trench of the required length and depth is developed on the basis of which the sand is filled and leveled under the required slope, thereby creating a solid and even foundation for the subsequent laying of a sewer pipeline. Further, through rubber seals, sewer pipes are connected and laid on the prepared base.

Laying pipes of external sewerage

includes connecting a sewer pipeline to a sewage receiver. This connection must be absolutely tight, otherwise there is a high probability of flooding the sewage receiver with groundwater.

»rel=»lightbox» href=»assets/cache/directresize-wm/wm_podkluchenie_topas.jpg»> Topas-type deep biological treatment plants and other polypropylene containers are connected to the supply pipelines by means of a socket connection, the connecting socket is welded with a special welding gun into sidewall of the installed container.

The connection of the pipeline with the sewage receiver made of fiberglass is also completely sealed - the connecting pipe is inserted at the factory. The connections themselves are the socket - the pipe is made through special rubber seals. They provide complete tightness of the pipeline sewer system.

Our company "Comfort Dacha"

performs installation of external sewerage in the country in various designs, adhering to one very important principle - we ensure complete tightness of the entire sewer system. Underground sewerage in the country

produced, depending on various conditions, at a depth of 0.6 to 1.5 meters on a flat, previously prepared surface

Namely, on a compacted, sandy pillow spilled with water. Backfilling of the trench is carried out only after checking the required slope of the pipeline being laid

Underground sewerage in the country

It is produced, depending on various conditions, at a depth of 0.6 to 1.5 meters on a flat, previously prepared surface. Namely, on a compacted, sandy pillow spilled with water. Backfilling of the trench is carried out only after checking the required slope of the pipeline being laid.

When installing a sewerage system of great length

revision and, if necessary, rotary and distribution wells are installed.

Topology of sewer systems

Almost any modern sewer system consists of those sections that are located above the surface of the earth, and those that are laid directly into the ground or into cavities specially prepared for this purpose. In addition, it incorporates underground sewage tanks, which are intended for the accumulation of wastewater and their purification from impurities in accordance with accepted sanitary and hygienic standards.

As a rule, aboveground sewage is that part of the overall system that is located in buildings and structures, as well as in close proximity to the surface of the earth (for example, most of the stormwater communications). Underground sewage is characterized by the fact that it is buried in the soil, and therefore all its elements are hidden from view. These include pipelines and specialized tanks.

Underground sewerage

The design and installation of underground sewerage is usually a more technically complex, time-consuming and costly procedure. It requires mandatory consideration of such factors as the expected volume of wastewater discharge per unit of time, the geography of the area, as well as climatic conditions. According to the current rules and regulations, underground sewerage should be carried out below the freezing depth of the soil in winter. Almost all modern equipment used for wastewater treatment and part of sewer systems is designed specifically for underground installation.

Above ground sewerage

This part of the sewer system requires careful calculation and design, since it is it that is designed to collect all the effluents that are to be treated and further discharged into the environment. Above-ground laying of sewerage is a rather difficult task, the solution of which should be dealt with only by true professionals in their field. For the manufacture of its components, materials such as plastic and fiberglass are now often used, which are durable, resistant to various kinds of mechanical and chemical influences, as well as relatively low price.

Basically, PVC products are used for the construction of modern sewers, which have many advantages and disadvantages. But pipes of other materials can be used, having their own characteristics. Due to the fact that the consumer is primarily interested in which pipe to use for underground sewage in accordance with his budget, we will consider their suitable and affordable varieties.

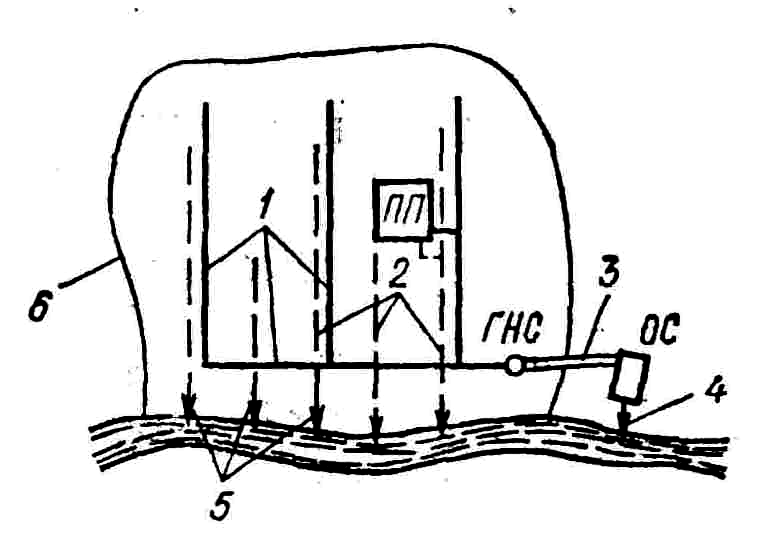

1. Complex of underground communications of a well-maintained city

Engineering

city networks are designed as an integrated

system,

uniting all aboveground, terrestrial

and underground networks

taking into account their development for the billing period.

Underground networks are laid mainly

under the streets and roads, why in them

transverse profiles provide

places for laying networks:

on the strip between the red line and the line

developments place

cable networks (power, communications, networks

signaling and dispatching);

under the sidewalks there are thermal

networks or passageways

collectors; on the dividing lines

- water pipes,

gas pipeline and household

sewerage. With a width

streets over 60 m within the red line

water supply networks and

sewers are laid on both

sides of the streets. During reconstruction

carriageways of streets and roads usually

networks located

under them, transferred under the dividing

lanes and sidewalks.

An exception may be gravity

utility networks

and storm sewers.

At

designing highways

underground utilities

they are made straight, parallel

axis or red

street lines, located from any

one side of the street without crossing it.

Underground networks should not be located

one above the other, except for sections

at intersections and branches,

where there are intersections at

in accordance with regulations

at different levels. most appropriate

is considered to be the location of underground

communications under the green area of the street

and sidewalks, but it is often necessary

use also

part of the space under the roadway

streets.

On the

case of reconstruction and expansion

communications with integrated

design provide for backup

plots

in the underground space of streets.

Where to drain the septic tank or drain pit

The question of how to make a sewer in a private house is inherently connected with the construction of a septic tank or a drain pit. Which of them is better is a moot point - here the voices of experts diverge. The only thing that can be said with certainty is that the drain pit will cost less - if done correctly, it will work no worse than the modern one, which is more designed for wastewater treatment and prevention of environmental pollution. The most interesting thing is that building a drain pit is quite simple and no special knowledge is needed for this. Personally, I would stop at this option for solving the problem.

Sewerage of a country house

Well, in conclusion, a few tips regarding two-story cottages.

- Firstly, these are basement floors - it is possible to ensure the drainage of water from a bathroom located below ground level only with the help of (KNS). It is sold assembled and is quite simply connected to the general system - it is mounted below (you will need to provide a place for the KNS).

- Secondly, the upper floors - for your own convenience and safety of operation, it is better to place the bathrooms clearly one above the other. In this case, it will be easier to combine them into a single drainage system, and the risk of flooding of residential premises will be significantly reduced.

This is what the sewerage of a country house looks like from the outside, or rather its installation and installation.

It is no secret that PVC pipes are actively used in the construction and repair of non-pressure pipelines of the external sewerage system of buildings. Since PVC pipes for outdoor sewage are resistant to chemical aggressive environments, they are used to drain various types of wastewater.

Installation of external sewerage in the country

The installation of external sewerage includes laying underground pipelines from the buildings to the wastewater receiver, installing a biological treatment station and draining treated water from the station to the discharge site.

Laying sewer pipes in the country

is carried out at a relatively shallow depth - from 0.6 to 1 meter at the place of its connection to the treatment plant.With a slope of 1.5 - 2 cm per meter, it is not difficult to calculate the depth of its laying at the point of connection to the internal sewer riser. Laying of external sewerage

carried out on a previously prepared surface of the base of the trench. The leveling of the bottom of the trench is carried out with the help of sand, which, after backfilling and distribution along the bottom of the trench, must be spilled with water. The bottom of the trench is thrombosed and only after that they proceed to the laying of sewer pipelines. For underground laying, thick-walled sewer pipes should be used. Only they are able to withstand the pressure of the soil above them. In the construction of underground sewerage, we use only thick-walled pipes made of soft polypropylene. Underground sewerage

mounted from such pipes is characterized by high strength, and as a result, a long service life of underground sewer pipelines.

Today, more and more country sewage is being equipped with biological wastewater treatment plants. We install some of the best Topol-eco treatment plants of the Topas brand. The sewage effluents entering the station are finally cleaned by almost 90%, the water flowing out of the station can be used for watering plants or for other technical needs.

The installation of biological treatment plants is the only correct solution for building a sewer system in clay soil. Clay and loam are absolutely waterproof soils, so the use of various types of septic tanks as receivers for wastewater treatment in such soils is a categorically wrong decision. In clayey types of soil, purified water is discharged only to the surface - to a roadside ditch, ravine, or simply to the surface. Due to severe environmental pollution, the removal of sewage from septic tanks and other sedimentation tanks to the surface is not possible! Installation of various types of septic tanks, including those built from reinforced concrete rings, is possible only in sandy soils and at a respectful distance from water sources. Water drainage in sandy soil types can be carried out not only to the surface, but also directly to the drainage well. From it, water gradually goes into the deep layers of the soil, gradually clearing itself in a natural biological way.

Treatment stations "Topas" - a range of models, including stations of various capacities from the most low-power designed for no more than 5 people to installations capable of cleaning sewage coming from a whole litter. In most cases, the installation of country sewerage is carried out using the biological treatment station Topas 5, Topas 8, Topas 10 and Topas 15. Of these most common models, the discharge of purified water can be carried out not only by gravity, but also by force. With the help of a special drainage float pump produced by the Spanish company VILA. In most cases, we install the stations with the forced ejection of purified water and we install them. Stations with gravity discharge of purified water can only be installed next to a ravine or a deep drainage channel, which, as you understand, is very rare.

Pipe material

Underground sewerage can be laid using the following materials:

- cast iron;

- polyvinyl chloride (PVC);

- (PP);

- polyethylene (PE);

- asbestos cement;

- ceramics.

The last two options are used very rarely, and more and more users opt for cast iron and plastic pipes.

Cast iron pipes

Advantages:

- durable;

- service life up to 85 years;

- withstand heavy loads;

- resistance to temperature changes.

Flaws:

- not suitable for saline soil;

- have a large weight, which increases the cost of delivery and complicates the installation process;

- a rough surface reduces the flow rate of effluents and provokes blockages;

- high price.

PVC pipes

PVC pipes intended for outdoor use are produced in orange. Gray ones have a wall thickness of 2.7 mm and are not able to withstand soil pressure, therefore they are used for the installation of exclusively internal sewage. Corrugated pipes are intended for laying in the ground without boxes to a depth of more than two meters.

Advantages:

- affordable price;

- resistance to temperature extremes;

- strength, wear resistance;

- do not break down under the influence of aggressive chemicals;

- the inner walls are smooth, so growths do not form on them;

- light weight, which facilitates installation;

- corrosion resistance.

Flaws:

- if the temperature of the drains is above 40 C °, they quickly become unusable due to the thermal elongation of the material;

- suitable only for gravity sewerage;

- used for small private houses.

It should also be noted that the characteristics of PVC pipes may vary depending on the manufacturer. In addition, these pipes can vary in hardness

, and depending on it, be used at different depths. The most rigid class S pipes can be used at depths up to 8 m, medium rigid class N pipes at depths up to 6 m, and light class L pipes at depths up to 2 m.

Polypropylene pipes

Advantages:

- smooth inner surface;

- service life up to 100 years;

- resistant to temperatures up to 100 C°;

- do not decompose under the influence of acids and alkalis;

- light weight, which simplifies transportation and installation;

- installation is quite simple and fast, does not require the use of special equipment.

Flaws:

- soft, can be deformed under high pressure;

- pipes with increased wall thickness, designed for burying to great depths, are more expensive;

- deteriorate under the influence of ultraviolet radiation, which complicates warehousing.