Do-it-yourself foaming agent for foam concrete

Foam Ingredients:

- caustic soda (caustic soda) - 0.15 kg;

- rosin - 1 kg;

- carpentry glue - 0.06 kg.

The manufacturing technology is somewhat laborious and time consuming. Therefore, it is advisable only for significant amounts of work.

How to make a blowing agent for foam concrete at home

Preparation involves two steps:

- mixing adhesive. To do this, pieces of dry glue are poured with water (1:10) and left for a day. During this time, the glue will swell a little, but will hold its shape. Therefore, a container with water and glue is heated to 60 ° C (with constant stirring). The adhesive solution is ready when all the pieces have dissolved and formed a homogeneous mass;

preparation of rosin soap. For this purpose, sodium is brought to a boil. Then rosin is gradually introduced into it. The boiling process will take about 2 hours until the rosin is completely dissolved.

Note. Rosin should be crushed beforehand.

Both compositions are mixed when the rosin soap has cooled to 60 ° C.

Note. When mixing, rosin soap is poured into the adhesive solution. Mixing ratio 1:6.

The resulting mixture is poured into a foam generator and high-density foam is obtained. Foam with a density of 80 g / dm3 is considered optimal for use. Using less dense (more airy) foam will degrade the quality of the block and lead to its rapid destruction.

Note. You can check the quality of the foam by filling a bucket with it. After turning the bucket over, the foam should be kept inside.

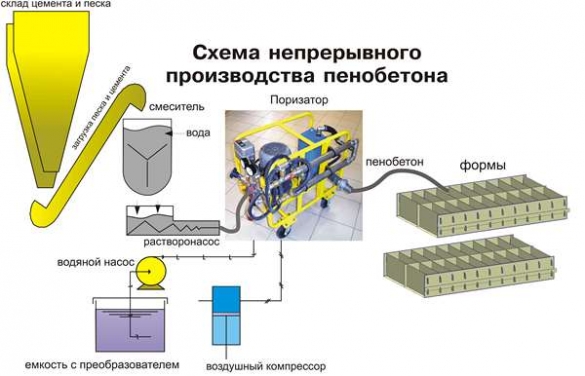

The scheme for the production of foam blocks is shown in the figure.

Note that like the first pancake, the first foam concrete blocks usually also come out lumpy. There are several reasons for this:

the complexity of dosing the constituent components in the solution;

increased / decreased water content in the solution;

increased content of the foaming agent in the solution. Its consumption should not exceed 1.5 liters. per 1 m / cu.

Unfortunately, such experiments not only prolong the construction time, but lead to additional costs. However, according to users, they are fully justified. Moreover, defective foam blocks can be used as backfill under the floor, and used equipment for the production of foam concrete can be sold.

Note. As practice shows, it is better to make structural foam blocks (grades D-900 and higher). They contain fewer pores than insulating ones, and it is easier for beginners to make them.

Pros and cons of using foam blocks

Like any other building material, the foam block has its own scope, disadvantages and advantages.

Advantages

- Environmental friendliness. The material is non-toxic. Even at enormous temperatures (up to 1200 degrees), it does not emit harmful substances into the air;

- Durability;

- Fire resistance;

- Noise isolation. Walls made of foam blocks poorly transmit extraneous sounds, and unlike bricks, they do not transmit low-frequency sounds;

- Manufacturability. The process is not expensive in terms of labor or electricity. For production and further use, the intervention of heavy construction equipment is not required;

- Profitability. This material is one of the cheapest. For example: a cubic meter of brick costs about twice as much as a cubic meter of foam blocks.

Flaws

- On self-built walls made of foam blocks, cracks may appear during the settlement of the building;

- Walls made of this material do not tolerate deformation, and it can only be used on strip foundations.

Separate consideration requires equipment for the manufacture of foam blocks.

Properties of foam concrete

Cellular concrete, or, as it is called, foam concrete is a porous stone and is an excellent substitute for wood. It contains in its sealed cells - pores the most effective heat insulator in the world - air. Cellular concrete is closer to wood than to stone, and brick is closer to stone, it is a heavy and cold material. Cellular concrete is environmentally friendly, and in this respect it is not only inferior to wood, but also has certain advantages, because wood is prone to decay, fungus and all sorts of harmful things settle in it, and these harmful things do not settle in stone, in silicate material.

Foam concrete has other advantages. It does not burn, lends itself well to processing, durable. Different brands of foam concrete can differ in density by several times, which makes this material universal: it is suitable for external walls, for internal partitions, for heat and sound insulation of roofs and floors.

We believe that this is the most Russian material, because it can be made from local raw materials. And as a result, you can make a square meter of the wall warmer than a brick house, but 2-3 times cheaper.

The resulting foam concrete products are not inferior to traditional autoclaved cellular aerated concrete in terms of their quality indicators. Due to the simplicity of the technology and the equipment used (exclusion from the technological cycle of grinding raw materials in ball mills and autoclave processing), the cost of products is 1.5-2 times lower than the cost of the same products from cellular aerated concrete.

Foam concrete obtained by a new non-autoclave and non-steaming technology has: - high heat and noise protection qualities; - high fire resistance; - durable; - environmentally friendly (has a certificate of the Ministry of Health of Russia for foam concentrates); - meets European standards; 2 - 2.5 times cheaper than similar volumes of bricks or expanded clay concrete).

What is needed for the manufacture of foam concrete

For the production of this building material you will need:

In order to obtain a homogeneous material, you will need to sift and sort the ingredients. Therefore, to obtain high-quality foam concrete, it is necessary to have a vibrating sieve. If a pressure unit is used in the production, it is necessary to have a compressor. If the technology is used for production without the use of a pressure unit, a concrete mixer will be needed. make them yourself. If you plan to pour the foam concrete solution using monolithic technology, you will need boards for mounting the formwork. A foam generator for foam production.

It is a special material with high resistance to cement mortar. This quality allows you to transport the finished mass to the desired distance without destroying the structure of the material. It can be purchased in the form of an industrial concentrate or made with your own hands. A complex such as a bar installation will greatly facilitate the work and reduce the amount of equipment.

When using it, a foam generator is not needed, the ingredients are mixed in the built-in activator. This process is carried out under high pressure, so when the solution is unloaded, the air pores swell even more and the mixture becomes more porous. Such equipment for foam concrete makes it possible to deliver the mass to the place of construction work and at the same time produce material with density parameters up to 1200 kg / m3. Water, sand, cement. Gloves for protecting hands and a mask for working with bulk materials.

Automatic dosing system for raw materials for the production of foam concrete

Many aerated concrete producers know how much time it takes to prepare and fill raw materials into an aerated concrete plant. For example, for 1 batch with V = 1 cubic meter. it is necessary to manually fill in 6 bags of cement (300 kg), sift and fill in 17 buckets of sand (270 kg), measure the required amount of water and foam. At best, it takes 10-15 minutes. Per shift with a productivity of 20 cubic meters. foam concrete leaves 1.5-2 hours of wasted time, 3-4 people manually pour 6 tons of cement and 5 tons of sand. In addition, we must not forget the human factor: errors in counting the number of bags of cement, buckets of sand, liters of water lead to incorrect dosage.

The result is low productivity, high cost, unstable quality of the foam concrete mixture. Therefore, manufacturers are trying to mechanize the entire process of foam concrete production.

The proposed Automated Dosing System is designed to control the entire foam concrete production complex from the supply of raw materials to the unloading of the finished mixture.

Dosing system for foam concrete production

The main parts of the dosing system:

1. Weight batcher of cement and sand on load cells. 2. Belt conveyor for sand supply. 3. Cement supply screw. 4. Cement big-bag dispenser (or cement storage silo). 5. Water dispenser. 6. Foam concentrate dispenser.

Description of the foam concrete production process:

The operator selects the recipe for the preparation of foam concrete and starts the process of automated production of foam concrete:

- The auger is turned on and cement is fed from the big-bag unloader (or silo) to the weight batcher. After gaining the required weight of cement, the auger is turned off.

- The conveyor for feeding sand into the weigher is switched on. After gaining weight of sand, the conveyor is switched off.

- Water is pumped into the mixer. After dialing the dose of water, the pump turns off.

- The mixer is turned on, the hopper valve opens automatically and the cement and sand are unloaded.

- The foam from the foam generator is added to the mixer through the foam concentrate dispenser.

- After mixing the components, foam concrete is unloaded into molds.

Benefits of using a dosing system:

|

The operator can adjust and set various recipes for the production of foam concrete, select the doses of raw materials, monitor the recipe and consumption of materials, set up and monitor all process parameters. The installed program in the console allows you to display the entire process of automated foam concrete preparation on the operator panel in real time. Benefits of using an automated dosing system: |

Automatic cement and sand dispenser

|

Dispenser device The dispenser consists of a frame on which a receiving hopper and a control panel are suspended. The bunker is equipped with a surface vibrator and an electric shutter. Weighing takes place with the help of strain gauges. The data is displayed on the operator panel of the console.

|

|

Automation tools

|

The control panel allows you to control the operation of the entire complex for the preparation of foam concrete mix: a weighing batcher, a screw conveyor, a belt conveyor, a pump and a water dispenser, a foam supply pump, a mixer, a vibrator of a cement dispensing station in "big bags" or a cement silo. |

- Setting doses for batches (amount of cement, sand, water, foam).

- Automatic set of cement in the receiving bunker.

- Automatic set of sand in the receiving bunker.

- Automatic set of water in the mixer - installation for foam concrete.

- Automatic activation of mixer rotation.

- Automatic unloading of cement and sand from the receiving hopper.

- Automatic set of foam in the mixer.

- Unloading the foam concrete mixture into the mold.

-

- Plant for the production of foam concrete

- Sand Feed Conveyor

- Cement big-bag unpacking station with auger

foam generator

With the help of this piece of equipment it is possible to convert the solution into foam. Builders with experience agree that it is better to buy it ready-made, and not do it yourself. A foam generator or foam concrete porizer is compiled using the following instructions:

- Preparation of a large and sealed container. For example, it is quite possible to use a barrel.

- Water and a special substance are placed inside. With the help of the latter, foam will be obtained.

- Connecting the compressor to the bottom of the unit. At the top, you will need to make a special outlet hole.

- It is convenient to regulate the supply of substances using a special valve.

- The outlet is connected by a tee. On the air supply side, you will also need to install a second valve.

- Drawings of equipment for the production of foam concrete contain two outlets. Each of them must have a valve. In this case, it will be possible to correctly adjust the supply of oxygen and fluid.

- According to the instructions, the mixture passes through the grates, and then enters the compartment. Through the process it is possible to form a foam. A special nozzle must also be installed at the outlet of the triple distributor. If the installation was done at home, then a muffler from the car is used in this capacity. Previously, a lattice or other porous material must be introduced into its structure.

Components of a foam generator

To ensure the operation of the unit, according to the technology, it must have a compressor, mixers for foam and concrete composition, an element for distributing and pouring the solution into molds, as well as a pump for pumping the composition. These are the main elements that form the apparatus, in addition to them, the presence of other mechanisms and elements is possible.

For the manufacture of a large volume of building materials, it is possible to build a foam generator from a combination of devices of the same type.

The power and other performance characteristics of the unit must ensure continuous operation at each stage of the technological process. The simplest option involves assembling the installation based on three components: a foam generator, a concrete mixer and a compressor.Often such a unit is used to make a solution directly at the time of construction for pouring structures.

The ratio of the parameters of the parts

While assembling the unit, it is important to maintain the necessary ratio between some of its components. Given the decrease in the diameter of the spiral when it is pulled out, it is necessary to ensure the difference between the diameters of the outer ring and the pipe by 12-15% (the ring diameter is larger), as well as the difference between the diameters of the ring inside and outside - 20%, in favor of the outer diameter

This difference provides the optimal ratio for pipes with different parameters.

Foam concrete characteristics and properties

Foam concrete has some properties that can be fully considered its advantages over a number of other building materials:

High quality thermal insulation. Thanks to the air-filled cells, the material has a high thermal resistance.

In winter, this quality saves about 25% on heating costs. Good fluidity, which allows easy and high-quality casting. Foam concrete is not affected by atmospheric factors and chemical influences. This is a practically ageless material that is as strong as a stone, does not rot, is not afraid of dampness. Excellent strength characteristics.

The foam concrete density of 400-1400 kg / cm³ allows you to endure compressive loads in the range of 10-100 kg / cm³. Such an increased characteristic makes it possible to use this material in the construction of objects with a lower volumetric weight, which leads to an even more increased thermal resistance of the walls. Unlike materials such as polystyrene and mineral wool, foam concrete does not lose its qualities over time. They only get better due to the long maturation of this material: after four months, its strength increases by one and a half times, and after a couple of years - more than two and a half times compared to monthly aged cellular concrete. Maintaining an optimal microclimate.

Foam concrete, reviews confirm this fact, it has good air permeability, allowing the walls to breathe. Environmental friendliness. Does not evaporate harmful substances, as it is made from natural raw materials. According to this indicator, foam concrete is second only to wood.

For example, the environmental friendliness index for a brick is 10, for cellular concrete - 2; brick - 10; tree - 1; expanded clay blocks - 20. Excellent sound insulator. The material absorbs sound well without reflecting it, especially low noises. Fire safety. The first degree of fire resistance allows a fifteen-centimeter foam concrete wall to protect the premises from fire for four hours. The large dimensions of the blocks ensure ease and speed of installation.

Easily gives in to processing by the cutting tool. High profitability. The accuracy of geometric dimensions makes it possible to put blocks on glue, avoiding cold bridges, which saves the cost of plastering and additional insulation. The lightness of the blocks allows you to save on the foundation and floors, easy to transport.

- Date: 01-03-2015Views: 866Comments: Rating: 44

Do-it-yourself foam concrete installation is made according to a certain technology. The final product of foam concrete is a foam block, which consists of the following components:

- cement; water; sand; foaming agent.

Scheme of the foam generator.

Home-made foam concrete is cheaper than a factory-made counterpart. Cement is considered the most expensive component of foam concrete, so the cost of the final product depends on its choice.

Do-it-yourself foam generator for foam concrete

The acquisition of this module is the most expensive part of production.

Purpose - to convert the foaming agent into foam, before feeding it into the solution.

The design of the foam generator consists of three nodes:

- supply module. A foaming agent solution is poured into it. This function can be performed by any container;

- conversion module. The quintessence of the installation is the transformation of the foam;

- dosing module. Provides the ability to supply foam to a solution of a given density (determined by the brand of the foam block).

Scheme of a foam generator for the production of foam concrete

Scheme of the device of a foam generator for the manufacture of foam concrete

To make a foam generator you will need: a metal pipe (2 blanks), a pump, hoses, valves. Also a welding machine. In more detail, the components are specified in the specification, which accompanies the drawing of the foam generator.

Assembling a foam generator for foam concrete (diagram-drawing)

Drawing of a foam generator for foam concrete

1. Making a foam generator

The specificity of the factory tube of the foam generator is that at first it has a narrow channel, which then expands. This technique allows you to increase the speed of passage of the emulsion through the tube. Then at the output it will have the maximum possible speed.

Manufacturing of the mixing chamber

Weld two pipes to one of the prepared pipes. Moreover, it is advisable to place one of them (through which air will be supplied) from the end. And the second, intended for supplying a foaming emulsion, is welded on the side (at an angle of 90 °).

Both inlet pipes (end and side) are supplied with two valves:

shut-off (allowing to shut off the supply of foaming agent);

adjusting (allowing you to adjust the supply parameters, change the pressure, pressure, quantity, etc.).

In practice, after the mixture supply parameters are adjusted, control valves are not used.

Note. The diameter of the side pipe should be 15-20% larger than the diameter of the end pipe.

Foam cartridge manufacturing

A branch pipe is welded to the second pipe blank. It is designed to exit the finished mixture. It is advisable to equip the outlet pipe with a device in the form of a funnel to reduce the rate of exit of the mixture. The filter is placed in the workpiece. The purpose of which is the transformation of the emulsion into foam. You can buy a ready-made filter.

But its function with no less success can be performed by metal meshes (brushes) for cleaning dishes.

At the same time, spiral ones are not suitable, only wire ones. These meshes must be tamped as tightly as possible along the entire length of the foam cartridge tube. To prevent mesh particles from flying out with the mixture, a “Ruff” is installed at the pipe outlet, inside which a mesh washer is installed.

Connection of mixing chamber and foam cartridge

Next you need to connect the mixing chamber and the foam cartridge. Naturally, this must be done in such a way that the welded pipes are placed at opposite ends. To ensure an increase in the speed of passage of the foam concrete mixture through the tube, it is necessary to install a Laval nozzle or a jet washer between them. Replacing the nozzle with a jet will reduce the efficiency of the design by 30-40%, by reducing the speed of the mixture passing through it. However, it is cheaper, easier to install, and can be used as a temporary option. The installation location of the nozzle or jet is shown in the diagram.

Scheme of a foam generator for foam concrete using a jet washer

The ratio of the dimensions of the foam generator for foam concrete (depth and inlet diameter)

The ratio of the dimensions of the foam generator for foam concrete

2. Connecting the compressor to the end pipe of the mixing chamber

Any compressor is suitable for operation, which will provide a pressure of 6 atm. Using a compressor with a receiver, a pressure reducing valve and a pressure gauge will allow you to regulate the pressure.

The material was prepared for the site www.moydomik.net

3. Connecting the foam concentrate container to the side connection of the mixing chamber

The container is installed on the floor, a hose is attached to it, through which the foaming emulsion (foaming agent plus water) will be fed into the mixer by moving through the side pipe.Installing a small pump (an ordinary household “stream”) will allow you to organize a more efficient supply of the foam concentrate to the foam generator. However, in order to save money, the supply can be organized by gravity.

A foaming agent for foam concrete made in such a simple way will cost much less than a purchased one. And the resulting foam will be in no way inferior to the foam obtained from the factory generator.

Simple equipment for making foam blocks with your own hands

If you have the right equipment for the manufacture of foam blocks, and purchase raw materials at competitive prices, there is a chance to achieve a high level of profitability. Moreover, financial investments in such production do not require huge amounts of money.

You need to carefully familiarize yourself with the production process of foam concrete blocks and competently approach the selection of equipment, and you will be able to launch the production of this popular building material.

What is needed for production

It is possible to produce foam concrete blocks, but this requires a set of equipment and various devices:

- Formwork for pouring foam concrete and forming blocks of specified sizes;

- Foam generator with appropriate technical parameters;

- Compressor;

- Concrete mixer with sufficient capacity.

The presence of such a kit brings excellent results to manufacturers - a typical shift is 3 cubic meters of foam concrete blocks. So a week of active and productive work, and there will be a ready number of foam concrete blocks for the construction of a load-bearing wall.

One of the important units included in the equipment for the manufacture of foam blocks is a foam generator that forms a foam solution, which then enters the formwork or molds. This unit is more profitable and easier to do on your own if you have the necessary components.

It is desirable to have a three-phase compressor, as it develops more power, but if there is none, a standard electrical voltage will do.

The classic foam generator consists of:

- Made of fine metal mesh housing,

- Capacities of the required volume,

- hose kit,

- compressor.

Foam generator operation

Self-assembled equipment for the manufacture of foam blocks in the form of a foam generator exists in order to mix the foaming agent with water and air, and then send the resulting mass through the cells of the metal mesh of the body into pre-prepared forms.

In the process of adjusting the quality of the foam, you need to constantly check its consistency, because the properties of the foam concrete block will depend on this. If the foam spreads too much, you need to make the necessary adjustments to the components or to the operation of the foam generator so that this process does not occur, otherwise it will be difficult to achieve a geometrically correct foam block.

And even if the foam concrete block is obtained from loose foam, this product will collapse under slight mechanical loads.

The composition of the solution used to produce foam concrete necessarily includes high-quality cement. There are different proportions for the production of foam concrete blocks, and they depend on the brand of cement used and the density of concrete. If the concrete has a density of 300-500 per square meter, a mixture without sand is allowed.

If the density reaches 600 kilograms per meter, natural sand will be required. It will be better for the final product if the sand is pre-screened.

Features of the production of foam concrete blocks

All components must be placed in the mixer and the mixing process started, adding the raw materials in turn. Mixing begins with cement, water and sand, and then foam is connected to the production process.

The final product will depend on the mixing speed of the starting materials.If a vertical mixer is used, the mixing process takes 20 minutes, and if you use a drum with paddles, this procedure is reduced by 10 times.

The manufacturer will have to choose between formwork and forms - how it will be more convenient for him, and for what purposes he will use foam concrete blocks. The formwork option requires the use of cutting the mass that has not completely hardened into separate fragments of equal size.

It is necessary to have marks on the formwork or use other measuring instruments in order to cut foam concrete blocks evenly without significant errors.

When using metal or plywood forms, foam concrete is poured into them and you need to wait a while until the mixture hardens and a foam concrete block is formed.

To speed up the hardening process, you need to use various additives and rooms with a suitable temperature regime.

It will be much more convenient to remove frozen foam blocks if a collapsible mold design is provided. Then you can remove the product without damaging its surface.

Equipment

From the whole set of equipment, the main and most commonly used types can be distinguished:

- foam generator;

- concrete mixer;

- Compressor;

- Foam concrete mixer;

- Forms.

foam generator

The foam generator performs the function of producing foam, on the basis of which foam concrete will be produced later in any type of concrete mixer.

Structurally, it consists of:

- lower tank serving for a mixture of water and foaming agent;

- upper tank for foaming agent;

- control and inlet valves;

- intake pipe that generates foam.

The device is connected to water (if there is no centralized water supply system, then it can be filled with buckets), the upper tank is filled with a foaming agent (any, you can even make it yourself, sometimes manufacturing instructions are supplied with the device).

Next, the device is connected to the compressor, which creates pressure and the foam starts to exit the pipe. Porosity can be set using outlet valves.

concrete mixer

Concrete mixer.

Concrete mixer.

This is a device for forced mixing of ingredients (sand, water, gravel, cement) in order to prepare a homogeneous mixture ready for use.

Concrete mixers are divided into:

- Gravity;

- With forced mixing of materials.

In a gravity mixer, the ingredients rotate in a drum, which is equipped with blades on the inside. During rotation, the materials collide with the blades, thereby mixing.

In a concrete mixer with forced mixing of materials, the components are in a fixed drum. Blades mounted on a shaft rotate in the drum.

According to the installation method, concrete mixers are divided into:

- Stationary;

- Mobile.

Devices with a ready solution output of more than 660 liters are usually stationary. Up to 65 l always mobile. From 330 l to 500 both mobile and stationary.

According to the nature of the work, concrete mixers are of continuous action, and cyclic. In cyclic loading occurs in portions, and in continuous loading of materials and the output of the mixture occurs constantly.

Foam concrete mixer

Designed for the production of cellular concrete. It is used for the manufacture of blocks by the method of foam barotechnology.

Combines three functions:

- Produces mixing;

- Generates foam;

- Works as a pump to transport the foam to the installation site.

Thus, this is the most complete unit for the manufacture of foam concrete. It combines the functions of a foam generator, a concrete mixer and a compressor.

Construction equipment for the production of foam concrete

For independent production of foam concrete, you need reliable industrial equipment that will work for years and bring profit to the owners.Therefore, it is advisable to buy construction equipment for the production of foam concrete from machine-building enterprises, and not from "handicraftsmen" for one year of work. Yes, the price of industrial equipment "bites", but it justifies itself with high productivity and excellent quality of the resulting foam concrete. But after all, foam blocks are already subsequently made from foam concrete. This means that with what quality we will produce foam concrete, foam blocks will be with the same quality. And who needs low-quality blocks? Nobody!

The article Choosing equipment for the production of foam concrete and foam blocks will help you choose the right equipment.

Equipment for the production of foam concrete - composition

The equipment for the production of foam concrete includes:

|

INSTALLATION FOR THE PRODUCTION OF FOAM CONCRETE

created on the basis of an industrial mixer (pneumatic blower) of concrete mixtures VB-06719 for the preparation of a foam concrete mixture and its supply to the place of laying. USED FOR MONOLITHIC CONSTRUCTION price 380,000 rubles. |

|

FOAM GENERATOR

designed for continuous supply of foam to the plant for the production of foam concrete. Foam is formed by supplying a foam solution and air to the foaming module. price 50 000 rub. |

|

COMPRESSOR

designed to supply compressed air to the foam generator for the production of foam and to the installation for the issuance of foam concrete. |

|

WATER TANK

is intended for the preparation and storage of a foam solution by adding a foaming agent to water in the required proportion.

It consists of one cubic container made of polyethylene. The outside has a metal crate. In the lower part there are drain taps, in the upper part there are filler necks. Mounted on wooden pallet. price 10 000 rub. |

The price of the kit is 515,000 rubles.

Equipment for the production of foam concrete - delivery, installation

Based on the quality of the equipment and many years of experience in the manufacture of equipment for the production of foam concrete, representatives of the company will advise you on all issues of organizing the production of foam concrete blocks. You will be prompted what additional equipment you need to use in your production.

Stroysnabzhenie LLC will perform the full range of services related to the order: delivery by road, installation and launch of construction equipment, as well as its further maintenance. It will help to train personnel to work on equipment and to study the technology of production of foam concrete.

WE RECOMMEND TO PURCHASE:

Cutting equipment for the production of foam blocks

Use of ready-made metal molds

The use of ready-made metal molds for foam concrete greatly facilitates the construction process, because there will be no need to spend time making your own mold. But in this case, you need to consider that you will have to spend some money on the purchase.

When using a standard form, blocks of certain sizes are obtained - 300x600x200 mm, to adjust them in order to obtain blocks of special designs, band saws are used.

Before using the forms, they are lubricated with a special composition that does not contain oil.

The use of finished metal molds has its advantages:

- Their simple disassembly allows you to quickly remove the finished blocks. Thanks to the exact geometric shapes, the manufactured blocks are even and identical. Metal structures have a collapsible-assembly system, so they do not take up much space during transportation. Metal forms are durable. which requires foam concrete in the amount of 1.08 m³.